Stator and permanent magnet brushless direct current motor

A stator and stator core technology, applied in the shape/style/structure of electrical components, electromechanical devices, winding conductors, etc., can solve problems such as running noise or resonance that is difficult to eliminate, large torque fluctuations, and large cogging torque , to achieve the effects of reducing cogging torque and torque ripple, increasing the slot-to-pole ratio, and increasing power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

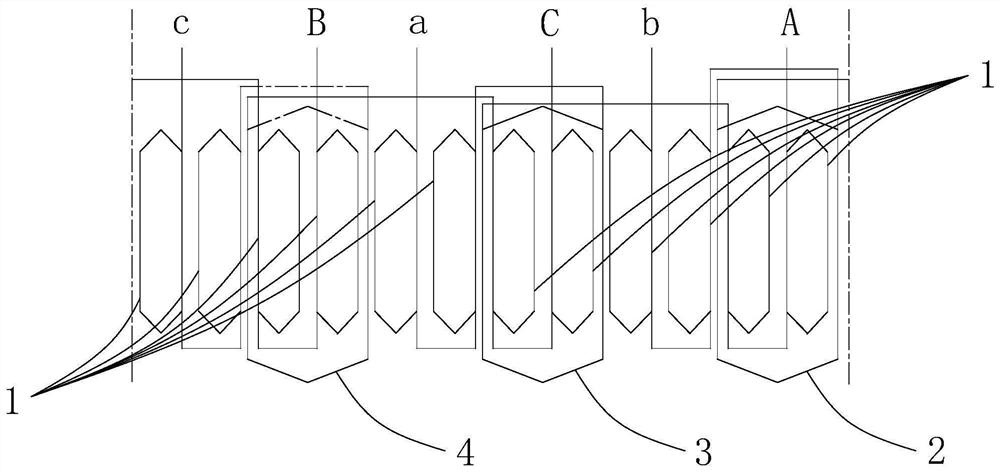

[0016] see figure 1 As shown, the above-mentioned stator includes a stator core, and the stator core is provided with at least one set of A phase, b phase, C phase, a phase, B phase, and c phase arranged in sequence, and each phase includes at least two sets of pitch. In this embodiment, each phase includes two sets of pitches.

[0017] The above-mentioned stator also includes a one-to-one corresponding element winding 1 arranged in the pitch, a B-phase auxiliary winding 2 wound on the A phase, an A-phase auxiliary winding 3 wound on the C phase, and a B-phase auxiliary winding wound on the B phase. Phase C auxiliary winding on phase 4. From figure 1 It can be seen that the B-phase auxiliary winding 2 is adjacent to the b-phase, the A-phase auxiliary winding 3 is adjacent to the a-phase, and the C-phase auxiliary winding 4 is adjacent to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com