Nonstick pan coating layer, and production method and nonstick pan thereof

A non-stick pan and coating technology, applied in coatings, anti-corrosion coatings, applications, etc., can solve problems such as environmental hazards, complicated construction, and high prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

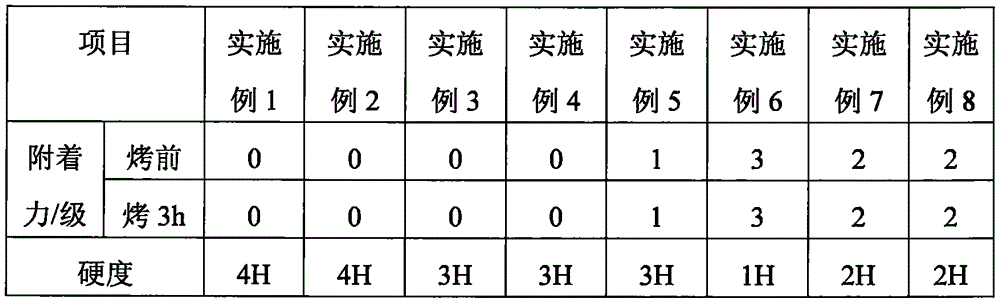

Examples

preparation example Construction

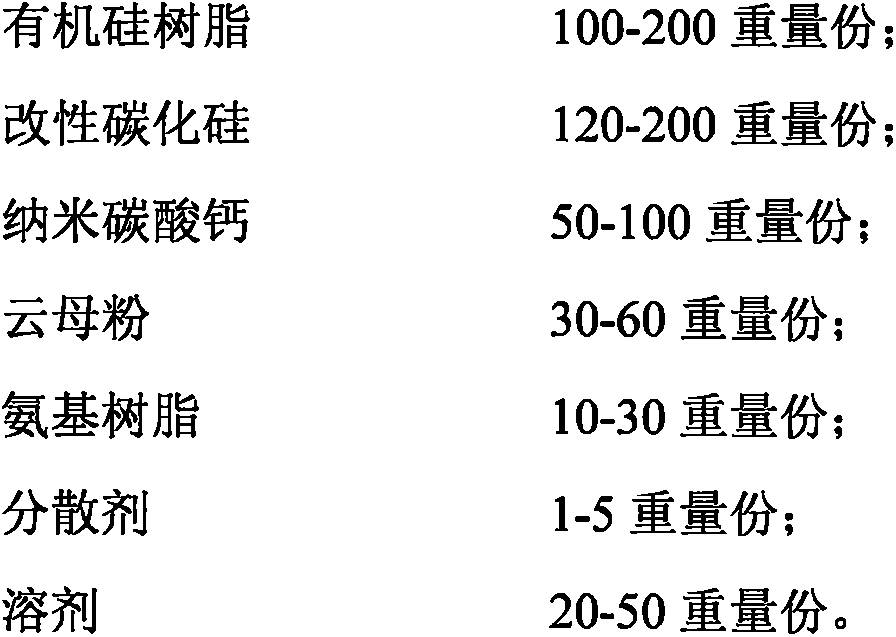

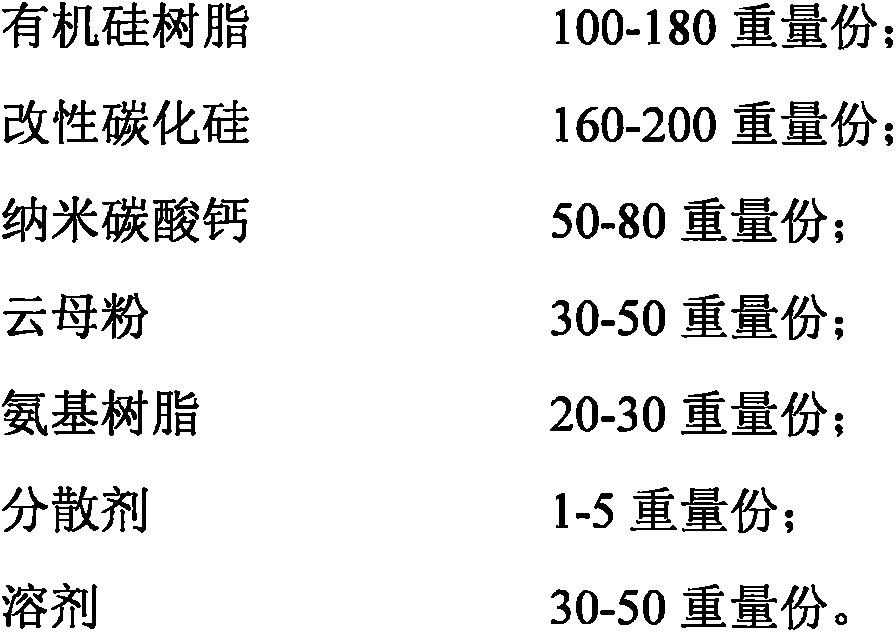

[0051] Correspondingly, the present invention also provides a preparation method of the above-mentioned non-stick coating, comprising the following steps: 100-200 parts by weight of silicone resin, 120-200 parts by weight of modified silicon carbide, 50-100 parts by weight of nano-carbonic acid Calcium, 30-60 parts by weight of mica powder, 10-30 parts by weight of amino resin, 1-5 parts by weight of dispersant and 20-50 parts by weight of solvent are mixed, ground, dispersed, and filtered to obtain a coating; the coating is sprayed on the The surface of the metal pan substrate is baked at 200-300° C. for 10-30 minutes to obtain a non-stick pan coating.

[0052]The modified silicon carbide is a composite powder synthesized by carbon nanoparticles and silicon powder through mechanochemical method, which can improve the mechanical properties, oxidation resistance and thermal stability of the non-stick coating. As a preferred solution, the modified silicon carbide is prepared acc...

Embodiment 1

[0065] The high-performance non-stick coating of the present embodiment is prepared from the following raw materials by weight: 100 parts by weight of silicone resin, 200 parts by weight of modified silicon carbide, 50 parts by weight of nano-calcium carbonate, and 30 parts by weight of mica powder 10 parts by weight of amino resin R717, 5 parts by weight of dispersant BYK161 and 20 parts by weight of mixed solvent, wherein the molar ratio of mixed solvent is water: ethanol=1:1.

