Patents

Literature

53results about How to "Avoid stomatal defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength foundry casting sand and preparation method thereof

InactiveCN104801655AHigh strengthHigh tensile strengthFoundry mouldsFoundry coresFoundrySodium Bentonite

The invention discloses high-intensity foundry casting sand and a preparation method thereof. The high-intensity foundry casting sand comprises the following raw materials in parts by weight: 45 to 65 parts of quartz sand, 20 to 30 parts of desert sand, 15 to 20 parts of illite, 12 to 18 parts of calcium carbonate powder, 5 to 10 parts of silicon boride, 2 to 3 parts of 3-isocyanatopropyltriethoxysilane, 8 to 12 parts of modified bentonite, 5 to 10 parts of emery powder, 4 to 8 parts of shale ash, 5 to 10 parts of malthacite, 3 to 5 parts of sodium alginate, 6 to 9 parts of light calcined powder, 3 to 7 parts of carbon nanofiber, 4 to 6 parts of polyethylene imine, 2 to 3 parts of polyvinyl butyral, and a proper amount of water. Compared with the traditional casting sand, the casting sand provided by the invention is relatively high in wet compression strength and tensile strength, further is excellent in heat resistance, plasticity and air permeability, is easy for pattern drawing and modeling, has the effect of bearing various external forces and high temperature, can improve casting quality obviously, and avoids defect of air holes produced by castings.

Owner:江守仲

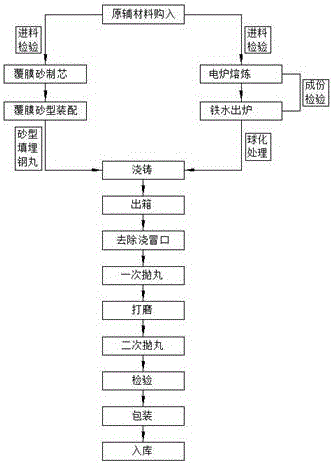

Casting method of main reducer housing

ActiveCN106825438AHigh dimensional accuracyHigh surface finishGearboxesFoundry mouldsPorositySurface finish

The invention relates to a casting method of a main reducer housing. The casting method includes: a precoated sand core forming process, a smelting ball iron process and a casting process, the precoated sand core forming process includes core-making of precoated sand, coated sand type assembly and sand-type steel shot filling; the smelting ball iron process includes electric-furnace smelting and charging of molten iron and treatment; the casting method is characterized by including casting, unboxing, de-gating, one-step shot blasting, grinding, secondary shot blasting and detecting. With the method, exhaust smoothness is guaranteed, generation of hole defects in the casting is avoided from the sand core exhaust process, sand hole and pore defective reject rate is controlled within 1%, shrinkage or porosity defect is avoided, the casting is stable in size and high in surface smoothness, the yield is higher as compared with that with a traditional casting method of the main reducer housing, the production process is easier to control, and production competitiveness has higher advantages.

Owner:抚州市羊易铸业有限公司

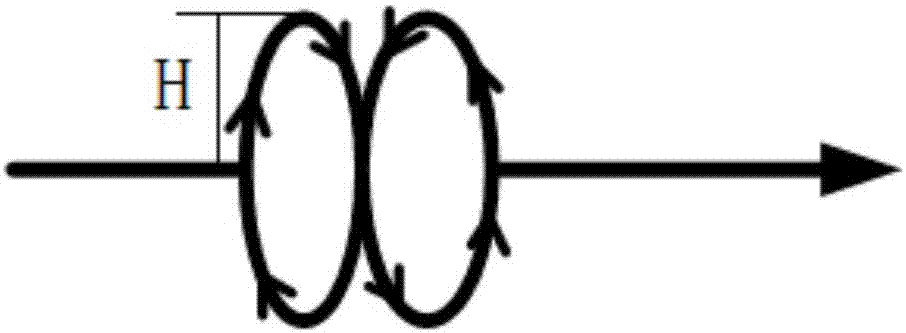

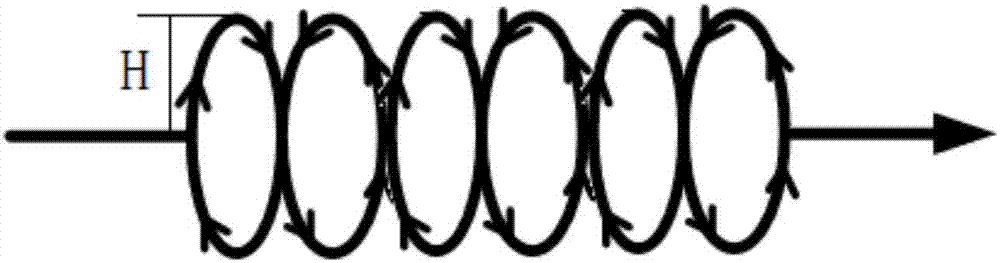

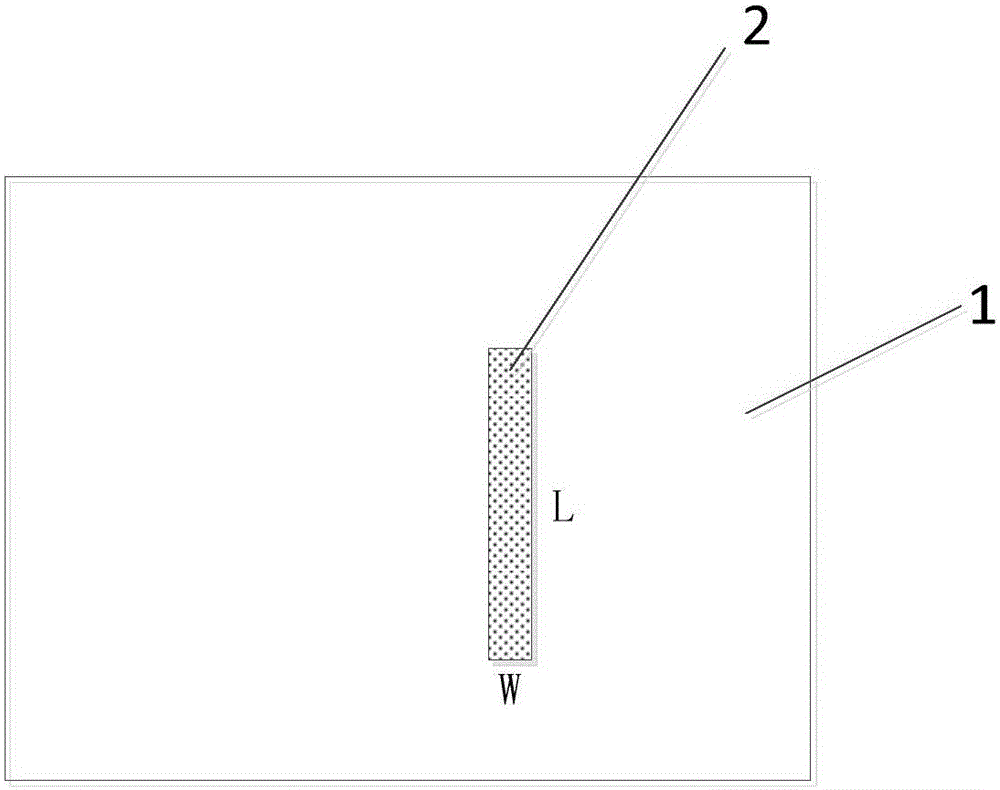

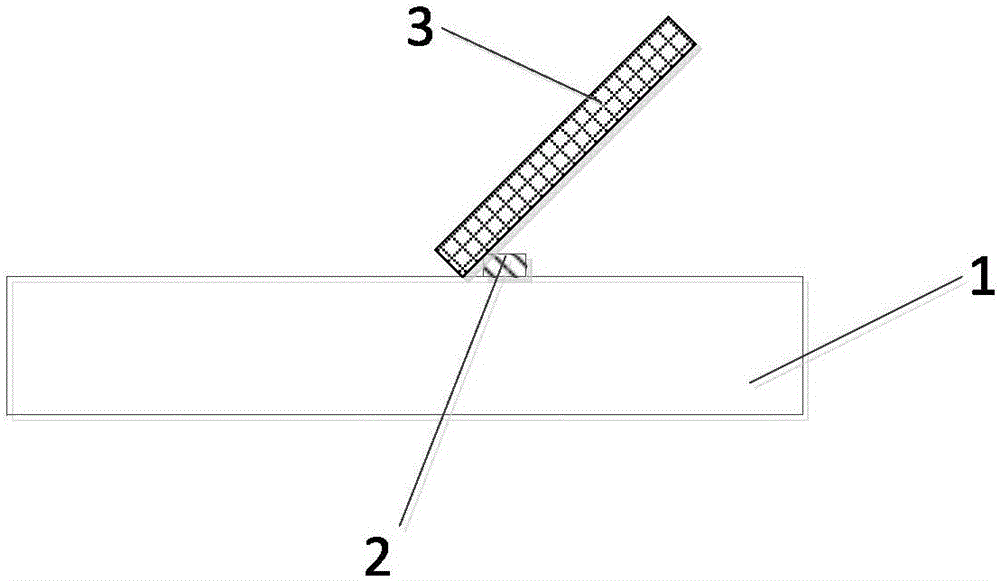

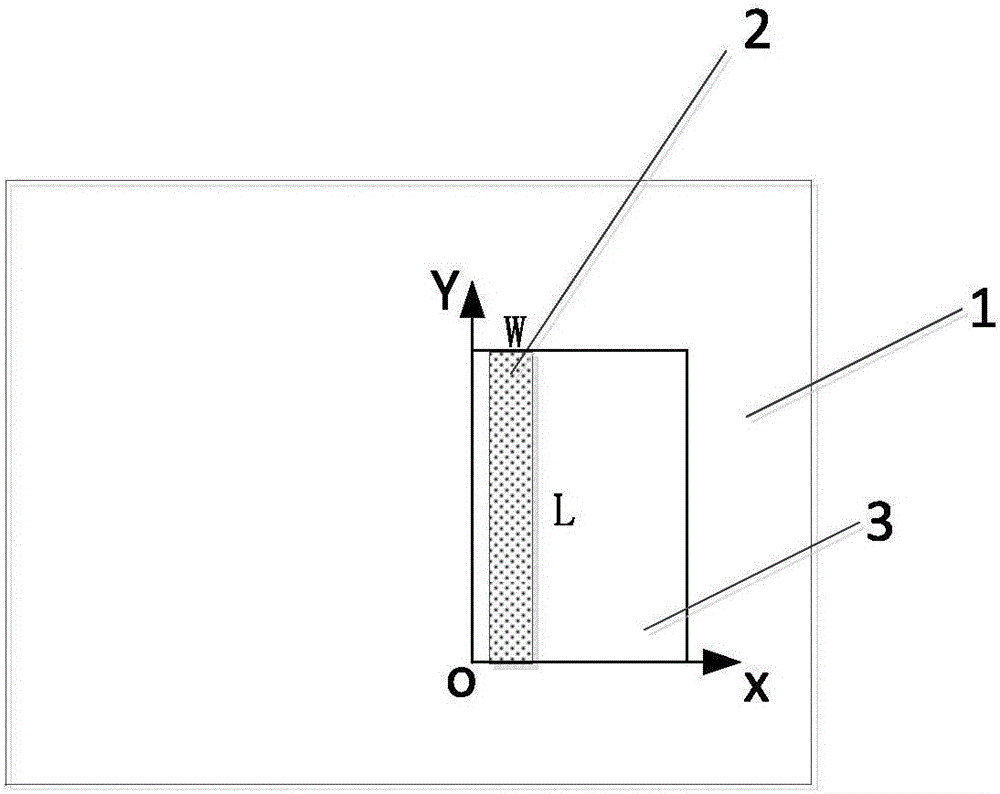

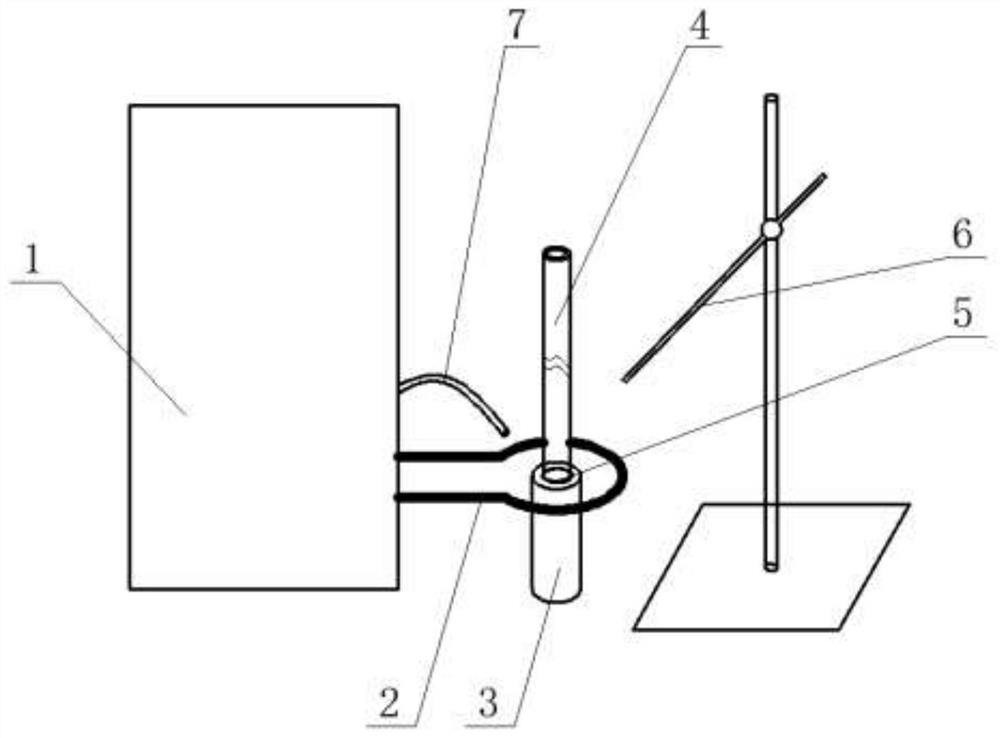

Laser welding technological method for saddle-shaped aluminum alloy structure

InactiveCN107511584AAvoid crackingAvoid stomatal defectsWelding/cutting auxillary devicesAuxillary welding devicesArabic numeralsSaddle shape

The invention discloses a laser welding technological method for a saddle-shaped aluminum alloy structure, and belongs to the technical field of welding. The method comprises the steps that a swing laser beam capable of achieving continuous outputting and uniform-speed movement is adopted for welding. In the welding process, the swing laser beam moves forwards along a shaft parallel to the welding direction. In the forward moving process, the swing laser beam swings with the shaft as a symmetrical shaft so as to from a movement path, and the movement path is composed of multiple paths shaped like a horizontal Arabic numeral 'eight'. By means of the method, laser welding joint internal cracks and air hole defects of the saddle-shaped aluminum alloy structure can be effectively avoided, a welding joint formed through welding is smooth in transition, and the welding joint comprehensive mechanical property is excellent.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

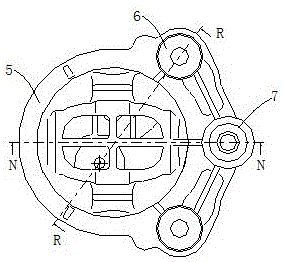

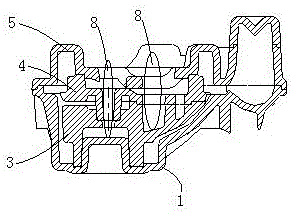

Process for manufacturing saloon car clutch pressure plate casting

The invention provides an optimized process for manufacturing a saloon car clutch pressure plate casting on a vertical modeling production line. The process comprises the following steps of mulling sand, modeling, melting burden, inoculating iron, pouring, cooling, opening case and clearing casting, wherein in the modeling step, two and more raw castings are horizontally and asymmetrically arranged; a pouring iron liquid enters into a straight pouring channel through a pouring cup and an upper cross channel; and the straight pouring channel enters into a lower cross channel by passing through the middle of a casting cavity and then asymmetrically enters into the cavity from the lower side of the cavity. The pressure plate casting produced by using the process of the invention has a single-cast coupon tensile strength equal to or more than 250 MPa, a casting body tensile strength equal to or more than 200 MPa and the casting body hardness from 170 to 241HBS. The product metallographic structure mainly uses the A type graphite; the length of the graphite is 4 to 6 level; the matrix contains more than 95% of small pearlites and less ferrites; and all the parts of the casting have no casting flaw and meet the technical requirements of the saloon car clutch pressure plate casting.

