Concrete stirrer for double-horizontal shaft experiment

A technology for concrete mixers and tests, applied to mixers, mixers with rotating mixing devices, cement mixing devices, etc., can solve the problems that the structure needs to be further improved, achieve simple structure, sufficient mixing, and improve the convenience of operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

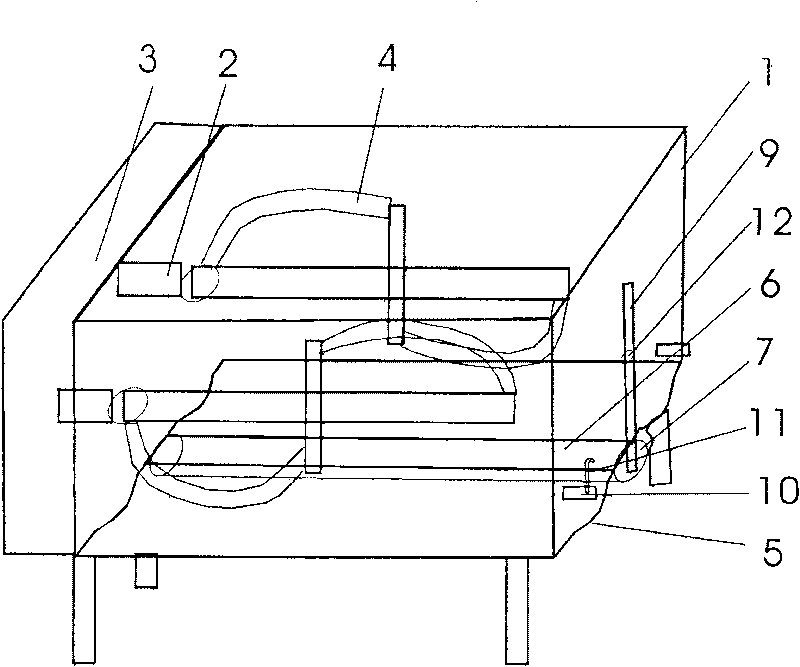

[0013] Such as figure 1 As shown, the concrete mixer for twin-horizontal shaft test of the present invention includes a barrel 1, and two parallel stirring shafts 2 horizontally arranged in the barrel, and the two stirring shafts 2 are in phase with the rotary mechanism 3 of the motor reduction box. Connect, have stirring curved blade 4 on the two stirring shafts 2, and above-mentioned structure is identical with the structure of the twin-shaft concrete mixer of prior art. In addition, components such as a control box can also be configured for actual needs. Since the above results have little connection with the inventiveness of the present invention, they are only briefly described.

[0014] The characteristics of the concrete mixer for twin-horizontal shaft test of the present invention are: the bottom of the barrel 1 has two depressions 5, the two depressions 5 are below the two stirring shafts 2, and the two depressions 5 are circular Arc, the radius of its arc is matche...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com