[0066] Wherein, the preparation method of the modified silicon carbide is as follows: the molar ratio of carbon nanoparticles and Si micropowder is C:Si=1.5:1 to prepare a mixed powder, and place it in a stainless steel vacuum tank to seal and vacuum it, and then introduce argon gas protection, using stainless steel balls as the grinding medium, and using a planetary ball mill for dry grinding at a speed of 150 rpm, a ball-to-material ratio of 20:1, and a ball milling time of 18 hours to obtain modifi...

Embodiment 2

[0069] The high-performance non-stick coating of this embodiment is prepared from the following raw materials by weight: 120 parts by weight of silicone resin, 180 parts by weight of modified silicon carbide, 80 parts by weight of nano-calcium carbonate, and 60 parts by weight of mica powder parts, 30 parts by weight of amino resin R747, 5 parts by weight of dispersant BYK162 and 50 parts by weight of mixed solvent, wherein the molar ratio of mixed solvent is water: ethanol=10:1.

[0070] Wherein, the preparation method of the modified silicon carbide is as follows: the molar ratio of carbon nanoparticles and Si micropowder is C:Si=2:1 to prepare a mixed powder, and put it in a stainless steel vacuum tank, seal and vacuumize, and then introduce argon gas protection, using stainless steel balls as the grinding medium, and using a planetary ball mill for dry grinding at a speed of 300 rpm, a ball-to-material ratio of 30:1, and a ball milling time of 36 hours to obtain modified si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com