Laser welding technology of automobile body

A laser welding and automobile body technology, applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve problems affecting the strength of automobile body weld seams, welding pore defects, and affecting welding quality, so as to improve welding quality, Pore defect prevention and quality improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

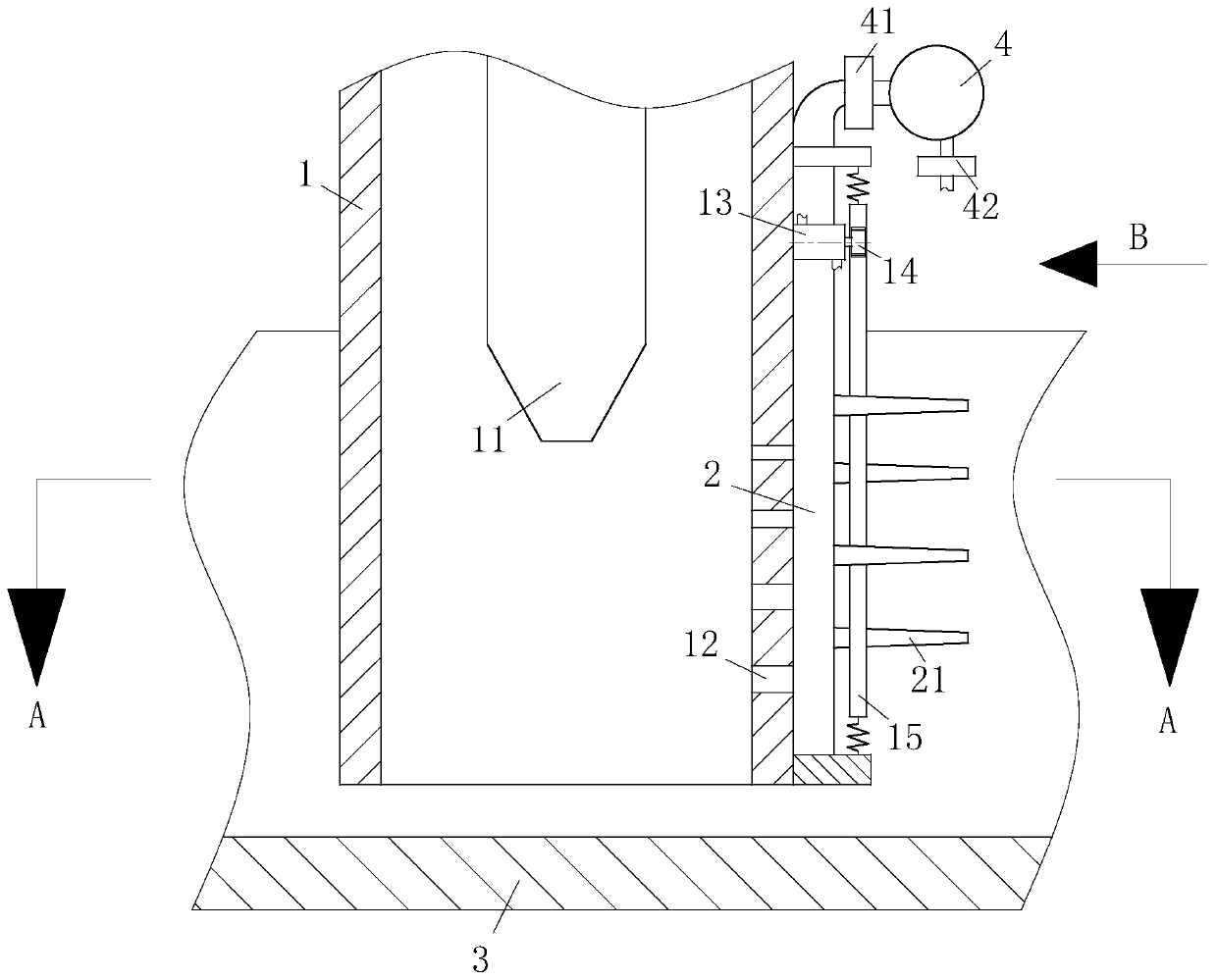

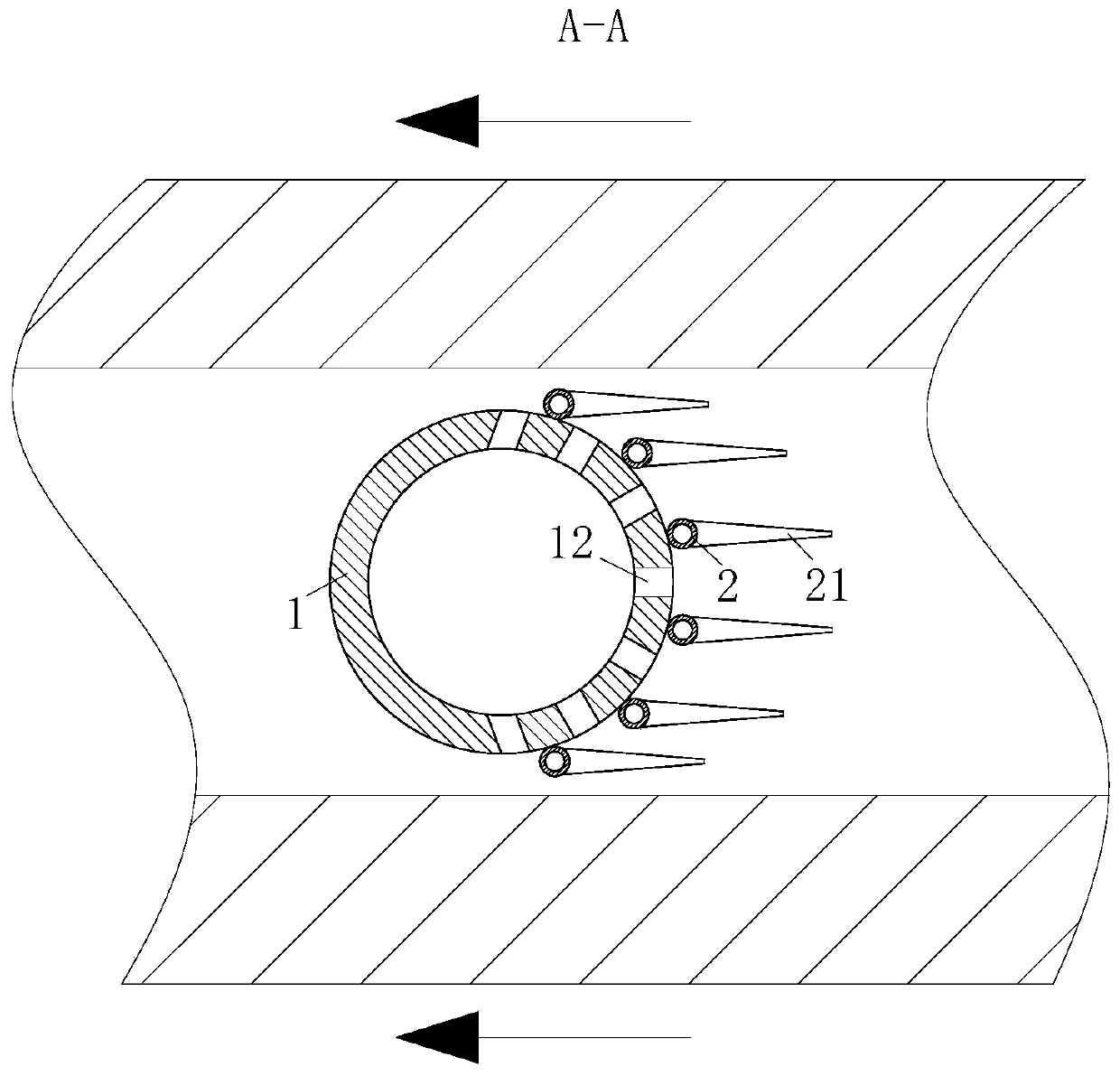

[0028] Such as Figure 1 to Figure 7Shown, the laser welding process of a kind of automobile body of the present invention, this process comprises the steps:

[0029] S1: Put the solder in the shell of the laser welding equipment, the laser torch of the laser welding equipment melts the solder into a welding fluid, and the welding fluid welds the car body;

[0030] S2: The conical suction pipe of the laser welding equipment in S1 moves in the welding liquid with the lower end of the shell, and the suction pump of the laser welding equipment works so that the conical suction pipe sucks the gas in the welding liquid and passes the gas through the gas guide tube and the suction pipe. The suction pump discharges; the gas in the welding liquid is suck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com