Humidity sensing arrangement for microwave oven with vented fume hood

A sensing device and microwave oven technology, applied in the field of microwave ovens, can solve problems such as inability to omit, inaccurate humidity, etc., and achieve the effects of smooth discharge, reduction in the number of parts, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

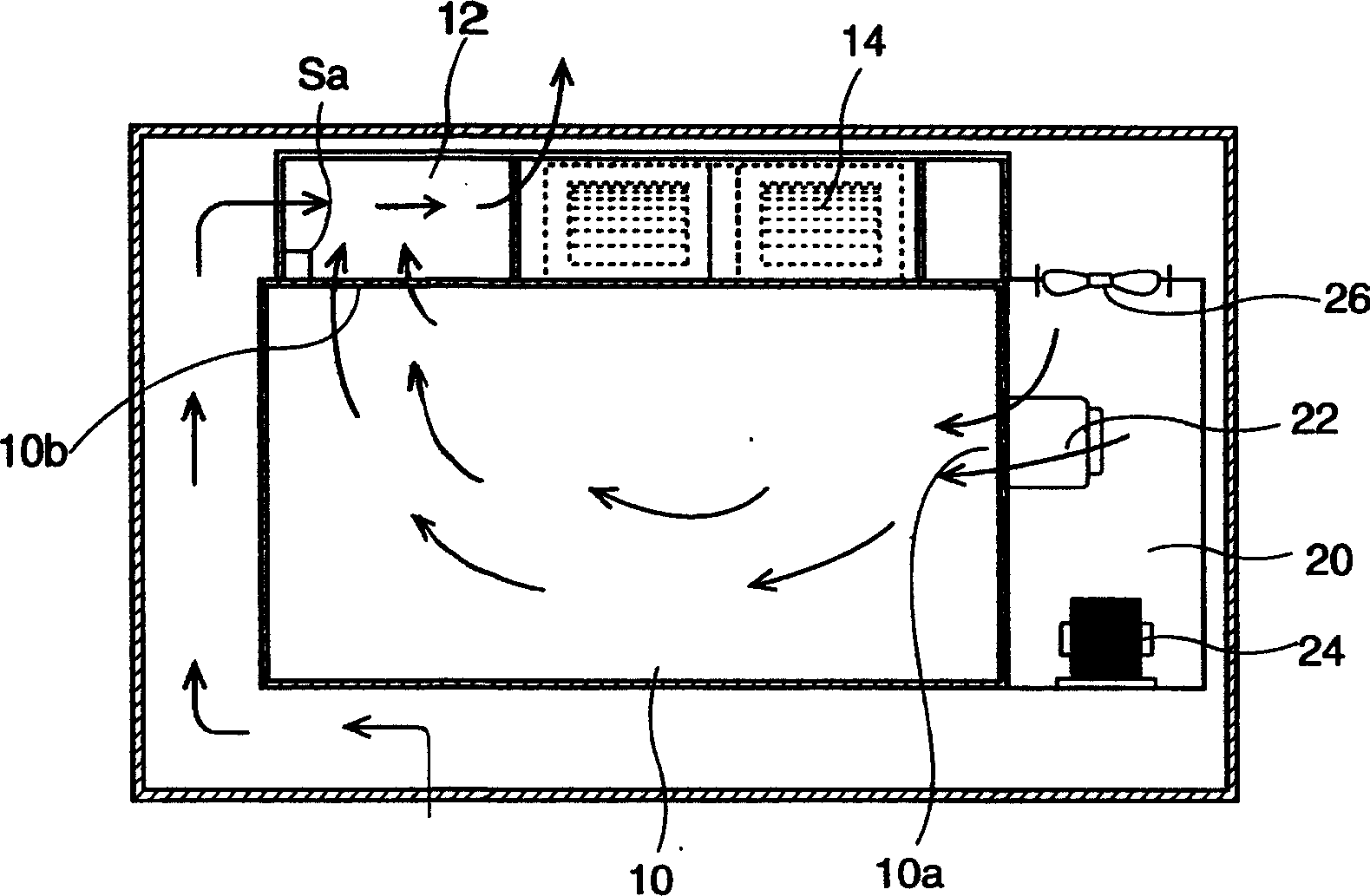

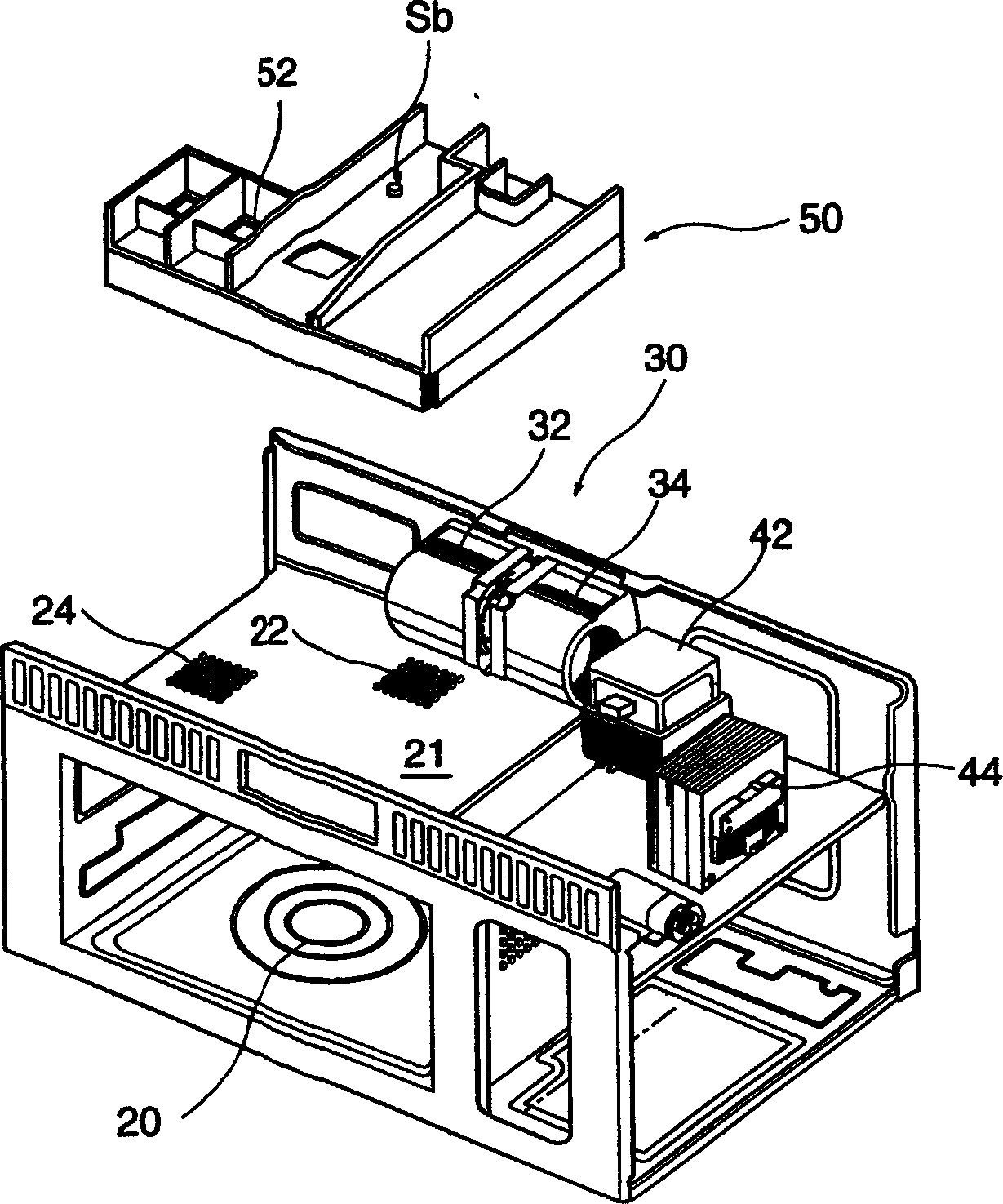

[0023] like figure 2 As shown, the present invention is used for the humidity sensing device of the microwave oven with ventilation hood and comprises: the cavity 21 above the heating chamber, the exhaust motor assembly 30 arranged at the rear of the cavity 21 above the heating chamber, the exhaust motor assembly arranged at the 30 is connected to the exhaust port 22 of the heating chamber 20, and the front part of the cavity 21 above the heating chamber is connected to the air inlet 24 of the heating chamber 20, and is arranged near the exhaust port 22 to measure the humidity of the exhausted air. Humidity sensor Sb.