Owner:上海华新合金有限公司

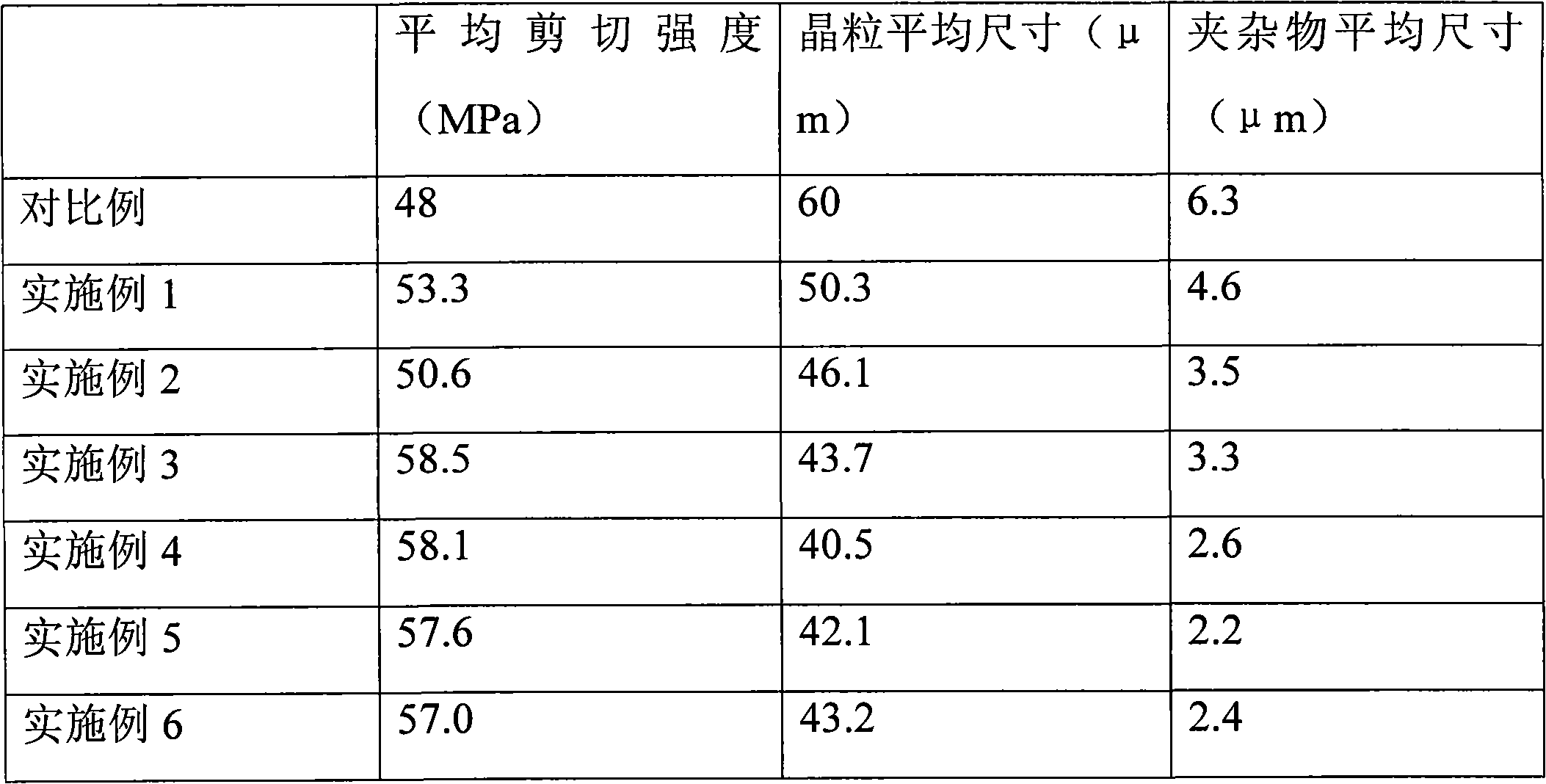

Method for preparing magnesium alloy solder

InactiveCN102071337AEvenly distributedReduce in quantityWelding/cutting media/materialsSoldering mediaSlagLiquid surfaces

The invention discloses a method for preparing a magnesium alloy solder, which comprises the following steps of: preheating a crucible or a smelting furnace, spreading a covering agent, and heating an alloy ingot in protective atmosphere to the temperature which is 50 to 150 DEG C higher than the prepared solder liquid phase line; melting the alloy ingot, collecting slag, and stirring; applying ultrasonic waves to the melted magnesium alloy solder by adopting an ultrasonic generator, namely inserting a preheated ultrasonic rod to a position 5 to 50mm lower than the liquid surface of the melted magnesium alloy solder, wherein the difference between the preheating temperature of the ultrasonic rod and the melting temperature of the solder does not exceed 20 DEG C, the frequency of the ultrasonic waves is 18 to 22kHz, the intensity of the ultrasonic waves is 0.5 to 5W / cm<2> and the time is 0 to 150 seconds; moving the ultrasonic rod out, and standing alloy melt; and injecting the melted solder into a stainless steel mold, and cooling to room temperature to obtain the solder. Alloy elements, particularly microalloy elements are uniformly distributed, the crystals are fine, the toughness is improved, and the shearing strength of brazing lap joints is improved by 5 to 20 percent.

Owner:BEIJING UNIV OF TECH

Sand core good in air permeability and preparation method thereof

InactiveCN106077497AImprove breathabilityOvercome the problem of prone to porosity defectsFoundry mouldsFoundry coresActivated carbonHoneycomb

The invention discloses a sand core good in air permeability and a preparation method thereof. The sand core good in air permeability is prepared from 12-13.5% of pottery clay, 4.5-6.5% of activated carbon powder, 3.5-6% of dry sand, 4-6% of aerogel and the balance molding sand and inevitable impurity elements. The preparation method includes the following steps of dry sand filling, aerogel layer wrapping, sand core box coating, drying, shaping and material taking. The surface of a core bar is filled with dry sand through honeycomb holes, and the dry sand is used for adsorption for air. Because the surface of the core bar is further wrapped by an aerogel layer, the air permeability of the aerogel is especially good, good air permeability is achieved, the problems that because a sand core in the prior art is poor in air permeability once the core bar is adopted, and consequently a casting is prone to the cavity defect are solved, and therefore the air permeability of the sand core is improved, occurrence of the cavity defect of the casting is avoided, the aerogel layer further has high high-temperature resistance, damage to an air-permeable layer caused by high-temperature casting is avoided, and the requirement of casting work of various materials can be met.

Owner:ANHUI QUANCHAI TIANHE MACHINERY

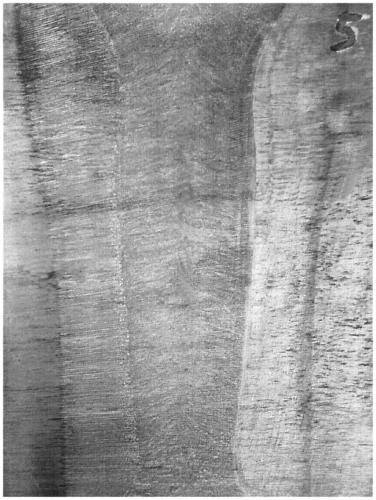

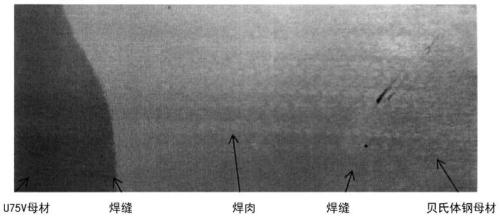

Aluminothermic welding method of seamless steel rail

PendingCN111590192AGuaranteed temperatureGuaranteed interface temperatureRailsMetal working apparatusAl powderIron powder

The invention relates to an aluminothermic welding method of a seamless steel rail. A welding flux comprises C, Si, Mn, Cr, Ni, Mo, V, aluminum powder and oxide and iron powder, the process comprisesthe following steps of polishing, derusting and dehumidifying a steel rail; preheating the steel rail until the rail head turns red; igniting and preheating the aluminothermic welding flux, and reacting and pouring; after pouring, heating the steel rail at 250-300 DEG C within the position, 500 mm away from the outside of a sand mold frame, of the two sides of the sand mold frame; knob removing,meanwhile, keeping the temperature of the steel rail at 250-300 DEG C within the position, 500 m away from the outside of the sand mold frame, of the two sides of the sand mold; cooling the welded junction to 500 DEG C, performing hot grinding, cooling weld metal part after the hot grinding, keeping the temperature of the steel rail at 250-300 DEG C within the position, 500 m away from the outsideof the sand mold frame, on the two sides of the sand mold frame in the process till the weld metal part reaches 250-300 DEG C, and performing cover heat preservation on the welded junction for 20 min; and removing the cover, and naturally cooling to room temperature. The method ensures the welding quality.

Owner:BEIJING TEYE IND & TRADE

Molding sand for cast aluminum and preparation method thereof

InactiveCN103567364AImprove breathabilityAvoid stomatal defectsFoundry mouldsFoundry coresSilicic acidWood ash

The invention discloses molding sand for cast aluminum and a preparation method thereof. The molding sand is prepared from the following raw materials in parts by weight: 50-70 parts of magnesia, 35-45 parts of red sand, 10-15 parts of coal gangue, 5-10 parts of alundum powder, 4-7 parts of chalk powder, 8-12 parts of bentonite, 3-6 parts of loess, 2-3 parts of glass beads, 3-5 parts of anhydrous sodium sulfate, 2.5-3.5 parts of aluminum-magnesium silicate, 2-4 parts of polyacrylamide, 1.5-2.5 parts of sugar calcium, 1-2 parts of plant ash and 5-9 parts of water. The molding sand has high air permeability, the defect that an air hole is formed in a casting is overcome, the casting is high in surface smooth finish, the rejection rate of the casting can be greatly reduced, the production cost is reduced, and the molding sand has significant economic benefits.

Owner:TONGLING JINGWEI FLUID SCI & TECH

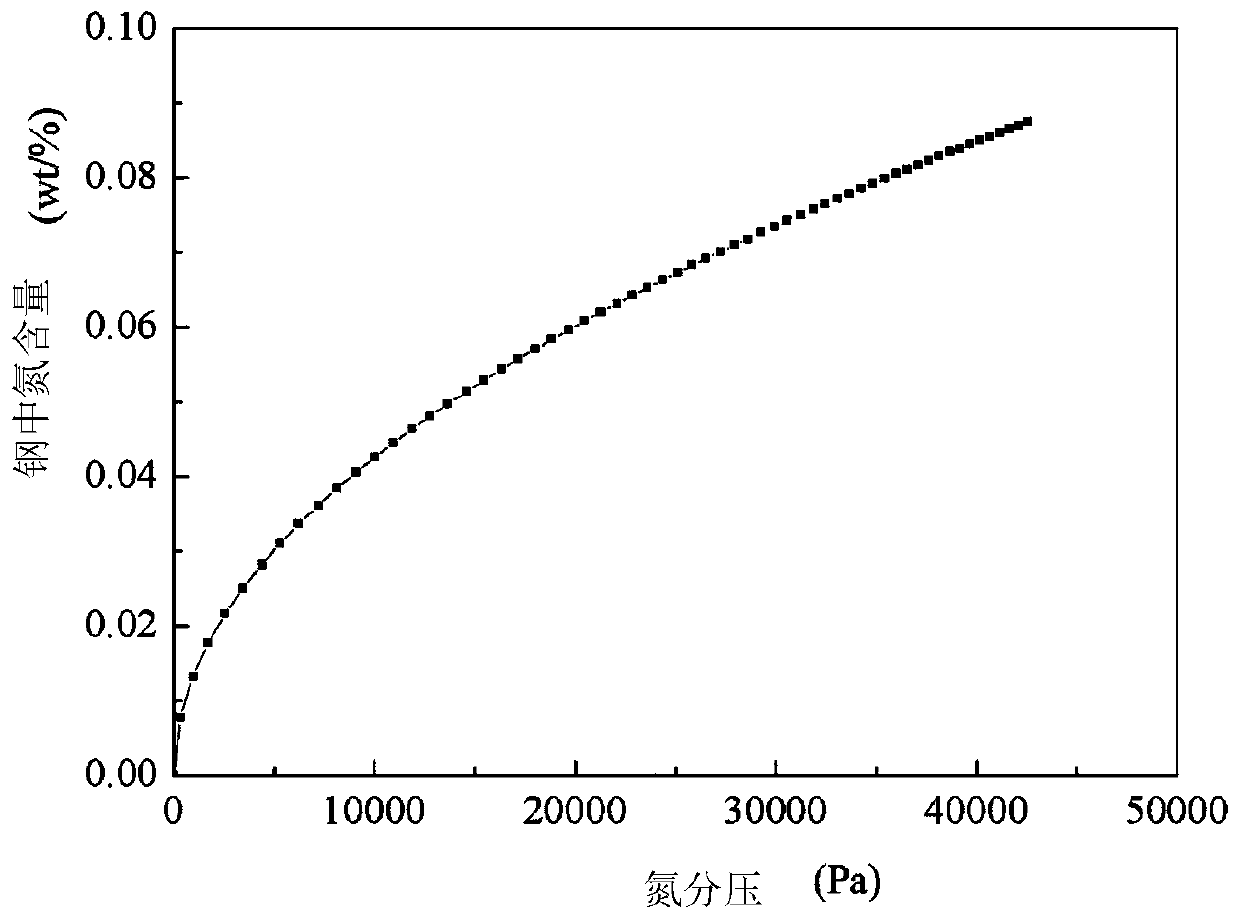

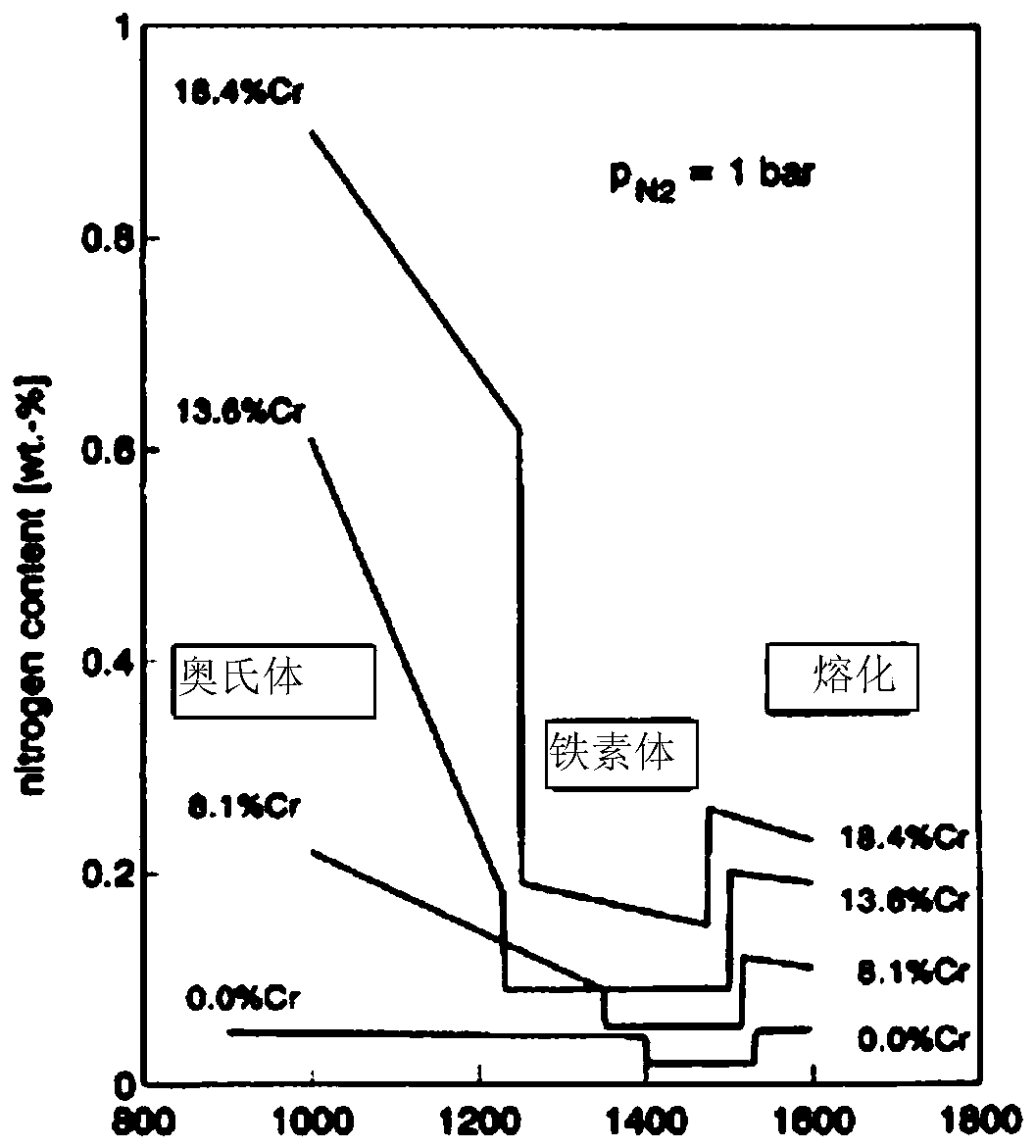

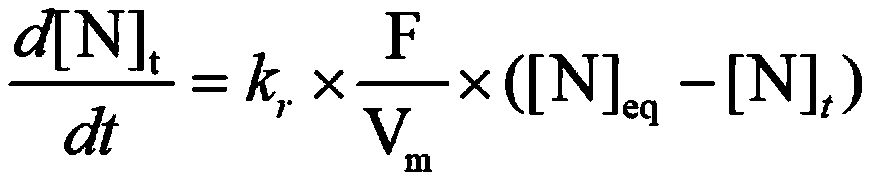

Method for smelting COST-FB2 steel through gas-phase nitriding under negative pressure condition

ActiveCN110093582APrecise temperature controlUniform compositionSolid state diffusion coatingGas phaseManganese

The invention relates to a method for smelting COST-FB2 steel through gas-phase nitriding under a negative pressure condition. The method comprises the following steps that firstly carbon deep deoxidation is performed under the condition of high vacuum degree, deoxidation is completed after the surface of molten steel is stable and bubbles do not rush out any longer; then an alloy element for promoting nitrogen dissolution is added and completely molten, and then gas-phase nitriding is started; during gas-phase nitriding, nitriding pressure during gas-phase nitriding is calculated by using thermodynamic calculation software Factsage, the molten steel temperature is accurately controlled, and the nitriding time is calculated and determined through the surface area of the molten steel, the volume of the molten steel and the nitrogen balance content; when gas-phase nitriding is about to be completed, the alloy element boron and the volatile manganese are added, then through argon filling,pressurization is performed until the high pressure is reached, pressurization casting is performed under the condition that the nitrogen partial pressure is kept unchanged, the under-pressure stateis kept in the solidification process, vacuum breaking is performed after complete solidification, and a COST-FB2 steel cast ingot which has the content of N being 0.015%-0.03% and the content of O being less than or equal to 0.0035%, is uniform in component and compact in structure is prepared.

Owner:NORTHEASTERN UNIV

Packless casting temperature-resistant coating

InactiveCN101596575ANo accumulationImprove high temperature strengthFoundry mouldsFoundry coresHydrogen phosphateAqueous solution

A packless casting temperature-resistant coating is characterized in that the coating is prepared by the following components by weight percent: 60-70% of aluminium hydrogen phosphate, 0.01-0.05% of wetting agent, 0.001-0.005% of methylene blue and the allowance water and the specific gravity of the prepared solution is 1.2-1.3. The invention has the advantages that the new coating is aqueous solution without any filler so as to avoid all the problems in preparation, storage and use; coating can not be stacked so that castings without surplus or with little surplus can be obtained easily; the effects of avoiding burr, veining, sand penetration and sintering of the coating are incomparable to traditional coatings; blowhole is effectively prevented; the production cost can be promoted to reduce.

Owner:徐俊伟

Investment casting process for thin-wall annular casing casting

InactiveCN112122550AGuaranteed dimensional accuracyImprove molding qualityFoundry mouldsMould handling/dressing devicesInvestment castingCrazing

The invention provides an investment casting process for a thin-wall annular casing casting. The investment casting process comprises the following steps that a wax mold is prepared according to a design drawing, the wax mold comprises an inner wax ring and an outer wax ring which are coaxially arranged, and the outer circumferential surface of the inner wax ring is connected together through a plurality of wax rib plates; brown pulverized corundum is put into a drying oven for drying and cooled to room temperature; the brown pulverized corundum is sprayed on the inner surface of the inner waxring and the outer surface of the outer wax ring and filled between any two adjacent wax rib plates to form a casting mold component, and the casting mold component is roasted to obtain a shell; anda metal material smelted into a liquid state is poured into the shell, and the thin-wall annular casing casting is manufactured after the metal material is condensed. By the adoption of the technicalscheme, the brown pulverized corundum is baked in advance, the defect of air holes in the casting is avoided, the brown pulverized corundum and the wax mold are firmly bonded by vibrating the brown pulverized corundum and using silica sol, the shell is roasted by adopting fine-grain brown pulverized corundum, the temperature difference of a local area is prevented from being too large, the defectof cracks in the casting is avoided, and the casting quality of the casting is improved.

