Chemical reactor tool having mixing function

A chemical reaction and functional technology, which is applied in the direction of mixers with rotating containers, chemical/physical/physicochemical mobile reactors, mixers, etc., can solve the problem of low stirring effect, achieve structural optimization, strong stirring effect, The effect of high stirring rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

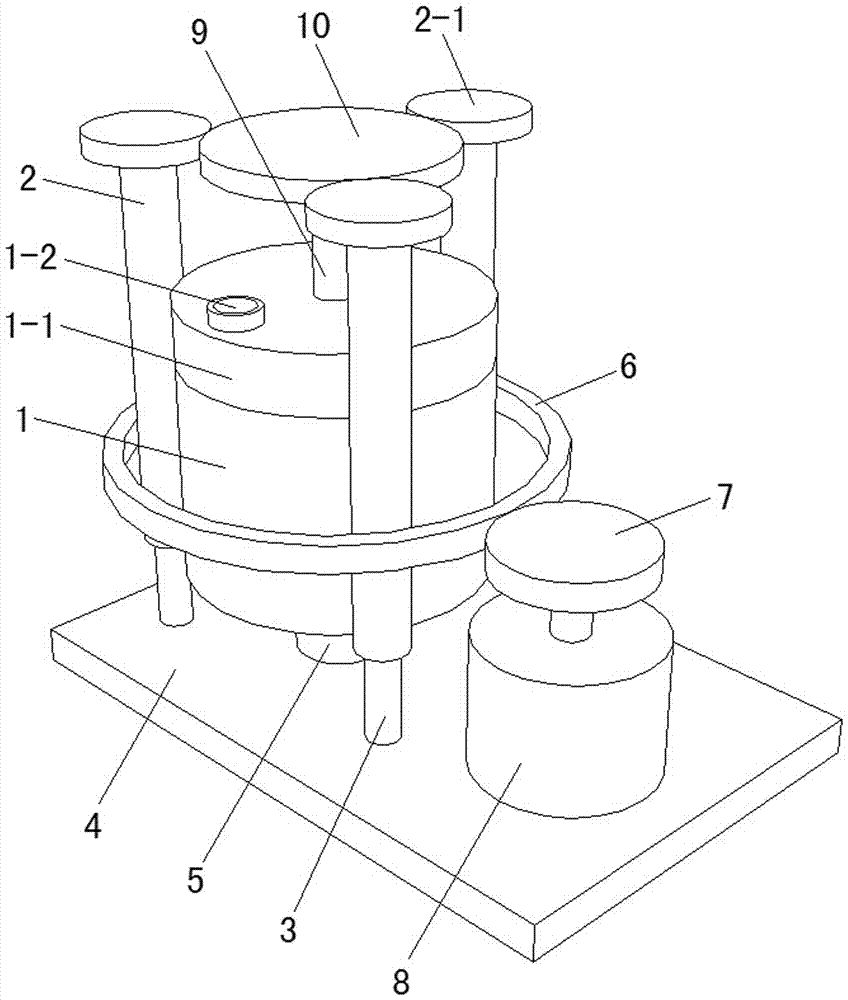

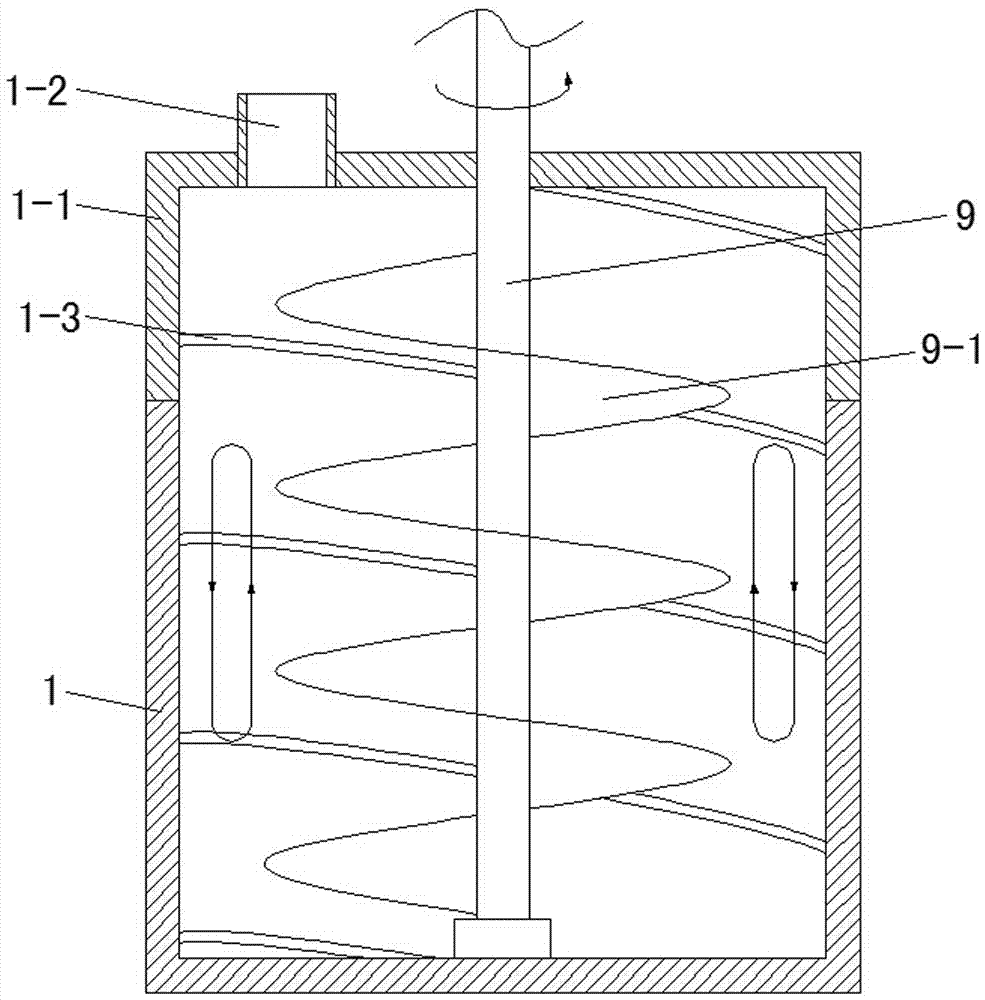

[0009] Specific implementation mode one: as Figure 1~Figure 2 As shown, the present invention discloses a chemical reaction appliance with a mixing function, including a stirring tank 1, a bottom plate 4, a support column 5, a ring gear 6, a gear 7, a motor 8, a stirring shaft 9, a transmission disc 10, three Transmission pole 2 and three positioning shafts 3, the mixing tank 1 is vertically arranged, the top of the mixing tank 1 is fixed with a tank cover 1-1 by bolts, and the center of the tank cover 1-1 is provided with The stirring shaft is perforated, and the lower end of the stirring shaft 9 is rotated and inserted in the stirring tank 1 through the perforation of the stirring shaft. , the inner wall of the stirring tank 1 is fixed with a spiral stirring blade 1-3, the spiral stirring blade 1-3 and the spiral stirring blade 9-1 are arranged oppositely, and a bottom plate 4 is arranged under the stirring tank 1, and the described Between the bottom plate 4 and the mixin...

specific Embodiment approach 2

[0010] Specific implementation mode two: as figure 1 As shown, this embodiment is a further description of the first embodiment, and the three transmission poles 2 are arranged at equal intervals.

specific Embodiment approach 3

[0011] Specific implementation mode three: as figure 1 , 2 As shown, this embodiment is a further description of Embodiment 1 or Embodiment 2, and the tank cover 1-1 is provided with a feed port 1-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com