An electronic expansion valve coil

An electronic expansion valve and coil technology, applied in the field of expansion valve coils and unipolar coils, can solve the problems of complex coil structure and process, disordered winding lead ends, and cumbersome parts assembly, and achieve excellent resistance to permanent deformation. Effect of surface magnetic flux density, excellent electrical insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

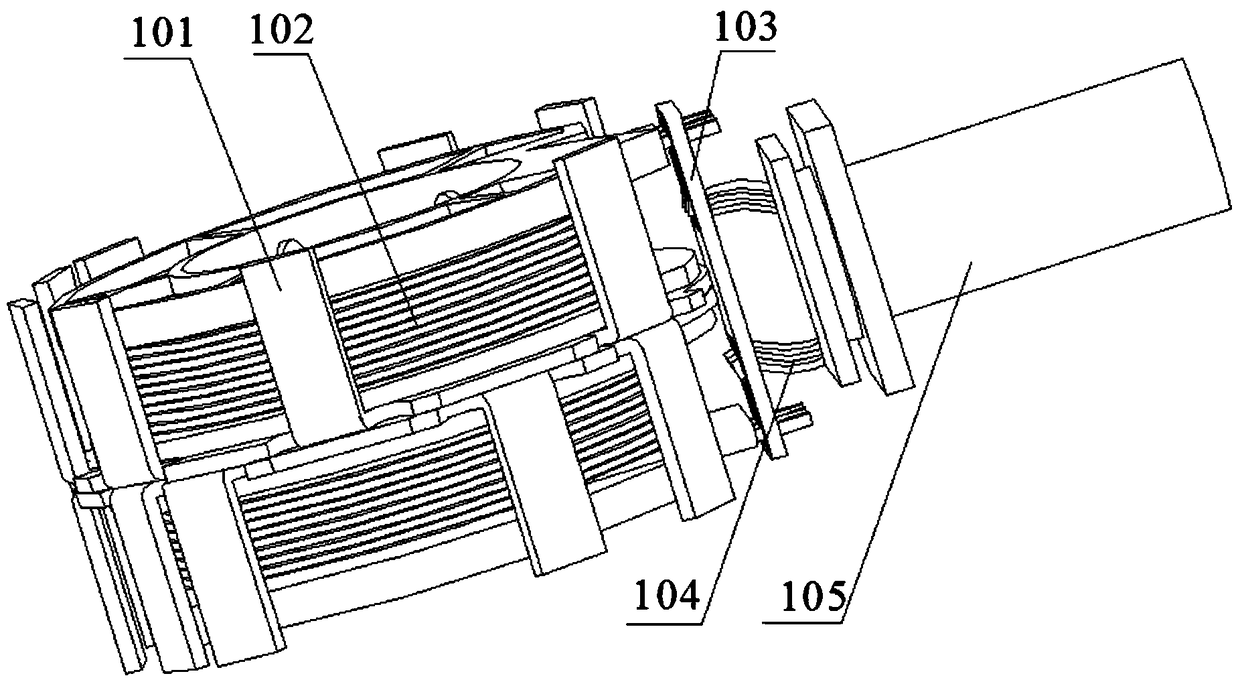

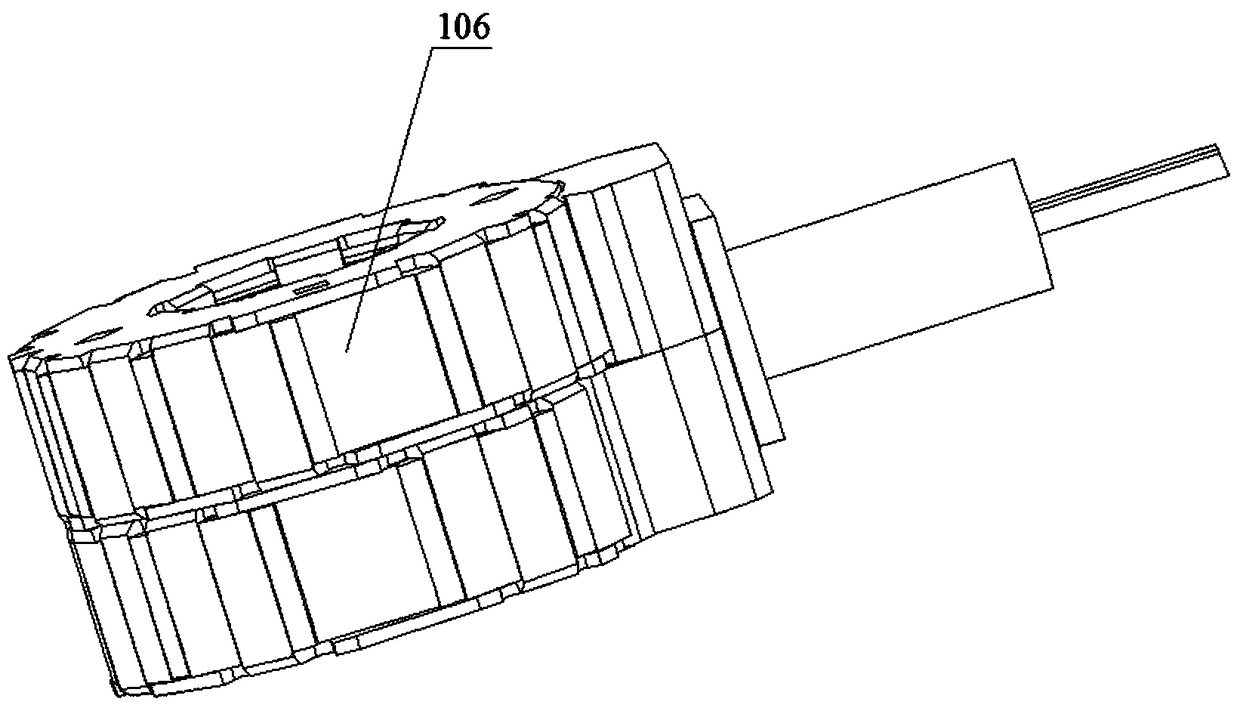

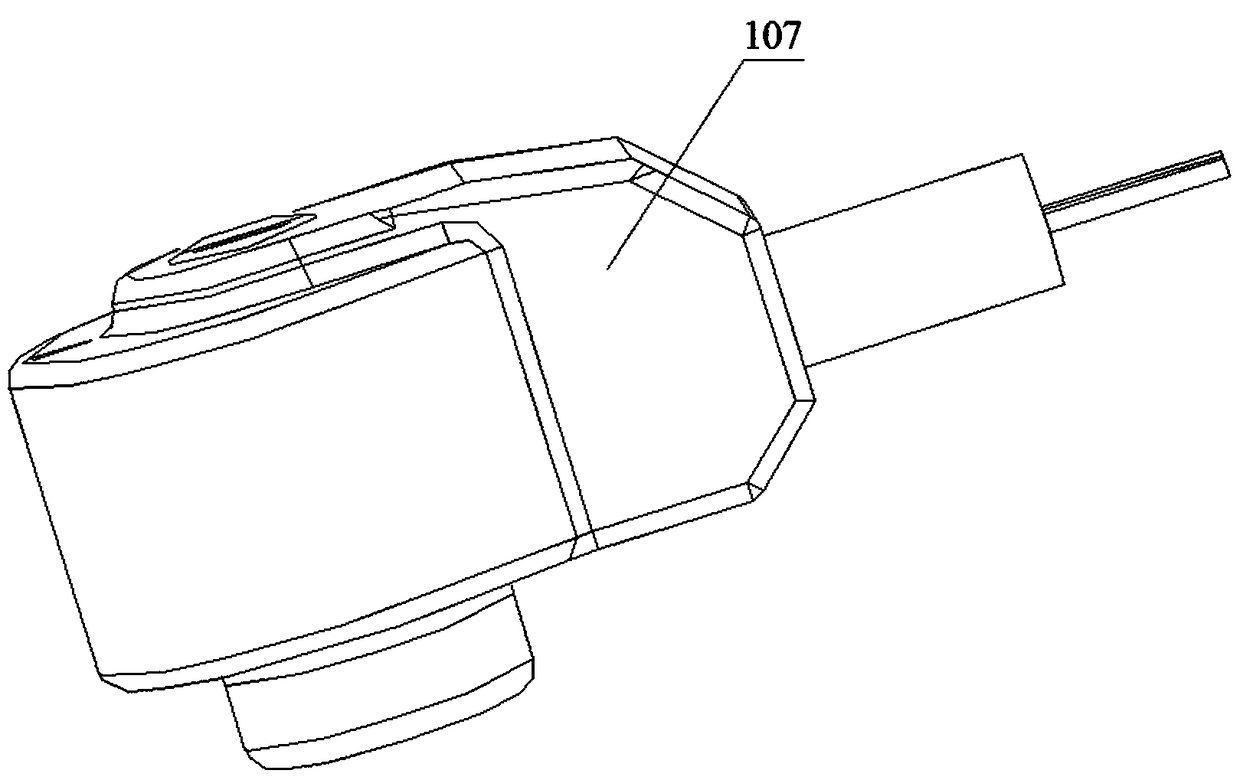

[0045] Such as Figure 5 , Image 6 , Figure 7 , Figure 8 with Figure 9 As shown, an electronic expansion valve coil includes a stator assembly, a circuit board 6, a connecting wire 7, and a sealant 12. The stator assembly is wrapped by a coil frame 2, an enameled wire 9 wound in the coil frame, and a middle pole plate 1. Coil bobbin 2 and casing 4 of enameled wire 9, outlet box 3, connecting post 10 connected to coil bobbin 2 and passing through outlet box 3, pole claw 11 is respectively arranged on middle pole plate 1 and casing 4, and sleeve Located outside the stator assembly, the injection molding body 5 is formed by integral injection molding of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com