Assembly type recycled concrete node with steel bar truss girders at end parts and manufacturing method thereof

A technology of recycled concrete and steel trusses, which is applied in building components, earthquake-proof, buildings, etc., can solve problems such as earthquake damage and poor seismic performance, and achieve good overall results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] specific implementation plan

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

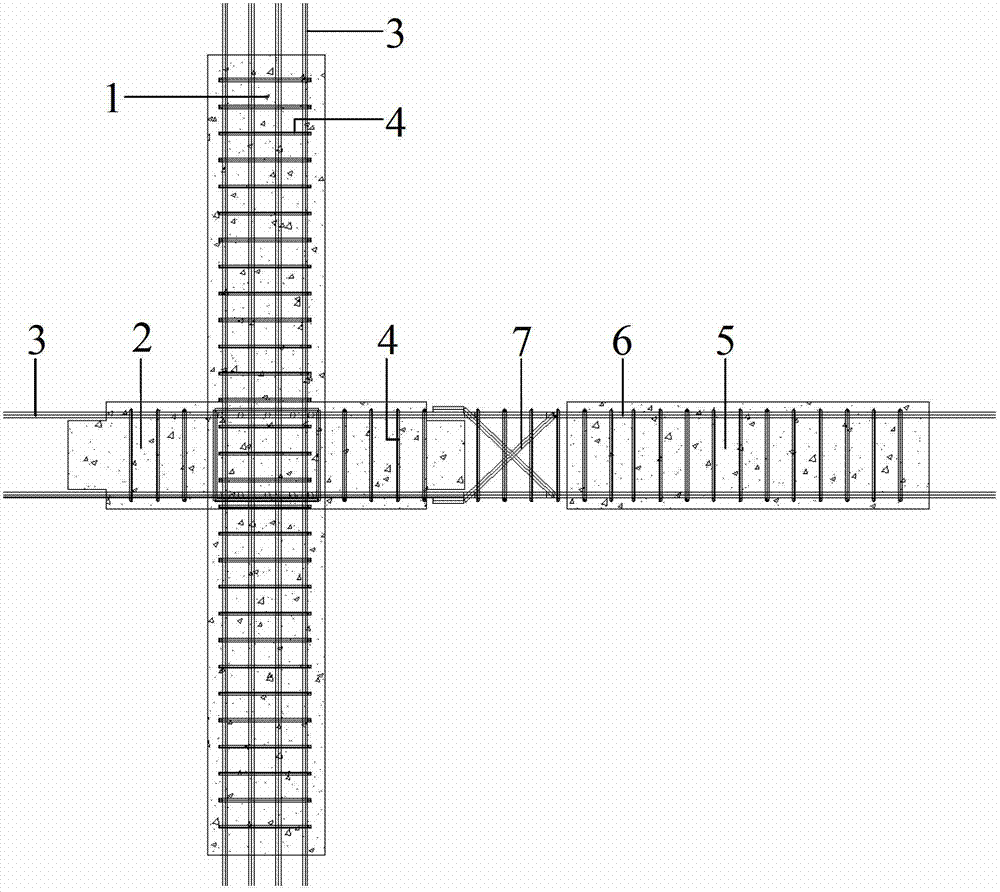

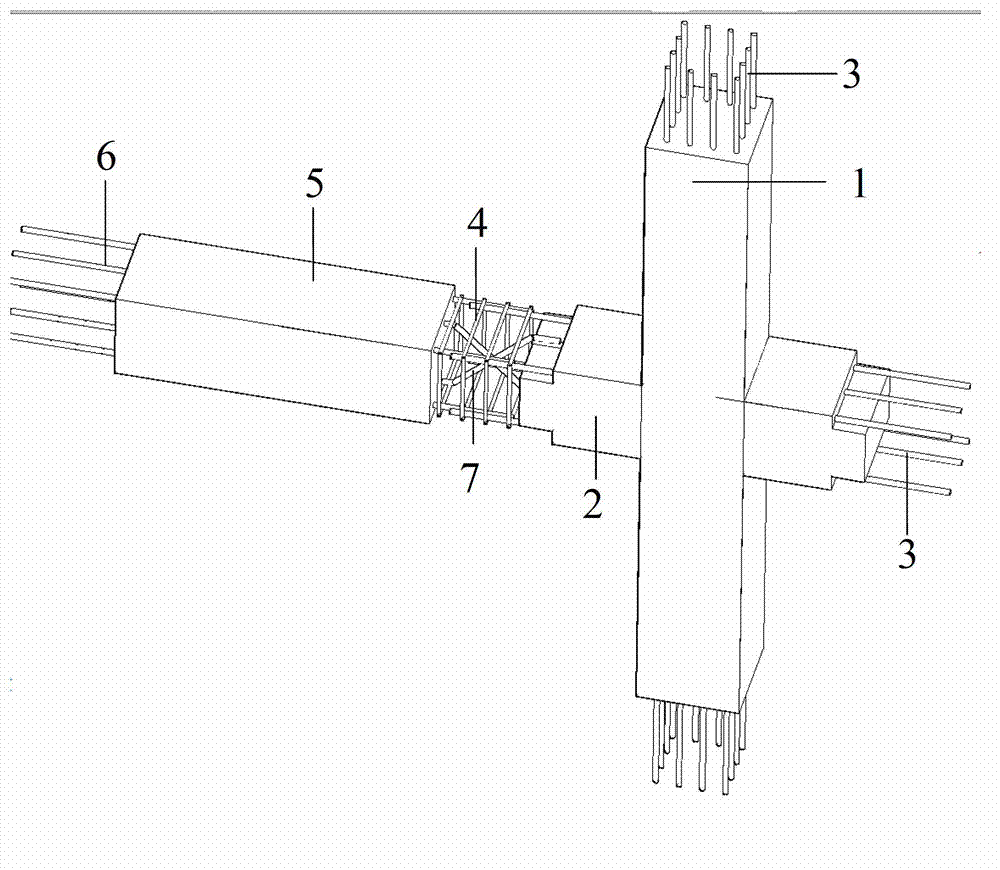

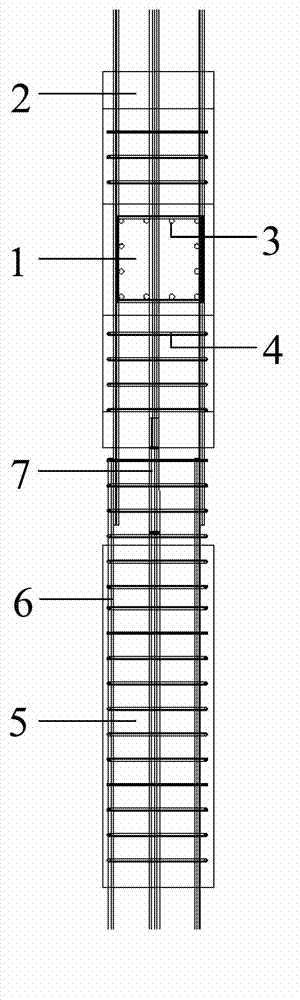

[0024] Prefabricated recycled concrete joints with reinforced truss beams at the end, including column 1, wing end beam 2, prefabricated beam 5, column 1 and wing end beam 2 pre-embedded longitudinal reinforcement 3, stirrup 4, and integrally poured with high-strength recycled concrete, Autoclave curing after vibration to form key nodes, prefabricated beam 5 pre-embeds longitudinal reinforcement 6 and stirrup 4 of prefabricated beam, pours high-strength recycled concrete, autoclaves curing after vibration, wing end beam and prefabricated beam pass through longitudinal reinforcement 3 and prefabricated The longitudinal reinforcement 6 of the beam is overlapped and the steel truss 7 is connected, and a post-casting belt is set at the connection, and the relatively low-strength concrete is used for pouring.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com