Agitating device of high-performance agitating tank

A stirring device and stirring tank technology, which is applied to mixers with rotating stirring devices, mixer accessories, transportation and packaging, etc., can solve problems such as increased energy consumption, increase scouring force, reduce shear, and facilitate growth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

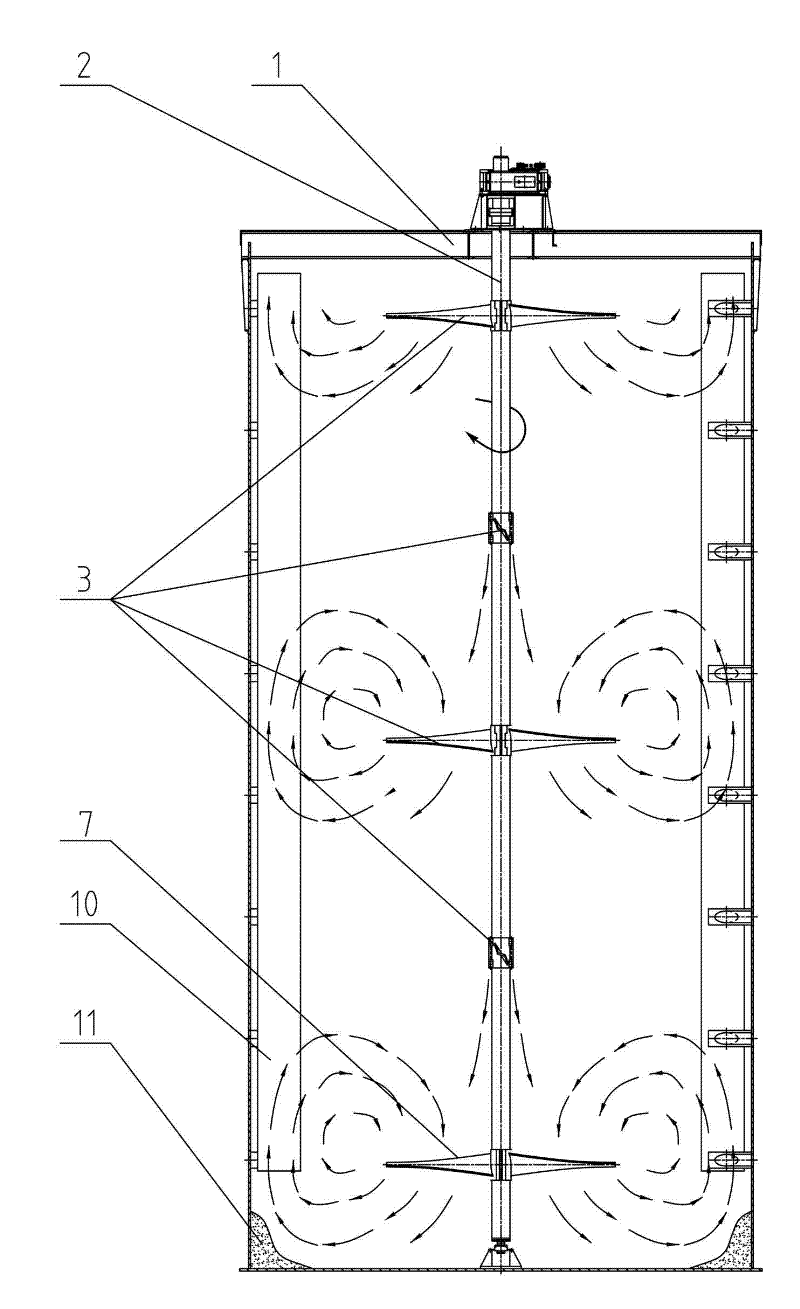

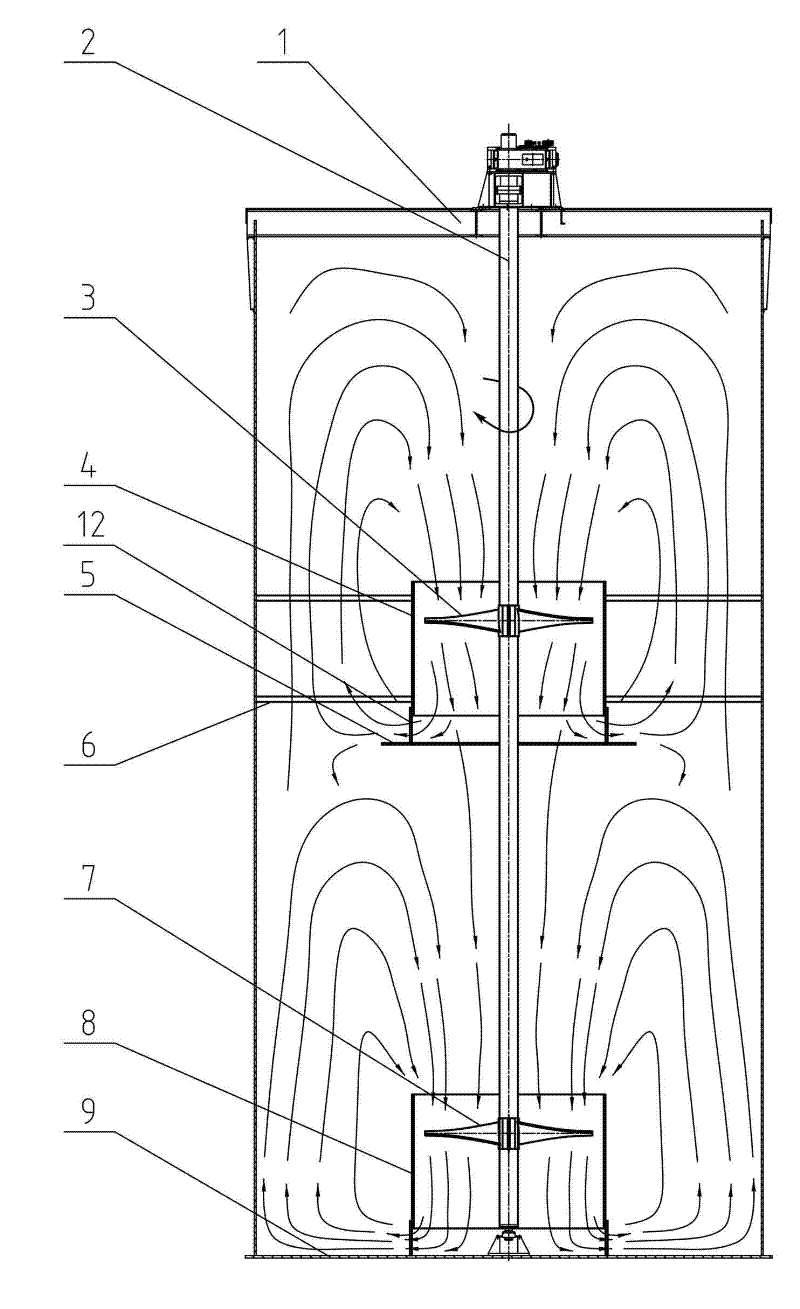

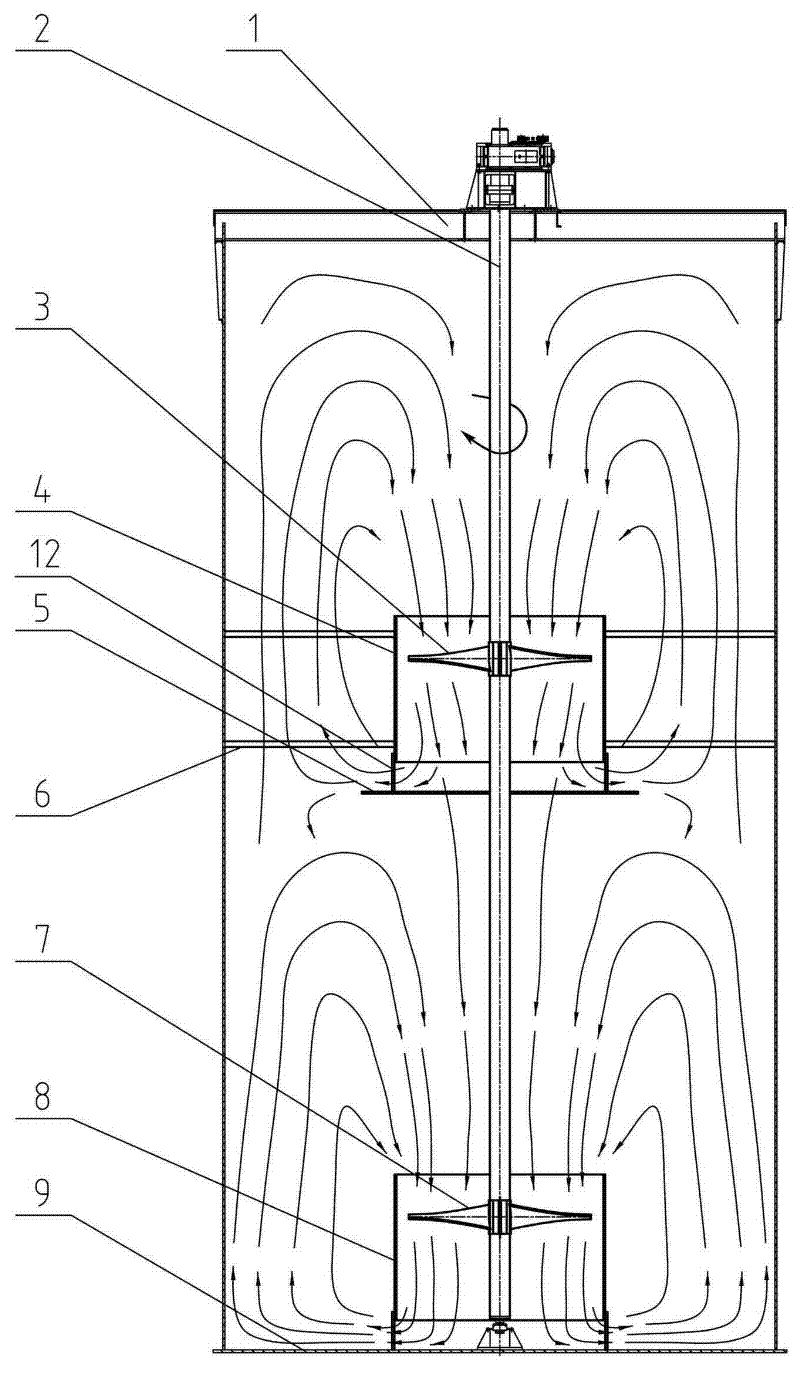

[0021] Such as figure 2 The agitating device of the high-performance stirring tank of the present invention as shown comprises a stirring paddle, and the agitating paddle is divided into an upper paddle 3 and a bottom paddle 7, and the upper paddle 3 and the bottom paddle 7 are arranged on the top and the bottom of the stirring shaft 2 respectively. An upper steel plate cylinder 4 is arranged on the outer circle of the outer circle, and an annular baffle 5 is arranged below the upper steel plate cylinder 4. The upper steel plate cylinder 3 is connected with the side wall of the stirring tank 1 with a support plate 6, and the outer surface of the bottom paddle 7 A circle of lower steel plate cylinders 8 is arranged in a circle, and the support plates of the lower steel plate cylinders 8 are fixed on the groove bottom plate 9; 1.02-1.1 times the diameter, the height of the upper steel plate cylinder 4 is equal to the diameter of the upper layer paddle 3, the upper layer paddle ...

Embodiment 2

[0024] The lower steel plate cylinder in Example 1 is in the shape of a conical tube, in the shape of a trumpet mouth, with an opening that is small at the top and large at the bottom, and the extension line of the opening at the lower end points to the bottom corner of the groove. Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com