Owner:GUIZHOU ANJI AVIATION PRECISION CASTING

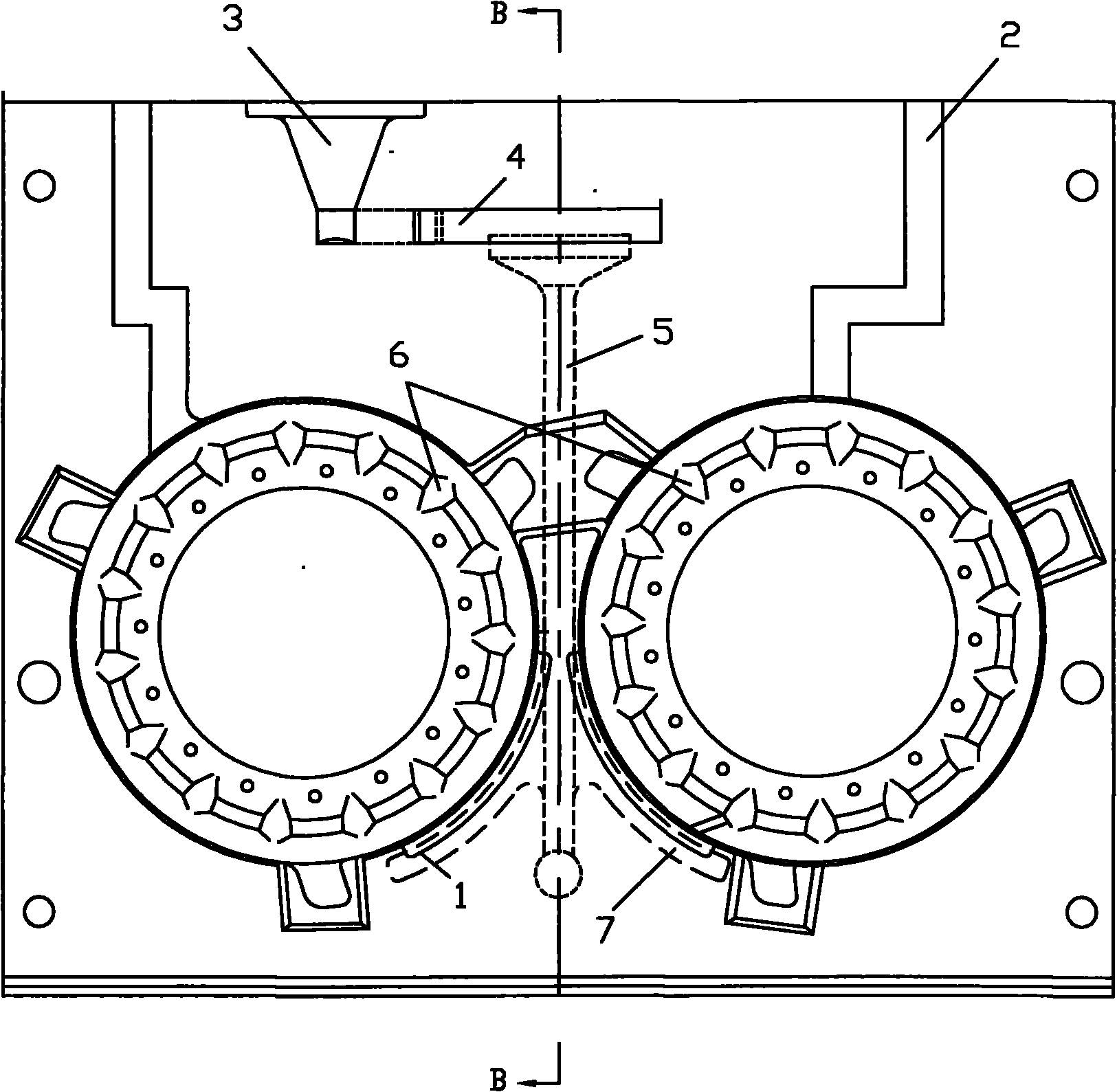

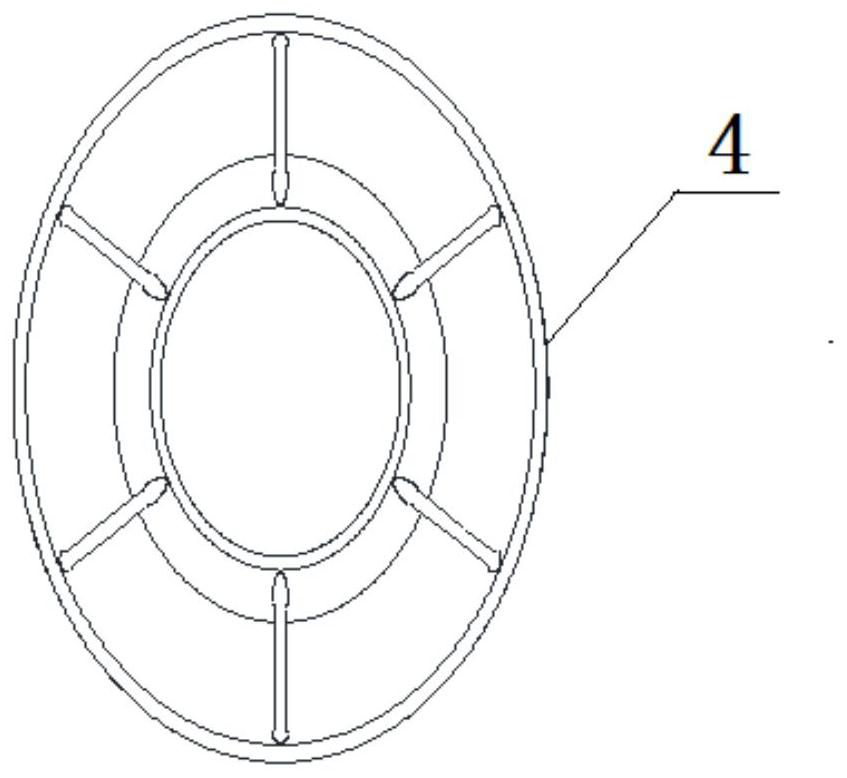

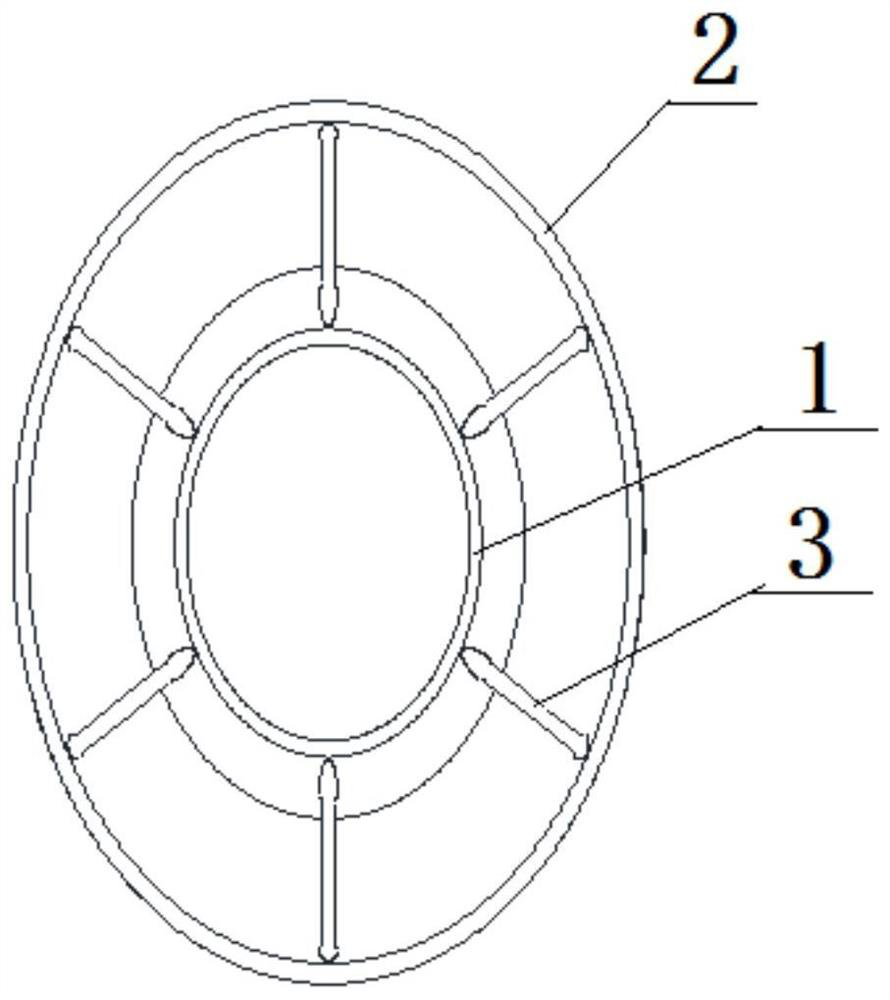

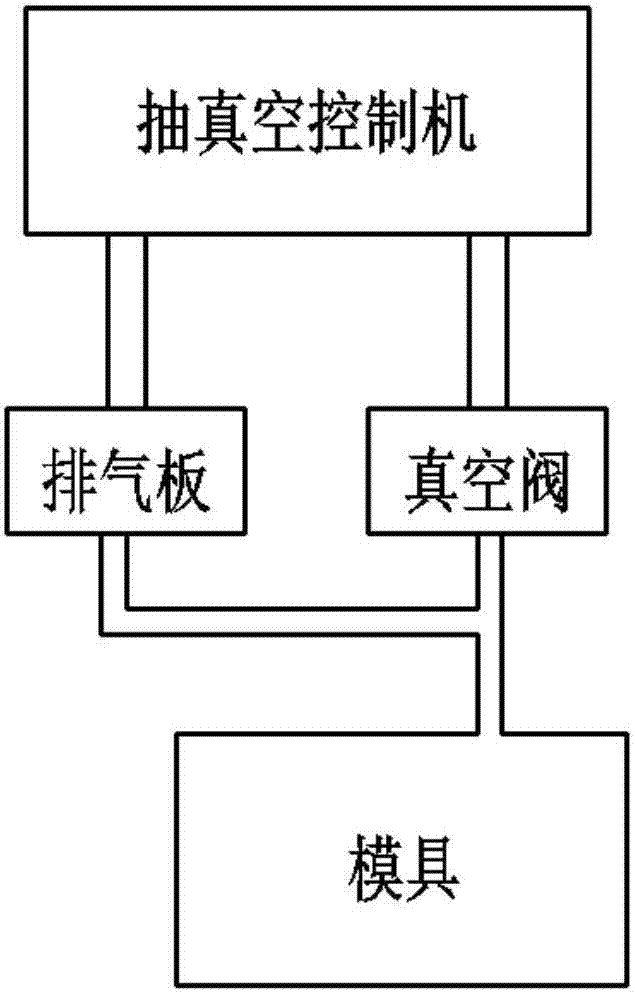

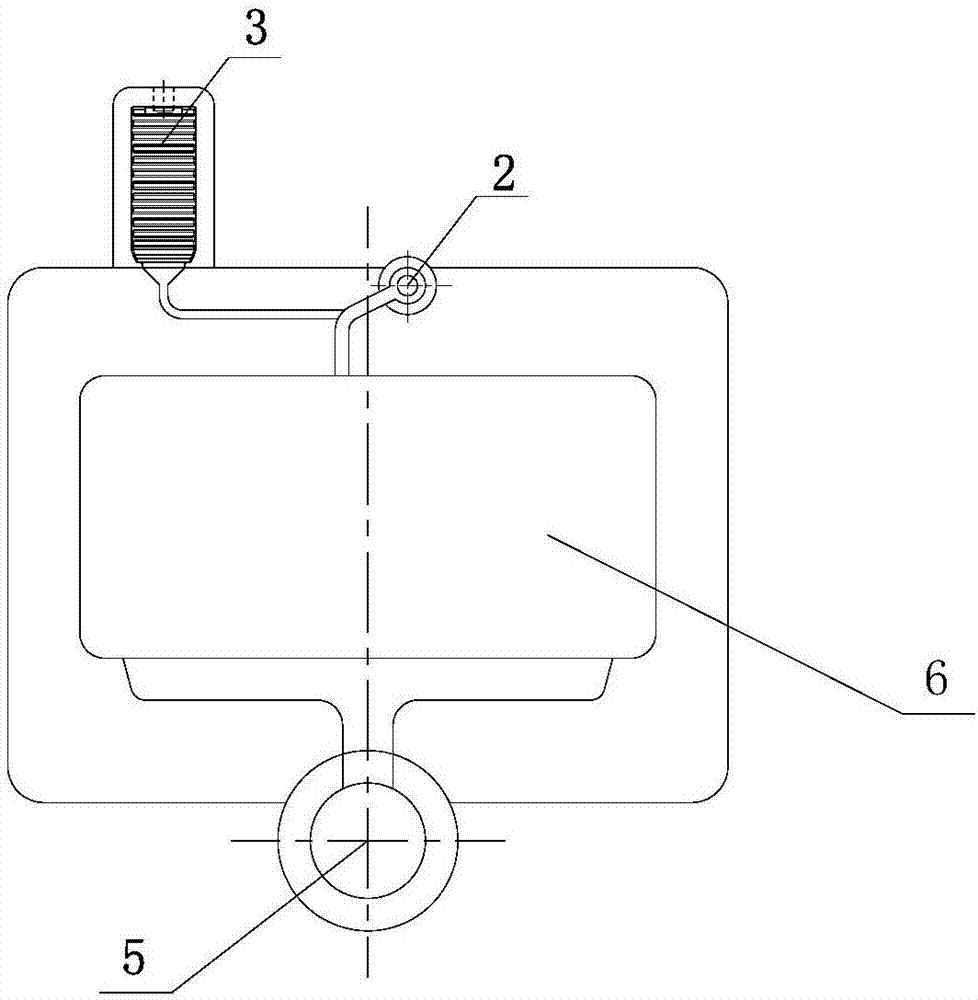

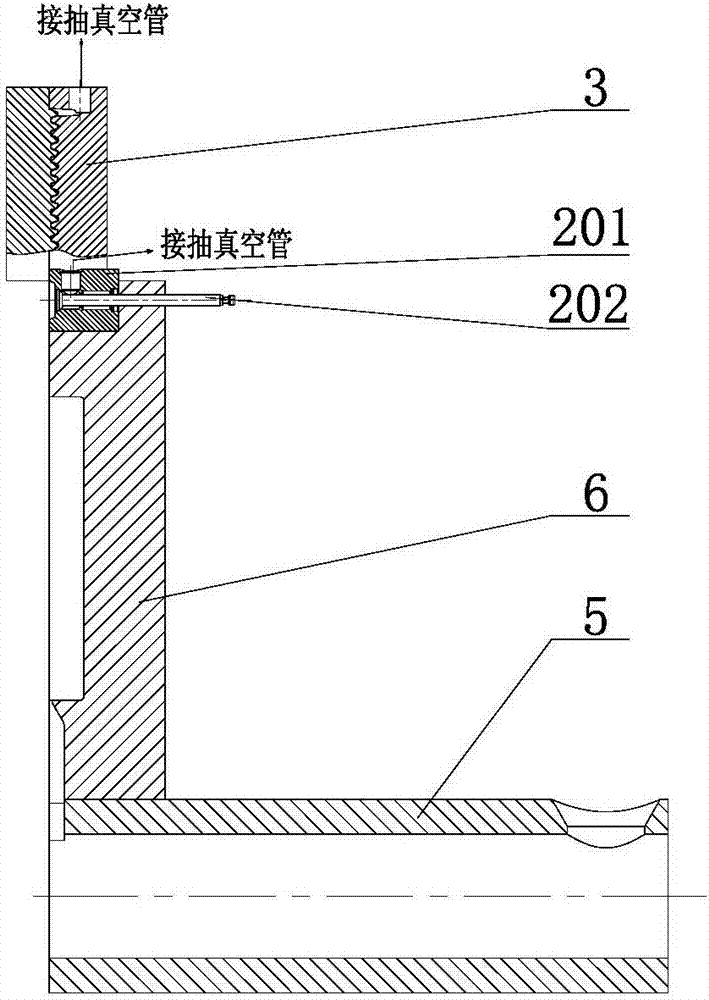

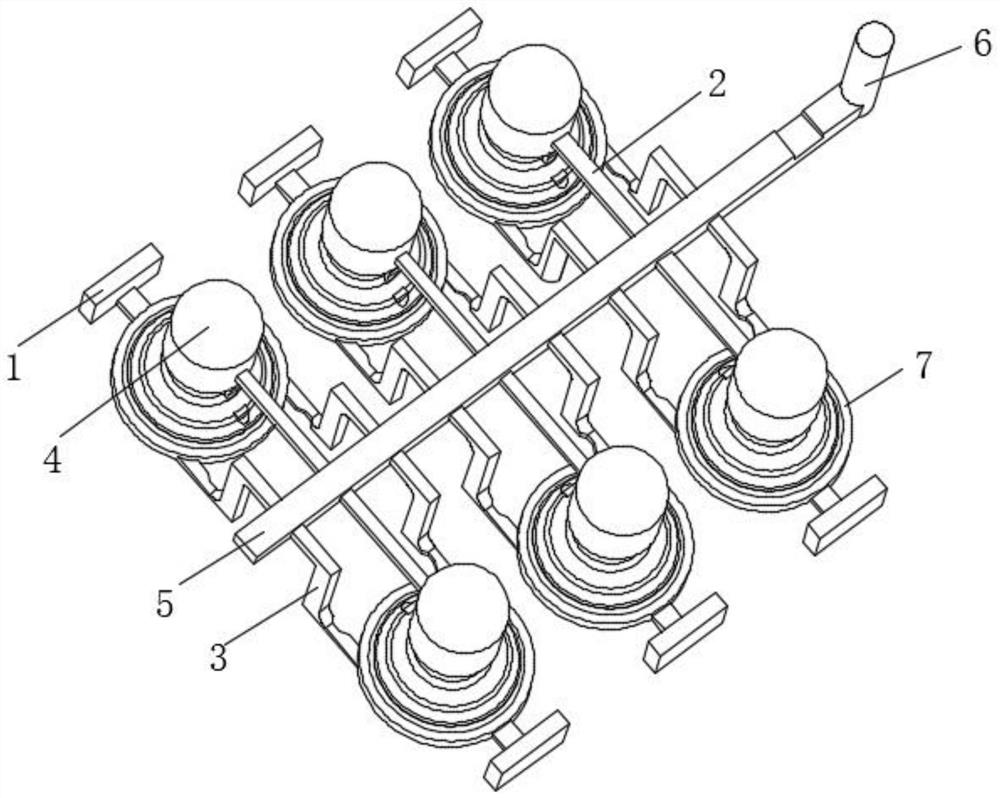

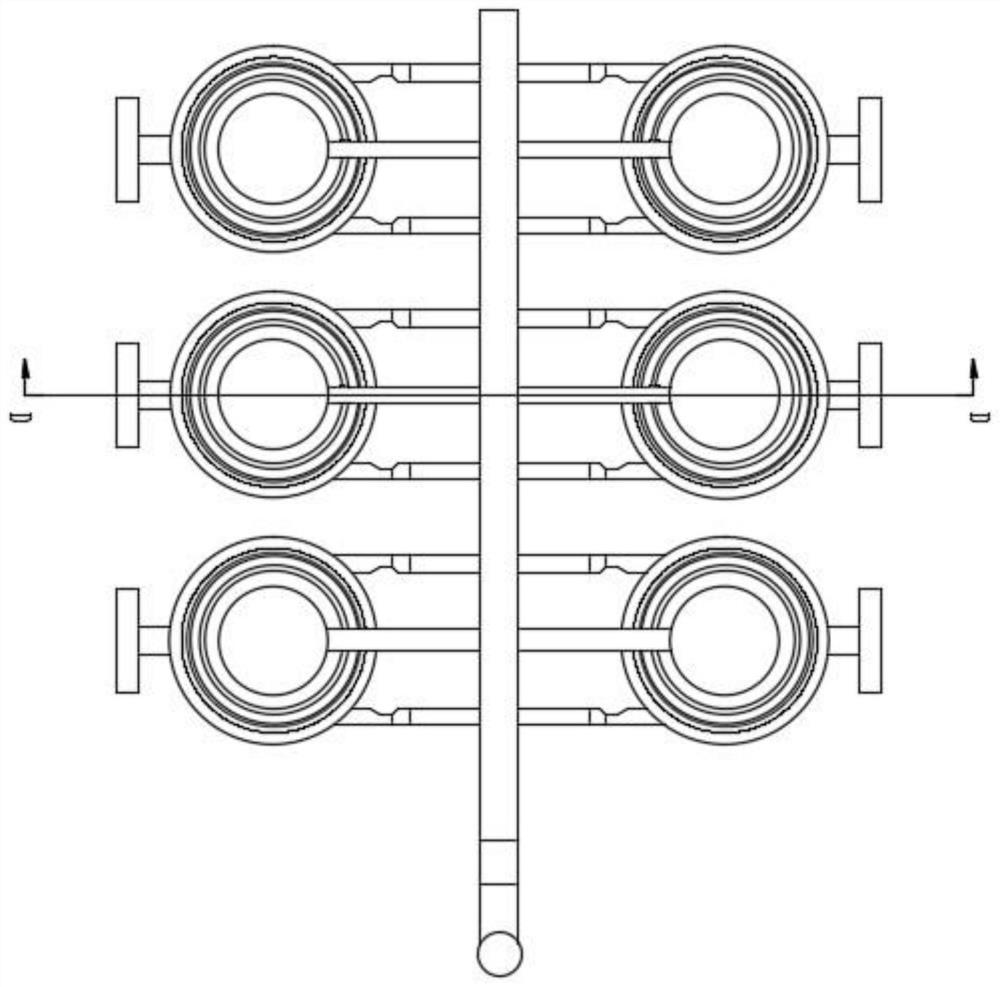

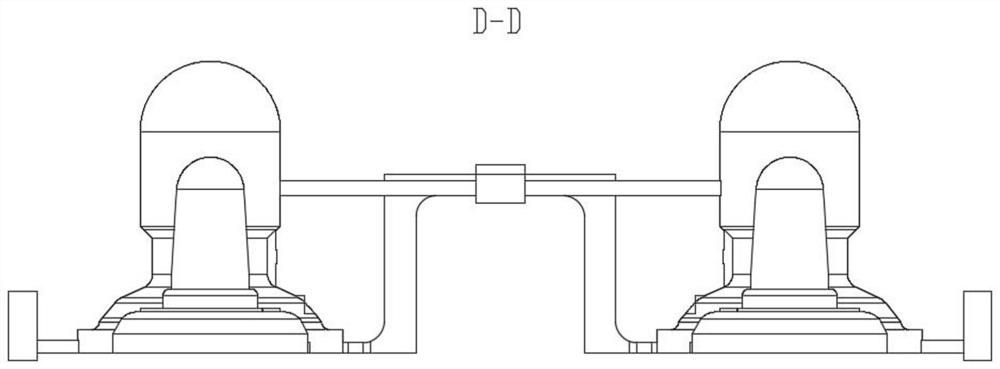

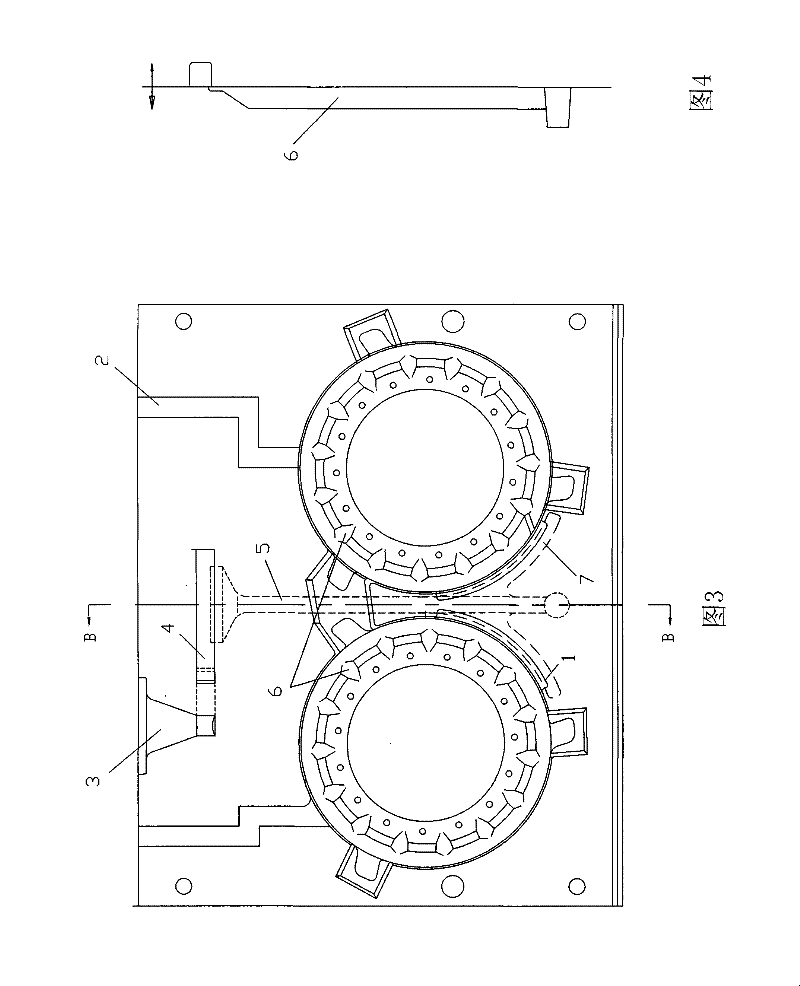

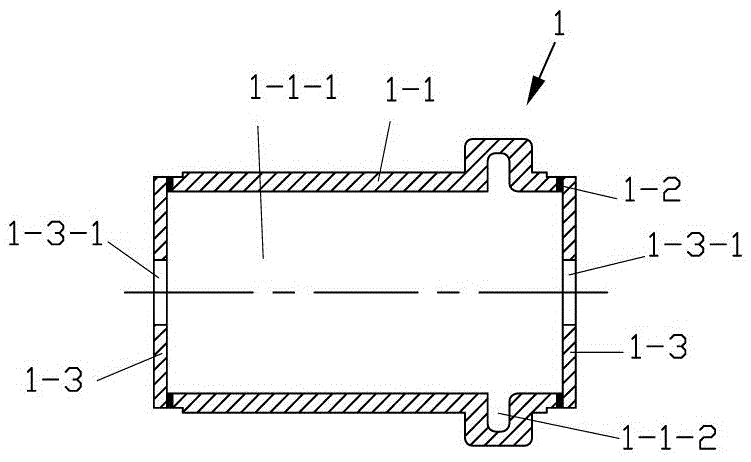

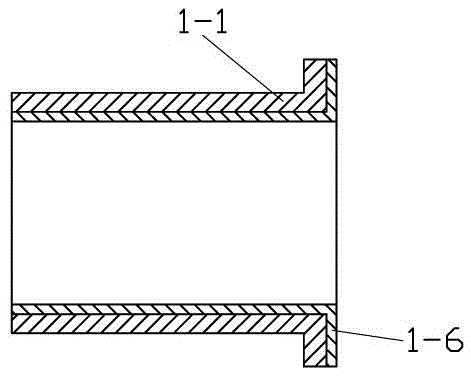

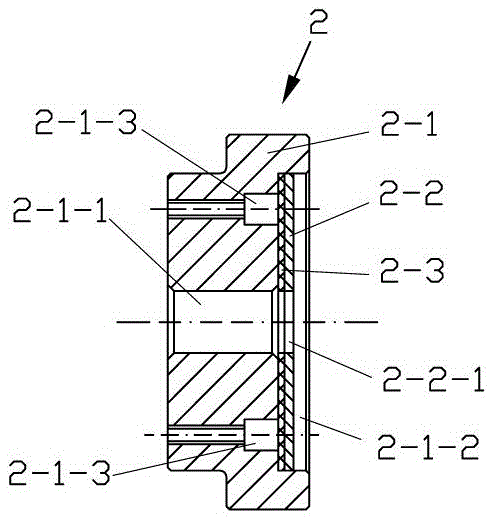

Die-casting die vacuumizing structure with vacuum valve connected with exhaust plates in parallel

The invention discloses a die-casting die vacuumizing structure with a vacuum valve connected with exhaust plates in parallel. The die-casting die vacuumizing structure comprises the vacuum valve (2), an exhaust block (3), a vacuumizing controlling machine (4) and a vacuumizing pipe; one end of the vacuum valve (2) is connected with the vacuumizing controlling machine (4), one end of the exhaust block (3) is connected with the vacuumizing controlling machine (4), and the other end of the vacuum valve (2) and the other end of the exhaust block (3) are connected with a cavity of a die; and the exhaust block (3) comprises the first exhaust plate (301) and the second exhaust plate (305), wherein tooth tops and tooth roots of the first exhaust plate (301) and the second exhaust plate (305) are arranged in a staggered mode, and accordingly, a zigzag and narrow channel is formed. According to the die-casting die vacuumizing structure, the vacuum valve and the exhaust plates are organically combined, and thus, the defect that pores are formed in a die-casting die due to the fact that a vacuumizing valve is closed too early can be well overcome.

Owner:广东鸿图武汉压铸有限公司

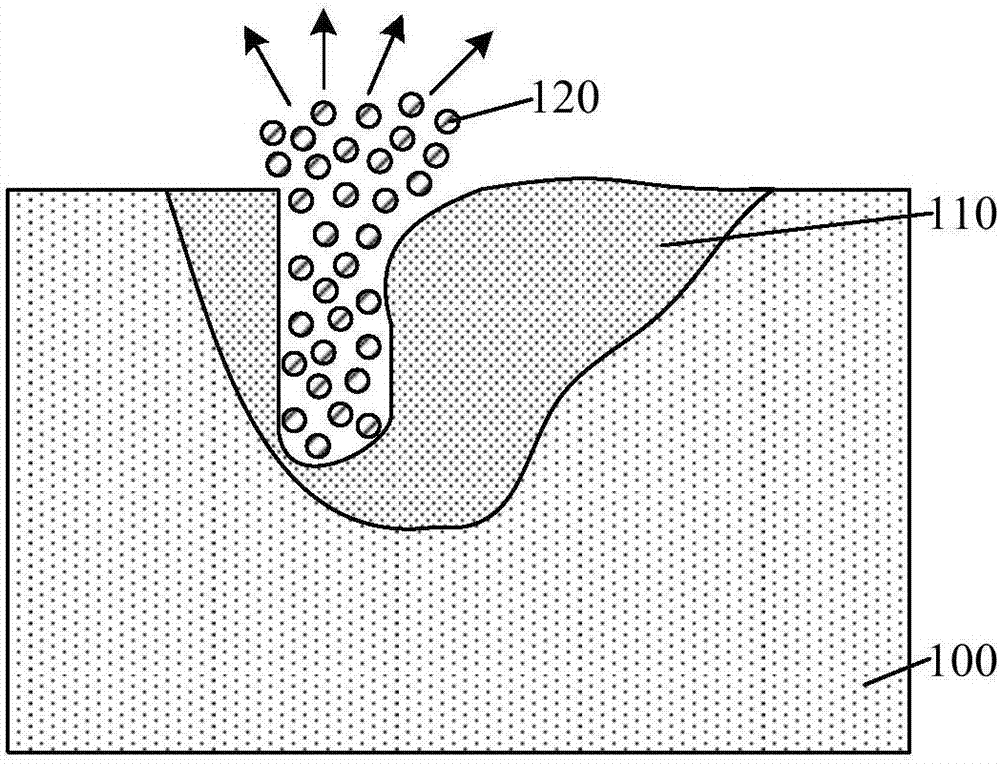

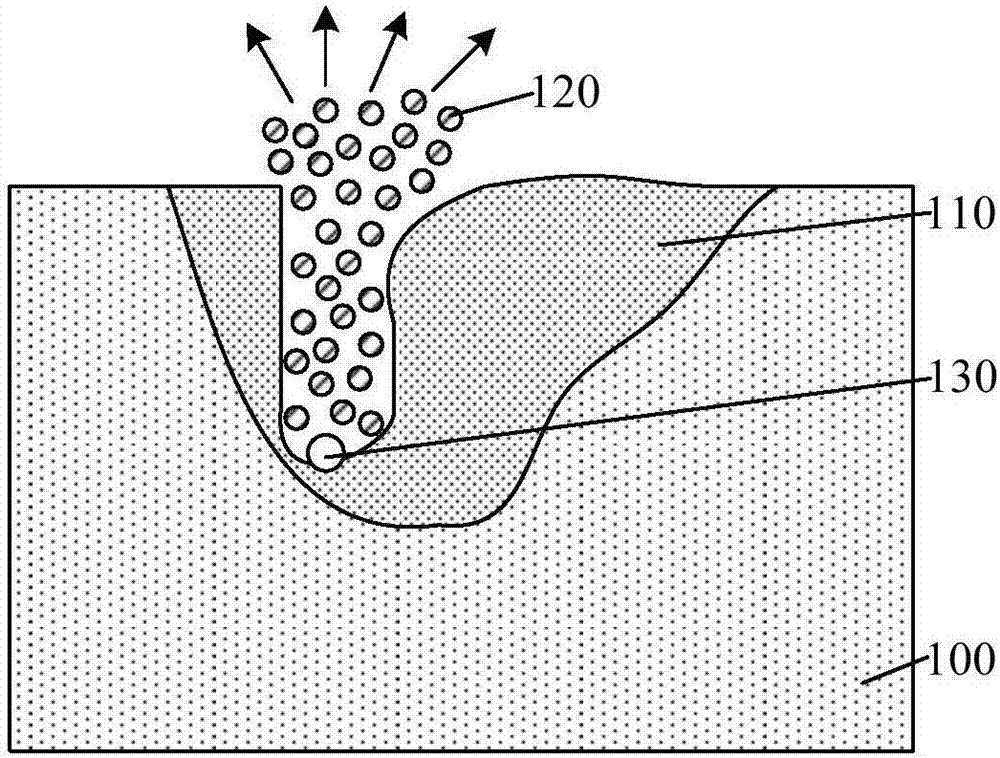

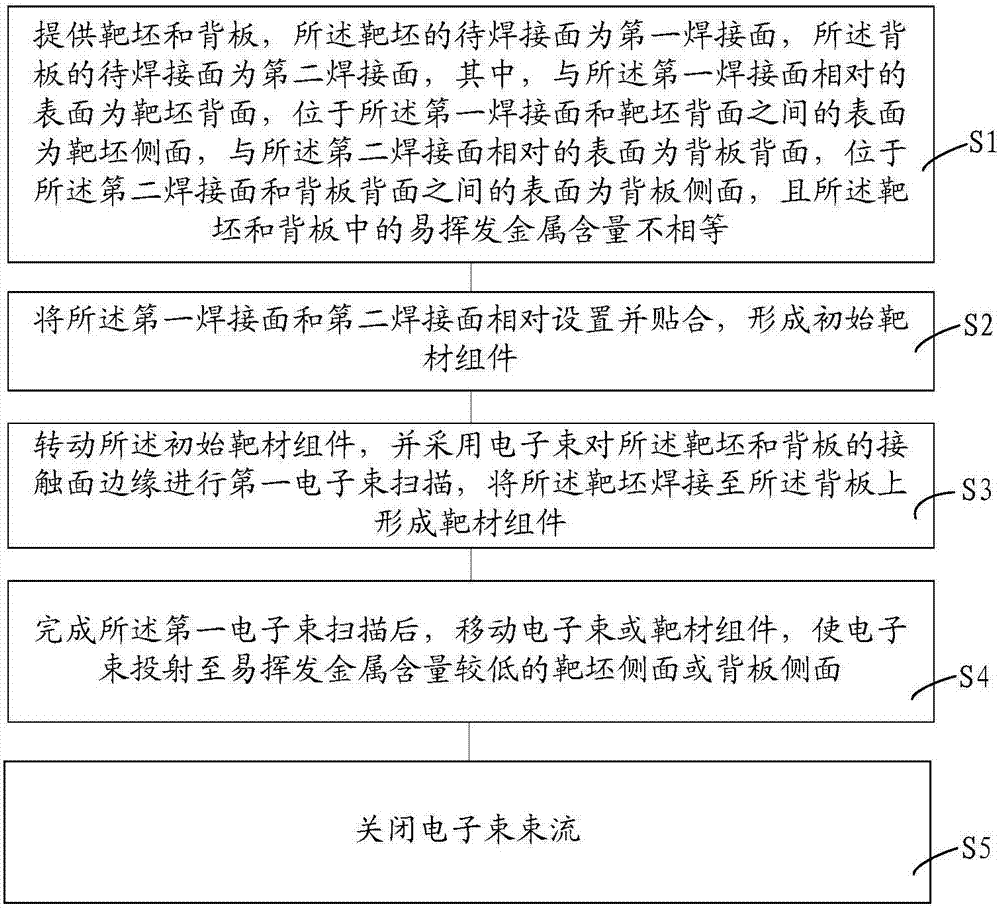

Manufacturing method for target material assembly

InactiveCN107304470AImprove welding strengthImprove yieldVacuum evaporation coatingSputtering coatingBeam scanningEngineering

The invention provides a manufacturing method for a target material assembly. The manufacturing method comprises the steps that a target blank and a back plate are provided, wherein a face to be welded of the target blank is a first welding face, a face to be welded of the back plate is a second welding face, a face opposite to the first welding face is a back target blank face, faces located between the first welding face and the back target blank face are side target blank faces, a face opposite to the second welding face is a back back plate face, faces