Process and equipment for treating wastewater containing cyanide ions

A technology for wastewater treatment and cyanide ion, applied in water/sewage treatment, adsorbed water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of increasing the salinity of wastewater, consuming energy, endangering life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

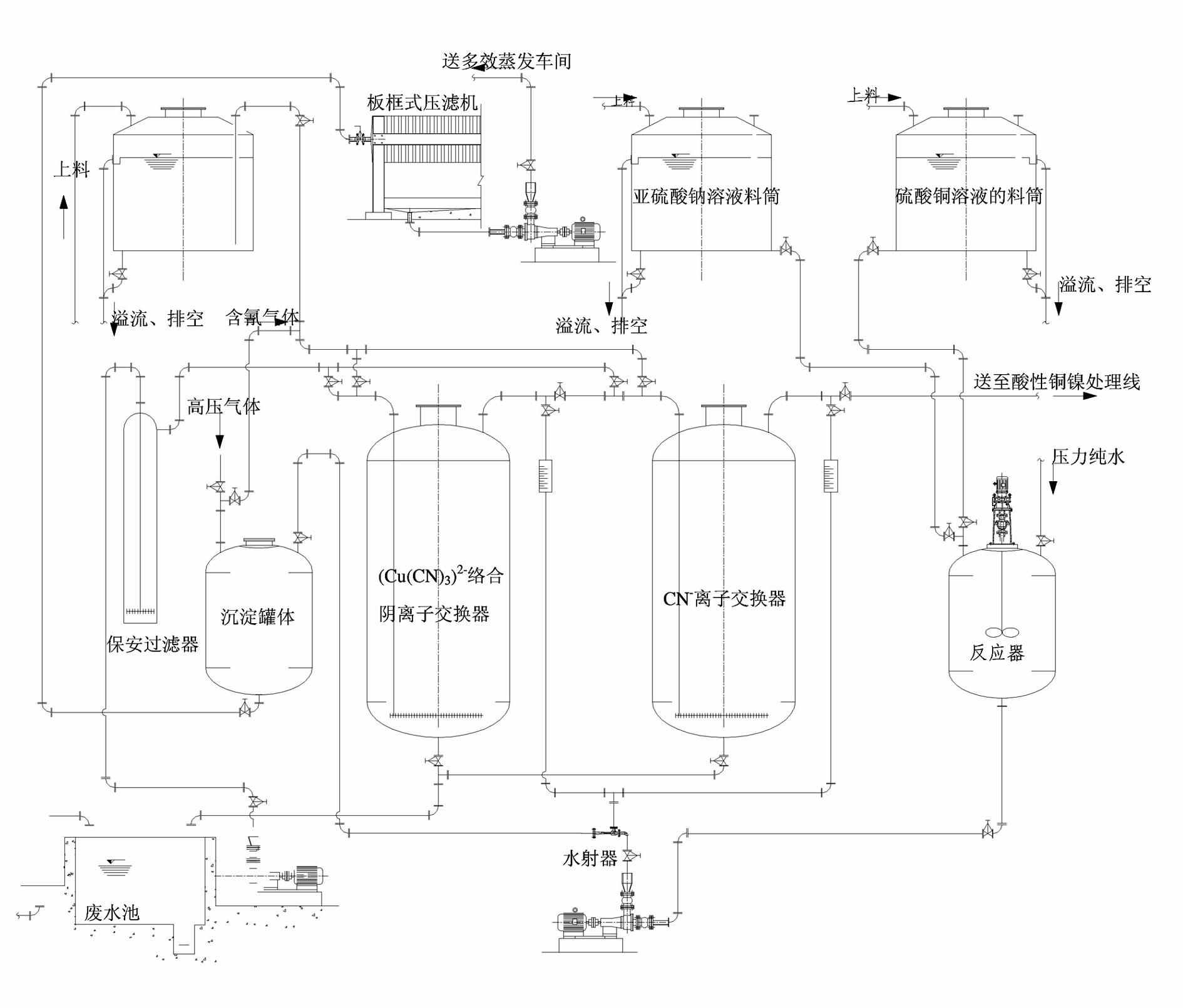

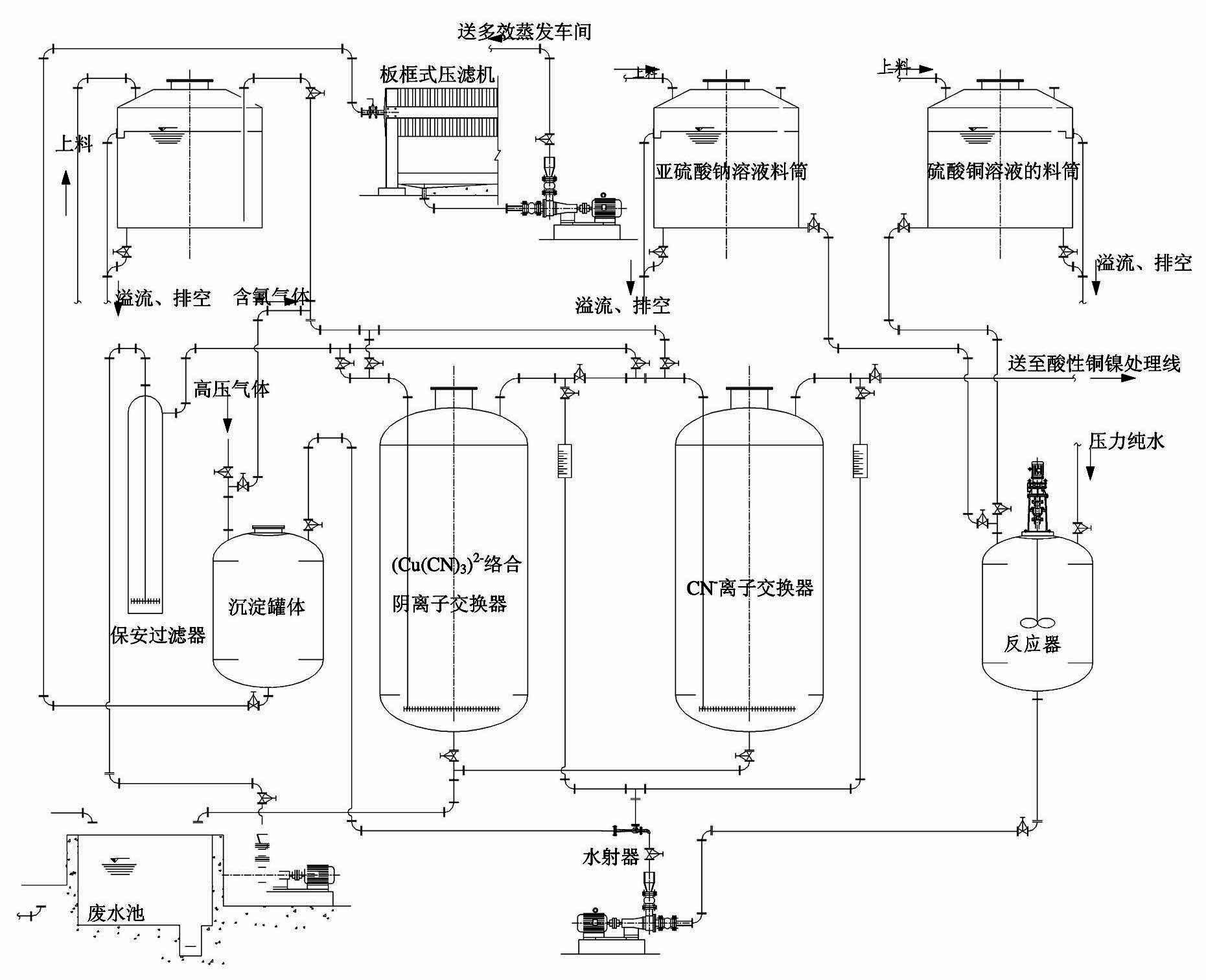

[0018] Cyanide-containing wastewater treatment process, after the wastewater is pre-filtered, the cyanide in the wastewater is adsorbed by the cyanide-removing resin, and the cyanide-removing resin is saturated and then eluted, and the hydrocyanic acid formed by elution is formed under negative pressure at the outlet of the water injector It is sucked out and reacts with the cuprous salt solution ejected from the injector to form a cuprous cyanide precipitate.

[0019] Specifically, it includes the following process steps: first, the waste water passes through a security filter to remove suspended solids and organic matter in the waste water; then the waste water enters the cyanide removal resin, and the cyanide ions in the waste water are chelated and adsorbed by the resin; Enter the salt organic acid solution to elute and regenerate the resin; during elution, connect the reactor loaded with the cyanide removal resin to the outlet of a water injector, and the inlet end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com