Electrodialysis separation plate for homogeneous membrane and preparation method thereof

An electrodialysis, homogeneous membrane technology, applied in the field of water treatment, achieves the effects of good electrical insulation, thin thickness and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

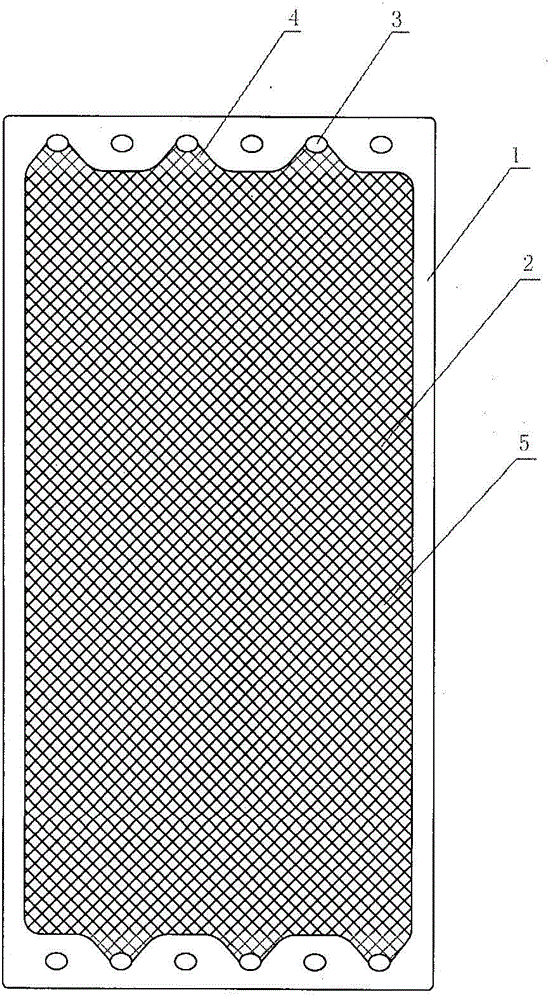

[0024] As a specific example, such as figure 1 As shown, an electrodialysis separator for a homogeneous membrane is made, which is composed of a separator frame 1 and a separator net 2, in which a circular water distribution hole 3 is arranged, and there is a gap between the upper and lower circular water distribution holes 3. Dead-end non-loop water distribution channel 5 and mesh distribution water tank 4. Choose thermoplastic elastomer (TPE) with a thickness of 0.4mm, punch holes according to the shape and cut it into a partition frame; use a polyester (PET) woven mesh with a thickness of 0.4mm, punch and cut it into a partition net according to the shape; Stack them together and put them into heat pressing equipment for heat pressing. The temperature was 105°C. The pressure is 25kg / cm2, and the heat-pressing time is 20 seconds; the separator after heat-pressing is punched and trimmed according to the size to prepare a usable electrodialysis separator. The actual thickne...

Embodiment 2

[0027] With the same structure as in Example 1, select thermoplastic elastomer (TPE) with a thickness of 0.5 mm, punch holes according to the shape and cut it into a partition frame; Stack the separator frame and the separator net together, and put them into the heat-pressing equipment for heat-pressing. The temperature is 120°C. The pressure is 30kg / cm2, and the heat pressing time is 10 seconds; the heat-pressed separator is punched and trimmed according to the size to prepare a usable electrodialysis separator. The actual thickness of the separator is 0.55mm.

[0028] According to the assembly method of ordinary electrodialyzers, 100 electrodialysis separators processed above, and 50 pairs of homogeneous ion exchange membranes (positive and negative membranes) (the size of the separators and membranes are both 200X400mm) are assembled into an electrodialyzer. dialyzer. Water flow, water inlet pressure 1.3bar, no water leakage; the pressure difference of each chamber was 0...

Embodiment 3

[0030] With the same structure as in Example 1, select thermoplastic elastomer (TPE) with a thickness of 0.5 mm, punch holes according to the shape and cut it into a partition frame; Stack the separator frame and the separator net together, and put them into the heat-pressing equipment for heat-pressing. The temperature is 100°C. The pressure is 40kg / cm2, and the heat-pressing time is 15 seconds; the separator after heat-pressing is punched and trimmed according to the size to prepare a usable electrodialysis separator. The thickness of the separator is measured to be 0.46mm.

[0031] According to the assembly method of ordinary electrodialyzers, 100 pieces of electrodialysis separators processed above and 50 pairs of homogeneous ion exchange membranes (positive and negative membranes) (the size of the separators and membranes are both 400X800mm) were assembled into an electrodialyzer. dialyzer. Water flow, water inlet pressure 1.5bar, no water leakage; the pressure differe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com