located between the second welding face and the back back plate face are side back plate faces, and the contents of volatile metal in the target blank and the back plate are not equal; the first welding face and the second welding face are oppositely arranged and are attached to each other; and first electron beam scanning is carried out on edges of contact faces of the target blank and the back plate through electron beams, and the target material assembly is formed; after first electron beam scanning is completed, the electron beams or the target material assembly is moved so that the electron beams can be projected to the side target blank faces or the side back plate faces where the contents of the volatile metal are low. According to the manufacturing method, after first electron beam scanning is completed, the electron beams or the target material assembly is moved so that the electron beams can project to the side target blank faces or the side back plate faces where the content of the volatile metal are low, the welding intensity is improved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Extrusion forming laser welding brazing method

ActiveCN106077862ASpread evenlyEasy to overflowSoldering apparatusWelding/soldering/cutting articlesMelting tankLaser beams

The invention provides an extrusion forming laser welding brazing method. The extrusion forming laser welding brazing method comprises the steps that (1) a solder powder strip is paved in a to-be-welded position of a lower welding block in advance; (2) a first end of an upper welding block is placed in the position, close to the solder powder strip, on the lower welding block, and a 0 to 60-degree included angle space is formed between the upper welding block and the lower welding block; (3) laser beams obliquely shoot from the included angle space, and the laser beams are focused on the solder powder strip to form a strip-shaped brazing molten pool; (4) a second end of the upper welding block is pressed downwards, the strip-shaped brazing molten pool is pushed to be spread on a welding surface between the upper welding block and the lower welding block, and the upper welding block completely fits the lower welding block; and (5) solder is solidified to form a welding connector. According to the extrusion forming laser welding brazing method, the laser beams are utilized to melt solder to form the strip-shaped brazing molten pool, the liquid solder is pushed to be spread on a to-be-welded surface through extrusion, bubbles in the molten pool are released, the metallurgy reaction of a welding brazing connector is sufficient, the technological quality of the welding brazing connector is good, and the mechanical property is high.

