Combined impeller of rotating-type erosion test apparatus

A wear test, combined technology, used in measuring devices, testing wear resistance, instruments, etc., can solve problems such as unreasonable impeller shape and structure design, unsatisfactory stirring effect of slurry, motor and rotating spindle shaking, etc., to save energy. Raw material cost, light weight, effect of preventing settling of solid particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the drawings.

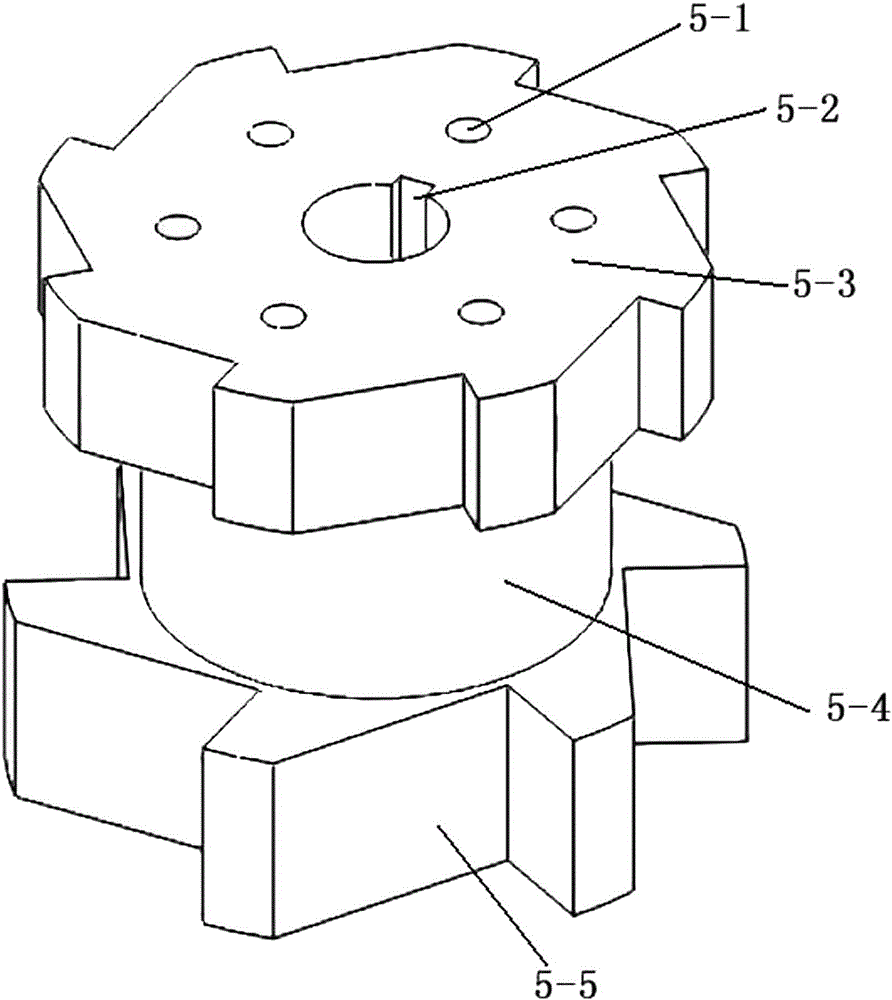

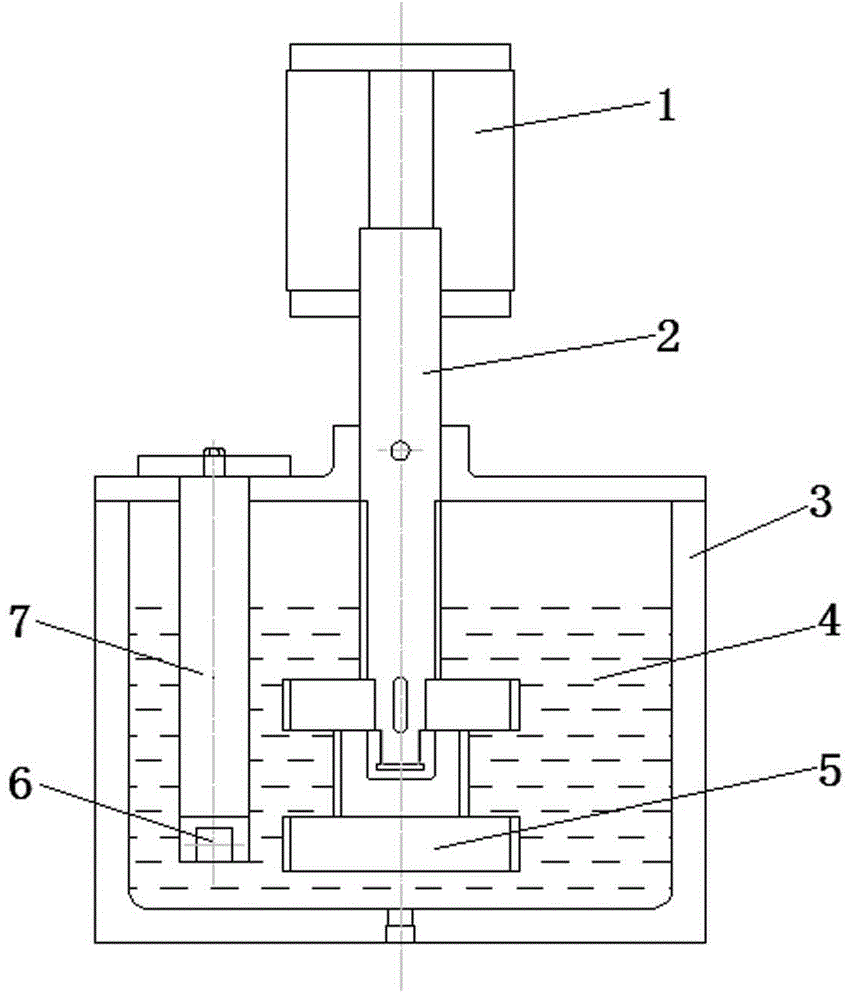

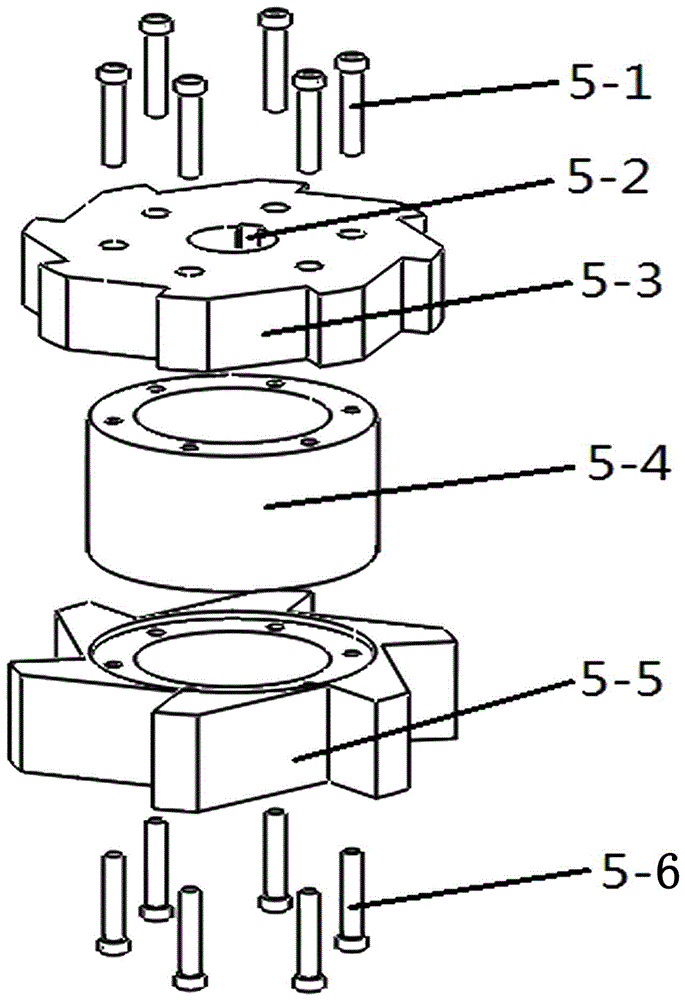

[0025] Such as figure 1 As shown, 1-servo motor, motor spindle 2, 3-slurry tank, 4-fluid, 5-combined impeller, 6-test sample, 7-sample protection device; figure 2 As shown, 5-1 is the upper screw, 5-2 is the keyway, 5-3 is the upper blade, 5-4 is the connecting sleeve, and 5-5 is the lower blade; image 3 As shown, 5-6 are the lower screws.

[0026] See Figure 1-3 . A combined impeller of a rotary erosion and abrasion test device includes a servo motor 1 of a rotary erosion and abrasion test device, a motor spindle 2, etc., and the combined impeller 5 includes an upper blade 5-3 and a connecting sleeve 5 -4. Lower blades 5-5 and upper screws 5-1 and lower screws 5-6. The upper blades 5-3 are eight toothed blades, and the eight toothed blades are equally angularly distributed around the ring, and the lower blades 5-5 is six toothed blades, the six toothed blades are equally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com