Reciprocating piston built-in chained connecting rod dead-point-free engine piston connecting rod set

A technology of reciprocating pistons and piston connecting rods, which is applied to engine components, machines/engines, pistons, etc., can solve the problems of easy wear, waste of resources, and dead spots at the joints between pistons and connecting rods, and achieve the elimination of engine dead spots, The effect of avoiding waste and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

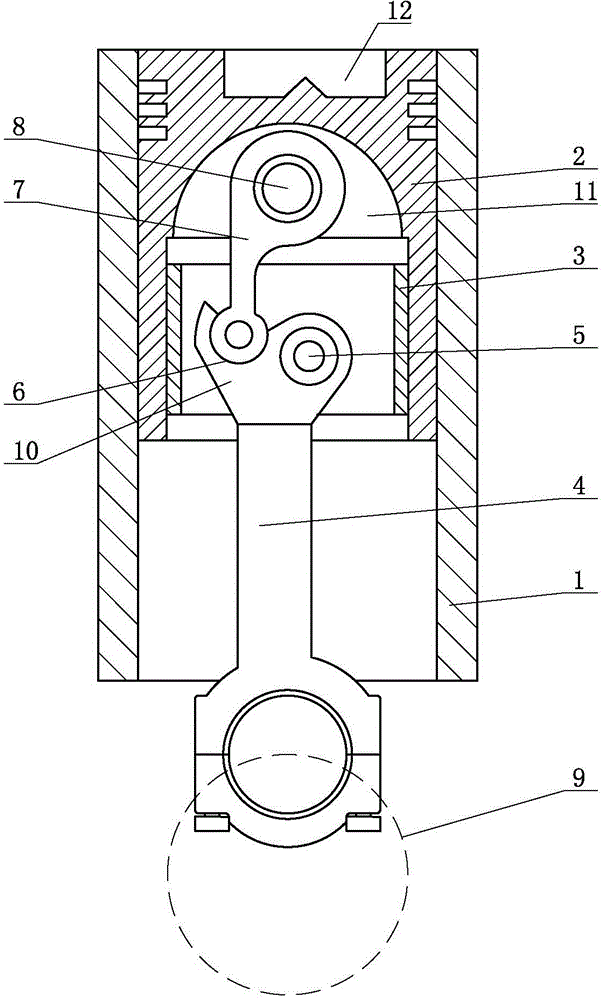

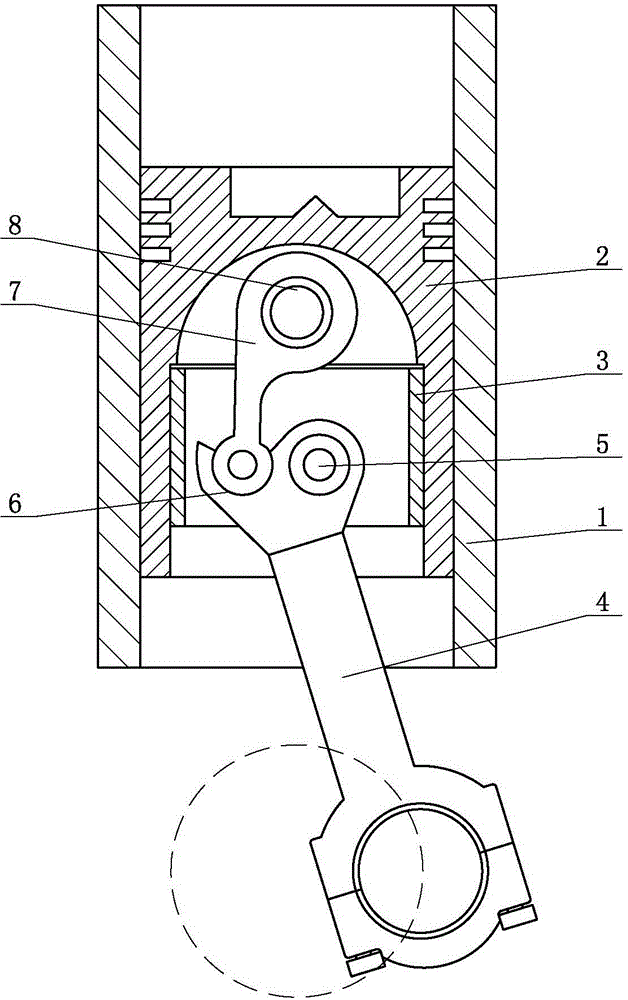

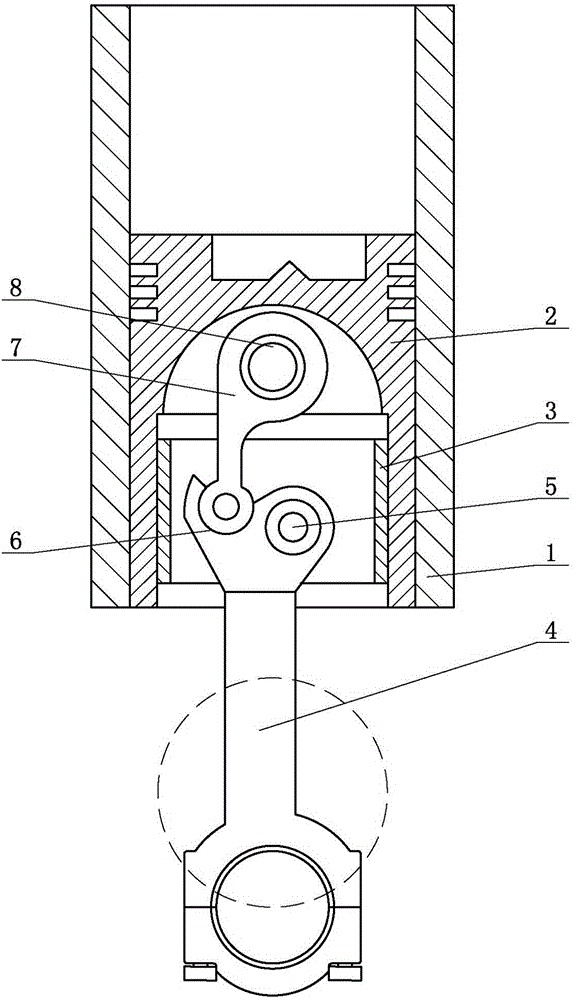

[0009] The reciprocating piston built-in chain-type connecting rod of the present invention has no dead point engine piston connecting rod group, such as figure 1 As shown, the connecting rod 4 and the piston 2 are included, and the bottom of the piston 2 is hollow. A movable sleeve 3 is arranged in the inner cavity 11 at the bottom of the piston 2 , and the movable sleeve 3 can move axially along the inner wall of the inner cavity 11 . The piston 2 provides guidance for the movable sleeve 3 so that the movable sleeve 3 can reciprocate along the axis of the inner cavity 11 . A first fixed shaft 5 is arranged in the movable sleeve 3, and the small head of the hinged connecting rod 4 is connected on the first fixed shaft 5. One side of the small head of connecting rod 4 is provided with shifting block 10. Offer groove or pin hole 6 on shifting block 10, groove or pin hole 6 are positioned at first fixed shaft 5 one side, one end of push rod 7 is arranged in groove or pin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com