Backlight unit

A backlight module and backlight technology, applied in optics, light sources, light guides, etc., can solve the problems of low thermal conductivity of heat dissipation glue, heavy heat sink, and unfavorable light weight of backlight modules, so as to eliminate local hot spots and improve heat dissipation. effect, the effect of uniform heat distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

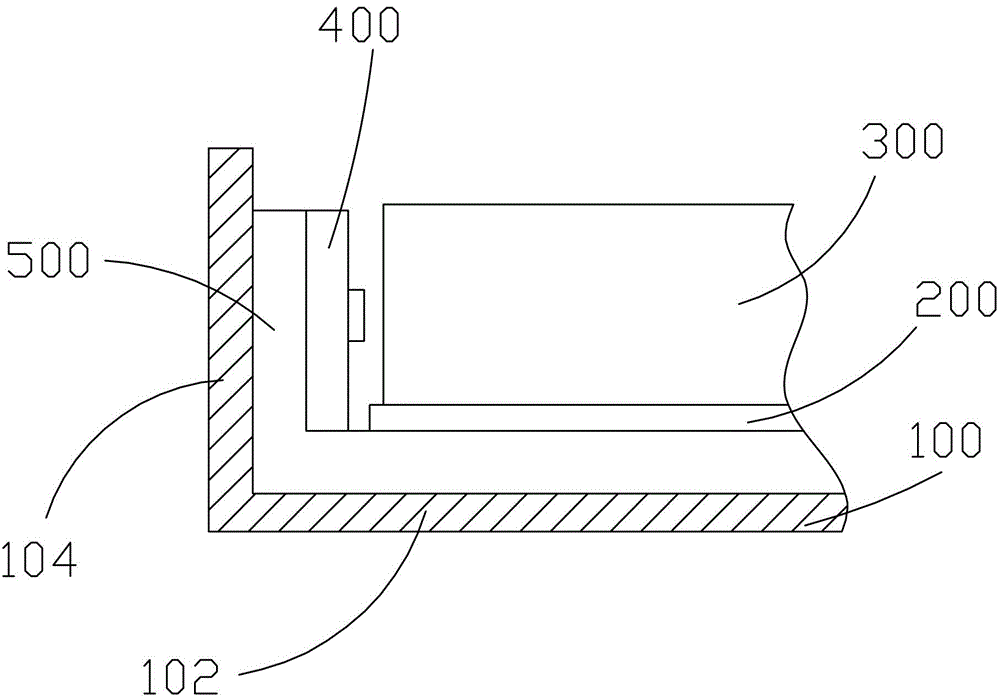

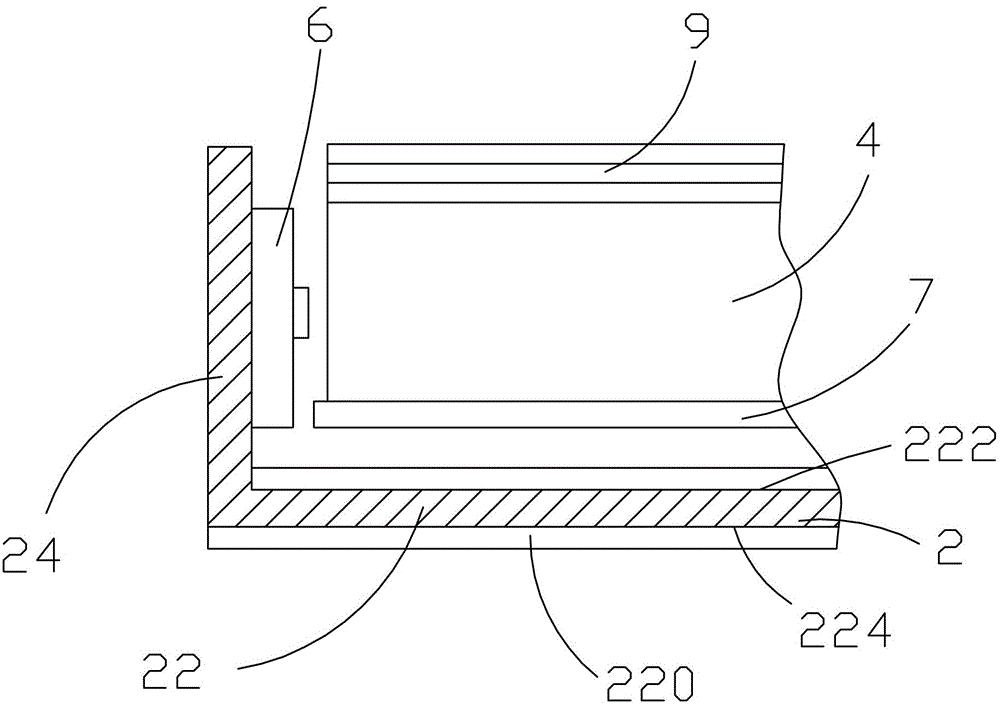

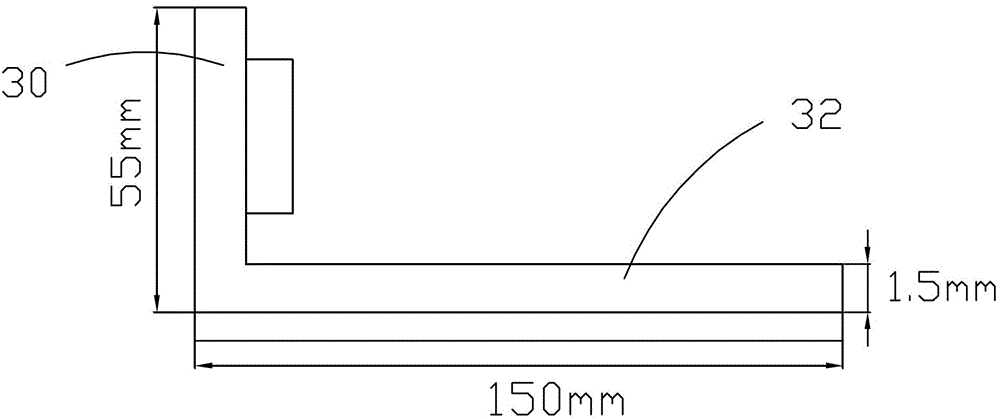

[0034] see figure 2 , is a structural schematic diagram of the first preferred embodiment of the backlight module of the present invention. The backlight module provided by the present invention includes: a backplane 2, a light guide plate 4 installed on the backplane 2, a backlight installed in the backplane 2 The source 6 and the heat dissipation film 220 disposed on the back plate 2, the heat dissipation film 220 is made of graphene, which can be a single-layer or multi-layer structure. The heat dissipation film 220 is formed on the backplane 2 by coating.

[0035] Graphene is a new type of material, which has the advantages of high temperature resistance, small thermal expansion coefficient, good thermal conductivity and electrical condu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com