Wet type electrostatic precipitator

A wet electrostatic and dust collector technology, applied in the direction of external electrostatic separator, electrostatic separation, electrode structure, etc., can solve the problem that it is difficult to accurately maintain the concentricity of the circular electrode tube, the corona intensity of the rod-shaped electrode is not high enough, and the purified gas carries dirty wastewater and other problems, to achieve the effect of simple structure, precise manufacturing, and improved discharge corona intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

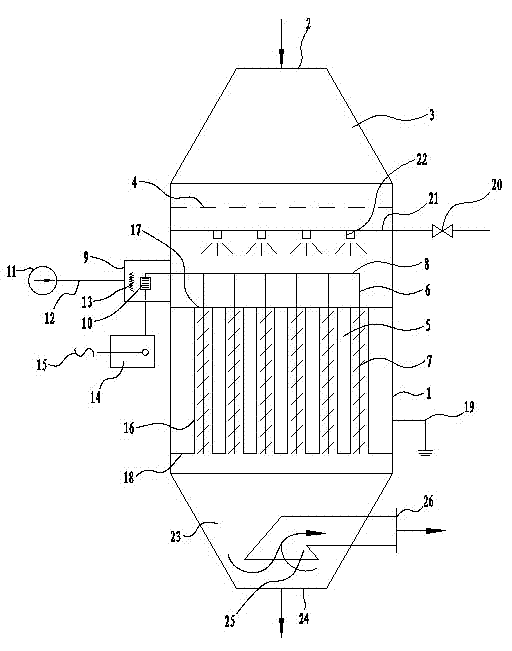

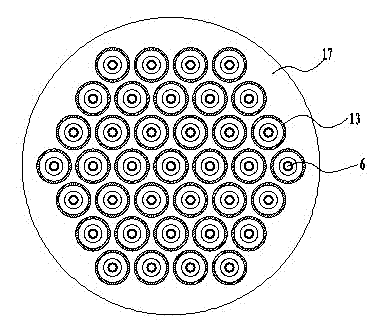

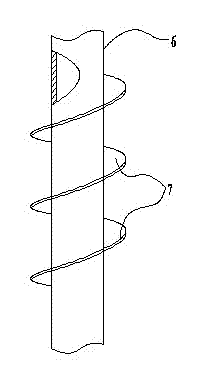

[0042] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0043] Such as figure 1As shown, the shell 1 is a cylindrical steel structure with open upper and lower ends, the upper port of the shell 1 is the air inlet 2 , and the lower port is the drain port 24 . The upper part of the casing 1 is in the shape of a cone with a small top and a large bottom, and the bottom part is a tapered shape with a large top and a small bottom, and the casing 1 is grounded through a wire 19 . An upper tube plate 17 is provided in the middle of the housing 1, the plate surface of the upper tube plate 17 is perpendicular to the axis of the housing 1, and the outer edge of the upper tube plate 17 is fixed to the inner wall of the housing 1 . A lower tube plate 18 is arranged at the bottom of the shell 1 , the lower tube plate 18 is parallel to the upper tube plate 17 , and the outer edge of the lower tube plate 18 is fixed to the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com