Patents

Literature

43results about How to "Reduce the difficulty of filling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

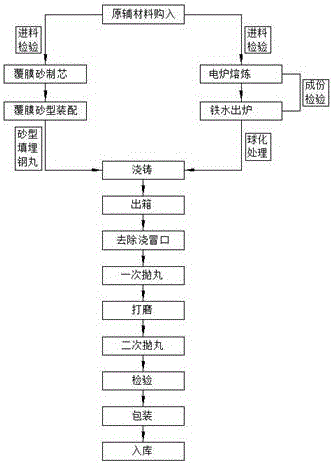

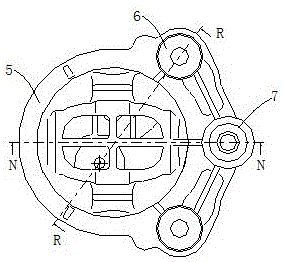

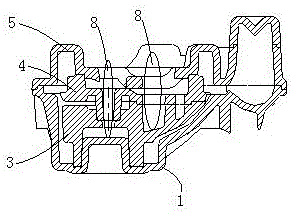

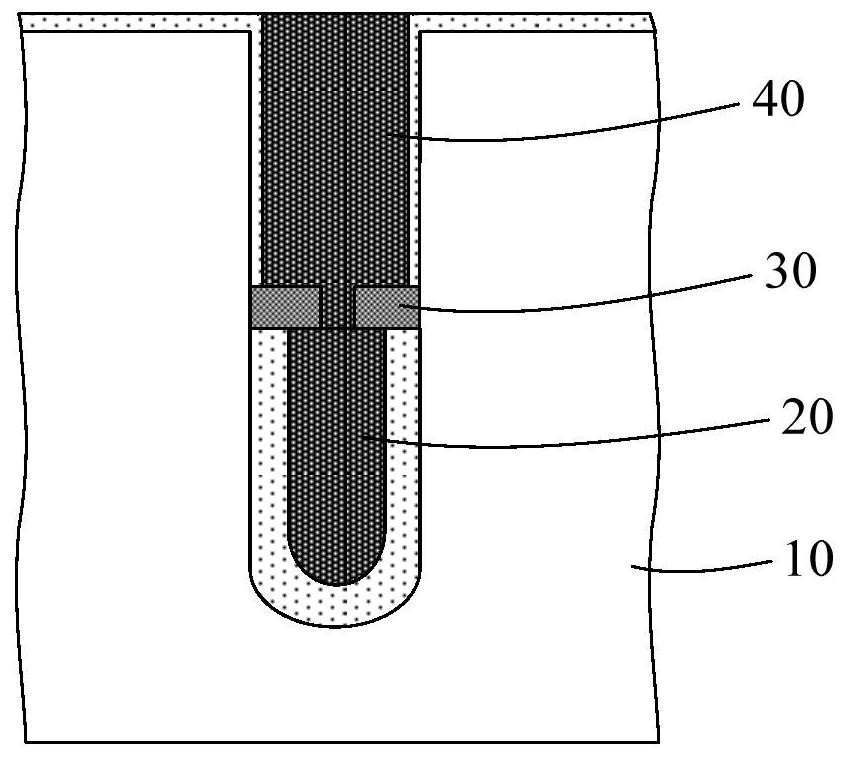

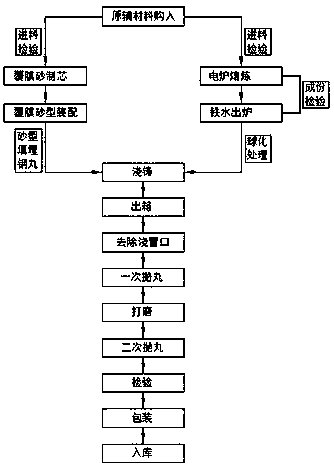

Casting method of main reducer housing

ActiveCN106825438AHigh dimensional accuracyHigh surface finishGearboxesFoundry mouldsPorositySurface finish

The invention relates to a casting method of a main reducer housing. The casting method includes: a precoated sand core forming process, a smelting ball iron process and a casting process, the precoated sand core forming process includes core-making of precoated sand, coated sand type assembly and sand-type steel shot filling; the smelting ball iron process includes electric-furnace smelting and charging of molten iron and treatment; the casting method is characterized by including casting, unboxing, de-gating, one-step shot blasting, grinding, secondary shot blasting and detecting. With the method, exhaust smoothness is guaranteed, generation of hole defects in the casting is avoided from the sand core exhaust process, sand hole and pore defective reject rate is controlled within 1%, shrinkage or porosity defect is avoided, the casting is stable in size and high in surface smoothness, the yield is higher as compared with that with a traditional casting method of the main reducer housing, the production process is easier to control, and production competitiveness has higher advantages.

