Butt-joint brazing method for Kovar alloy and copper

A brazing method and alloy technology are applied in the field of butt brazing of valve alloys and copper, which can solve the problems of poor fluidity of brazing filler metals, affecting the strength of welds, and scrapping parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

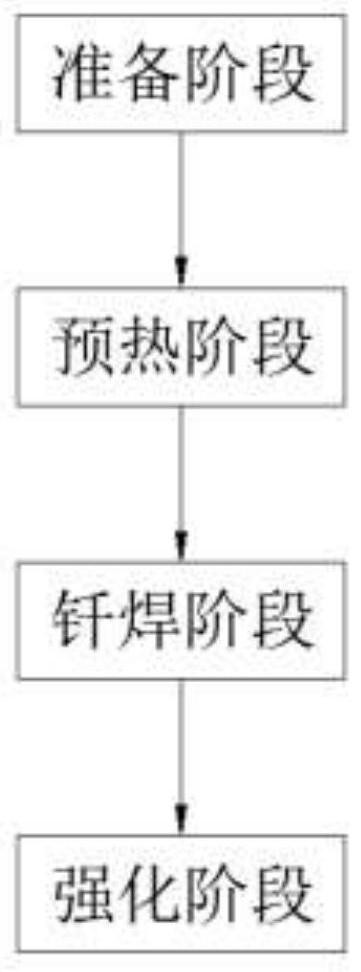

[0024] Such as figure 1 As shown, the present invention provides a kind of butt brazing method of valveable alloy and copper, comprising the following steps:

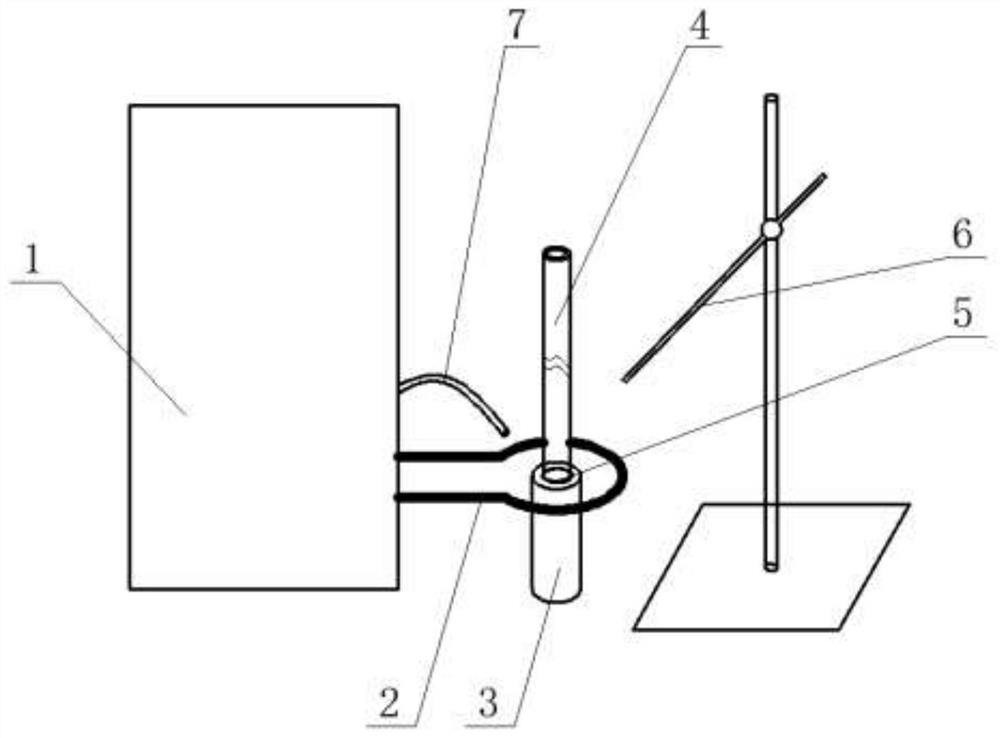

[0025] Step 1; preparation stage: provide high-frequency induction heating equipment 1, high-frequency induction heating equipment 1 includes a heating rod 2, the heating rod 2 is a closed ring structure, and the workpiece A3 made of valveable alloy and the workpiece made of copper are first After B4 is docked, place an appropriate amount of solder at the joint between workpiece A3 and workpiece B4, and then apply an appropriate amount of flux at the joint between workpiece A3 and workpiece B4, and then place the heating rod 2 around the joint between workpiece A3 and workpiece B4. Four weeks; in step 1, the workpiece A3 and the workpiece B4 are butted together through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com