Extrusion forming laser welding brazing method

A brazing method and extrusion molding technology, applied in welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problem of uneven mechanical and electrical properties, uneven flow of liquid solder, and uneven metallurgical process of solder. Complete and other problems, to achieve the effect of precise and controllable energy distribution, wide applicability and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0028] The invention provides a kind of extruded laser welding method, comprising the following steps:

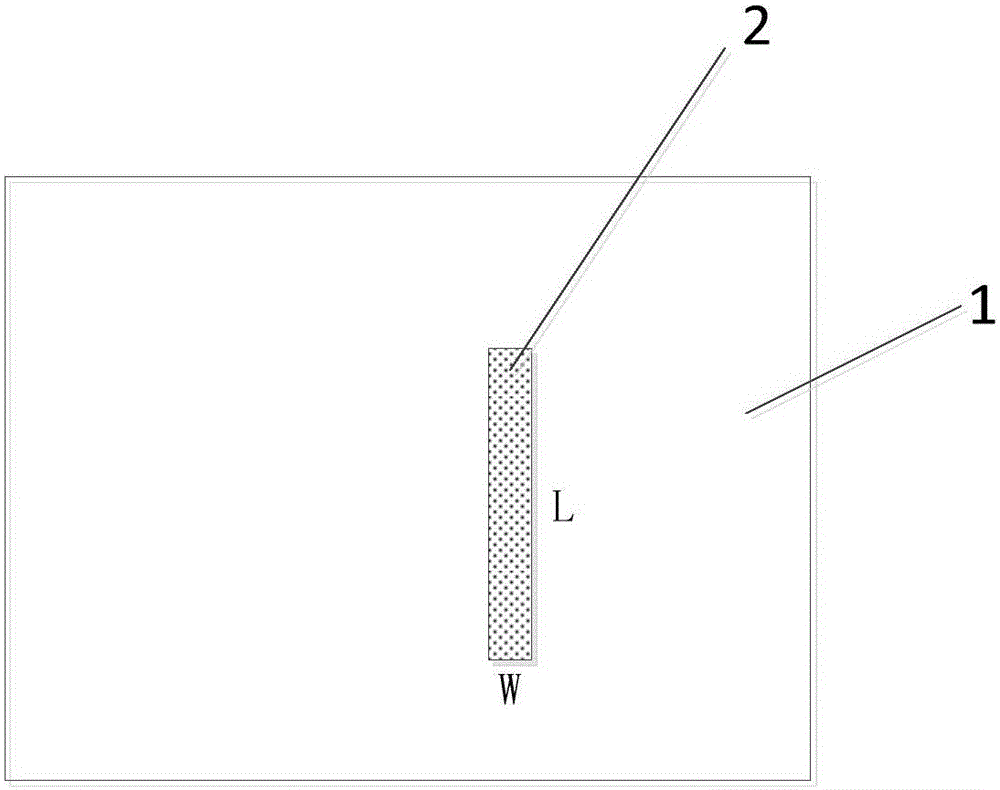

[0029] (1) if figure 1 As shown, a solder powder bar 2 is laid in advance at the position to be welded of the lower solder block 1 (base metal), and the solder powder bar 2 is elongated;

