Upper-layer paddle for high-performance agitating tank

A stirring tank and high-performance technology, applied in the field of upper-layer paddles, can solve problems such as increased energy consumption, and achieve the effects of increased scouring force, enhanced stirring intensity, and strong stirring performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

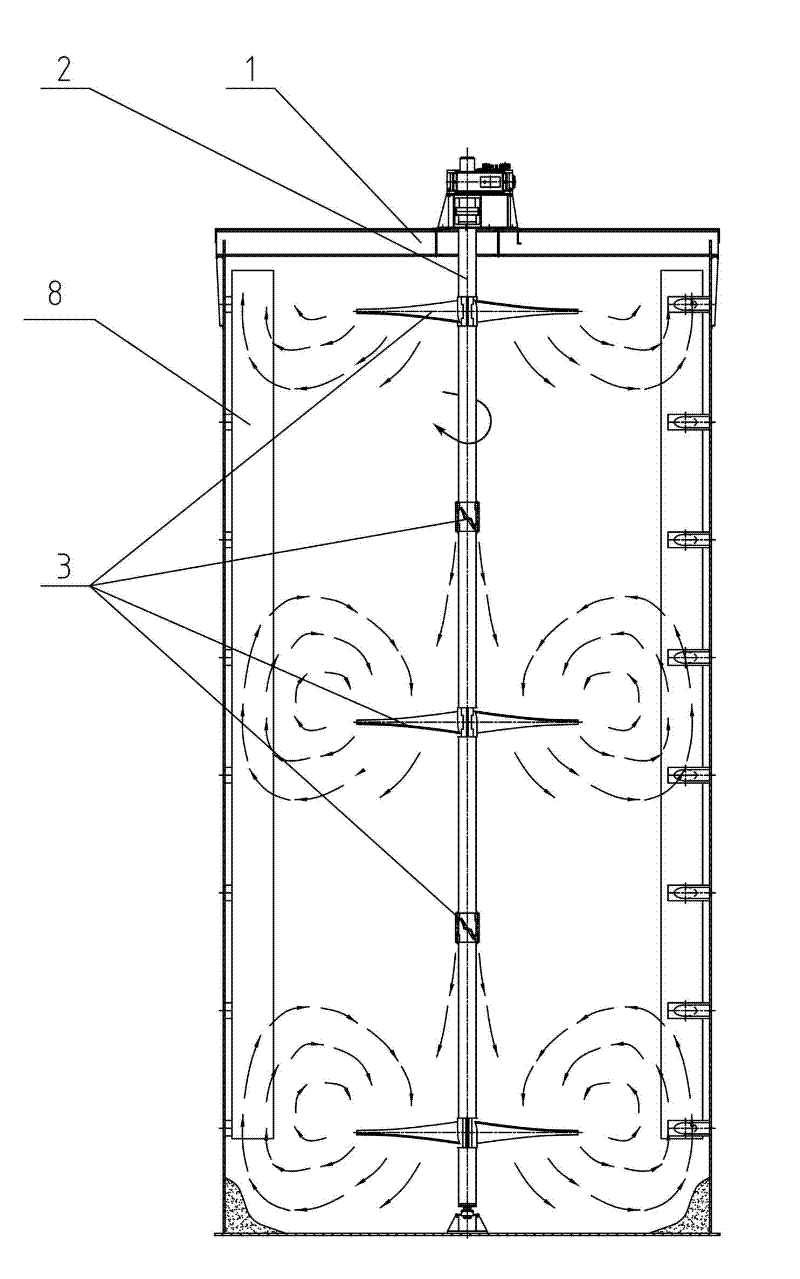

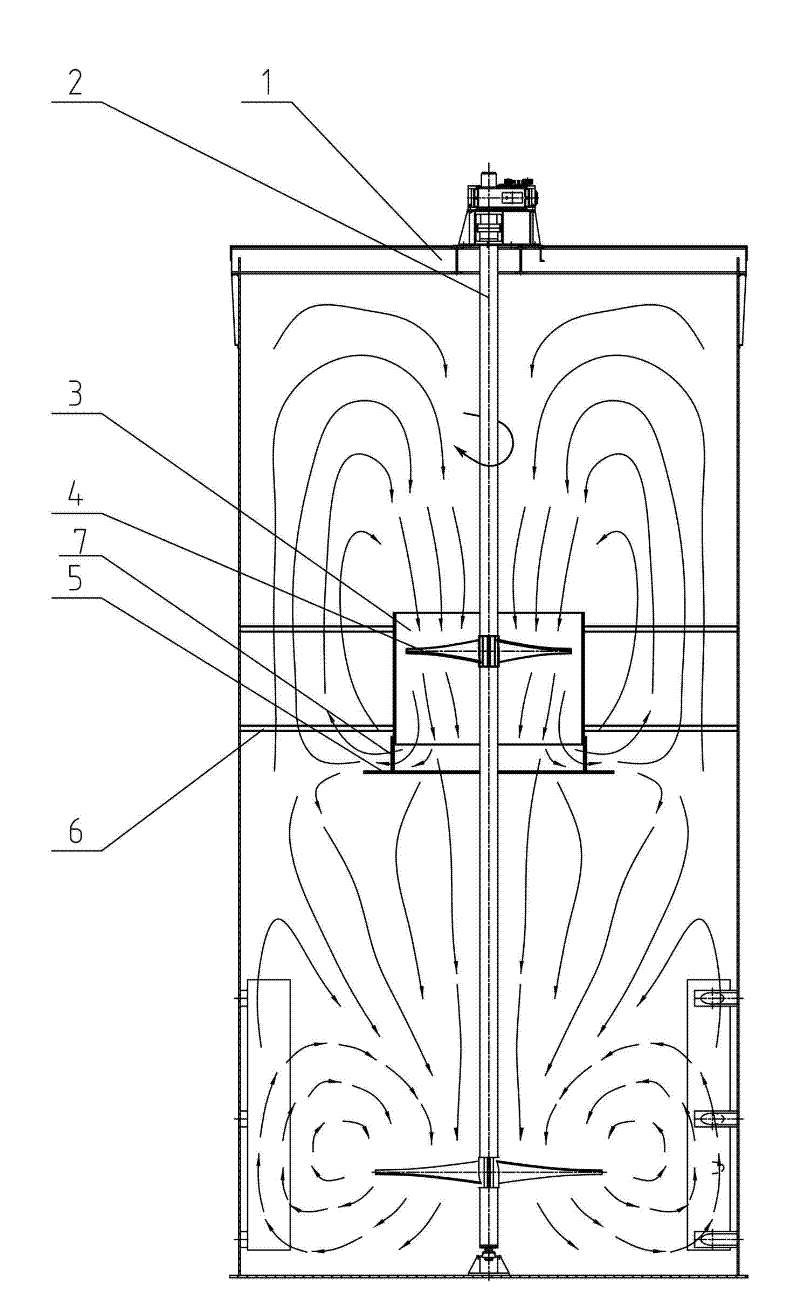

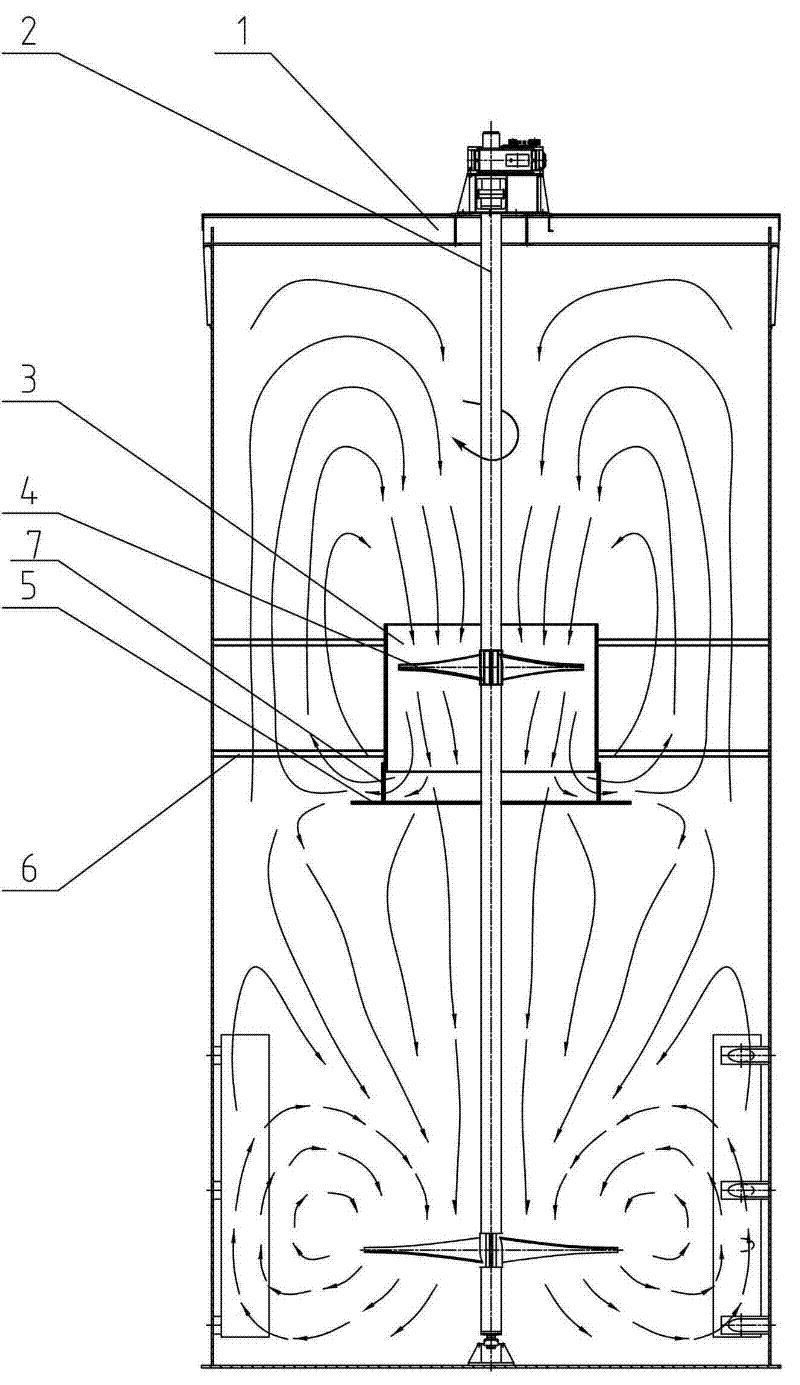

[0015] Attached below figure 2 The present invention is described in further detail.

[0016] Such as figure 2 The upper paddle of the high-performance stirring tank shown includes the paddle 4, and the outer circle of the paddle 4 is provided with an upper steel plate cylinder 3, and an annular baffle 5 is arranged under the upper steel plate cylinder 3, and the upper steel plate cylinder 3 and the stirring tank The side walls of 1 are connected by support plates 6, the upper steel plate cylinder 3 is cylindrical or conical, the diameter of the upper steel plate cylinder 3 is 1.02-1.1 times the diameter of the blade, and the height of the upper steel plate cylinder 3 is Equal to the diameter of the paddle 4, the paddle 4 is located at the upper 1 / 3 of the upper steel plate cylinder 3, the annular baffle 5 is fixed to the upper steel plate cylinder 3 through the connecting plate 7, and the distance between the annular baffle 5 and the upper steel plate cylinder 3 It is 1 / 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com