A kind of preparation method of light-stable antistatic polyoxymethylene material

A technology of polyoxymethylene material and light stability, which is applied in the field of preparation of polyoxymethylene materials, can solve the problems of reducing the machinability of plastics, and achieve the effects of improving machinability, permanent antistatic effect, and green and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

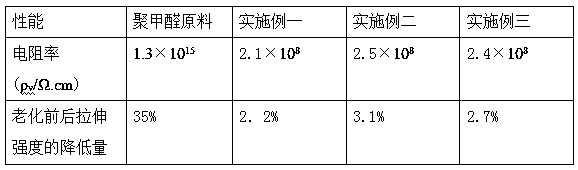

Examples

Embodiment 1

[0018] After mixing 4-hydroxy-2,2,6,6-tetramethylpiperidine-1-oxyl radical (TEMPO) as a hydrogen bond donor with urea and water in a molar ratio of 1:2:3, at 80 Heat at ℃ for 2 hours in an oil bath to form a uniform, transparent light-stable eutectic reagent with antistatic effect; mix the light-stable eutectic reagent with antistatic effect, carbon black and polyoxymethylene at a ratio of 1:0.3:98.7 After the mass ratio of the extruder is blended evenly, set the temperature of the feeding port to 160°C, the temperature of the extruder zone 1 to 175°C, the temperature of the extruder zone 2 to 180°C, the temperature of the extruder 3-4 zone to 180°C, and the temperature of the extruder zone 1 to 180°C. The temperature in zone 5 is 185, the outlet temperature is 180°C, and the screw speed is 120rpm, the mixture is extruded and granulated in a twin-screw extruder to obtain an antistatic masterbatch, and the obtained antistatic masterbatch is vacuum dried at 75°C Standby for 4 ho...

Embodiment 2

[0020] After mixing 4-hydroxy-2,2,6,6-tetramethylpiperidine-1-oxyl radical (TEMPO) as a hydrogen bond donor with urine glycerol and water at a molar ratio of 1:2:3, in Heat at 80°C for 1.5 hours in an oil bath to form a uniform, transparent light-stable eutectic reagent with antistatic effect; combine light-stable eutectic reagent with antistatic effect, polyethylene glycol / quaternary ammonium After the methacrylate copolymer and polyoxymethylene are blended uniformly at a mass ratio of 1:0.2:98.8, set the temperature of the feeding port to 160°C, the temperature of the first zone of the extruder to 175°C, and the temperature of the second zone of the extruder to 180°C , extruder 3-4 zone temperature is 180, extruder 5 zone temperature is 185, discharge port temperature is 180 ℃, after the screw speed is 100rpm, the mixture is extruded and granulated in twin-screw extruder to obtain antistatic Masterbatch, vacuum-dry the obtained antistatic masterbatch at 85°C for 4 hours for ...

Embodiment 3

[0022] After mixing 4-hydroxy-2,2,6,6-tetramethylpiperidine-1-oxyl radical (TEMPO) as a hydrogen bond donor with ethylene glycol and water in a molar ratio of 1:2:3, in Heat at 80°C for 1 hour in an oil bath to form a uniform, transparent light-stable eutectic reagent with antistatic effect; mix the light-stable eutectic reagent with antistatic effect, polymetallic fiber and polyoxymethylene at a ratio of 1:0.1 : After the mass ratio of 98.9 is blended evenly, set the temperature of the feed port to 160°C, the temperature of the first zone of the extruder to 175°C, the temperature of the second zone of the extruder to 180°C, and the temperature of the 3-4 zone of the extruder to 180°C. The temperature in the 5th zone of the machine is 185, the outlet temperature is 180 °C, and the screw speed is 150 rpm. Vacuum dry for 4 hours for later use; mix the prepared antistatic masterbatch, long-chain fatty acid, hindered amine antioxidant, and pure polyoxymethylene in a ratio of 40:1:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com