Double-horizontal axle concrete-mixer

A concrete mixer and twin-shaft technology, which are applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of complex structure and poor mixing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

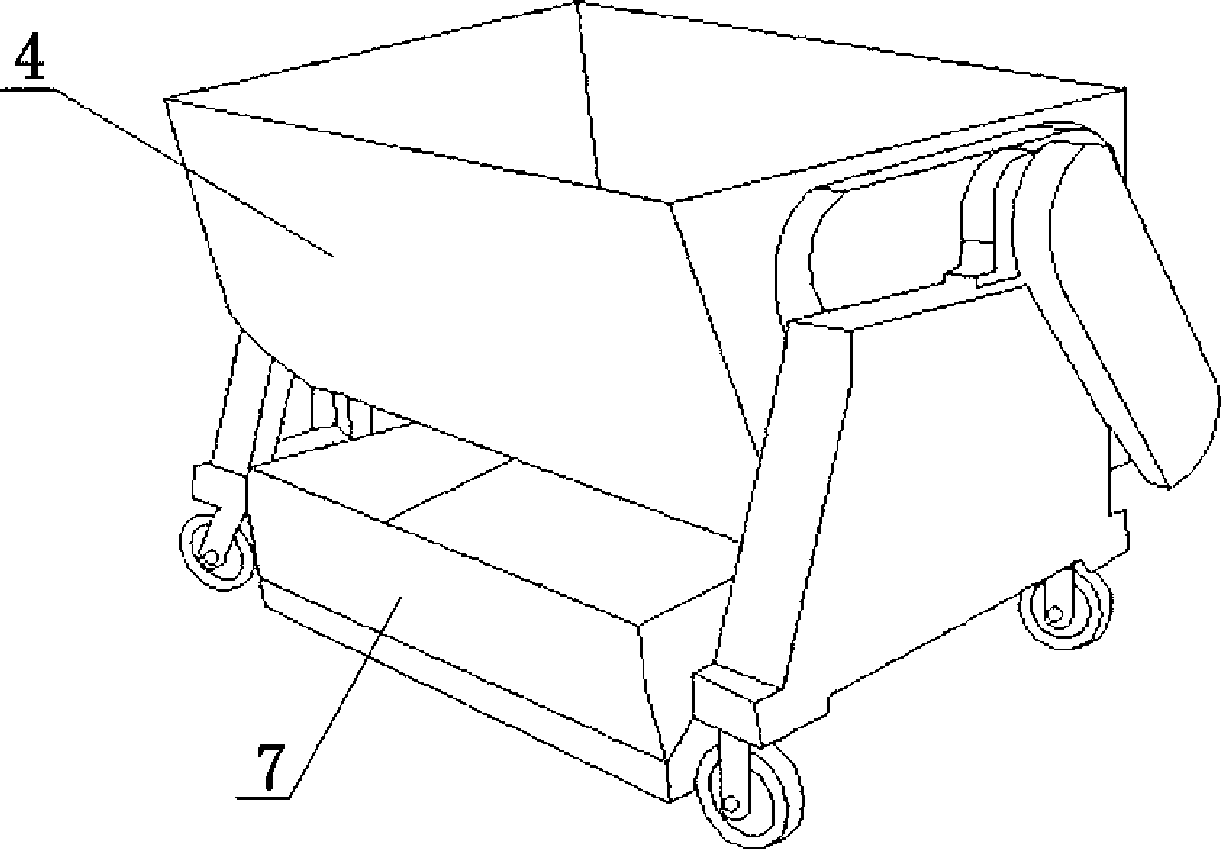

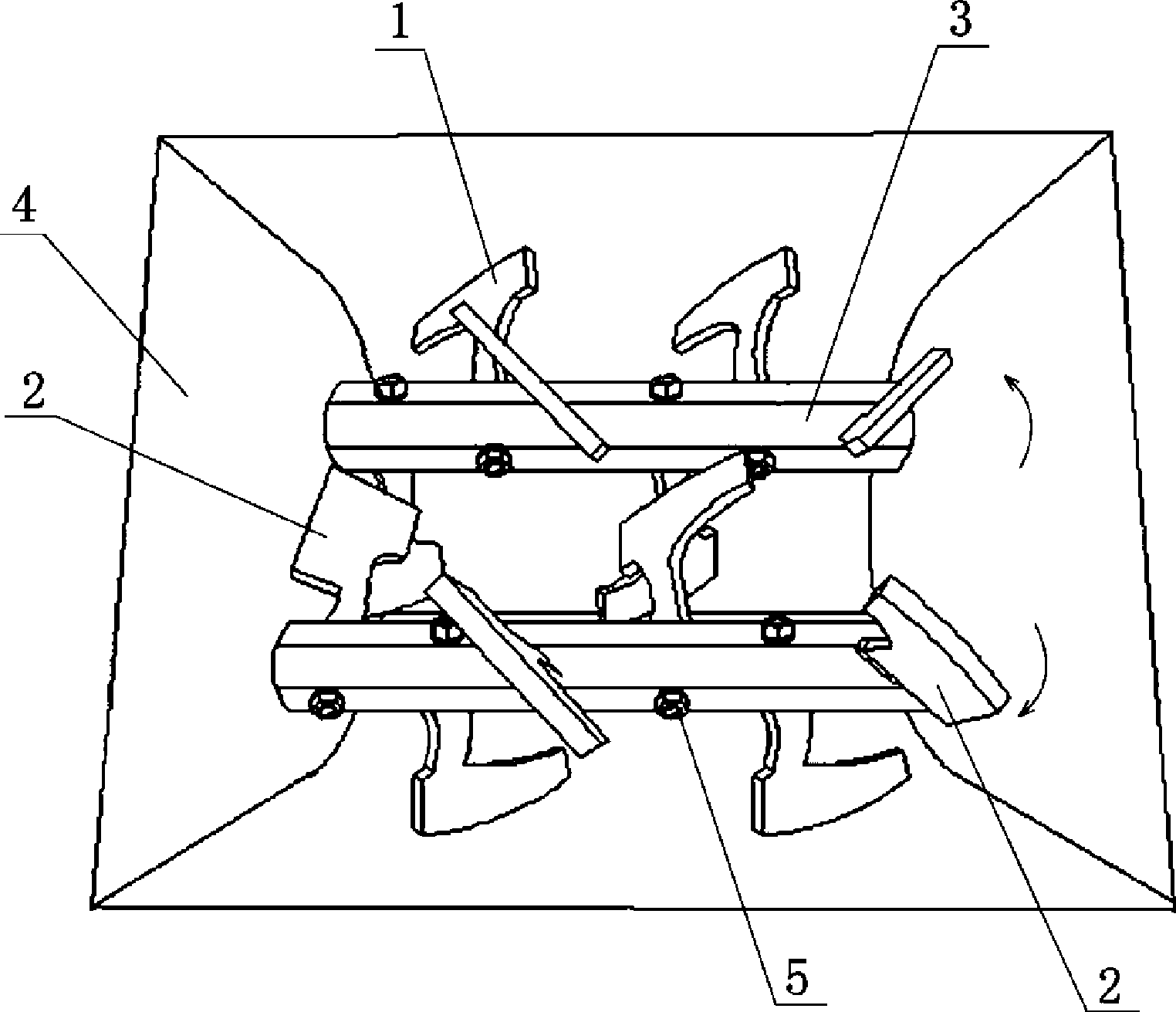

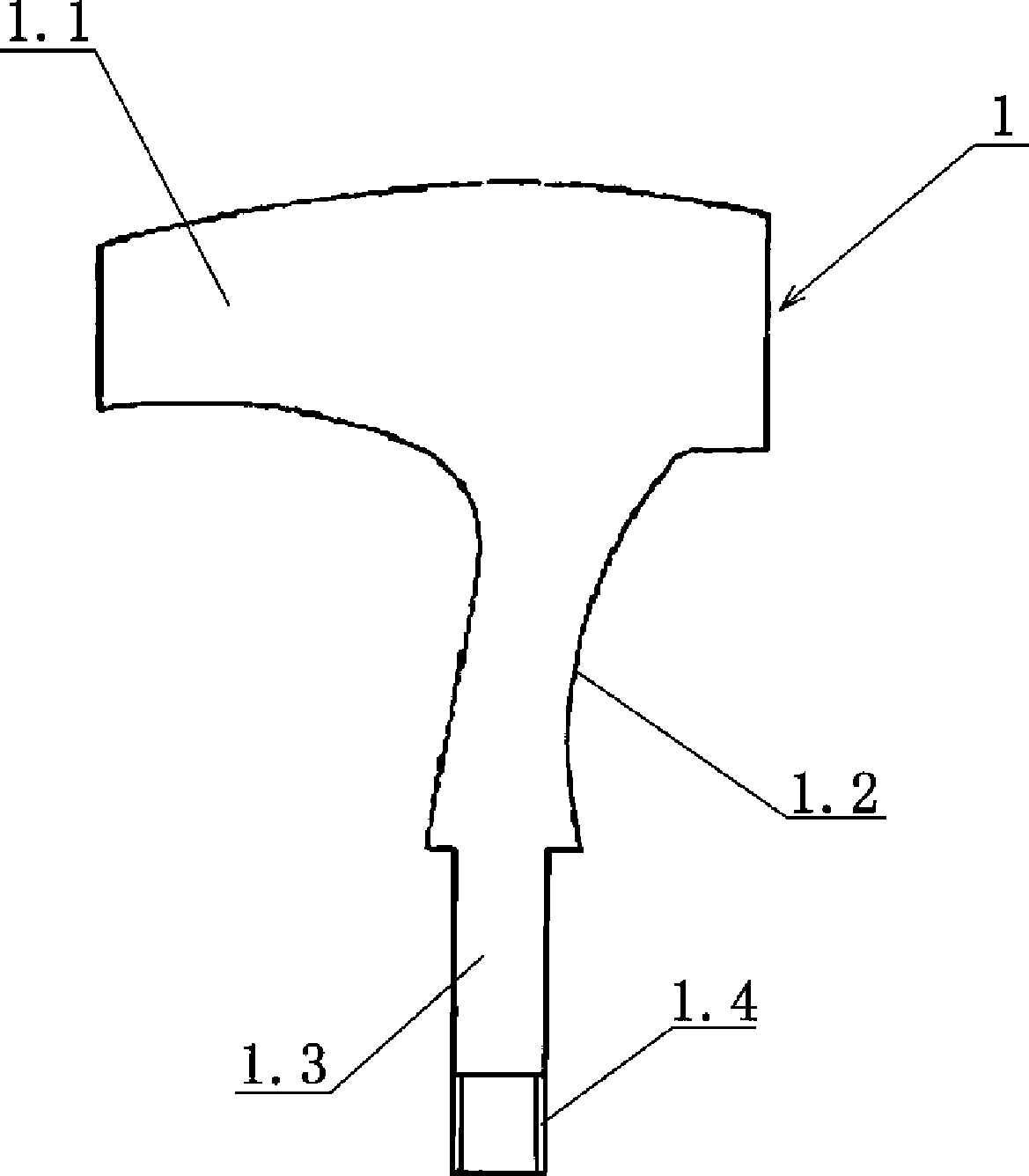

[0027] Examples see Figure 1-5 As shown, this twin-shaft concrete mixer includes a barrel 4, a stirring shaft 3 inside the barrel, and a stirring blade connected to the stirring shaft. The stirring shaft 3 is connected to the rotary mechanism of the main motor reducer. Unloading container 7. Two stirring shafts 3 are arranged in parallel in the barrel 4, the installation forms of the stirring blades on the two stirring shafts are exactly the same, and the installation directions are opposite; The cross section can be a regular hexagonal prism. The middle part of the stirring shaft 3 is connected with four middle stirring blades 1 , and the two ends of the stirring shaft are connected with two end stirring blades 2 . The knife faces of the middle stirring blade 1 and the end stirring blade 2 form an angle of 45° with the axis of the stirring shaft, and the handles of two adjacent stirring blades differ by 120° along the circumferential direction of the stirring shaft. There...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Overlap width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com