Owner:苏州奥钦商贸有限公司

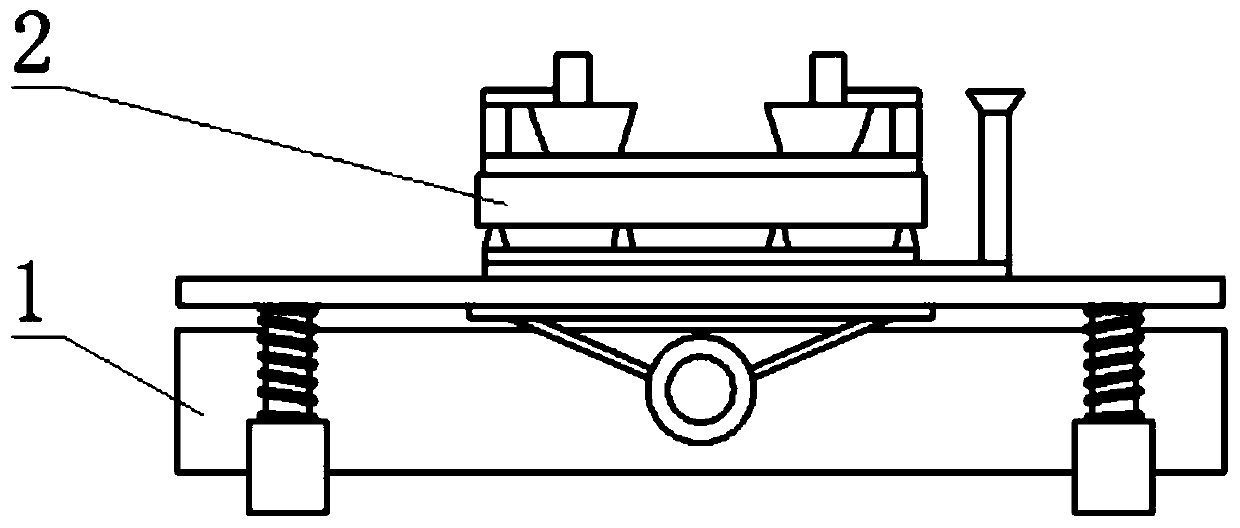

Gravity pouring investment casting method

InactiveCN110449551AImprove mechanical propertiesImprove molding qualityFoundry mouldsFoundry coresInvestment castingHigh frequency vibration

The invention provides a gravity pouring investment casting method. The gravity pouring investment casting method comprises the steps of acquiring a vibration table, preparing a corresponding mold shell according to the shape of a casting to be manufactured, and placing the mold shell on the vibration table; then preparing a corresponding metal raw material according to the material of the castingto be manufactured, smelting the metal raw material to prepare metal liquid, and starting the vibration table to enable the mold shell to vibrate along with the high-frequency vibration table; and meanwhile, pouring the metal liquid into the mold shell through an investment casting process, and obtaining the casting after the metal liquid is condensed. According to the technical scheme, the moldshell vibrates along with the vibration table, so that the metal liquid poured in the mold shell vibrates along with the vibration table as well, the growth direction of crystal grains in the metal liquid is interrupted, and the crystal grains in the metal liquid are refined; the dissolved gas in the metal liquid can escape, and the defect that pinholes or gas holes are generated on the surface ofa casting after the metal liquid is condensed is avoided; and the molding quality of the finished product casting and the mechanical properties of the casting are improved.

Owner:GUIZHOU ANJI AVIATION PRECISION CASTING

Bismuth-free stainless steel flux cored wire gas shielded welding technology for connecting pipes

ActiveCN103273175AWeld firmlyEliminates the effects of welding stabilityArc welding apparatusButt weldingEngineering

The invention discloses a bismuth-free stainless steel flux cored wire gas shielded welding technology for connecting pipes. According to the technology, a welding manipulator is transformed, a connecting plate provided with a T-shaped groove is fixed at one end of a cross beam of the welding manipulator, a transition frame provided with a slide rail is clamped through the T-shaped groove, a mechanical arm swing mechanism is installed on the slide rail, a cross arm beam is mounted at the bottom of the mechanical arm swing mechanism, an extension arm is fixed at the bottom of the cross arm beam, the bottom of the extension arm is connected with a fastener, a welding torch locking block is installed on the fastener, and a welding torch is placed in the welding torch locking block. By means of the welding device, parameters such as welding currents, voltages, welding wire extension and weld bead lifting capacity are matched, the bismuth-free stainless steel flux cored wire gas shielded welding technology capable of performing stable welding is developed and applicable to circumferential bismuth-free stainless steel flux cored wire gas shielded build up welding and butt welding of regular connecting pipes, the welding process is stable, formed welding seams are attractive in appearance, and the productivity is improved by 6-7 times than that of A-GTAW.

Owner:HARBIN ELECTRIC CORP QINHUANGDAO HEAVY EQUIP

Sodium silicate curing agent and fused zirconia-corundum brick sand mold material prepared from same

InactiveCN112338133AImprove qualityReduce surface tensionFoundry mouldsFoundry coresBrickPhosphoric acid

The invention discloses a sodium silicate curing agent and a fused zirconia-corundum brick sand mold material prepared from the same. The curing agent comprises silicon phosphate and aluminum dihydrogen phosphate powder in a mass ratio of 6-8 to 2-4. According to the sodium silicate curing agent and the fused zirconia-corundum brick sand mold material prepared from the same, the silicon phosphateand the aluminum dihydrogen phosphate are mixed and roasted according to a certain proportion, so that the performance of the curing agent achieves a synergistic effect, the curing time of the sand mold bonding material sodium silicate is finished within required time, a sand mold is good in water resistance, high in strength and good in final collapsibility, can overcome the air hole defect, thewater wave defect and the color defect of the brick surface of a blank brick, and meanwhile, the used materials are environment-friendly pollution-free materials, so that the problem of a severe working environment with pungent smell is solved, experiments prove that the sodium silicate curing agent prepared by the invention can shorten the initial setting time of the sand mold to 20 minutes, thestripping time is 30 minutes, the strength of the sand mold can reach 1.3 Mpa, raw materials are cheap, the cost is low, the manufacturing process is simple, and good social and economic benefits areachieved.

Owner:郑州远东耐火材料有限公司

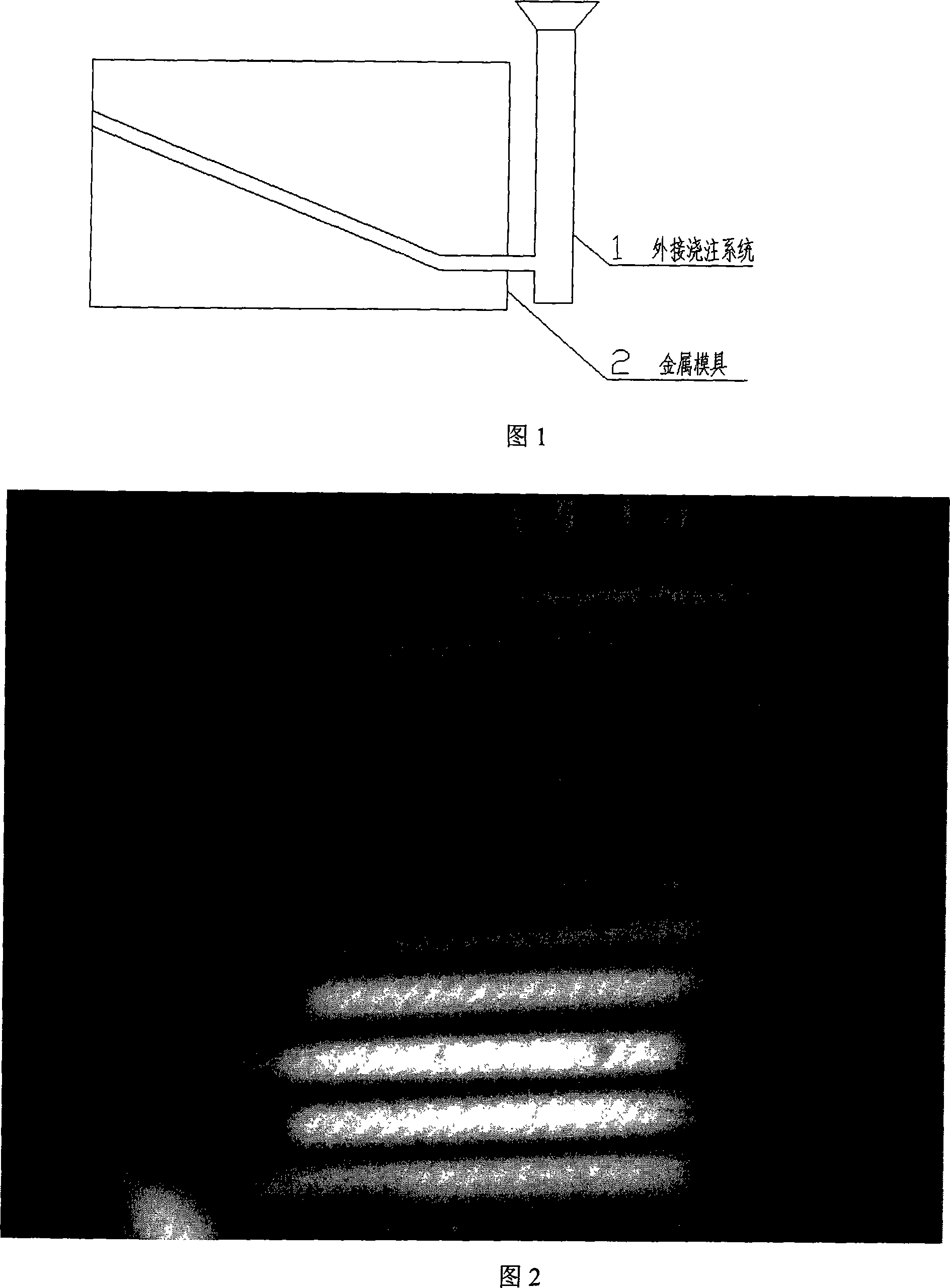

Voluminous defect free non-crystal alloy antigravity casting method and special purpose die

InactiveCN101121198AAvoid gas streaksImprove mechanical propertiesMolten metal conveying equipmentsProduct gasVolumetric Mass Density

The present invention relates to a large flawless amorphous alloy antigravity casting method and a special mold. The master alloy is heated until the temperature is higher than that with which the alloy melts and infused into a special mold used for fast cooling; the alloy flows from the bottom of the mold in the antigravity direction to fill the casting mold; the casting mold is a bottom pour and open one and the included angle between the central line of the casting mold and the vertical direction is greater than 0 and smaller than or equal to 90 degrees; the casting mold upper end is equipped with an air outlet groove which is communicated with the outside. With the present invention, the alloy flowing direction is the same as that of the air exhaust which is beneficial to producing large flawless plate or bar made of amorphous, nanocrystal and the compound materials or casts of complicated structure. The inside and surface of the produced sample do not have the flaw of air hole which increases the alloy density and surface finish.

Owner:BEIHANG UNIV

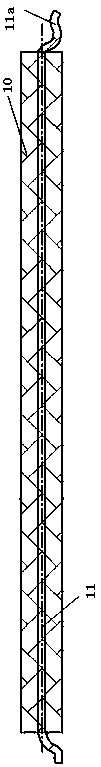

Forming method of exhaust hole of long and thin sand core of casting

PendingCN108326241APromote combustionEasy to igniteFoundry mouldsFoundry coresMolten metalSheet structure

The invention provides a forming method of an exhaust hole of a long and thin sand core of a casting, and belongs to the casting field. When the to-be-manufactured sand core is of a long and thin or sheet structure, a gunpowder wire is laid in the sand core, and the end of the gunpowder wire extends out of the sand core; after the sand core is manufactured, the sand core is coated with alcohol-based paint; and after the paint is air-dried, the end, stretching out of the sand core, of the gunpowder wire is ignited, so that the whole gunpowder wire arranged in the sand core is burnt, and an exhaust hole used for casting is formed in the sand core. Through the method that the hole structure used for exhausting is formed in the sand core by igniting the gunpowder wire, cast molten metal can beplaced in air, the sand core of the long and thin or sheet structure is not prone to being damaged, air in the sand core can be exhausted, and the problem of formation of air holes is solved.

Owner:河南旭锐合金新材料制造有限公司

V-method casting system for solving pore problem by using overflow riser

PendingCN112475230AAvoid it happening againGuaranteed retentionFoundry mouldsFoundry coresThin membraneEngineering

The invention discloses a V-method casting system for solving a pore problem by using an overflow riser. The V-method casting system comprises a pouring system and the overflow riser, the pouring system comprises at least two ingates, the overflow riser is arranged at the intersection of front-edge molten steel at the far end of a casting mold and is used for collecting the front-edge molten steelmixed with inclusions and gas, clean molten steel is kept in a casting body, and pore defects are avoided. Through directional design of a molten steel flow field in the V-method casting and pouringprocess, the overflow riser is arranged at the intersection of the front-edge molten steel at the far end of the casting mold, the front-edge molten steel mixed with inclusions and gas can be collected, the condition that clean molten steel is kept in the casting body is ensured, and the pore defects are avoided; and the condition that the front-edge molten steel mixed with the inclusions and gasthat are generated by the mold, a core, coating and a thin film in the pouring process can be collected in the overflow riser is ensured, and the condition that the molten steel is hermetically kept in a casting to generate pores is avoided. Pore defects of the V-method casting are greatly reduced, the product percent of pass is increased, the production efficiency is improved, and the practical value is high.