Owner:抚州市羊易铸业有限公司

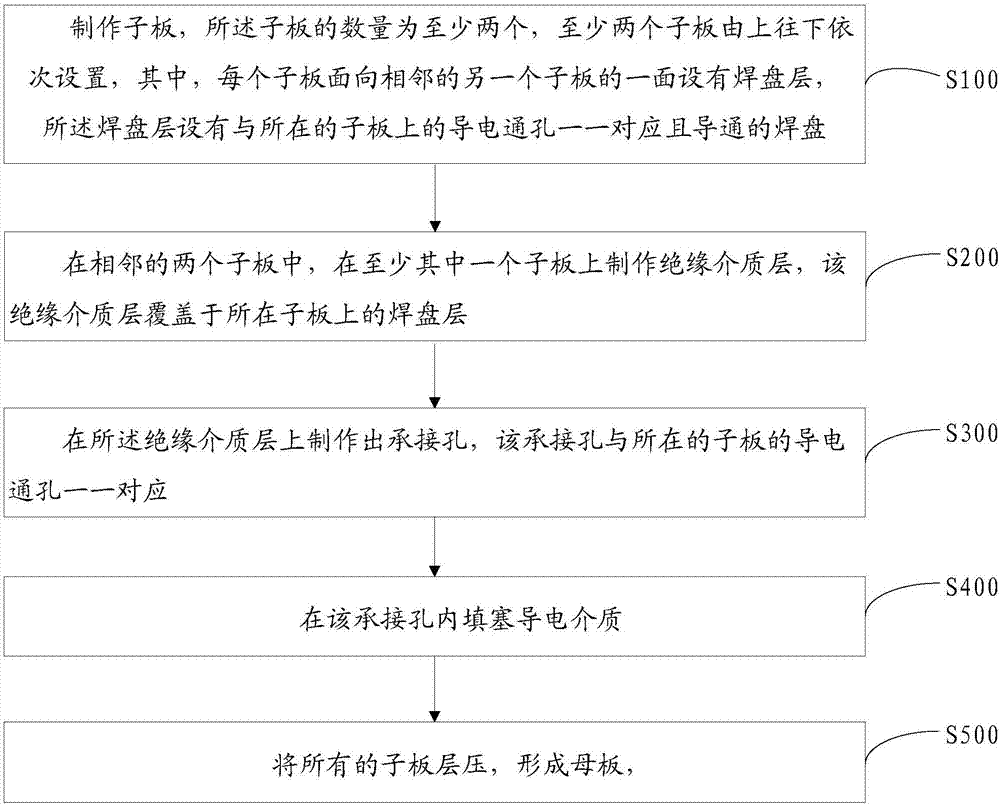

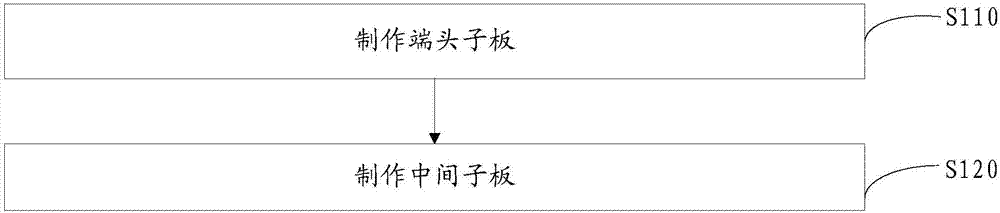

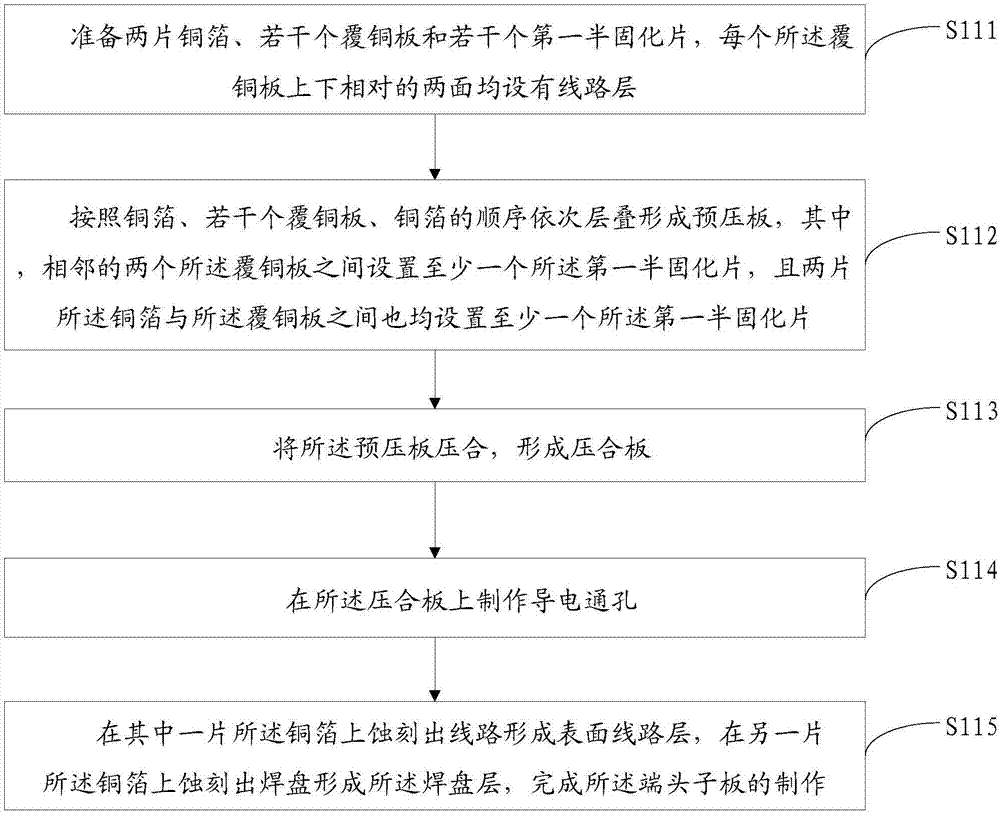

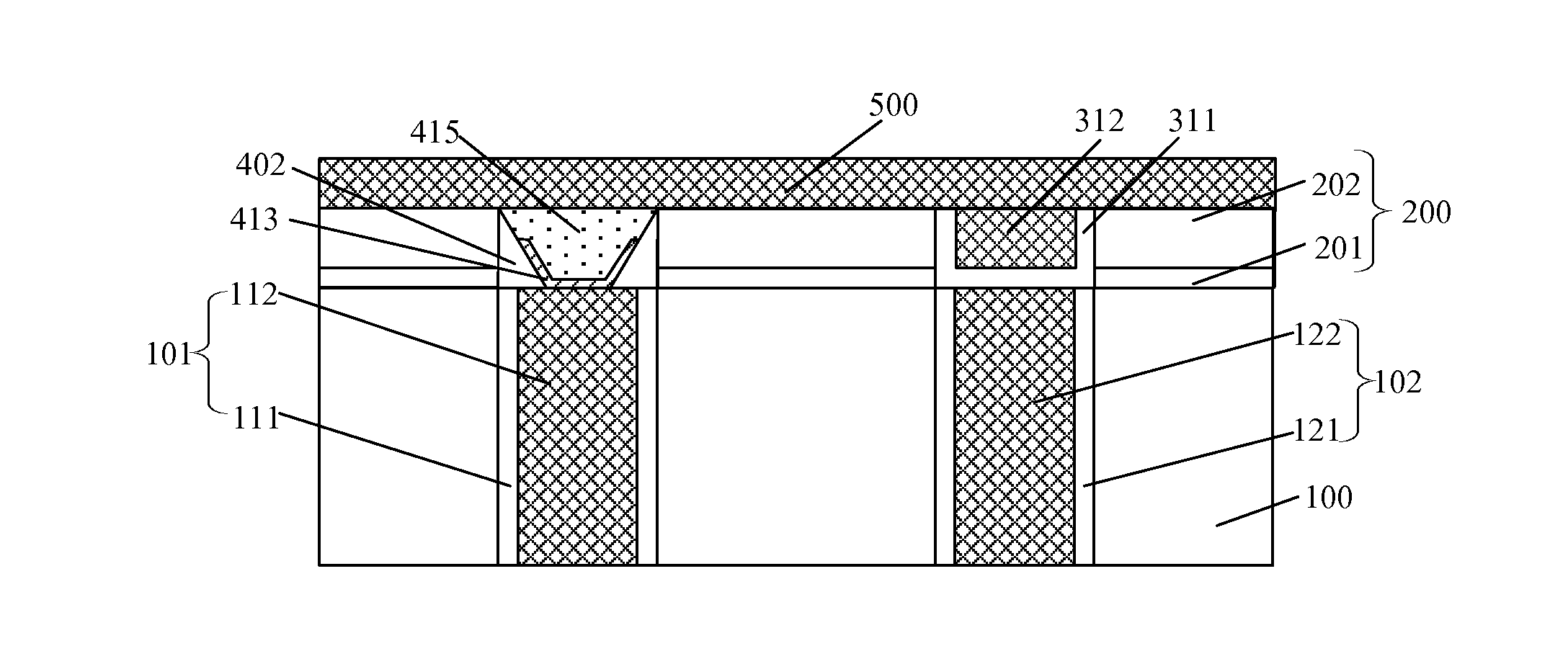

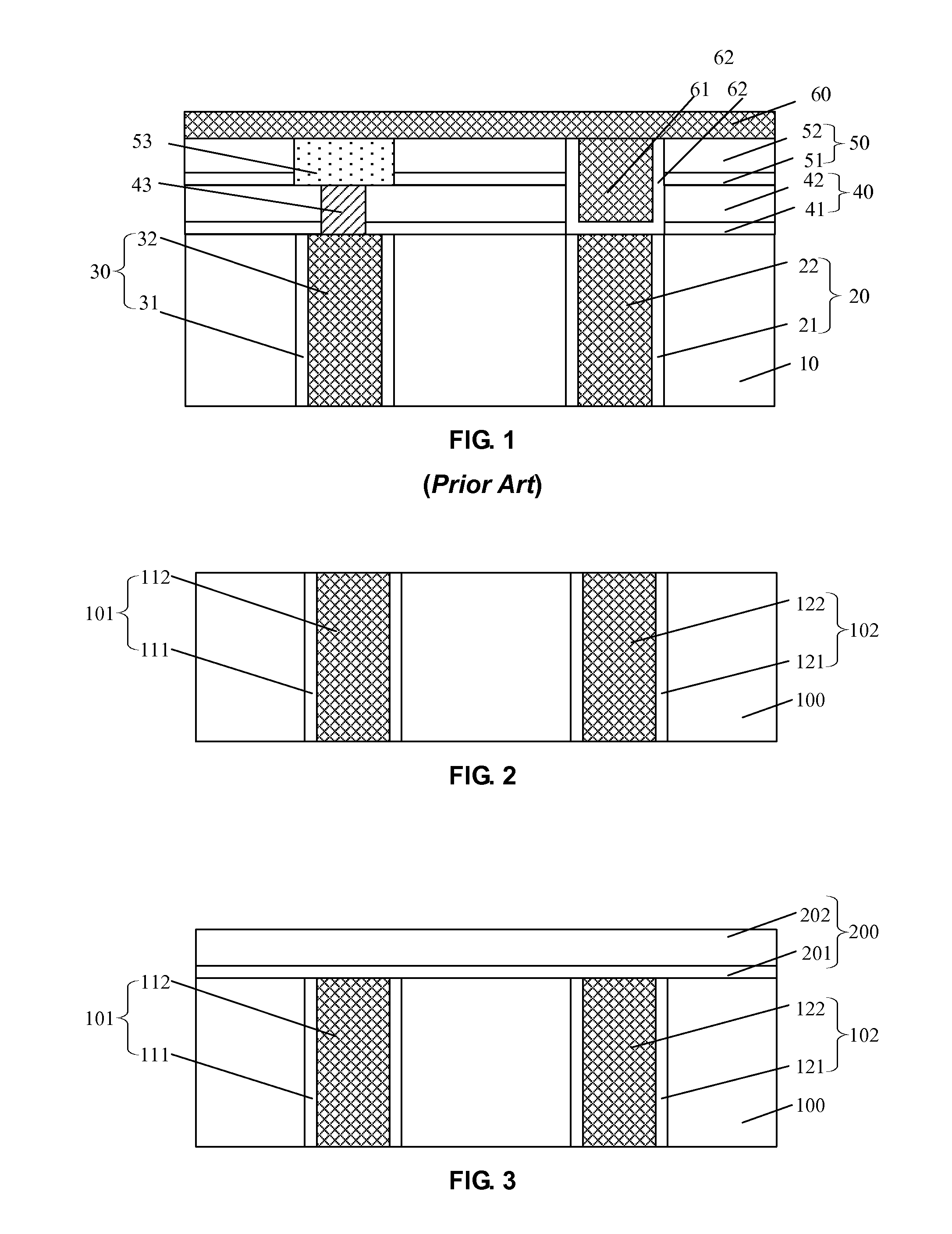

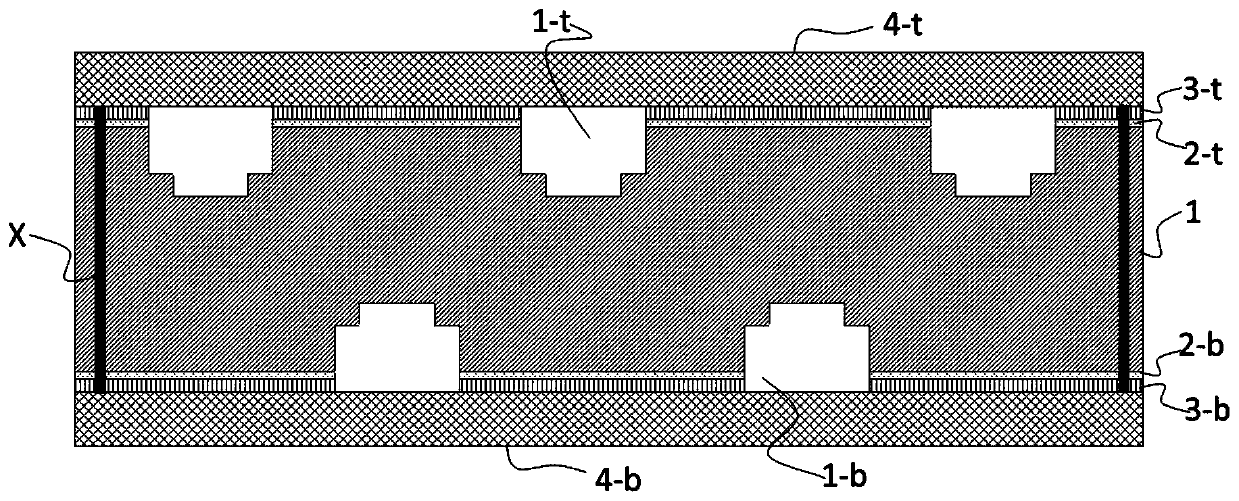

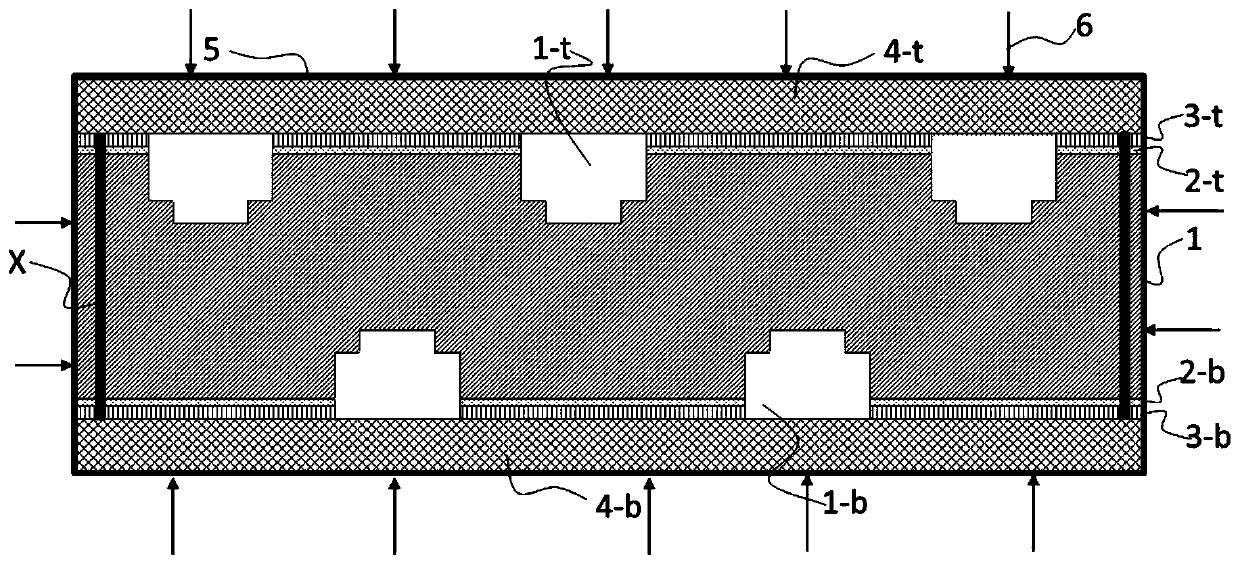

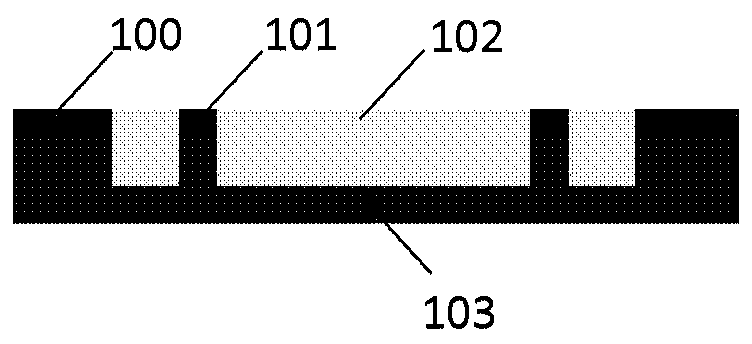

