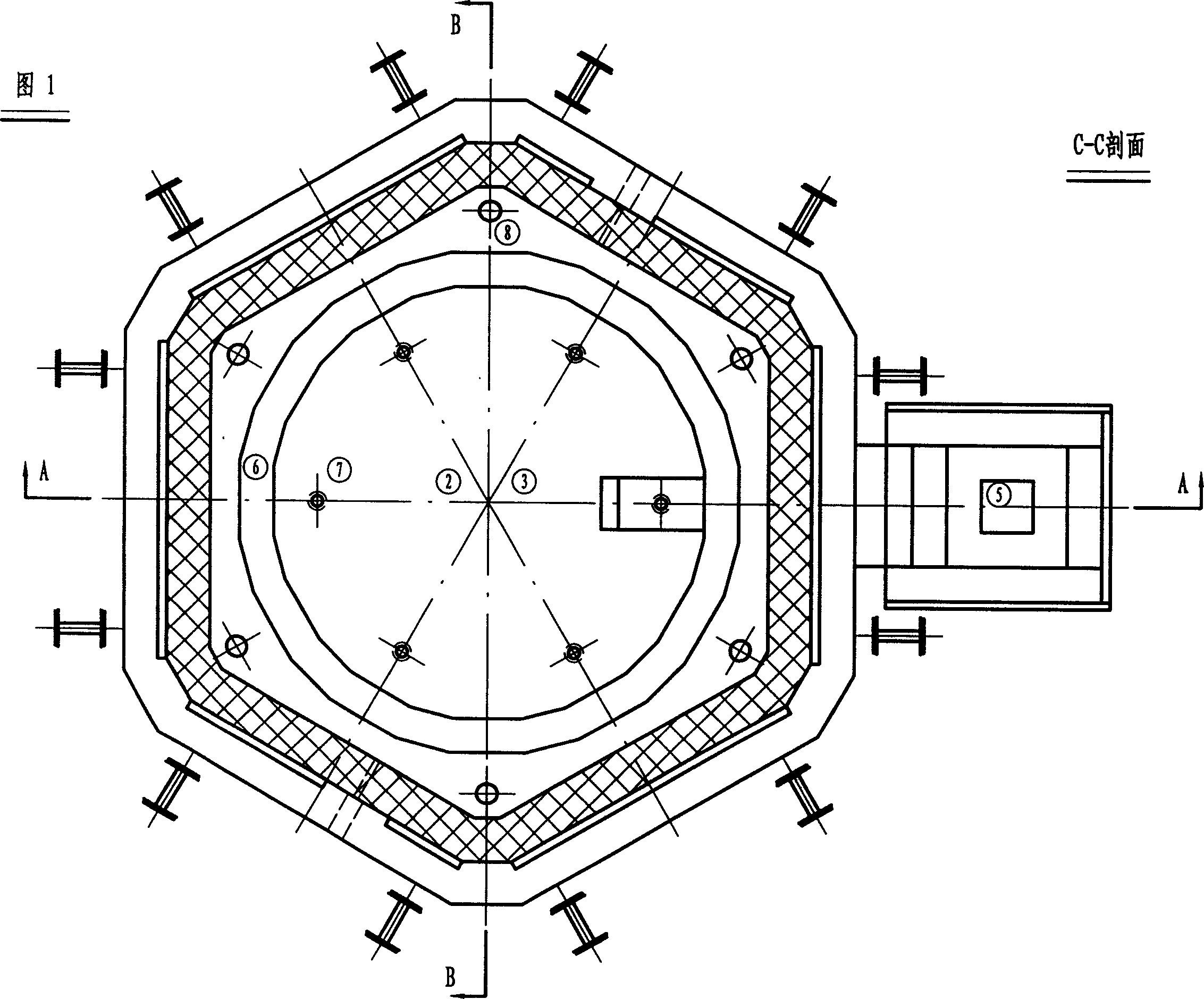

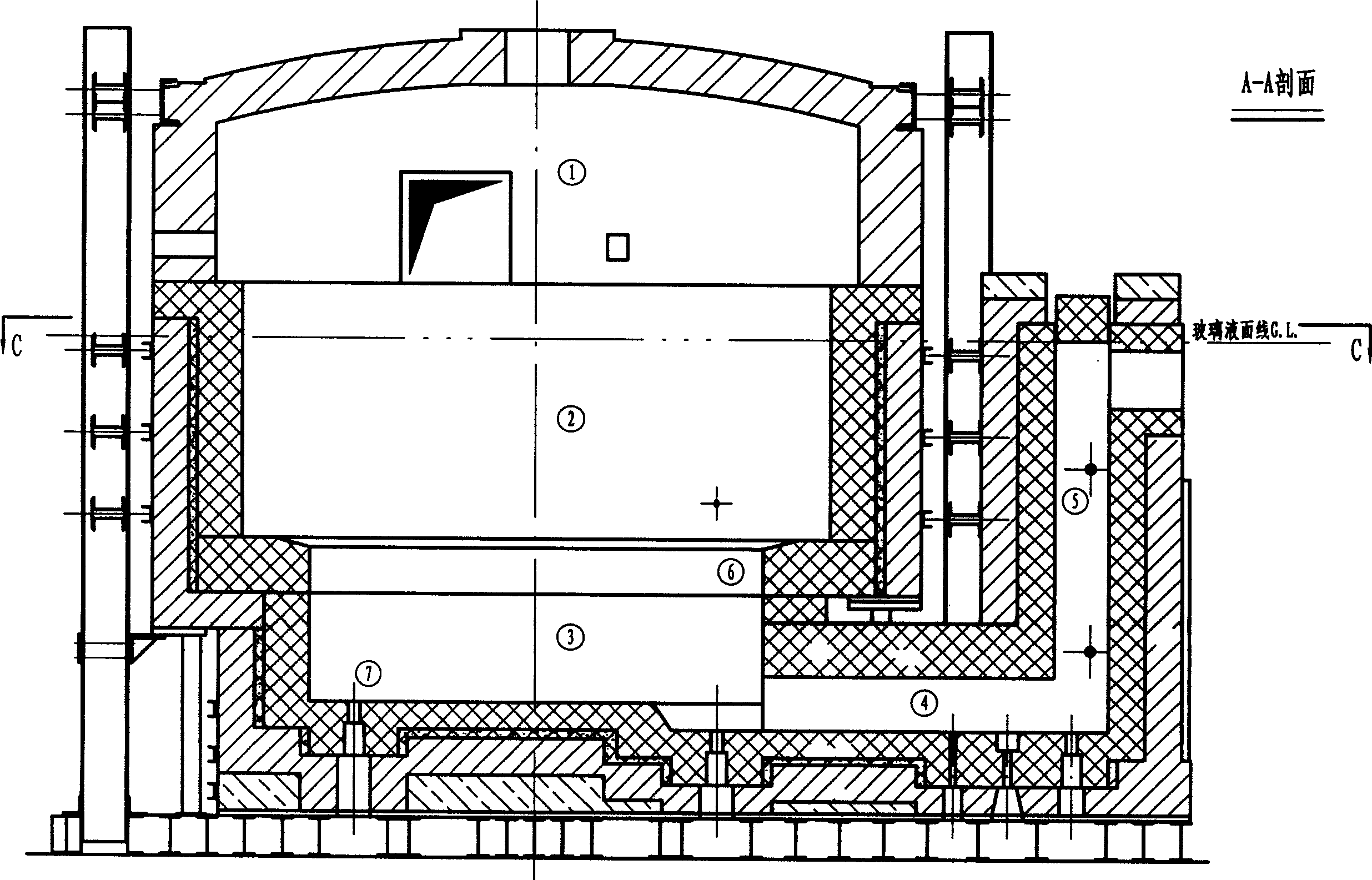

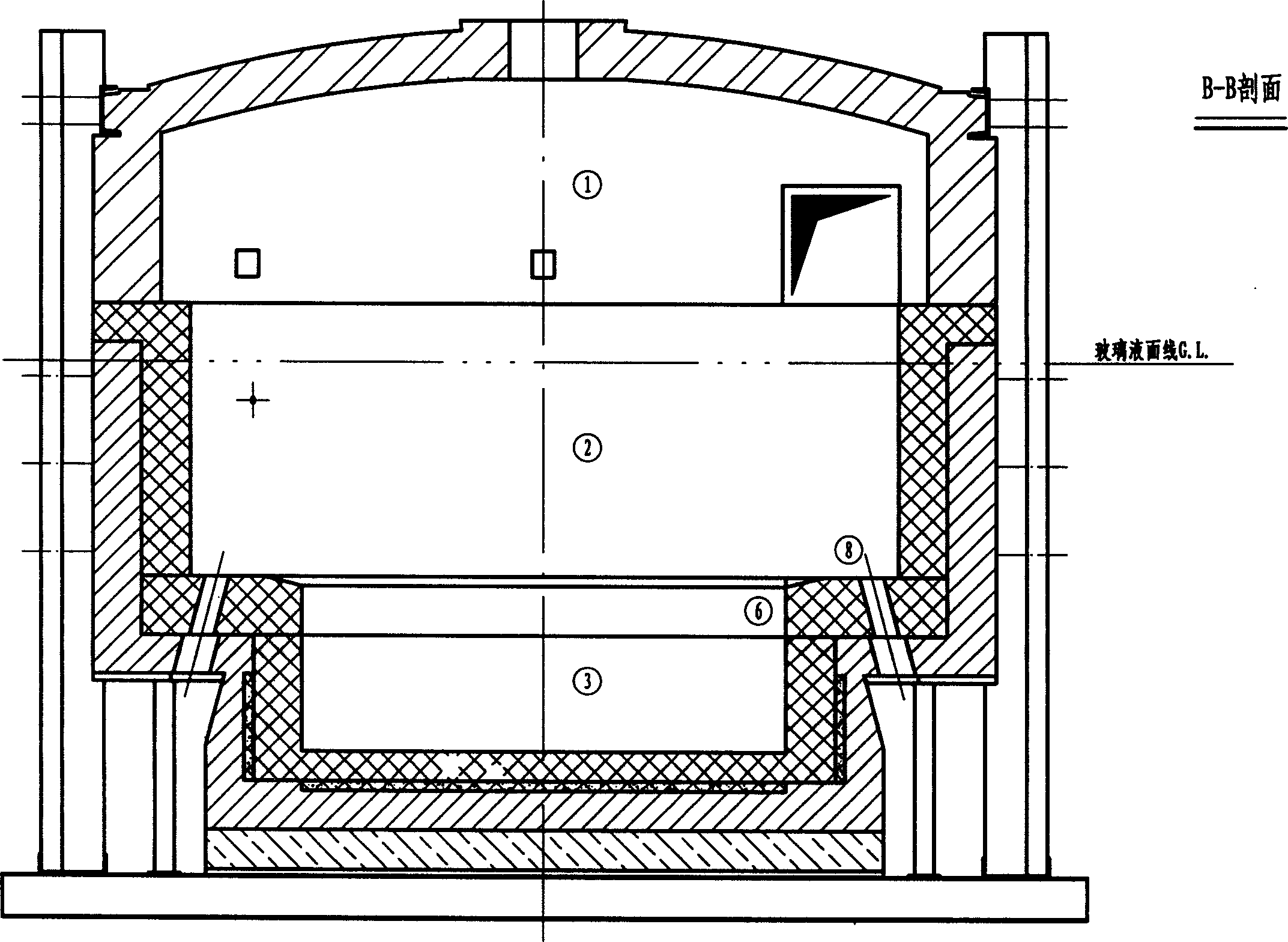

Hexagonal step type electrofusion furnace technology for high boron silicon instrument glass

A hexagonal, electric melting furnace technology, used in glass furnace equipment, electric furnaces, glass manufacturing equipment, etc., to achieve the effect of sufficient clarification and homogenization time, uniform heat distribution, and elimination of "dead corners"

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The batch material is added from the flame space (1) to the glass liquid surface of the upper pool (2) of the melting pool and covers the entire liquid surface; the glass liquid is provided by six molybdenum melting main electrodes (8) evenly installed vertically on the transition brick (6) The large load current and self-energization generate heat, so that the batch material is melted and the molten glass is clarified. The molten glass is further clarified and homogenized through the lower tank (3) of the melting pool, and the clarified and homogenized molten glass enters the molding channel through the liquid hole (4) and the ascending channel (5). The start-up molybdenum electrode (7) is only used when starting and charging the all-electric furnace, and only a small amount of electric load is added to the start-up molybdenum electrode to supplement the heat taken away by the cooling water of the electrode water-cooling jacket during the operation of the furnace after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com