Anaerobic mud bed reactor

A technology of anaerobic sludge bed and reactor, which is applied in the field of anaerobic sludge bed reactor, can solve the problem of high investment, and achieve the effect of saving investment, large processing capacity and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

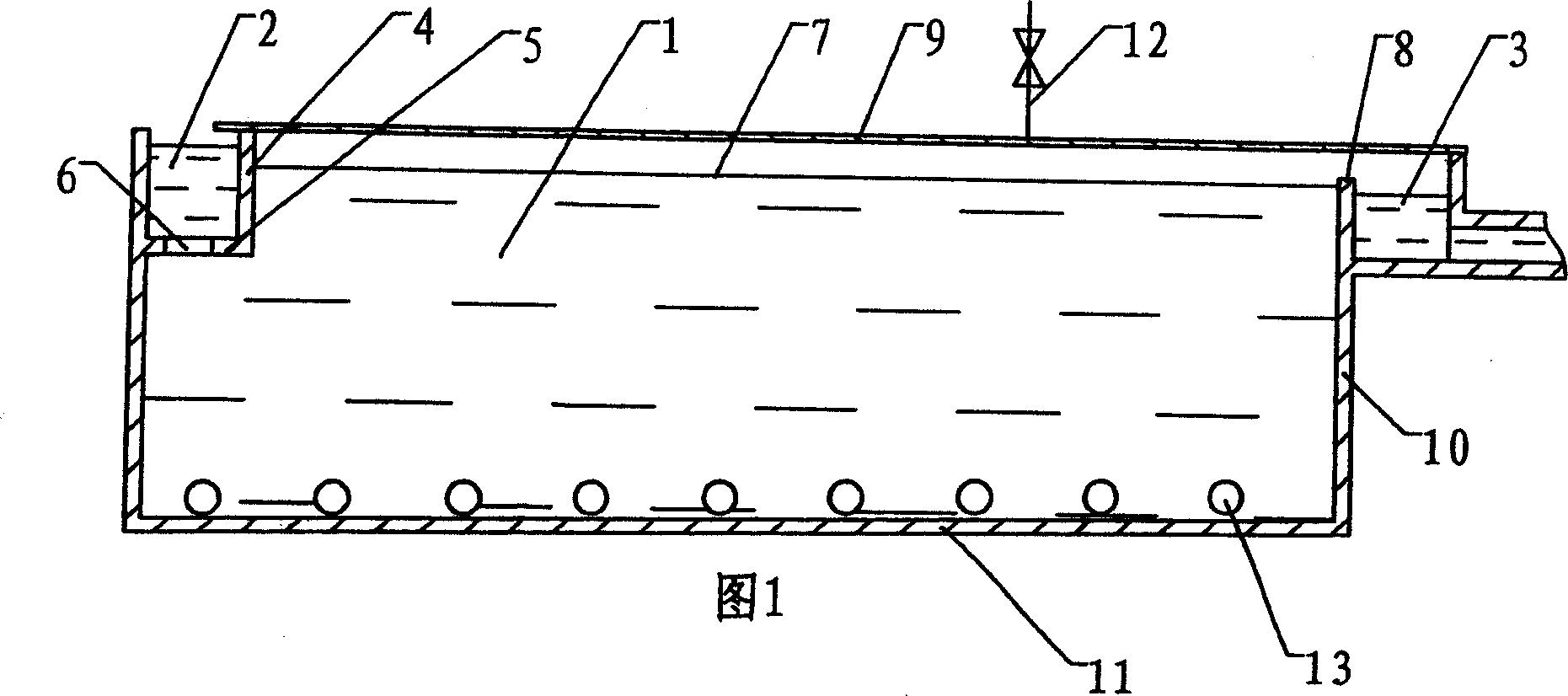

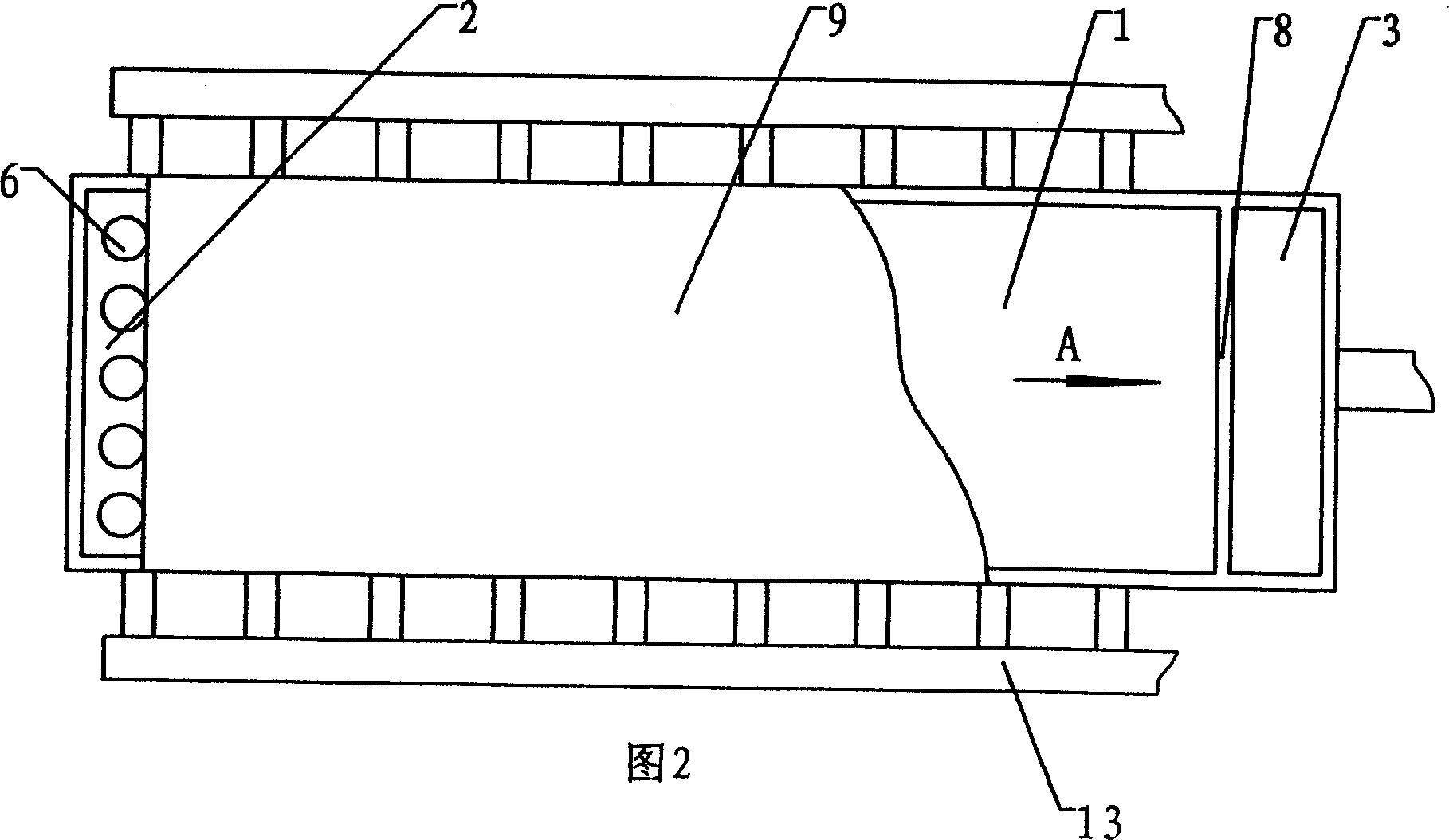

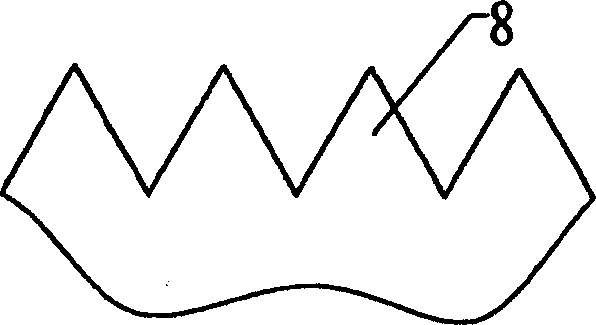

[0029] Embodiment: the anaerobic sludge bed reactor of the present invention, as shown in Figure 1, Figure 2, image 3 As shown, the container 1 is made into a rectangular container with a horizontal cross-section, and its length is 24 meters, wide 5 meters, deep 2 meters (the length of the pool is 12 meters), the slope of the bottom surface 11 is 0.02, and the volume is 240 cubic meters. Oxygen sludge bed reactor. An inflow device 2 is provided at one end of the container 1 in the width direction, and an outflow device 3 is provided at the other end. The inflow device 2 comprises a water retaining wall 4 and a bottom plate 5, the water retaining wall 4 traverses the width of the entire container, the bottom plate 5 is provided with evenly distributed submerged holes 6, the position of the submerged holes 6 is below the horizontal plane 7, and the submerged holes The shape of 6 is circular; the outflow device 3 is also arranged on the entire width direction of the container, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com