A structure-improved milk powder spoon

A technology of milk powder and spoon body, which is applied in packaging and other directions, can solve the problem that milk powder cannot be effectively removed, and achieve the effect of simple structure, strong practicability, and waste reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

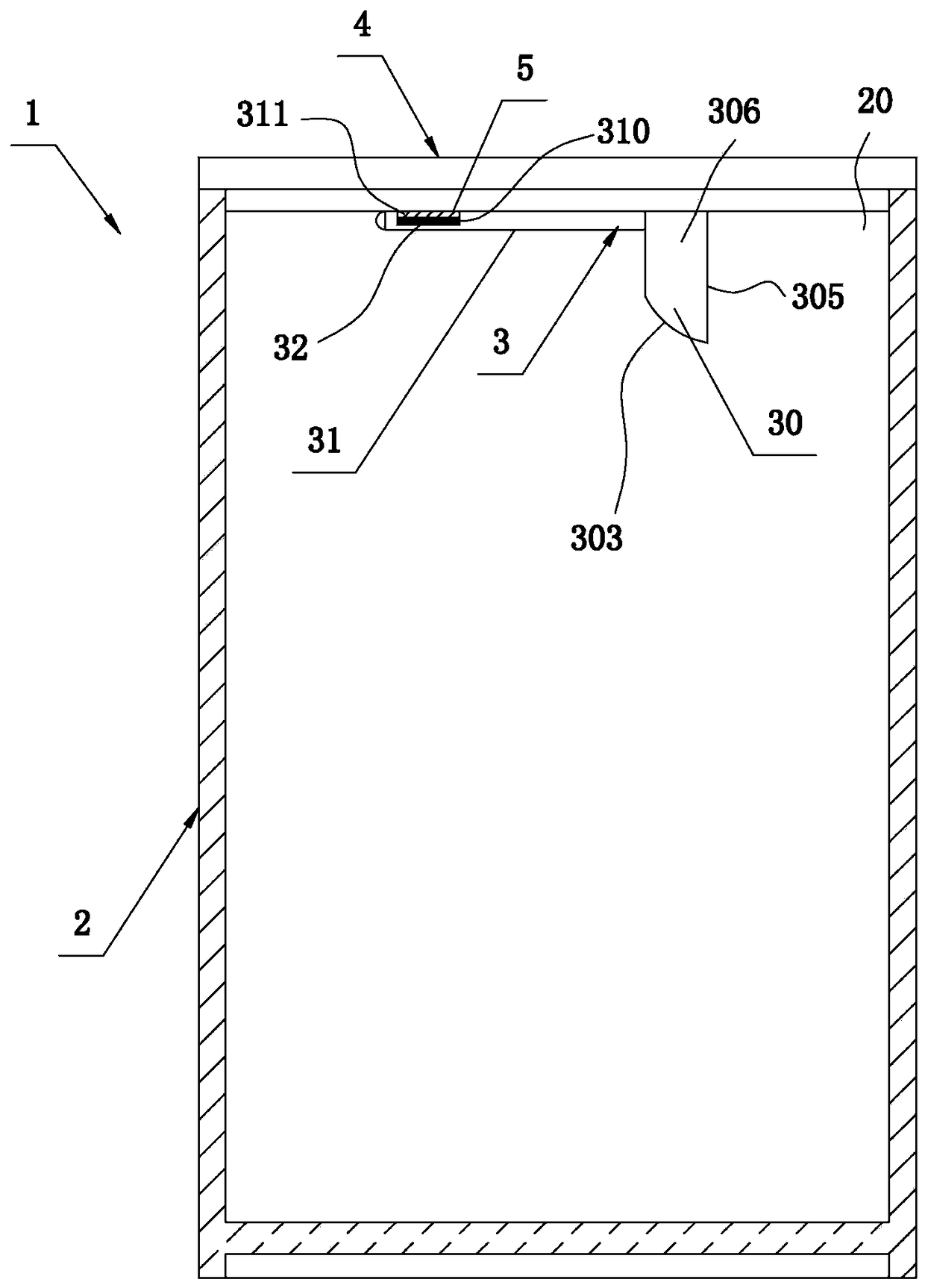

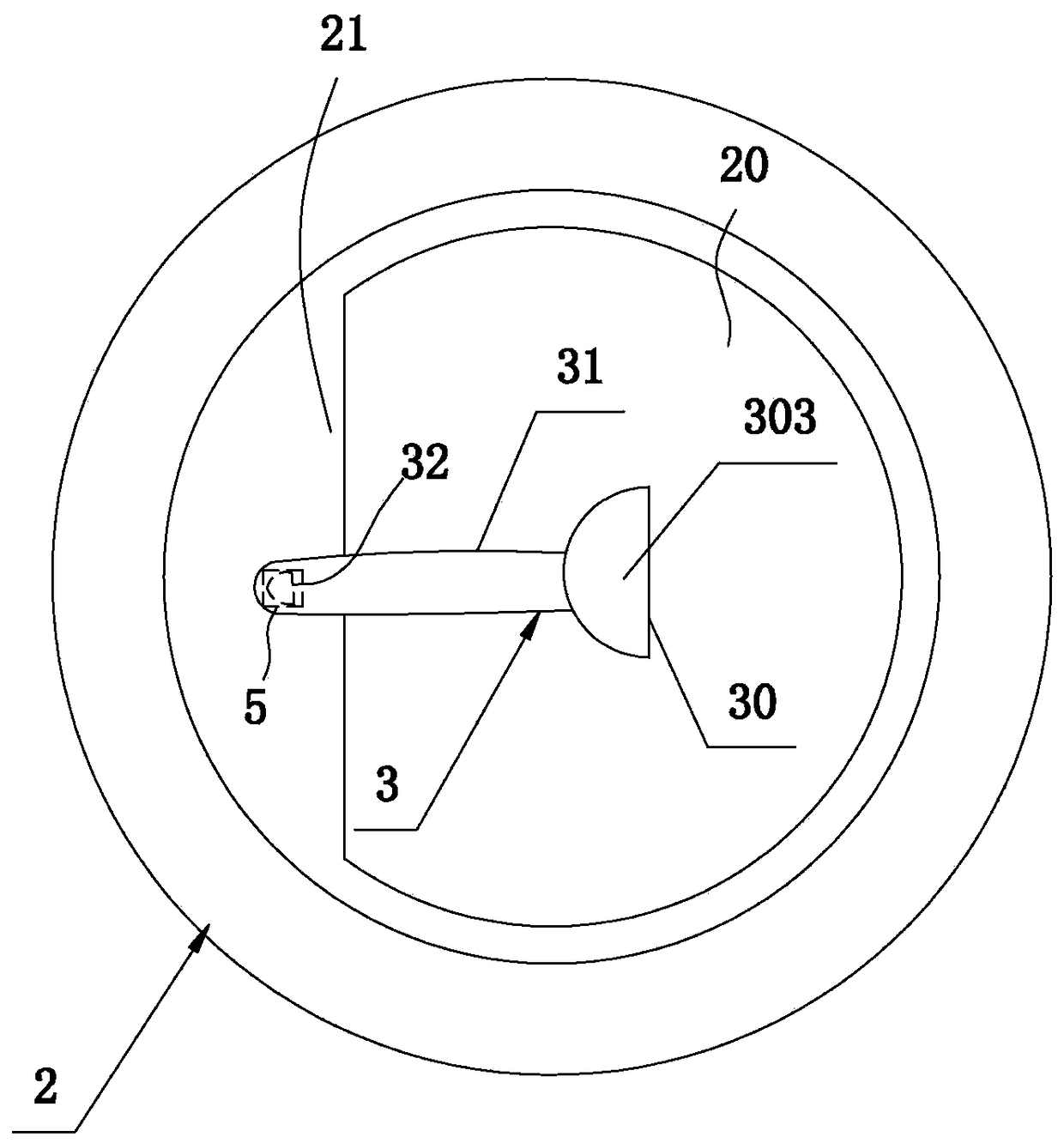

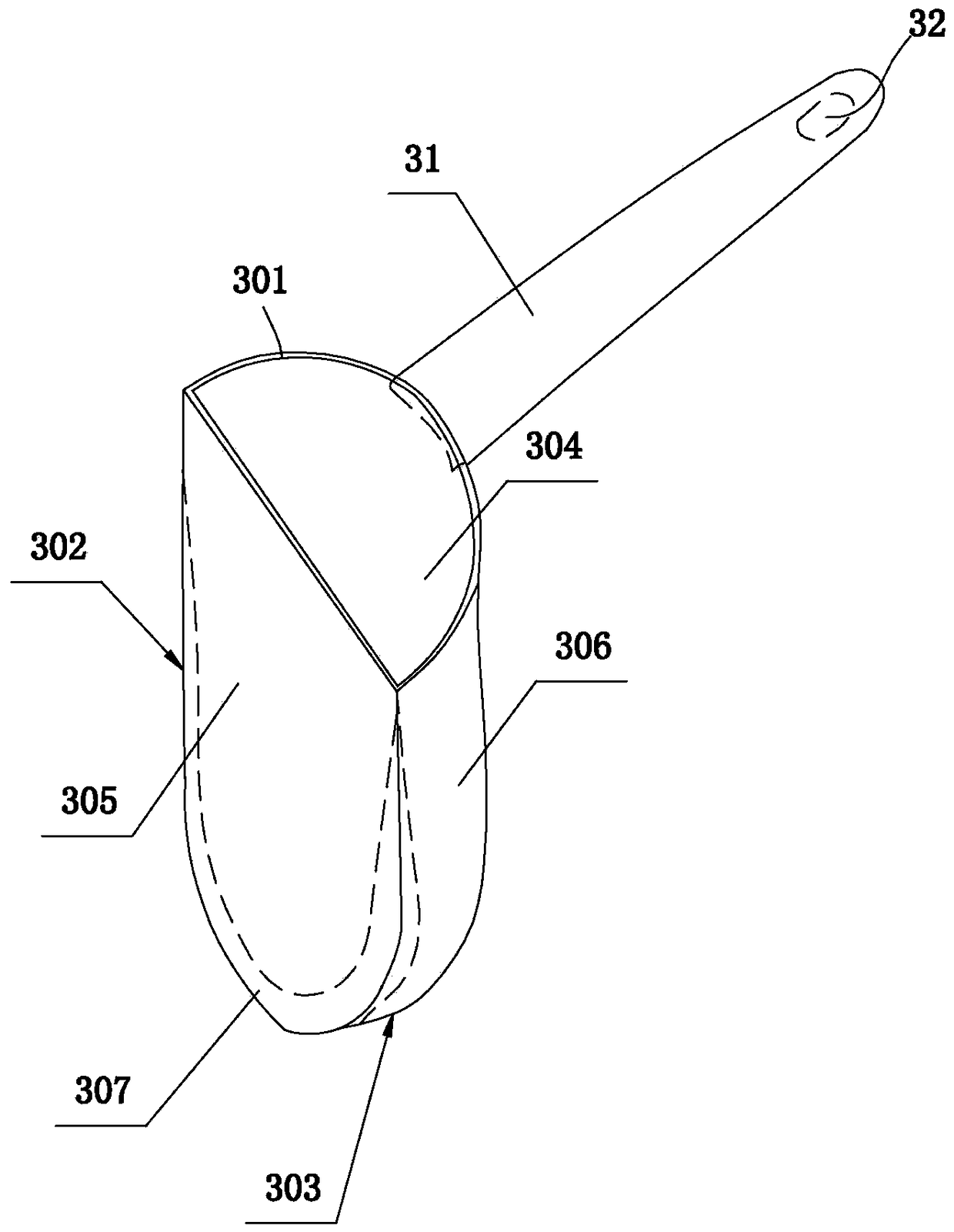

[0031] refer to figure 1 , figure 2 and image 3 . An easy-to-use milk powder can 1, comprising a can body 2, a milk powder scoop 3 and a can lid 4, the milk powder scoop 3 includes a scoop body 30 and a spoon handle 31 connected to one end of the scoop body 30, on the scoop handle 31 At least one magnet 32 is provided, and at least one iron part 5 is arranged at