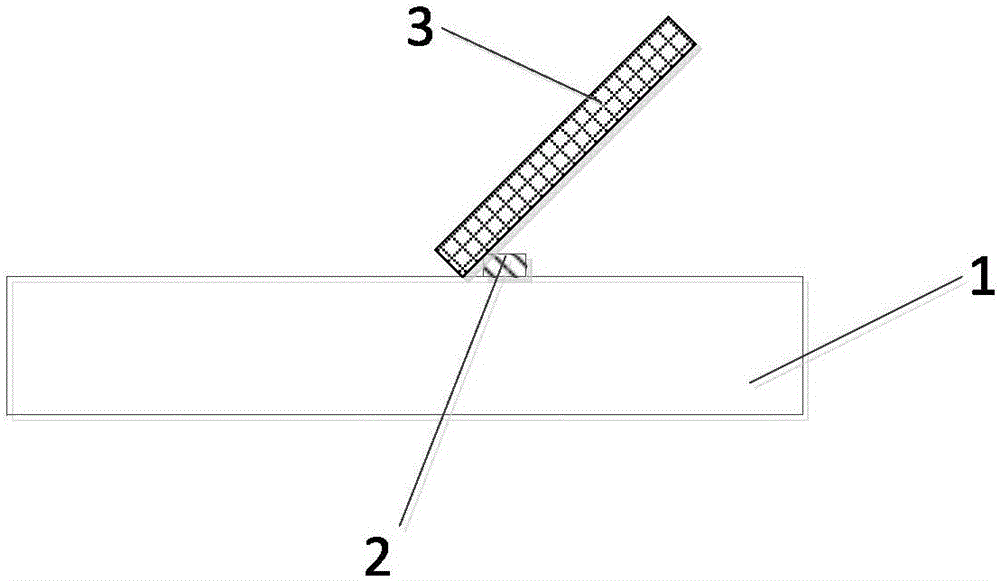

[0030] (2) if figure 2 As shown, the first end of the upper solder block 3 is placed on the lower solder block 1 and close to the position of the solder powder bar 2, and the second end is kept at a distance from the lower solder block 1, that is, between the upper solder block 3 and the lower solder block 1 Form an included angle space with an included angle of 0 to 60 degrees;

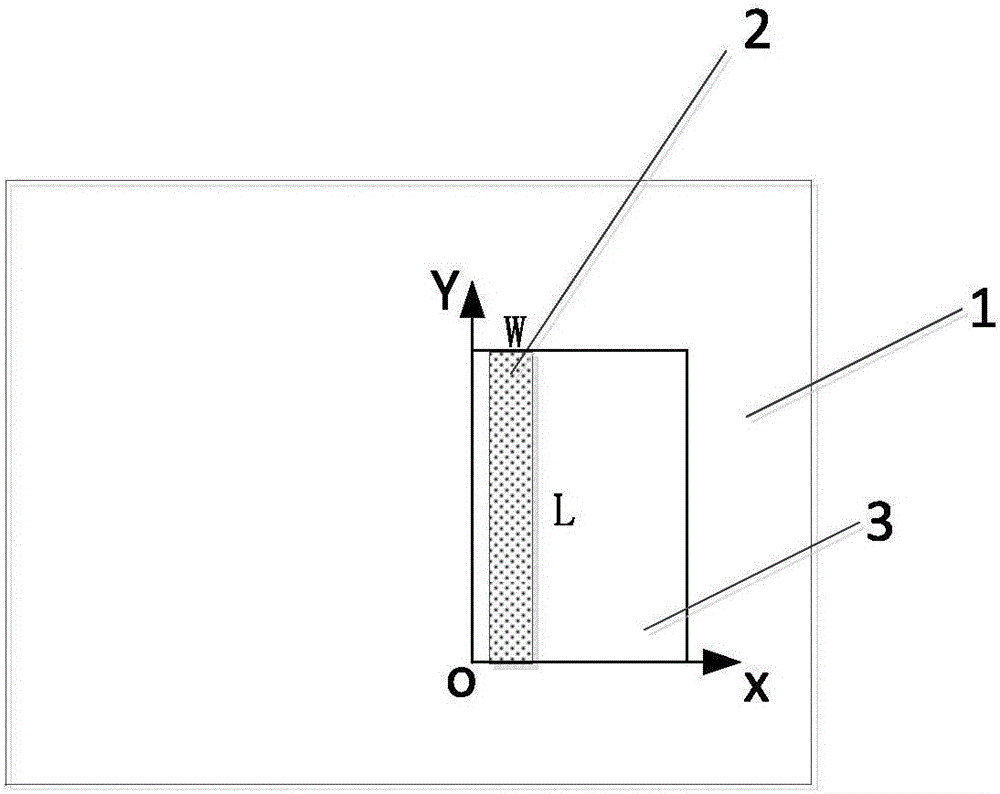

[0031] like image 3 As shown, the intersection line between the above solder block 3 and the lower solder block 1 is the Y axis, and one endpoint of the intersect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com