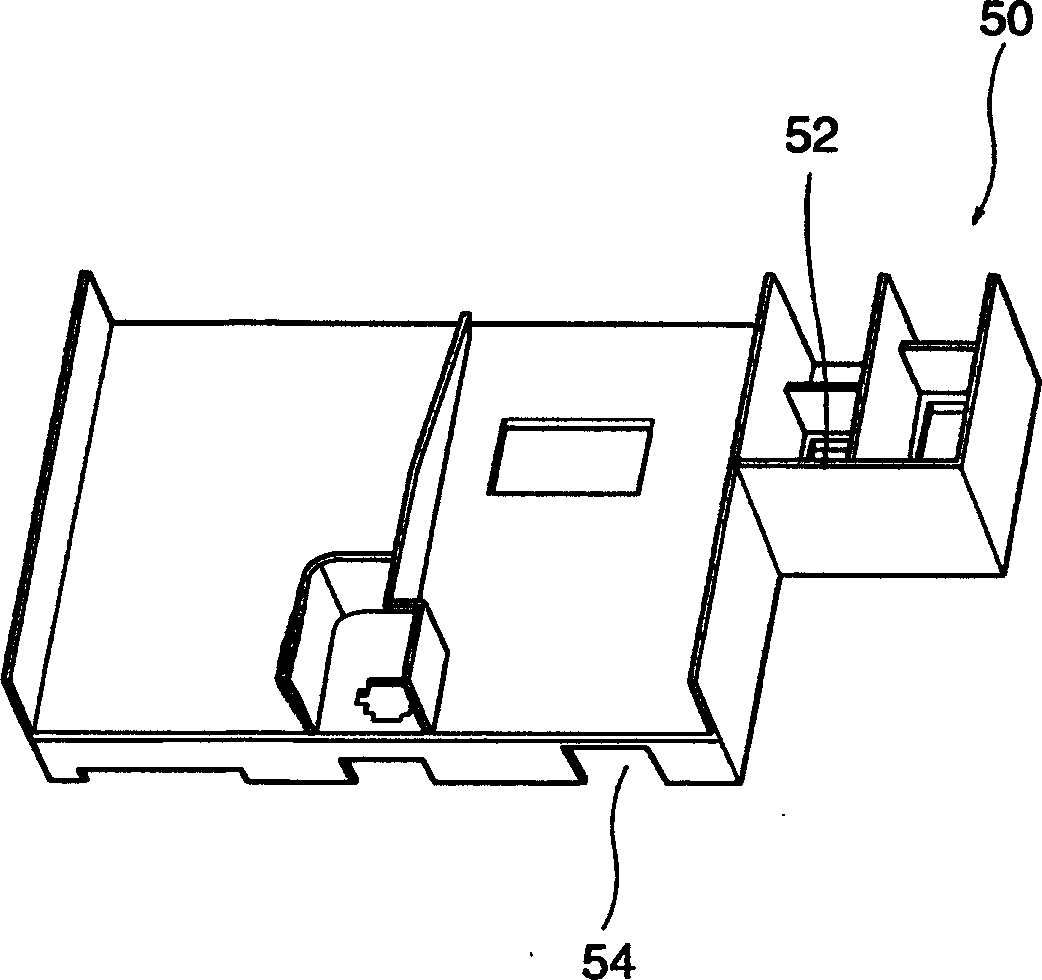

[0024] The cavity 21 above the heating chamber is provided with an air channel 50 for guiding air flow; the humidity sensor Sb is arranged on the air channel 50 corresponding to the upper part of the exhaust port 22 .

[0025]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com