the mouth position 20 of the can lid 4 or the tank body 2, and the milk powder scoop 3 communicates with the iron part through the magnet 32 on its spoon handle 31. 5 is connected by magnetic force, and the spoon handle 31 is installed on the tank mouth position 20 of the tank cover 4 or the tank body 2 in a transverse arrangement. The present invention has simple structure and strong practicability. A magnet 32 is set on the spoon handle 31 of the milk powder spoon 3, and an iron material capable of magnetically connecting with the magnet 32 is set at the position of the can mouth of the can lid 4 or the ...

Embodiment 2

[0039] In addition, refer to image 3 and Figure 6 . In another preferred embodiment of the present invention, the spoon handle 31 includes a fixed handle 313 connected to the spoon body 30 and a flexible bending part 314 rotatably connected to the end of the fixed handle 313, so The accommodating groove 310 is disposed on the flexible bending portion 314 .

[0040] More specifically, the accommodating groove 310 is disposed in the middle of the flexible bending portion 314, and the flexible bending portion 314 is pivotally connected to the end of the fixed handle 313 on the side where the accommodating groove 310 is located. , the rotation angle between the flexible bending part and the fixed handle is 0°-90°. More preferably, the flexible bending part can form two arrangement states of engaging at an angle of 0 degree and engaging at an angle of 90 degrees with the end of the fixed handle 313 . By setting the flexible bending part 314 and configuring the magnet 32 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com