Novel horizontal gear and gear rack engine

A technology of rack and pinion, engine, applied in machine/engine, gear lubrication/cooling, belt/chain/gear, etc., can solve the problem of reducing energy output efficiency, high structural strength requirements of connecting rod and crank, connecting rod and crank Excessive structural pressure and other problems, to achieve the effect of overcoming the problem of knocking the cylinder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

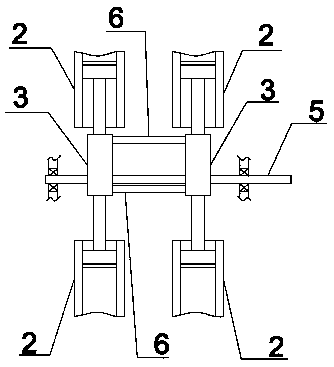

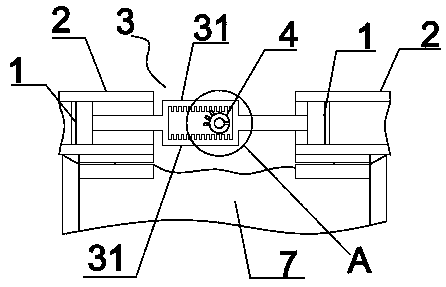

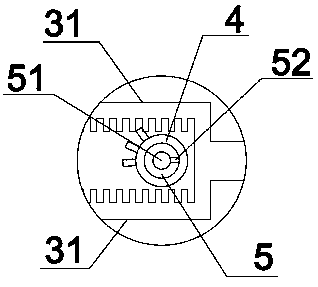

[0014] Such as figure 1 with figure 2 As shown, a novel horizontal rack and pinion engine includes a housing and an output shaft 5 that is rotatably connected with the housing. The output shaft 5 is sleeved with two transmission gears 4, and the transmission gear 4 is The central angle corresponding to the area covered by the gear teeth is 150°-180°, and the gear teeth of the two transmission gears 4 are located on the same side. The two transmission gears 4 correspond to the two transmission parts 3, that is, the four cylinders 2. If the intake and exhaust system of the engine is properly set, one of the four cylinders 2 is always in the power stroke, and then drives the other three cylinders 2 to complete the suction. Compared with the existing engine structure, the flywheel can be omitted and the system structure can be simplified.

[0015] Such as figure 1 with figure 2 As shown, a transmission member 3 corresponding to the transmission gear 4 is also included, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com