Bimetal thrust sliding bearing blank preparation method and used tooling

A sliding bearing and bimetal technology, which is applied in the field of centrifugal casting of bimetal thrust sliding bearing blanks, can solve the problems of difficult process control and difficult performance to meet requirements, etc., and achieves the effects of simple operation, long service life and easy cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

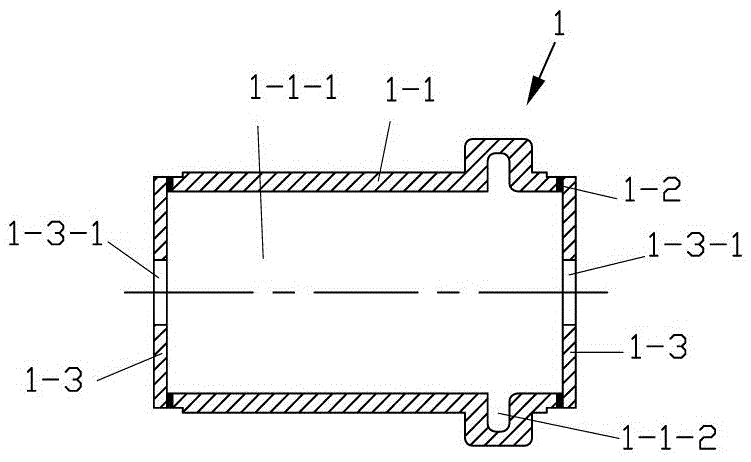

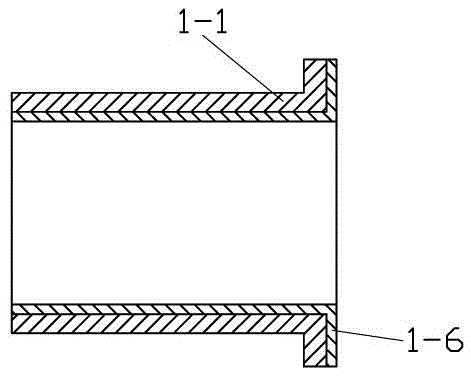

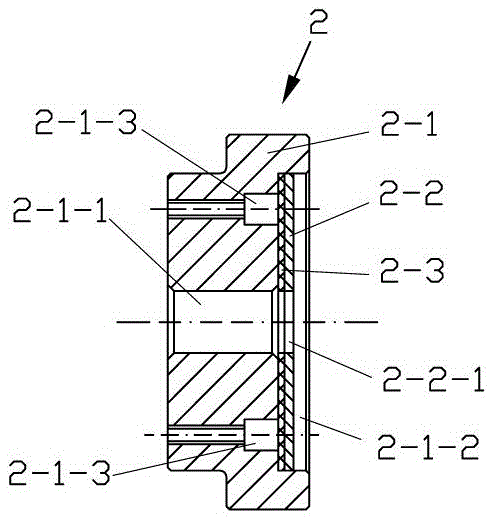

[0028] like figure 1 As shown, a bimetallic thrust sliding bearing blank preparation tooling of the present invention includes a mold 1 for bimetallic thrust sliding bearing blank preparation, a clamping flange device 2 and a mobile cooling device 3, the bimetallic thrust sliding bearing blank preparation The mold 1 for the preparation of the thrust sliding bearing blank includes a steel billet 1-1 and a first asbestos board 1-3, the steel billet 1-1 has an inner hole 1-1-1 and an annular groove 1-1-2, and the annular groove The groove 1-1-2 is arranged on the hole wall of the inner hole 1-1-1, the inner hole 1-1-1 communicates with the annular groove 1-1-2, and both ends of the steel billet 1-1 are passed through high temperature resistant The adhesive 1-2 is adhered with a corresponding first asbestos board 1-3, the first asbestos board 1-3 has a central hole 1-3-1, and the central hole 1-3 of the first asbestos board 1-3 3-1 communicates with the inner hole 1-1-1 of the bi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com