Automatic steering equipment capable of removing connecting rod dead points

An automatic steering and connecting rod technology, applied in mechanical equipment, transmissions, belts/chains/gears, etc., can solve the problems of non-parallel two axes, not simple and easy to operate, etc., and achieve the effect of eliminating dead spots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

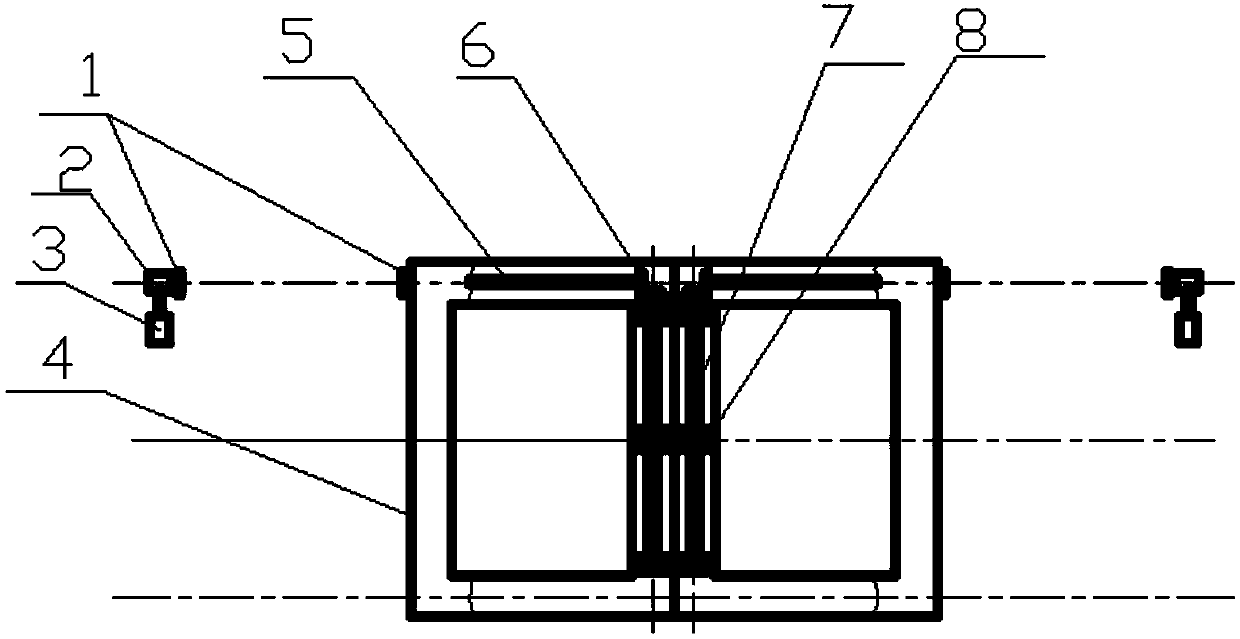

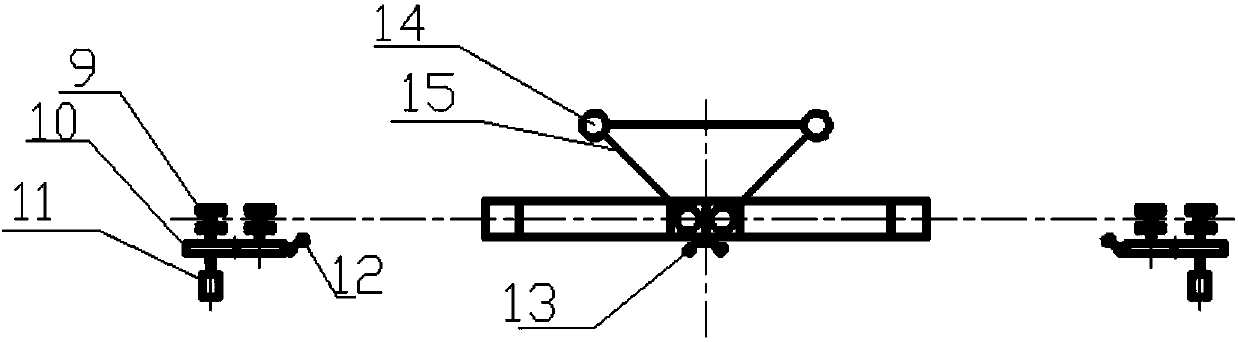

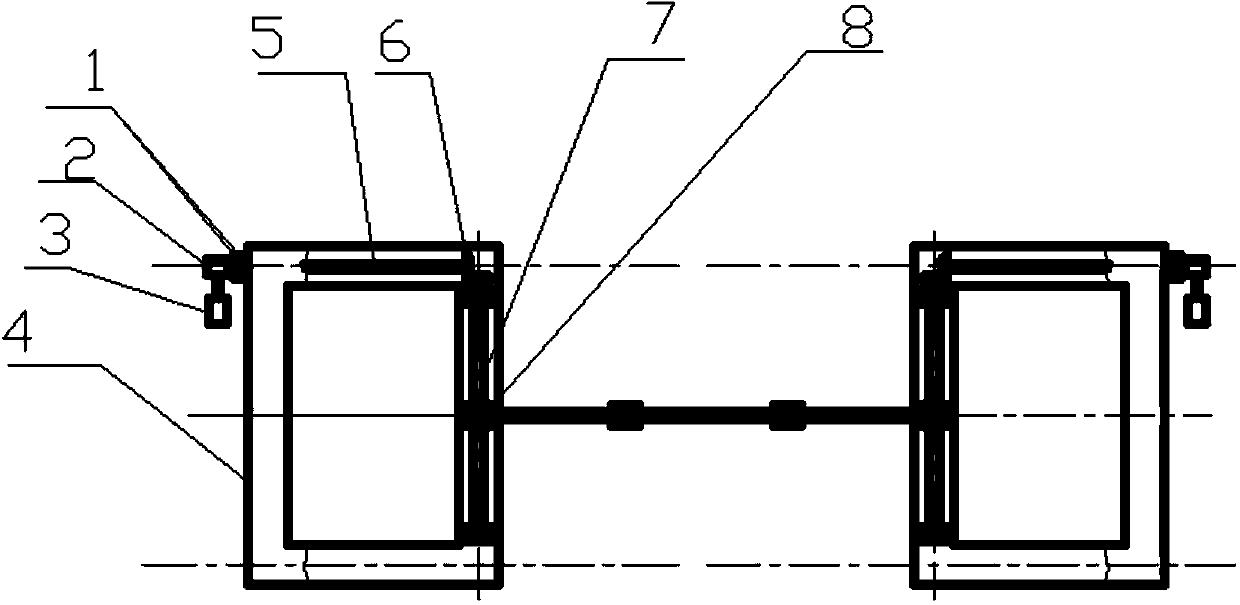

[0028] An automatic steering device that removes the dead point of the connecting rod, its structure is as follows Figure 1-6 As shown, the connecting rod is connected through the device, and the device includes a slider sliding device and a torque transmission device in a left-right symmetrical structure.

[0029] When the equipment is in motion, the three connecting rods 15 are Figure 1-2 The state of the folded triangle is pulled into such as Figure 3-4 in the form of a straight line. The straightening of the three connecting rods 15 depends on the opening and closing motor 11 to drive the spur gear 10 to rotate, and finally drives the positive and negative winding groups 9, and the rotation of the winding groups 9 on the left and right sides pulls the outer frame 4 connecting the connecting rods, thereby driving Connecting rod 15 makes it be in a straight line.

[0030] Such as Figure 3-4 As shown, now the outer frame 4 runs into the far point limit 12, the switch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com