Scutching device for textile production

A textile and cotton cleaning technology, applied in the field of textile production, can solve the problems of affecting the quality of cotton raw materials, poor cotton cleaning effect, and increased labor costs, and achieve the effect of simple and reasonable structure, good cotton cleaning effect, and reduced labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

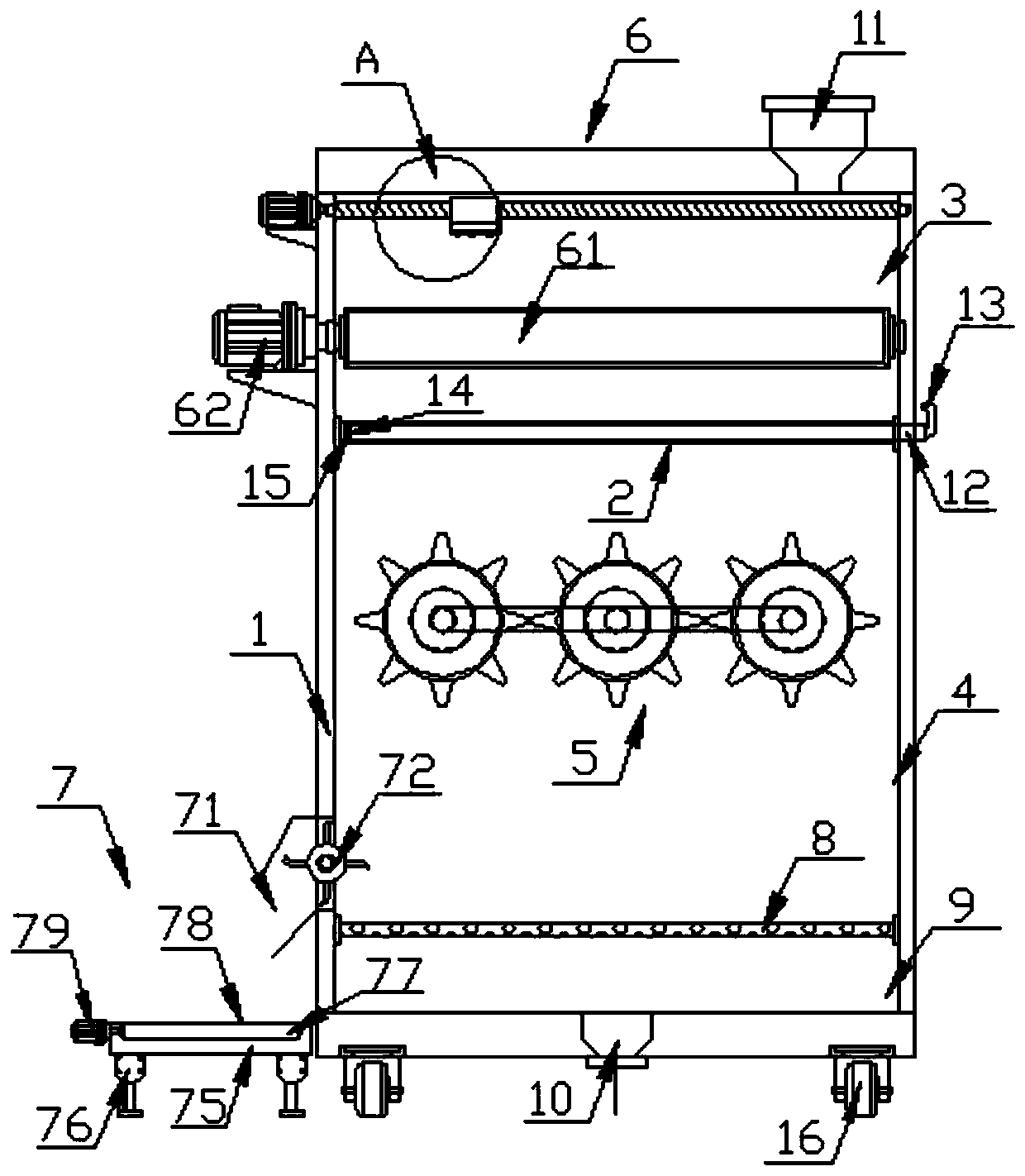

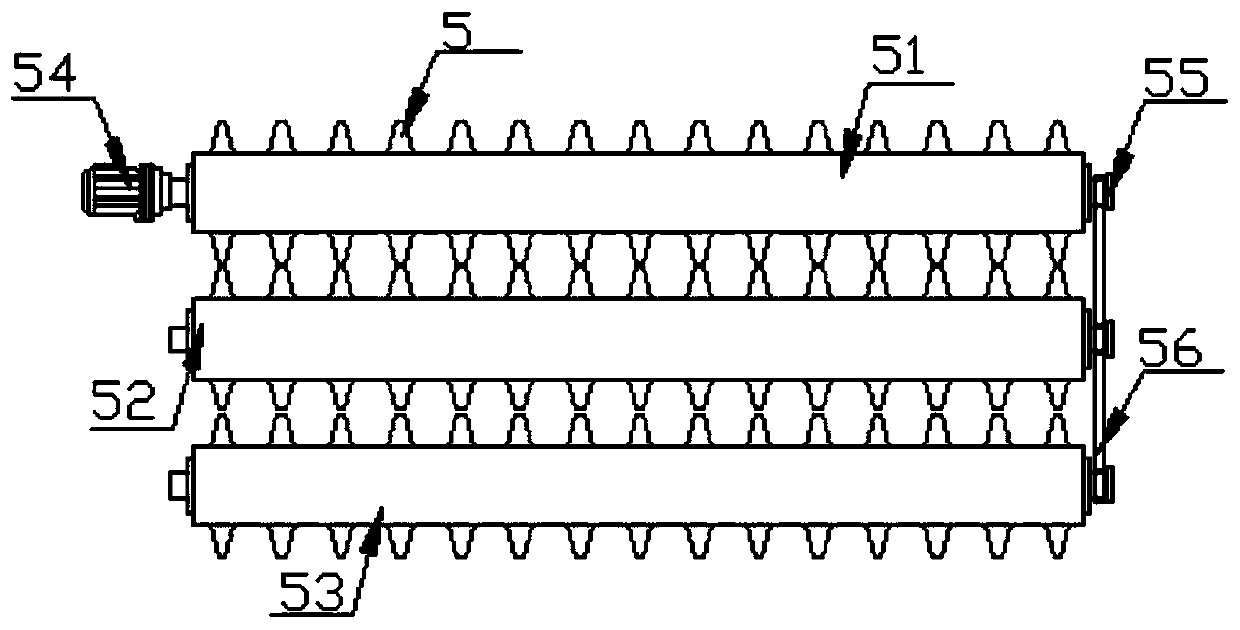

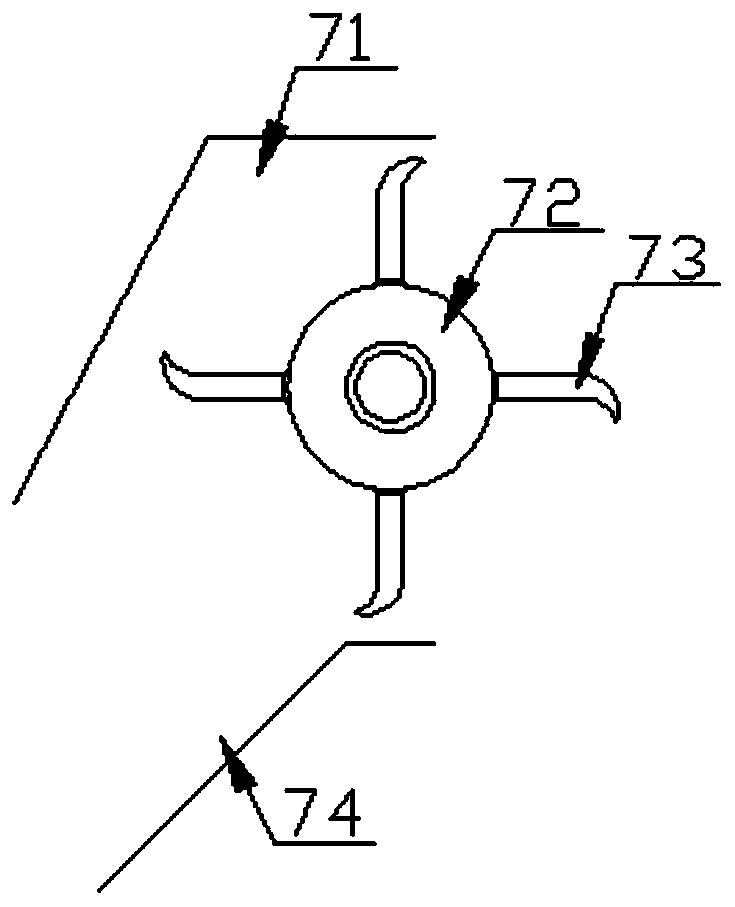

[0025] Such as Figure 1-4 As shown, this specific embodiment adopts the following technical solutions: a cotton cleaning device for textile production, including a box body 1, a cleaning mechanism for removing impurities 5, a mixing and cleaning mechanism 6, a discharge mechanism 7 and a screening screen for removing impurities 8. The inside of the box 1 is welded with a support bracket 2, and the support bracket 2 divides the box 1 into two parts, the upper box 3 and the lower box 4, and the inside of the lower box 4 is set There is an impurity cleaning mechanism 5, the inside of the upper box 3 is provided with a mixing and cleaning mechanism 6, and one side of the lower box 4 is provided with a discharge mechanism 7, and the lower part of the bottom of the impurity cleaning mechanism 5 is The inside of the box body 4 is welded with an impurity removal and screening net plate 8, and the lower box body 4 on the side far away from the impurity removal and cleaning mechanism 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com