A preparation method of permanent antistatic ionic liquid polymer masterbatch and its application in polymer materials

A polymer material, ionic liquid technology, applied in the field of antistatic polymer masterbatch, can solve the problems of difficult to achieve permanent antistatic, poor plastic compatibility, etc., to improve the wiping resistance and scratch resistance, reduce Crystallinity, effect of increasing hardness and impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

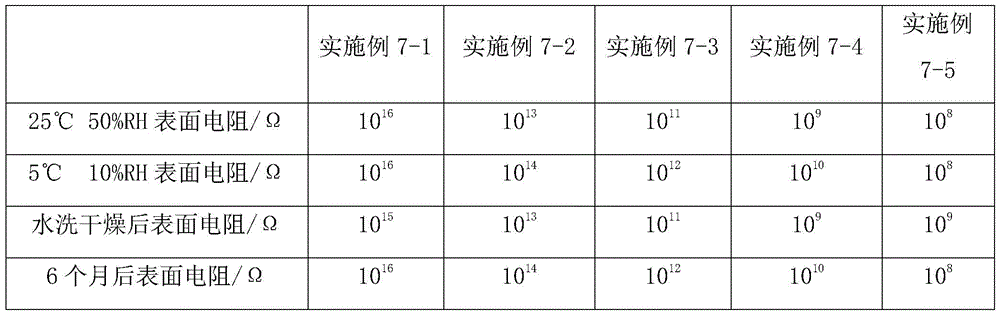

Examples

Embodiment 1

[0029] 165.23g (1.5mol) of styrene monomer, 98.1g (1.0mol) of maleic anhydride, 2,5-dimethyl-2,5-di-tert-butylperoxyhexane ) 0.5g into a four-necked flask, filled with nitrogen, heated up to 85°C, reacted for 3 hours and cooled down to obtain 255g of white solid, took out 100g of white solid, added 52.5g of 1-butyl-3-methylimidazolium hexafluorophosphate , under nitrogen protection, stirred at 250°C for 1 hour to obtain a block copolymer grafted with an ionic liquid. Take 99g of the block copolymer, 0.15g of antioxidant dilauryl thiodipropionate, and 3g of hydroxyl silicone oil. 20g of diatomite with a particle size D (0.9) of 8μm, 3.5g of calcium stearate, and 3.6g of silicone oligomer with a viscosity of 850,000 CP were put into an internal mixer, heated and stirred at 85°C for 30 minutes, and passed through a twin-screw The extruder was extruded and granulated at 95° C. to obtain the permanent antistatic ionic liquid high polymer masterbatch PS-MAH-SA750.

Embodiment 2

[0031]Add 165.23g (1.5mol) of styrene monomer, 98.1g (1.0mol) of maleic anhydride, and 0.5g of dicumyl peroxide into a four-necked flask, fill it with nitrogen, raise the temperature to 85°C, and react for 3 hours After cooling down to obtain 249.6 g of white solid, 120 g of white solid was taken out, 52.5 g of tri-n-butylmethylammonium bistrifluoromethanesulfonimide salt was added, protected by nitrogen gas, and stirred for 5 hours at 65 ° C to obtain ionic liquid grafted Block copolymer, get this block copolymer 120g, antioxidant 2,4,6-tri-tert-butyl pentaerythritol diphosphite 0.20g, hydroxyl silicone oil 3g, particle size D (0.9) is 25g of spherical calcium carbonate of 7 μm , 4.5g of calcium stearate, 4.6g of silicone oligomer with a viscosity of 850,000 CP, put it into an internal mixer, heat and stir at 85°C for 30 minutes, and then extrude and granulate through a twin-screw extruder at 95°C to obtain Permanent antistatic ionic liquid polymer masterbatch PS-MAH-SA250. ...

Embodiment 3

[0033] Add 165.23g (1.5mol) of styrene monomer, 98.1g (1.0mol) of maleic anhydride, and 0.5g of Shuangwuwu into a four-necked flask, fill it with nitrogen, raise the temperature to 85°C, and cool down after 3 hours to obtain 252g of white solid, take out 120g of white solid, add 60g of 1-butyl-2,,3 dimethylimidazolium tetrafluoroborate, protect with nitrogen, stir at 100°C for 4 hours, and obtain the block after grafting of ionic liquid Copolymer, get this block copolymer 120g, antioxidant pentaerythritol bis-diphosphite bis(2,4-di-tert-butylphenyl) 0.15g, hydroxyl silicone oil 3g, particle size D (0.9) is the precipitation method of 6 μm 25g of white carbon black, 4.5g of calcium stearate, 4.6g of silicone oligomer with a viscosity of 850,000 CP, put into the internal mixer, heat and stir at 85°C for 30 minutes, and then extrude through a twin-screw extruder at 95°C Granulate to obtain permanent antistatic ionic liquid polymer masterbatch PS-MAH-SA350.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com