Investment casting process for thin-wall annular casing casting

An investment casting and annular technology, applied in manufacturing tools, casting molding equipment, casting molds, etc., can solve problems that affect the performance of castings, affect the quality of castings, and affect the dimensional accuracy of castings. The effect of casting quality and dimensional accuracy assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

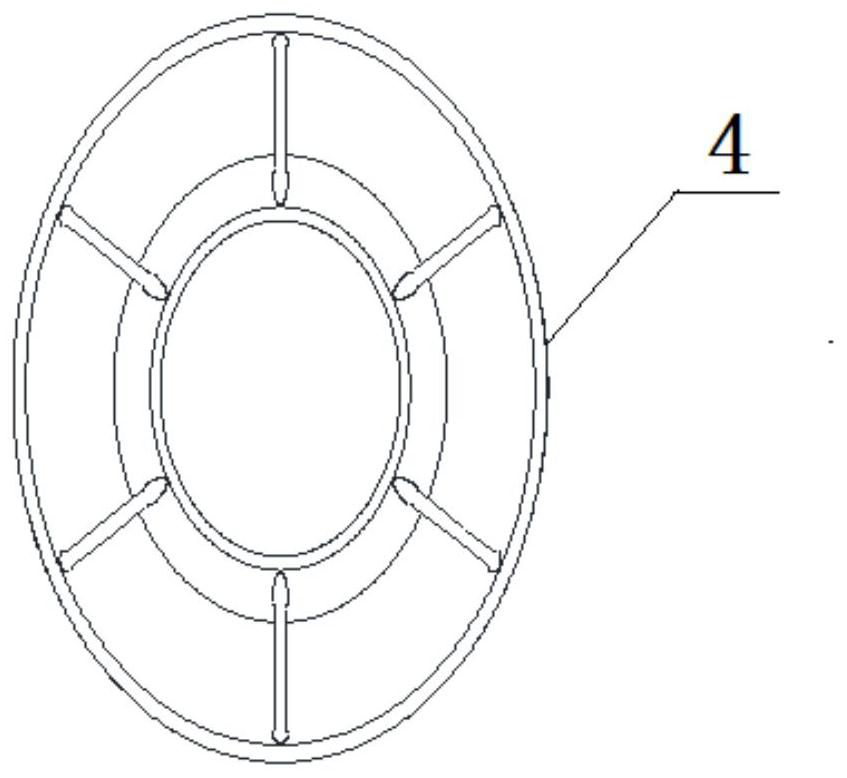

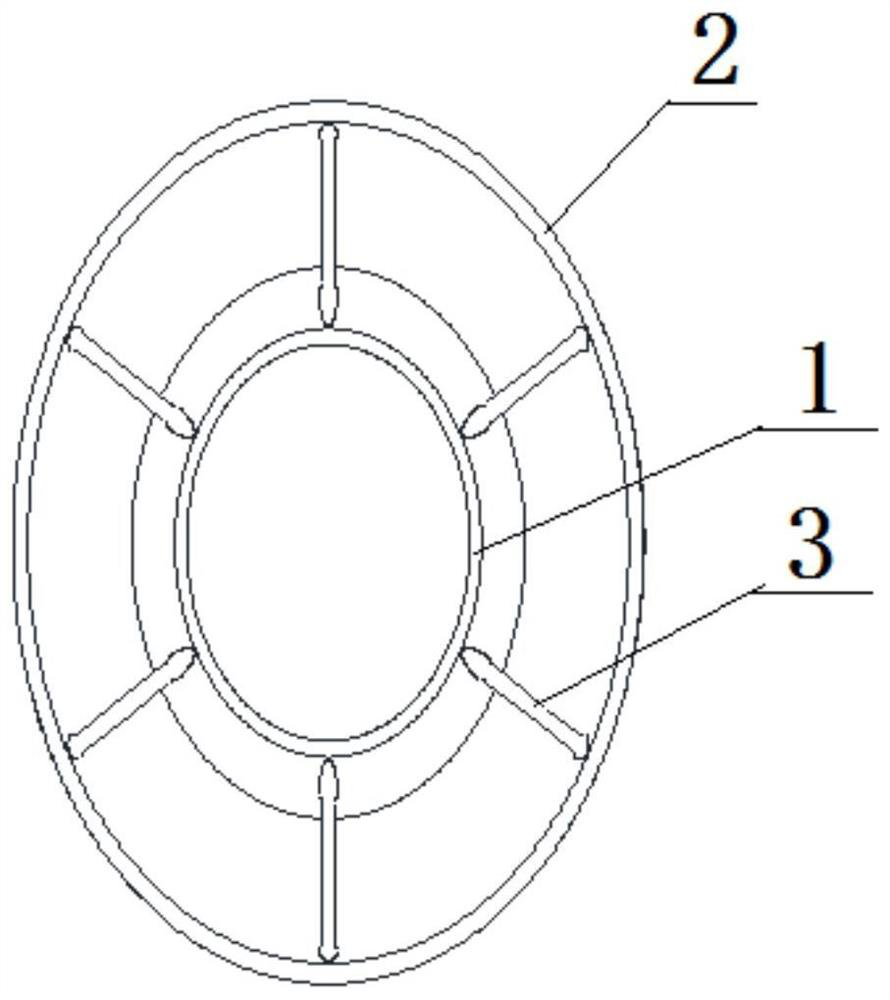

[0032] Such as figure 1 , figure 2 As shown, the present invention provides a thin-walled annular case casting investment casting process, comprising the following steps:

[0033] Step 1: Prepare a wax mold according to the shape of the design drawing provided by the user. The wax mold includes an inner wax ring 1 and an outer wax ring 2 arranged coaxially. The outer peripheral surface of the inner wax ring 1 is connected together by a plurality of wax ribs 3 ;

[0034] Step 2: First take the brown corundum sand and bake it in an oven to remove the moisture in it, then let it cool to room temperature and set aside;

[0035] Step 3: Sprinkle the brown corundum sand in step 2 on the inner surface of the inner wax ring 1 and the outer surface of the outer wax ring 2 in step 1, and fill it between any two adjacent wax rib plates 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com