Owner:HUBEI SANJIANG SPACE WANSHAN SPECIAL VEHICLE

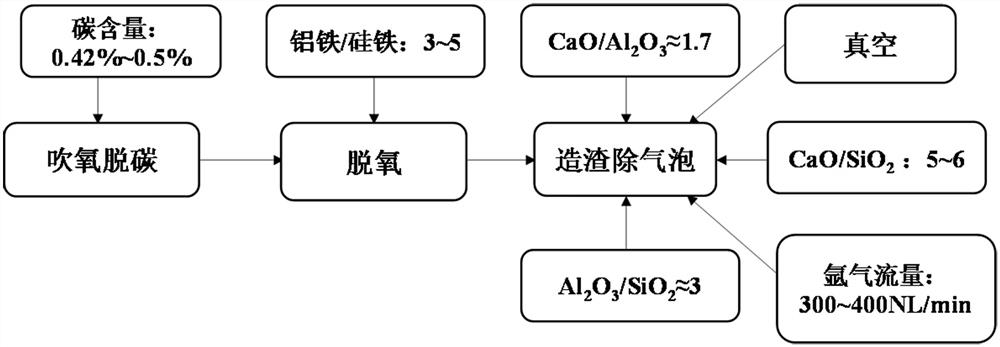

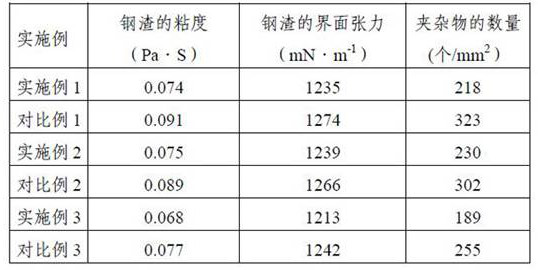

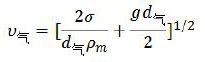

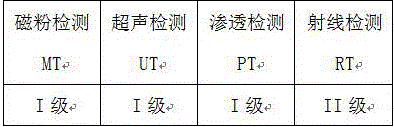

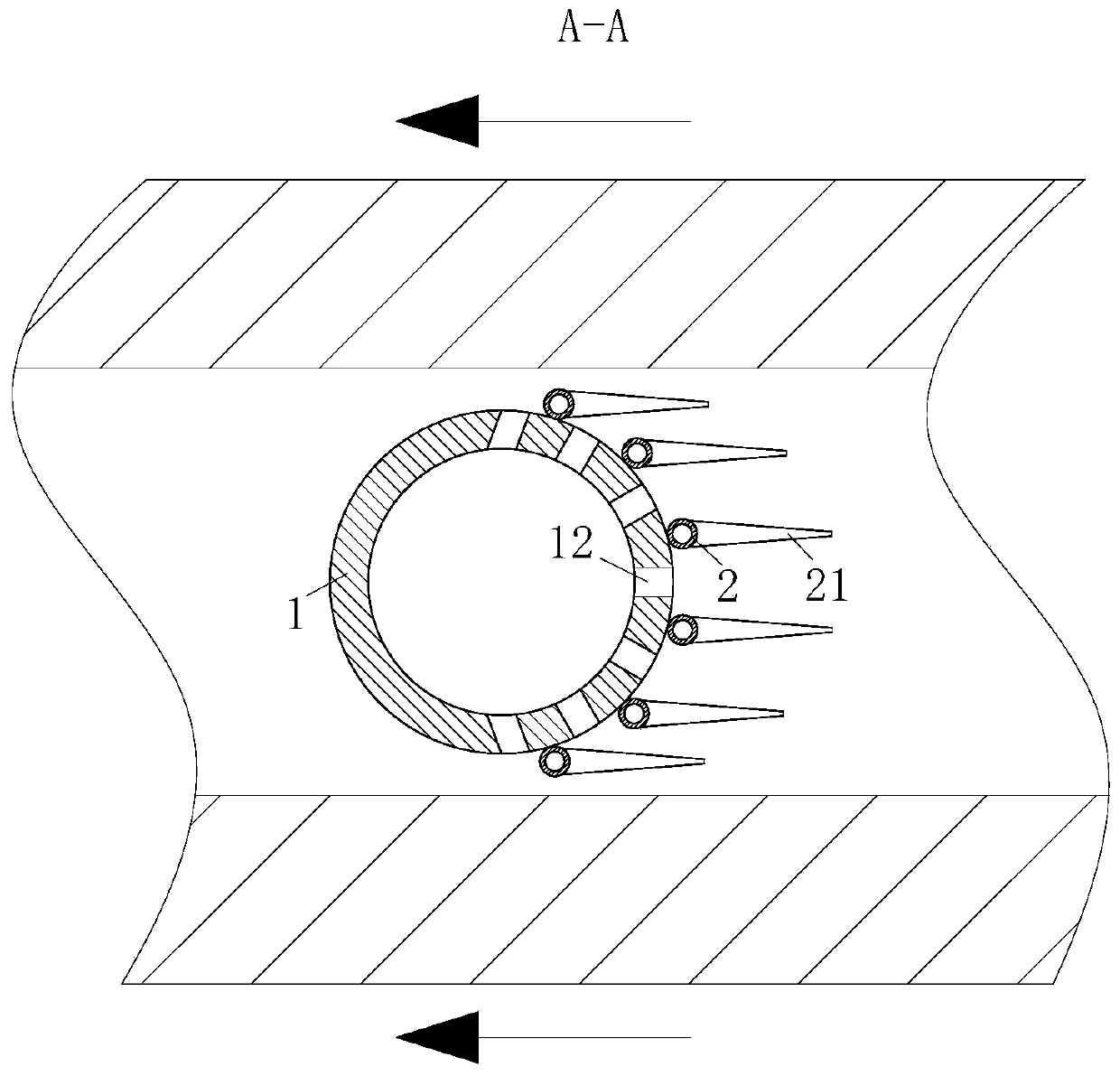

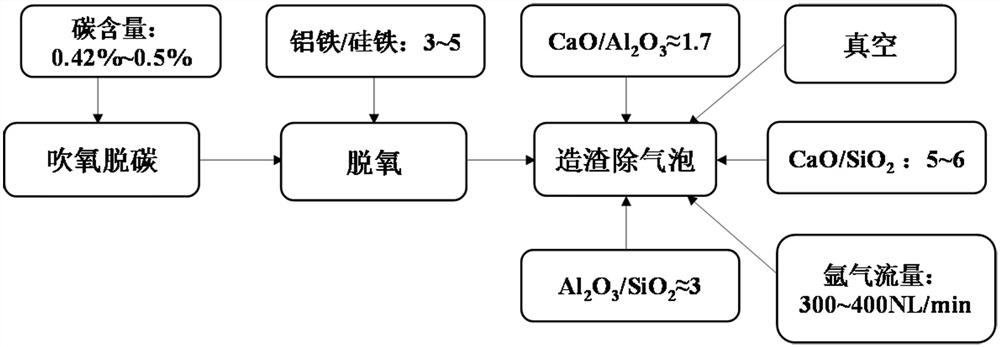

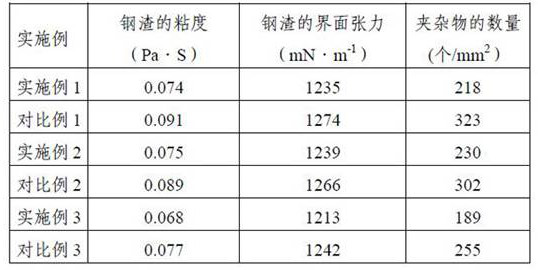

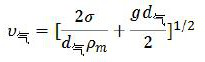

Method for removing bubbles in No.45 steel

ActiveCN112094981AChange passabilityLow viscosityManufacturing convertersProcess efficiency improvementChemical compositionSlag

The invention relates to a method for removing bubbles in No.45 steel. The method comprises: an oxygen blowing process; a deoxidation process; and a slagging and bubble removing process. Slagging andbubble removal are that a slagging agent is added into a ladle furnace to form steel slag. The steel slag comprises the chemical components of 45-55% of CaO, 26-32% of Al2O3, 0-6% of MgO, 9-12% of SiO2, 3-5% of CaF2, and the balance of impurities, wherein CaO / Al2O3 is 1.68-1.79, Al2O3 / SiO2 is 2.8-3.3, and the alkalinity (CaO / SiO2) is 5-6. In the ladle furnace, argon is blown from the bottom, a vacuum condition is created above the steel slag, and the bubbles in the No.45 steel are removed. According to the method, the interfacial tension and viscosity of the steel slag are reduced, the passingefficiency of the bubbles and inclusions is improved, the removal effect of the inclusions is enhanced, and the quality level of steel products is improved.

Owner:UNIV OF SCI & TECH BEIJING

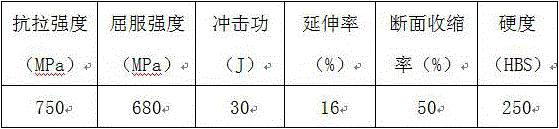

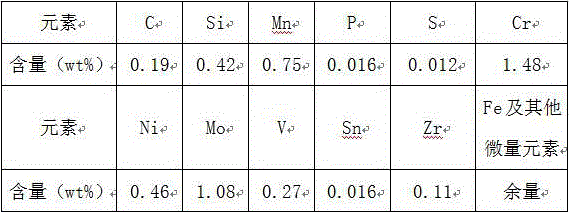

Cast steel part for nuclear power unit and production technology thereof

The invention discloses a zero-defect high-quality cast steel part for nuclear power. The cast steel part is characterized in that the cast steel part is chemically composed of, by weight, 0.18% to 0.20% of C, less than or equal to 0.60% of Si, 0.60% to 0.80% of Mn, less than or equal to 0.02% of P, less than or equal to 0.015% of S, 1.35% to 1.50% of Cr, less than or equal to 0.50% of Ni, 0.90% to 1.10% of Mo, 0.20% to 0.30% of V, less than or equal to 0.025% of Sn, 0.08% to 0.12% of Zr, the balance Fe and unavoidable trace impurities. The invention further discloses a technology used for producing the cast steel part, and according to the technology, the cast steel part has no defects, is high in quality, and is good in abrasion resistance and corrosion resistance, and high in toughness when in the high-temperature environment, and therefore, the cast steel part is suitable for a nuclear power unit.

Owner:SANMING CITY YIJUN MACHINERY FOUNDRY

The production process of the casting of the pressure plate of the car clutch

Production optimization process of car clutch pressure plate castings on vertical molding production line, the steps include sand mixing, molding, furnace charge smelting, tapping inoculation treatment, pouring, cooling, unpacking, and casting cleaning; among the molding processes, two and two More than two casting blanks are arranged horizontally and symmetrically. The pouring molten iron enters the sprue through the sprue cup and the upper runner. The sprue passes through the middle of the casting cavity and then enters the lower runner, and then passes symmetrically into the cavity. The tensile strength of the single-cast test bar of the pressure plate casting produced by the present invention is ≥250MPa, the tensile strength of the casting body is ≥200MPa, and the hardness of the casting body is 170-241HBS; the metallographic structure of the product is mainly A-type graphite, and the graphite length is 4 ~Grade 6, the matrix structure is more than 95% of fine pearlite and a small amount of ferrite; there are no casting defects in all parts of the casting, which fully meets the technical requirements of the clutch pressure plate casting of the car.

Owner:上海华新合金有限公司

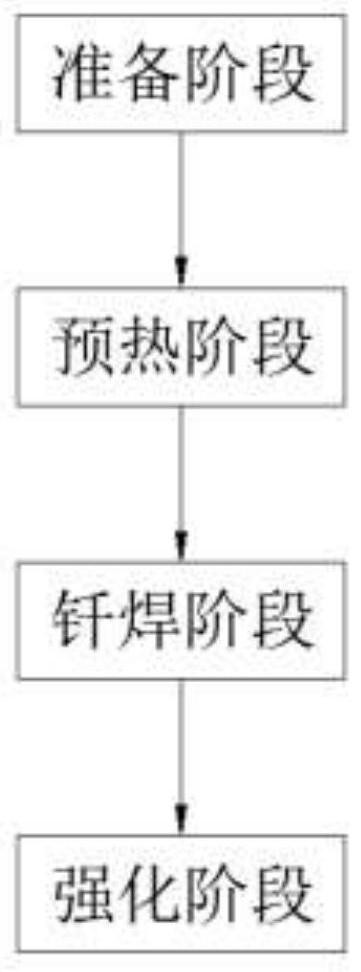

Butt-joint brazing method for Kovar alloy and copper

ActiveCN113351952AImprove welding qualityPlay a protective effectIncreasing energy efficiencyHigh frequency current welding apparatusButt jointHeater Rod

The invention provides a butt-joint brazing method for a Kovar alloy and copper. The butt-joint brazing method for the Kovar alloy and the copper comprises the following steps: after a workpiece A made of the Kovar alloy and a workpiece B made of the copper are in butt joint, placing a proper amount of brazing filler metal and brazing flux at the joint, and then placing a heating rod of high-frequency induction heating equipment around the periphery of the joint; heating the brazing filler metal and the brazing flux to a preheating temperature and keeping for a proper time; heating to a melting temperature to melt the brazing filler metal, the brazing flux and part of materials of the workpiece to form a welding seam; and naturally standing the welding seam for a proper time, heating the welding seam to a melting temperature, keeping the melting temperature for a proper time, and naturally cooling the welding seam to normal temperature. By the adoption of the technical scheme provided by the invention, the heating rod is arranged to be in the closed annular shape, the periphery of the joint of the workpieces is evenly heated, the step-by-step working procedures of preheating, heating and then strengthening are adopted in the welding process, and the brazing filler metal and the workpiece material are evenly fused so as to penetrate into the workpiece material through the capillary effect, so that the welding seam strength and the welding quality are improved.

Owner:GUIZHOU LIYANG INT MFG

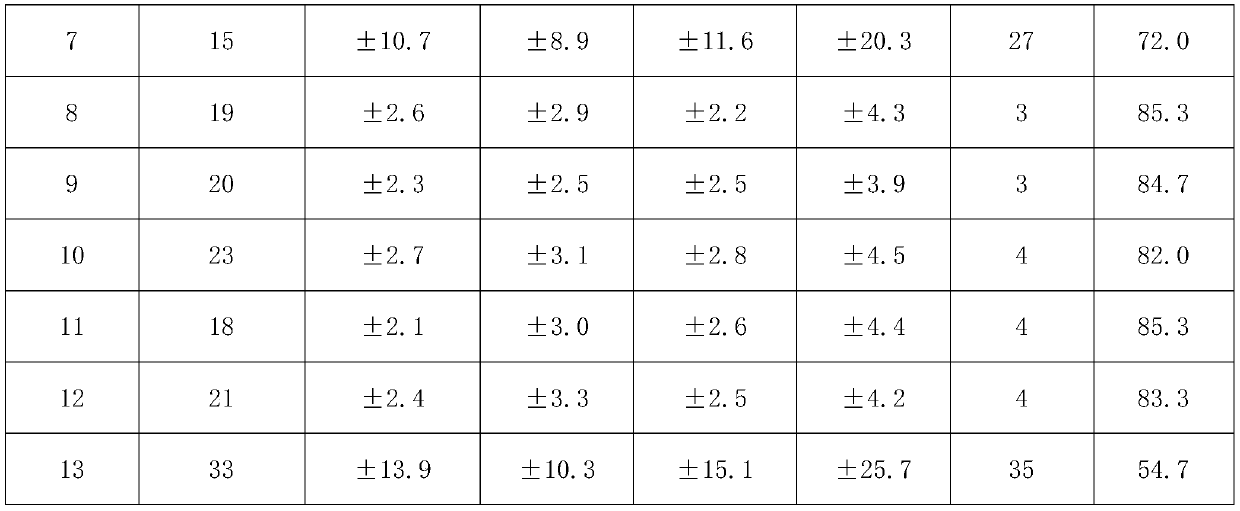

V-process casting process for producing engineering mechanical counterweight block

ActiveCN110625063AImprove wear resistanceImprove adhesionFoundry mouldsFoundry coresPolystyreneEngineering production

The invention provides a V-process casting process for producing an engineering mechanical counterweight block, and particularly relates to the technical field of counterweight block casting. The V-process casting process for producing the engineering mechanical counterweight block simplifies a thin film covering method in the process, polystyrene, calcium fluoride, calcined gypsum powder, artemisinin wax, trehalose and zinc oxide whiskers are added to a coating, the wear resistance and adhesive force of the coating are enhanced, meanwhile, filled dry sands are pretreated, carbon aerogel, soybean protein and cyclic olefin copolymer are added, the air permeability of the dry sands is enhanced, the compactness is increased, the non-fleshiness, non-air-holes, non-sand burning and unfilled corner counterweight block with a bright and clean surface is finally obtained, the weight deviation of the counterweight block is kept within the range of + / -6 kg, the dimensional deviation is kept within + / -4 mm, and the product yield is up to 80% or above. The V-process casting process is simple to operate, controllable in parameter and easy to realize, and is suitable for large-scale production.

Owner:柳州市顺昇机械有限公司

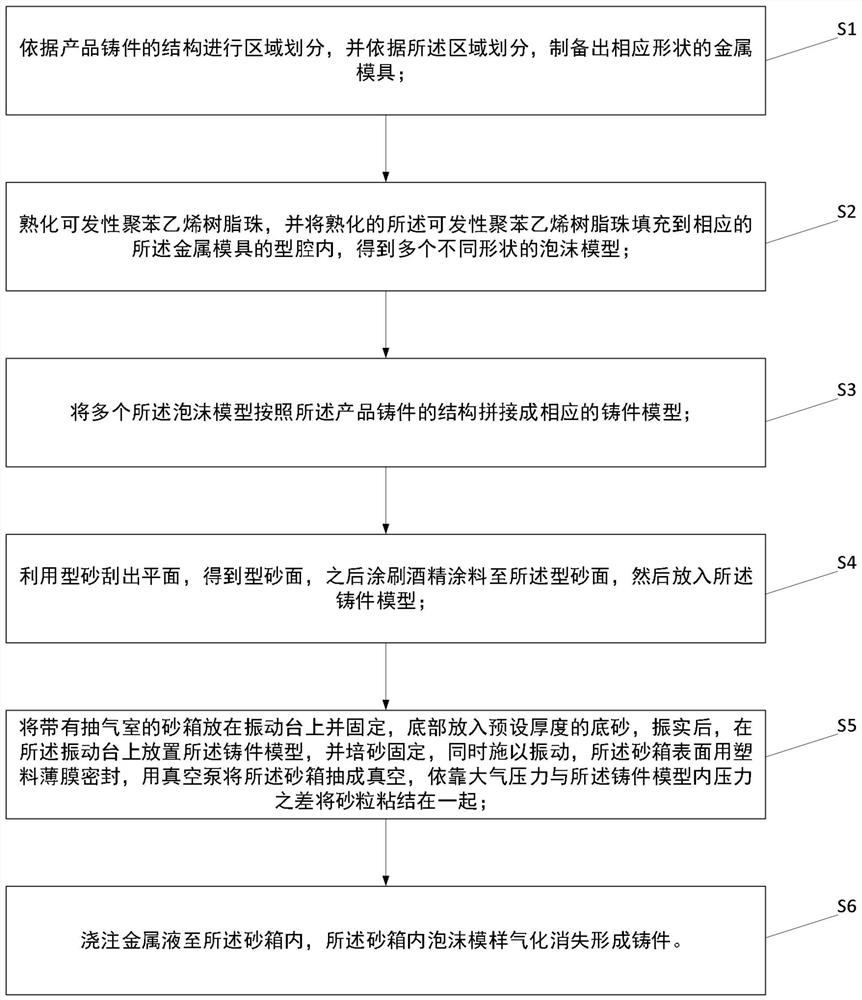

Manufacturing method for machine tool castings

The invention discloses a manufacturing method for machine tool castings. The manufacturing method comprises the following steps that region division is performed according to structures of the product castings, and metal molds in corresponding shapes are prepared according to the region division; expandable polystyrene resin beads are cured, and the cured expandable polystyrene resin beads are filled into mold cavities of the corresponding metal molds to obtain a plurality of foam models in different shapes; the multiple foam models are spliced into corresponding casting models according to the structures of the product castings; planes are scraped by using molding sand to obtain molding sand surfaces, then alcohol paint is brushed on the molding sand surfaces, and then putting into the casting models is performed; a sand box is vacuumized by using a vacuum pump, and sand grains are bonded together by virtue of the difference between the atmospheric pressure and the pressure in the casting models; and molten metal is poured until foam patterns in the sand box are gasified and disappear to form the castings. By means of the manufacturing method for the machine tool castings, the casting quality is improved, and the casting manufacturing period is shortened.

