Processing method for groove of oscillating follower cylinder cam

A technology of cylindrical cam and processing method, which is applied in the direction of metal processing equipment, manufacturing tools, milling machine equipment, etc., can solve problems such as unseen technical solutions, errors, etc., to meet the requirements of high-precision products, eliminate dead spots, and eliminate motion track errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

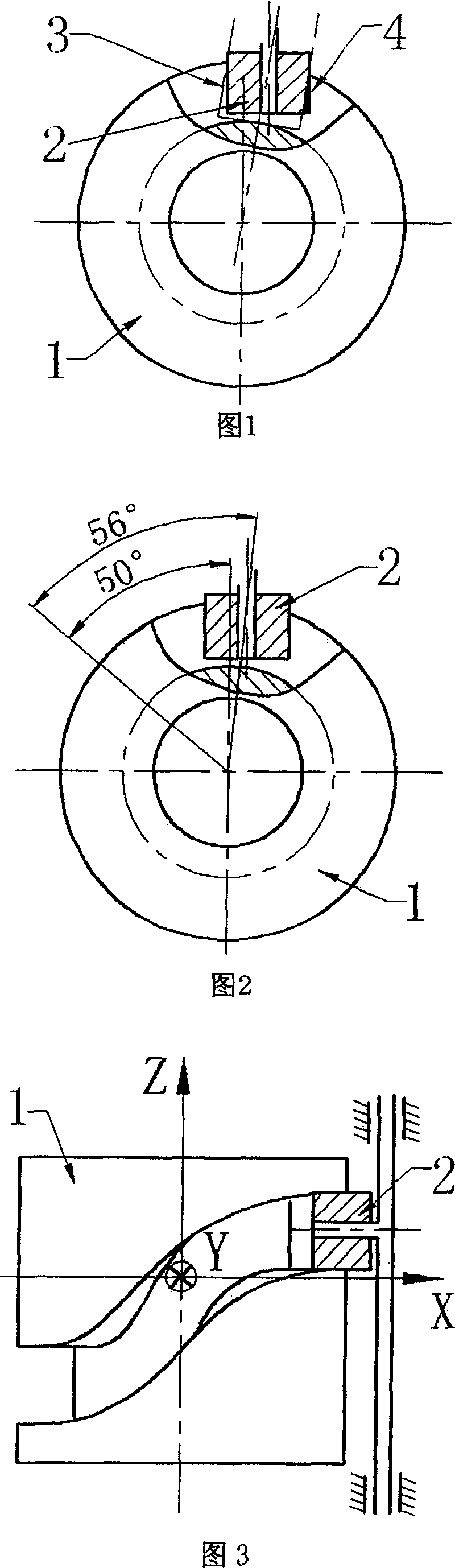

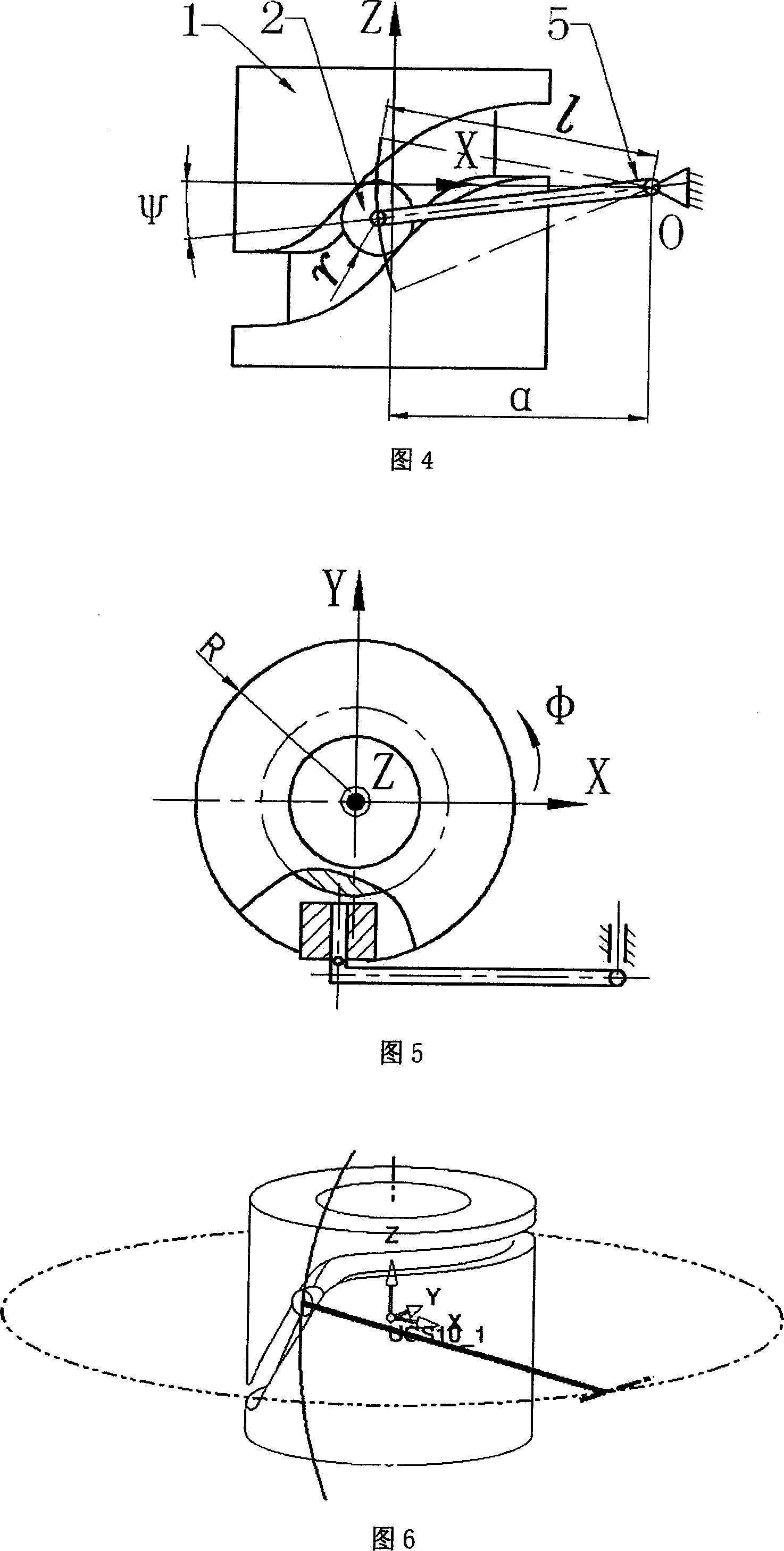

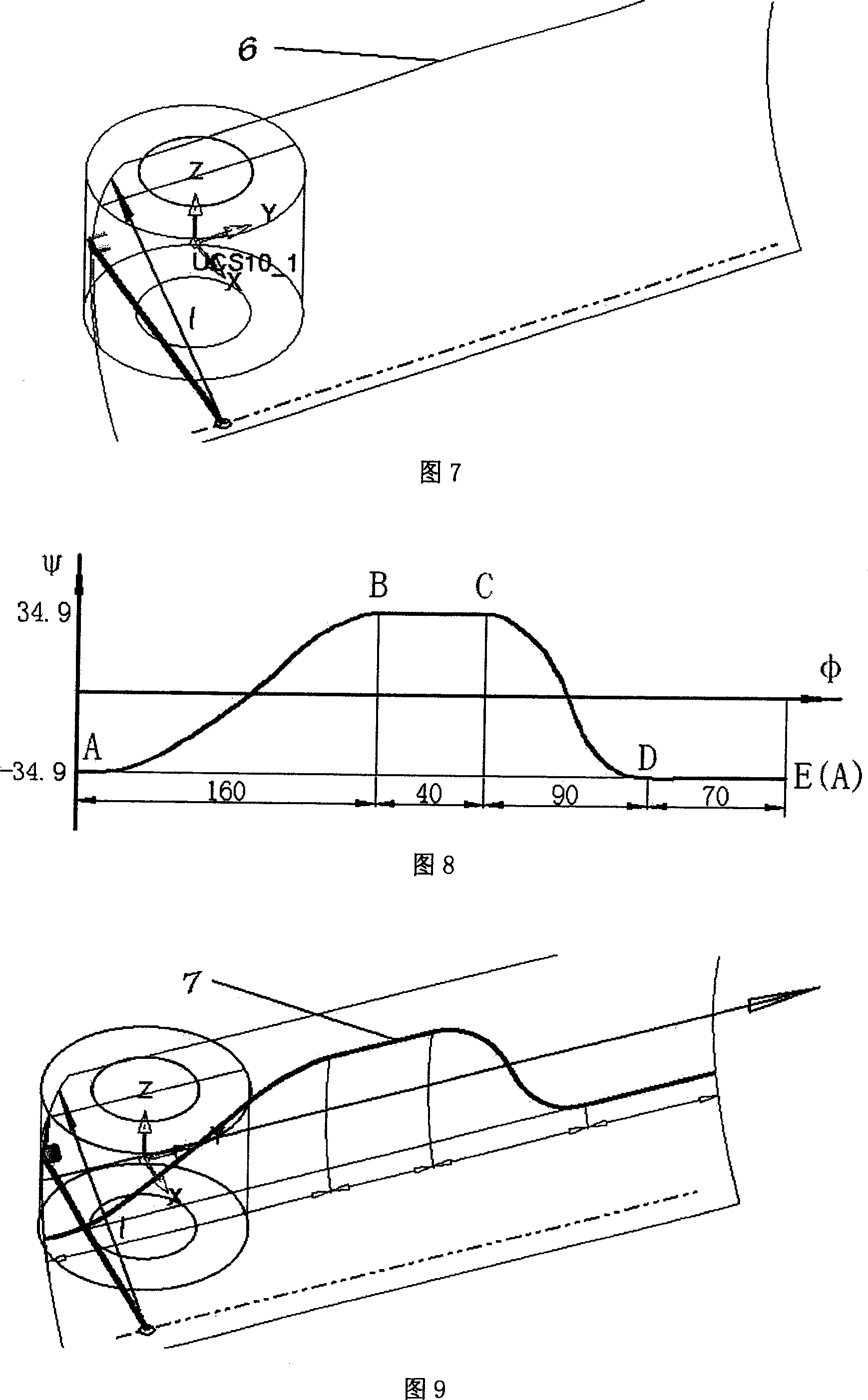

[0060] The present invention will be described in further detail below in conjunction with accompanying drawing and specific example, but the present invention is not limited to following embodiment (because the frequency that most of the objects marked with reference numerals in this embodiment, i.e. parts and coordinates, etc. occur too frequently High, if all add the mark then the file seems very cumbersome on the contrary, so, all marks all only mark when appearing for the first time, but the cylinder cam in the present embodiment, driven Part, tool, pendulum, unfolded surface, unfolded line, machining coordinates, and programming coordinates all refer to the same object).

[0061] As shown in Fig. 3, it is a linear follower cylindrical cam mechanism of the prior art, which can be programmed and processed by general plane expansion method (not discussed in the present invention).

[0062] In Figure 4 and Figure 5, the axis of the cylindrical cam is the Z axis, the common ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com