Owner:重庆江增机械有限公司

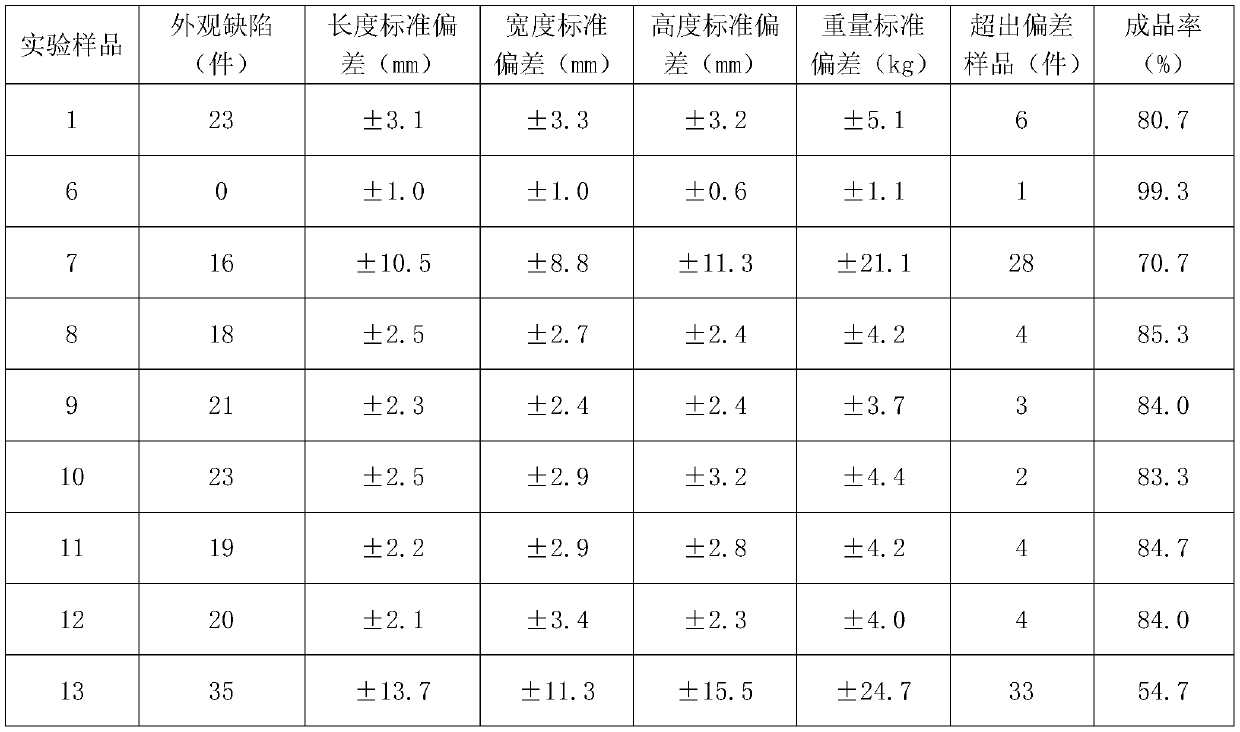

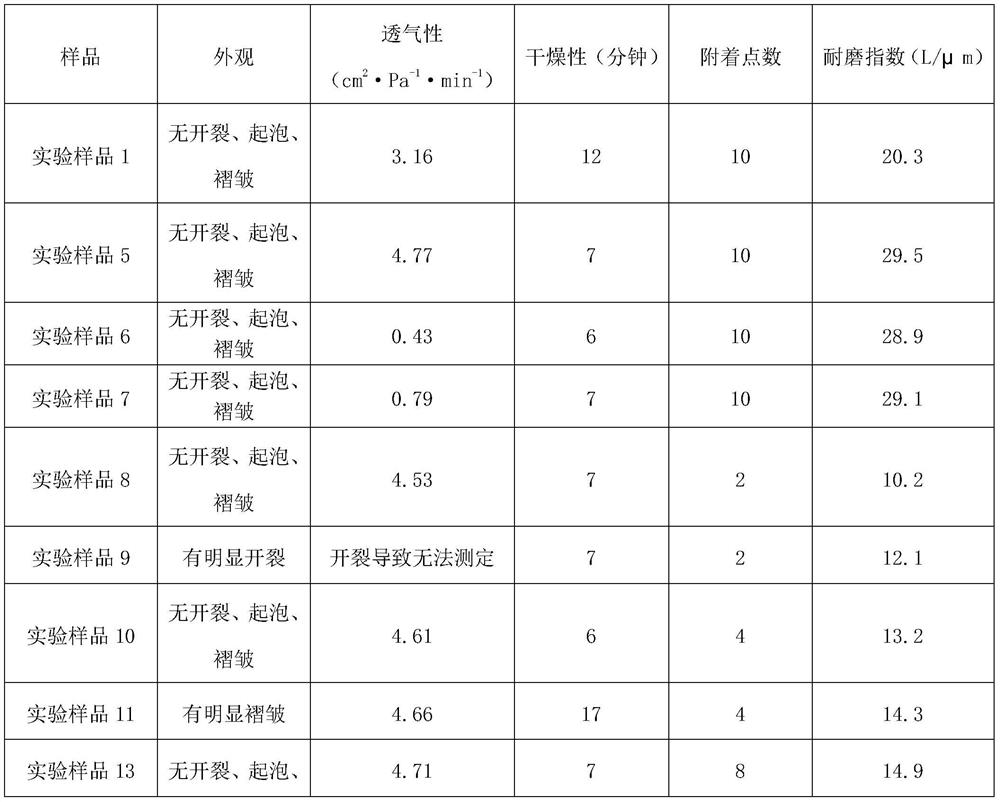

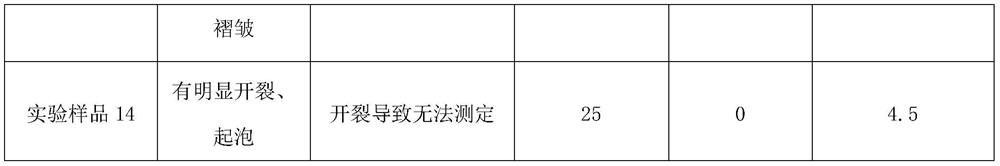

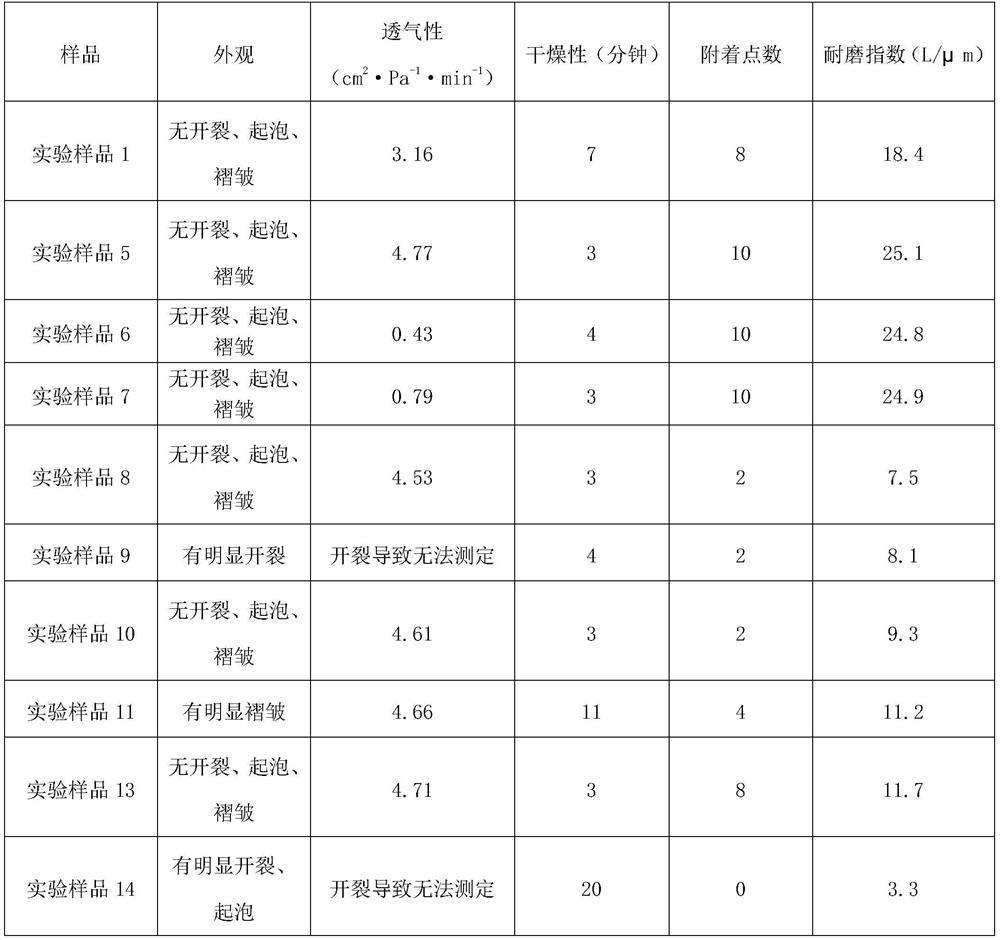

A kind of multifunctional coating for casting and preparation method thereof

ActiveCN110625061BPrevent sticky sandPrevent shrinkageFoundry mouldsFoundry coresPolystyreneLost-foam casting

The invention provides a multifunctional coating for casting and a preparation method thereof and particularly relates to the technical field of casting coatings. The method comprises the steps that firstly, a polystyrene fused solution is adopted for firing a compound, quartz sand powder and bentonite wrap the compound in batch in sequence, a wrapping compound is prepared, then powder of plasterof paris, sweet wormwood herb wax, trehalose and zinc oxide crystal whiskers are added to the wrapping compound, and the multifunctional coating for casting is prepared. The coating can be simultaneously used for two processes of lost foam casting and V-method casting, after coating is completed, cracks, bubbles and wrinkles do not exist, and the multifunctional coating for casting has the advantages of being resistant to wear, high in drying speed, adhesive force and air permeability and the like. The sand burning, shrinkage porosity and pore defects of a casting can also effectively prevented. The other aim of the invention is to provide the preparation method of the multifunctional coating for casting. The method is easy to operate, stable in process and suitable for large-scale production, and parameters can be controlled.

Owner:柳州市一乐科技有限公司

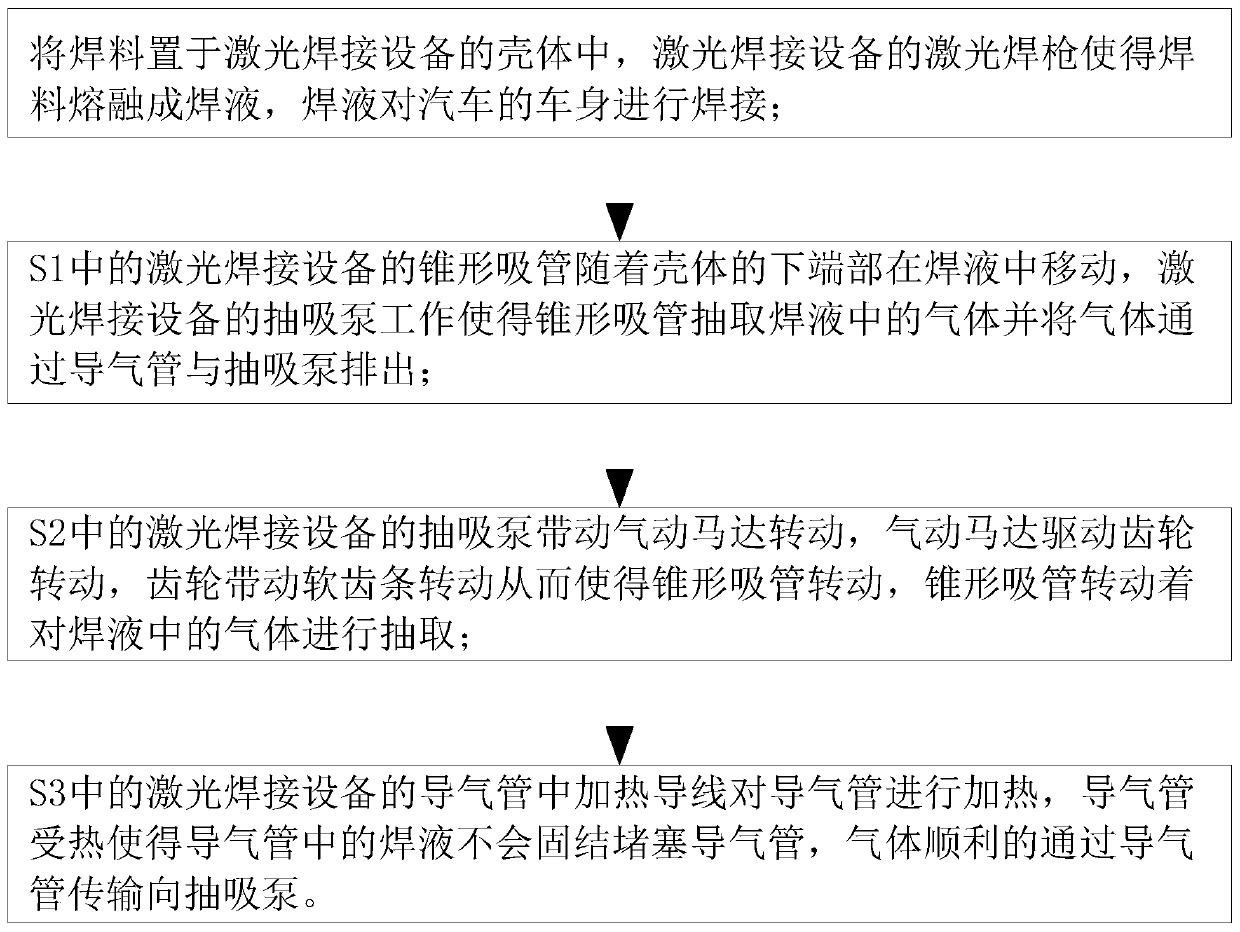

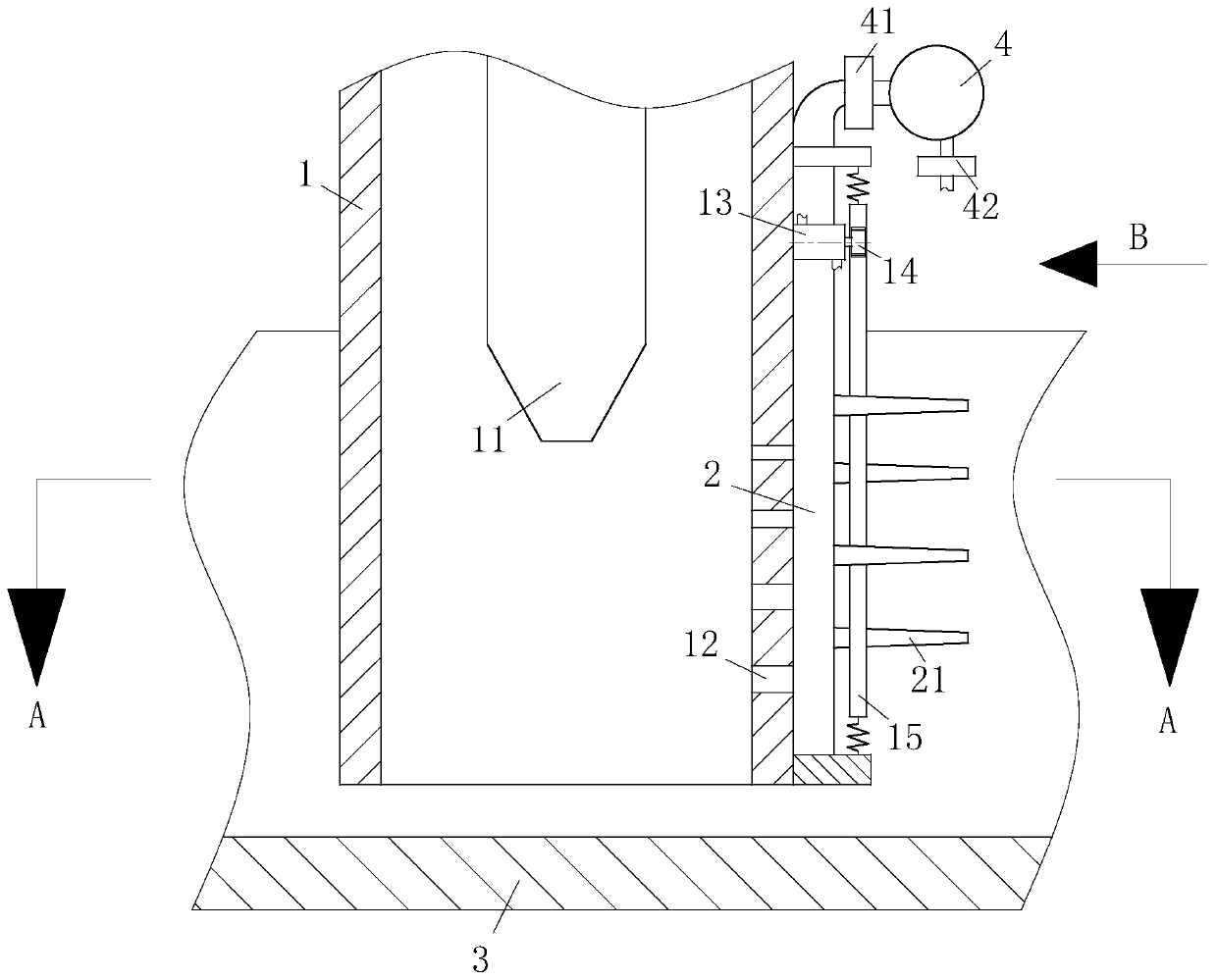

Laser welding technology of automobile body

ActiveCN109759702AQuality improvementAvoid stomatal defectsLaser beam welding apparatusEngineeringPneumatic motor

The invention belongs to the technical field of laser welding, and specifically relates to a laser welding technology of an automobile body. The technology comprises the following steps: arranging a welding flux into a housing of a laser welding device; melting the welding flux into welding liquid through a laser welding gun of the laser welding device; and welding the automobile body through thewelding liquid, wherein a tapered sucking tube of the laser welding device moves in the welding liquid together with the lower end part of the housing; a pump of the laser welding device works to drive the tapered sucking tube to pump air in the welding liquid and drain the air through an air guide pipe and the pump; the pump of the laser welding device is capable of driving a pneumatic motor to rotate, and the pneumatic motor drives a gear to rotate; the rotating gear drives a soft rack to rotate so as to drive the tapered sucking tube to rotate; and the tapered sucking pipe rotates to pump air from the welding liquid; the air guide pipe of the laser welding device is heated through heating conductors in the air guide pipe; the welding liquid in the air guide pipe cannot be solidified toblock the air guide pipe after the air guide pipe is heated, and thus air can be smoothly transferred pump through the air guide pipe.

Owner:陈光贡

A method for removing air bubbles in No. 45 steel

ActiveCN112094981BChange passabilityLow viscosityManufacturing convertersProcess efficiency improvementChemical compositionSlag

The invention relates to a method for removing air bubbles in No. 45 steel. The method comprises: an oxygen blowing process; a deoxidation process; a slagging and air bubble removal process; the slagging and air bubble removal is as follows: adding a slagging agent in a ladle furnace to form steel slag; the chemical composition of the steel slag is: CaO: 45-55%, al 2 o 3 : 26~32%, MgO: 0~6%, SiO 2 : 9~12%, CaF 2 : 3~5%, of which CaO / Al 2 o 3 1.68~1.79, Al 2 o 3 / SiO 2 2.8~3.3, alkalinity (CaO / SiO 2 ): 5~6, the balance is impurities; in the ladle furnace, argon gas is blown at the bottom to create a vacuum condition above the steel slag to remove the bubbles in the No. 45 steel. The invention reduces the interfacial tension and viscosity of steel slag, improves the passage efficiency of air bubbles and inclusions, enhances the removal effect of inclusions, and improves the quality level of steel products.

Owner:UNIV OF SCI & TECH BEIJING

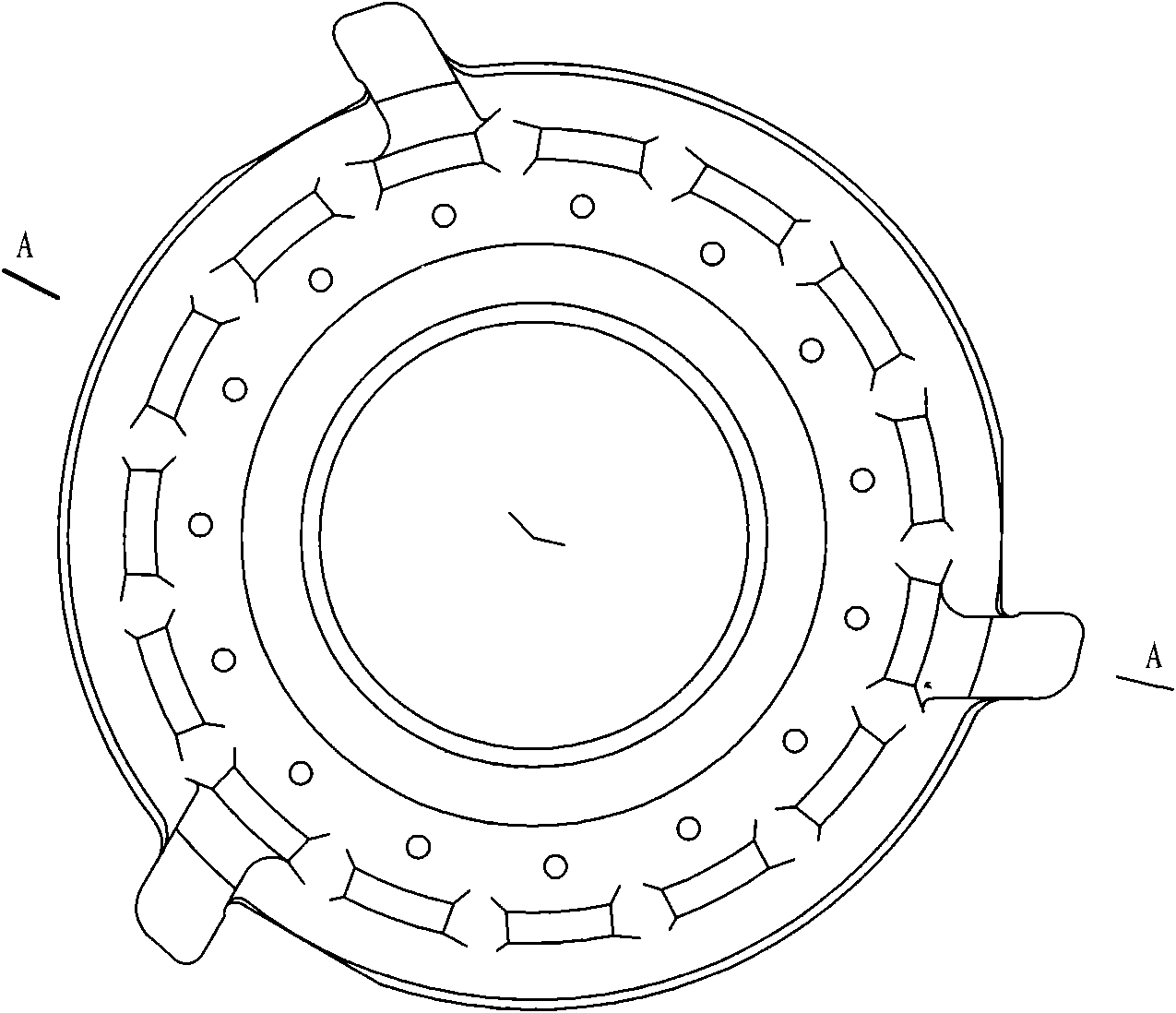

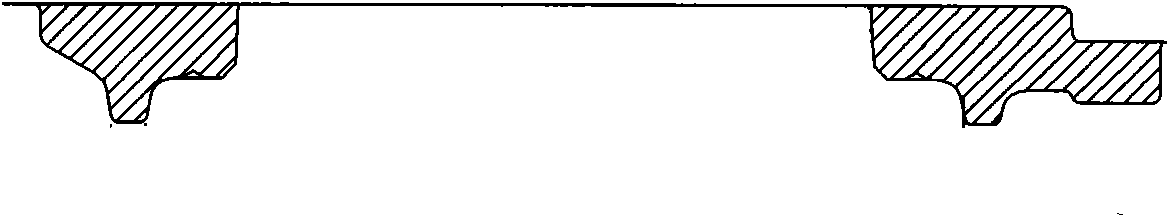

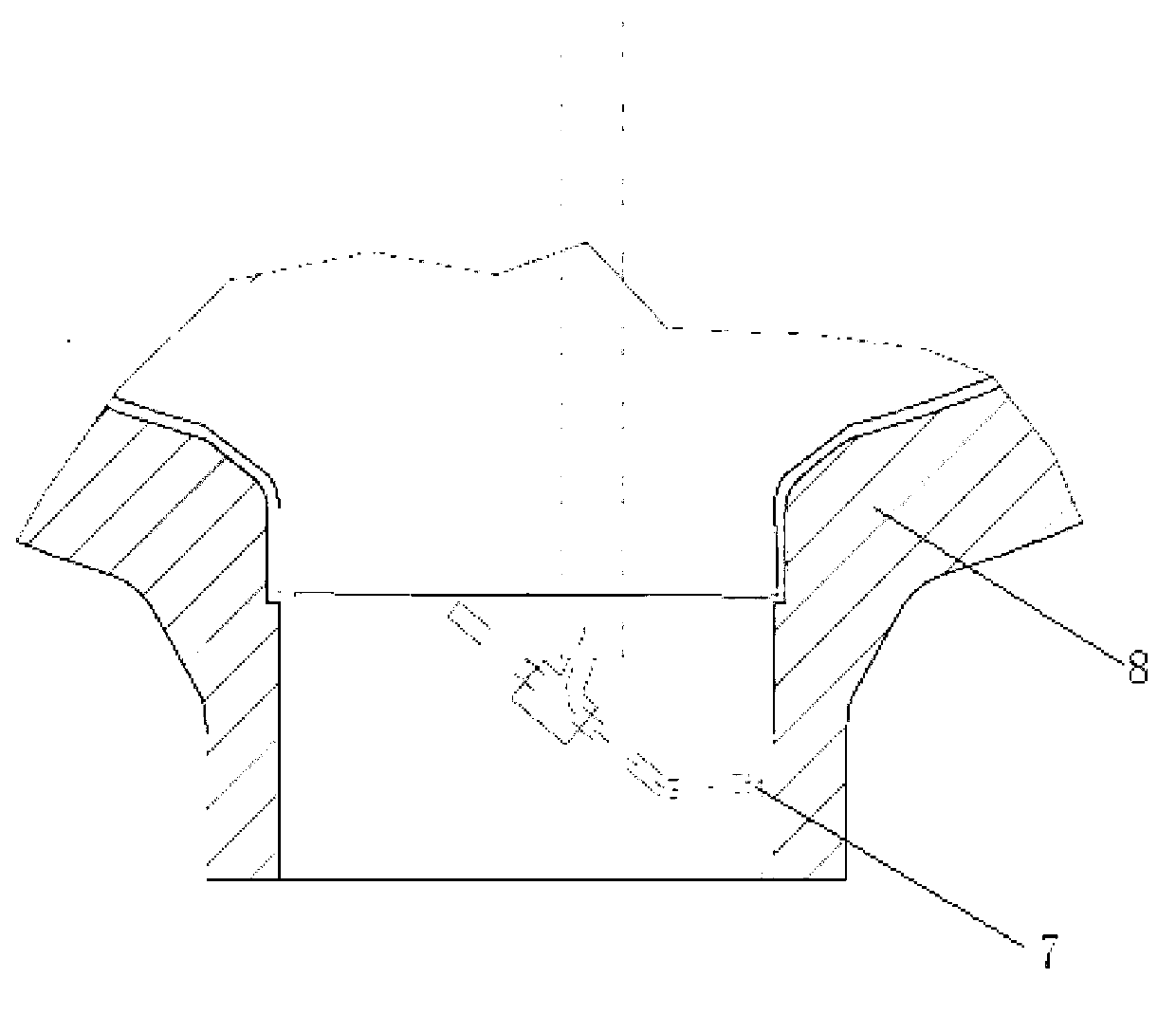

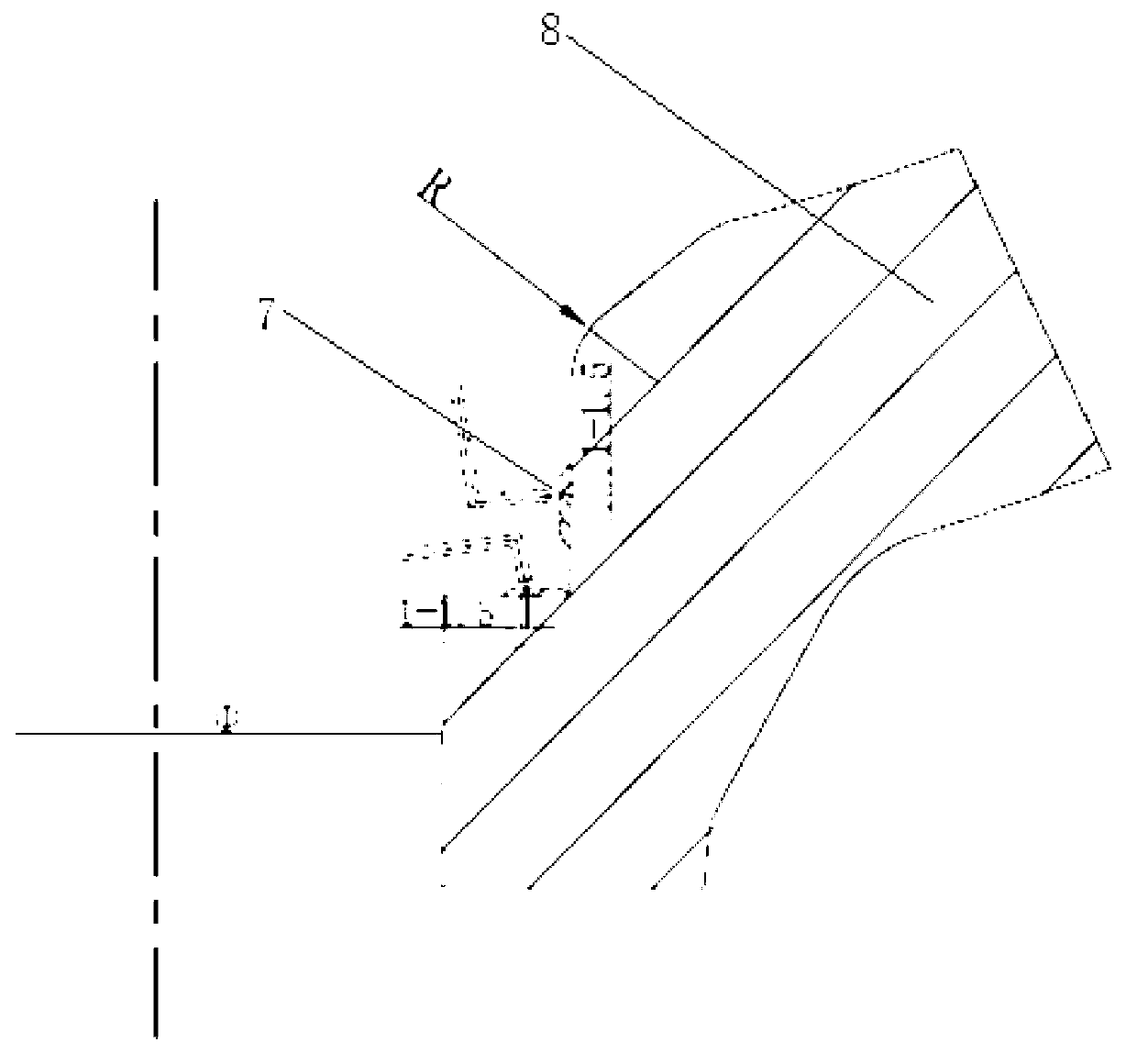

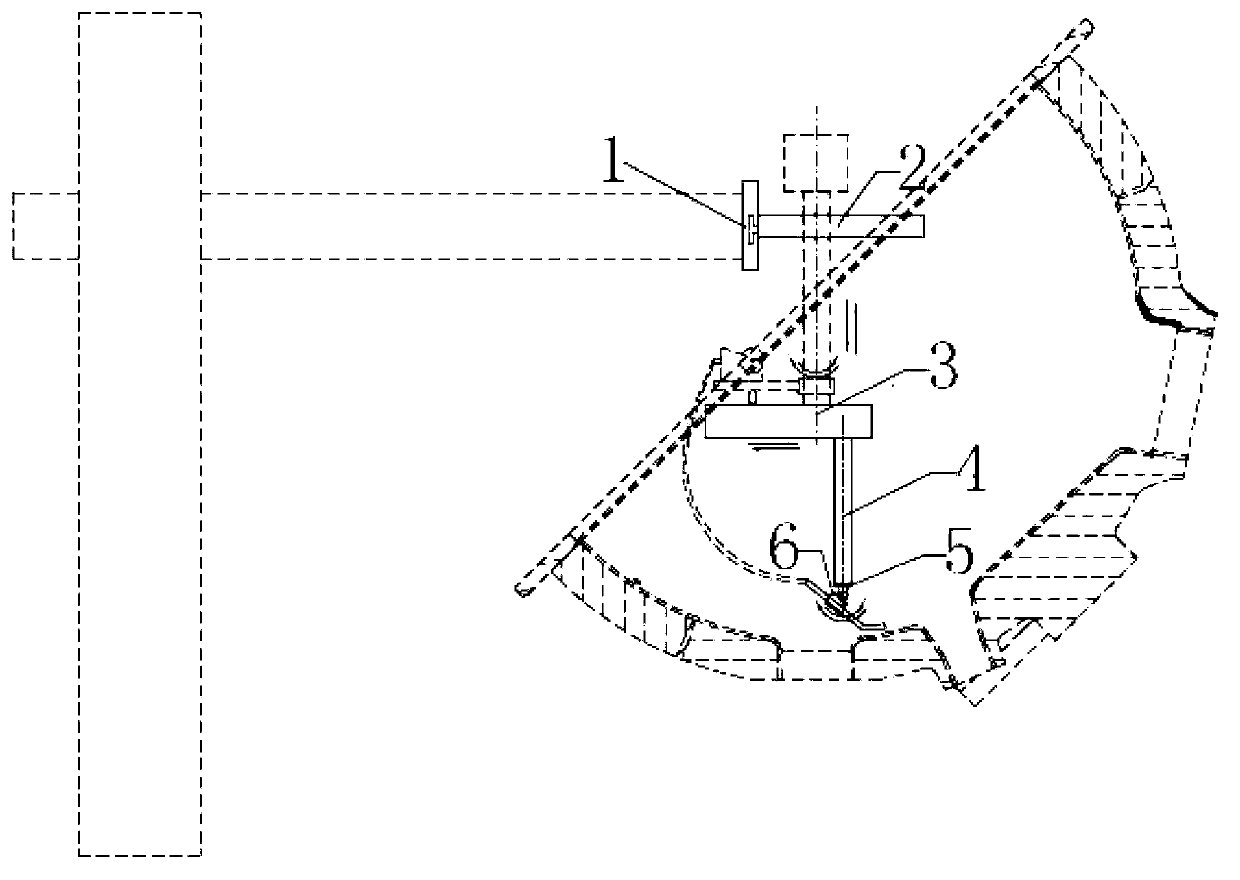

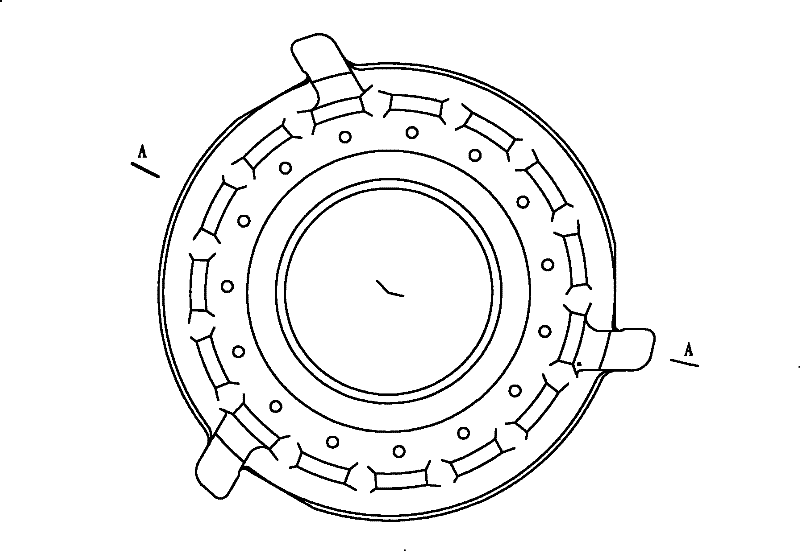

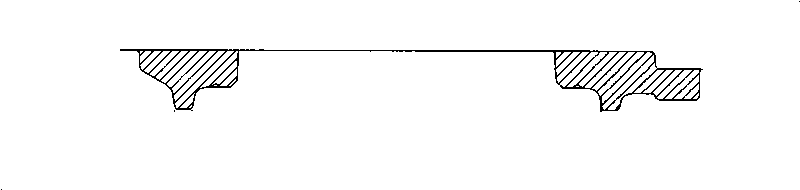

Bimetal thrust sliding bearing blank preparation method and used tooling

The invention discloses a method for preparing a blank of a bimetallic thrust sliding bearing and the tooling used. The method includes the following steps: the first step, mixing alloy materials and auxiliary materials: uniformly mixing copper alloy particles, copper gas flux, and charcoal particles; The second step is to put the mixed alloy material and auxiliary materials into the mold, and press the two clamping flange devices on the two ends of the mold respectively through the external force application device; the third step is to place the induction heating device on the outer periphery of the mold , then rotate the mold, adjust the centrifugal speed and the heating power of the induction heating device, and melt the alloy particle mixture; the fourth step, remove the induction heating device, and place the bimetallic blank prepared in the third step in a mobile cooling device, First use the lower water spray device to cool for a certain period of time, and then turn on the upper water spray device to work together to cool the bimetallic blank to room temperature. Tooling consists of moulds, clamping flange units and mobile cooling units. The invention has reasonable process and can reduce the defects of bimetallic blanks.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com