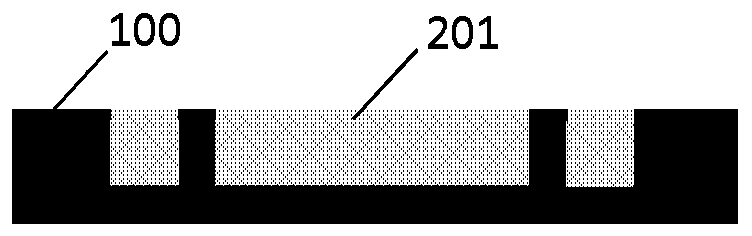

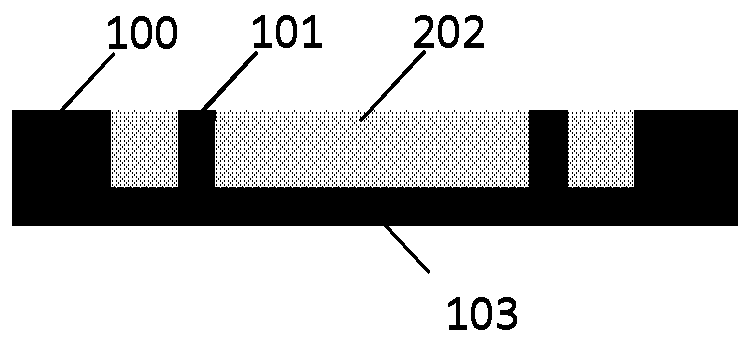

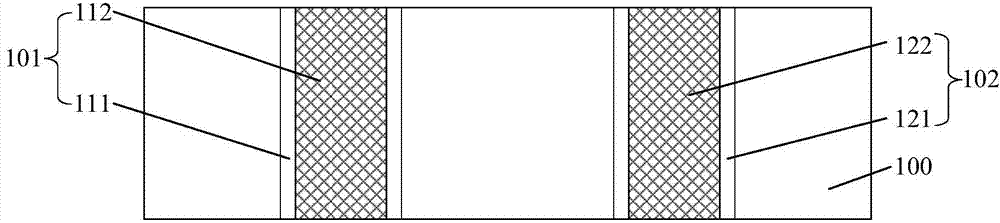

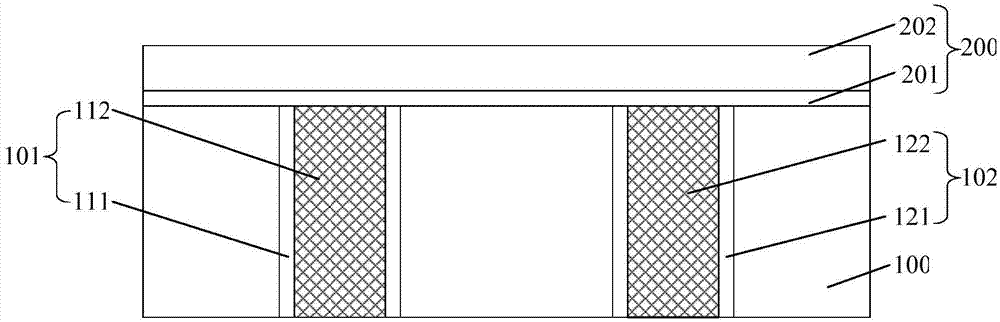

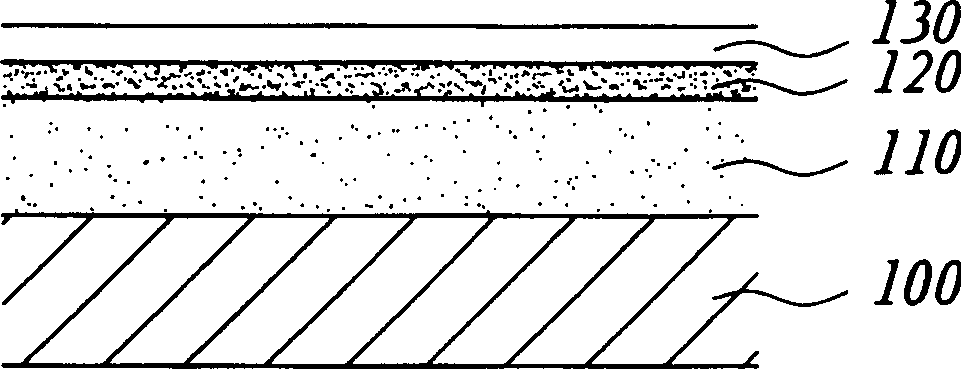

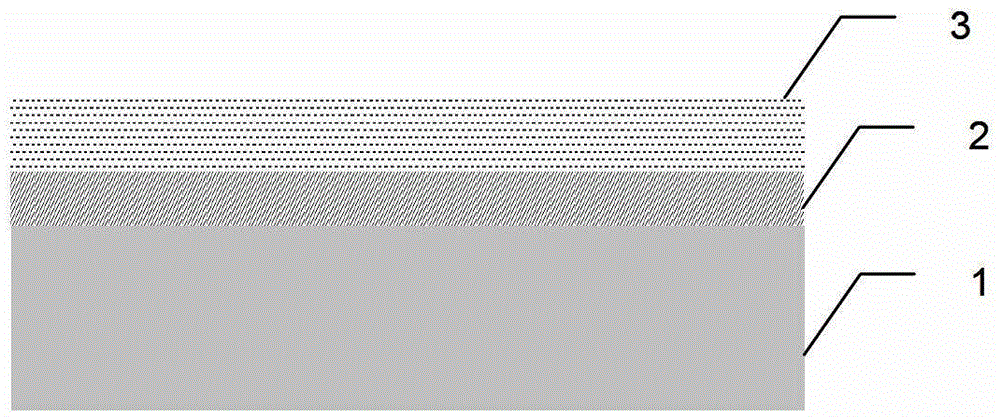

Z-direction interconnection circuit board and manufacturing method thereof

ActiveCN107155266AHigh bonding strengthAvoid stratificationMultilayer circuit manufactureConductive pattern layout detailsEngineeringInterconnection

The invention discloses a Z-direction interconnection circuit board and a manufacturing method thereof. The manufacturing method of the Z-direction interconnection circuit board comprises the following steps: sub-boards are manufactured, wherein at least two sub-boards are sequentially arranged from top to bottom, a pad layer is arranged on a side, facing the other adjacent sub-board, of each sub-board, and pads conductive and corresponding to conductive through holes in the sub-board one by one are arranged on each pad layer; an insulating dielectric layer covering the pad layer is manufactured on at least one of the two adjacent sub-boards; receiving holes are manufactured in the insulating dielectric layer, wherein the receiving holes correspond to the conductive through holes in the sub-board one by one; the receiving holes are filled with conductive dielectrics; and all the sub-boards are laminated to form a mother board, wherein the pad on each sub-board is conductive to the pad on the other adjacent sub-board by the conductive dielectric. The manufacturing method provided by the invention can effectively reduce glue filling difficulty, reduce bubbles, holes and other defects generated in a lamination process, and ensure bonding strength between the adjacent sub-boards.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

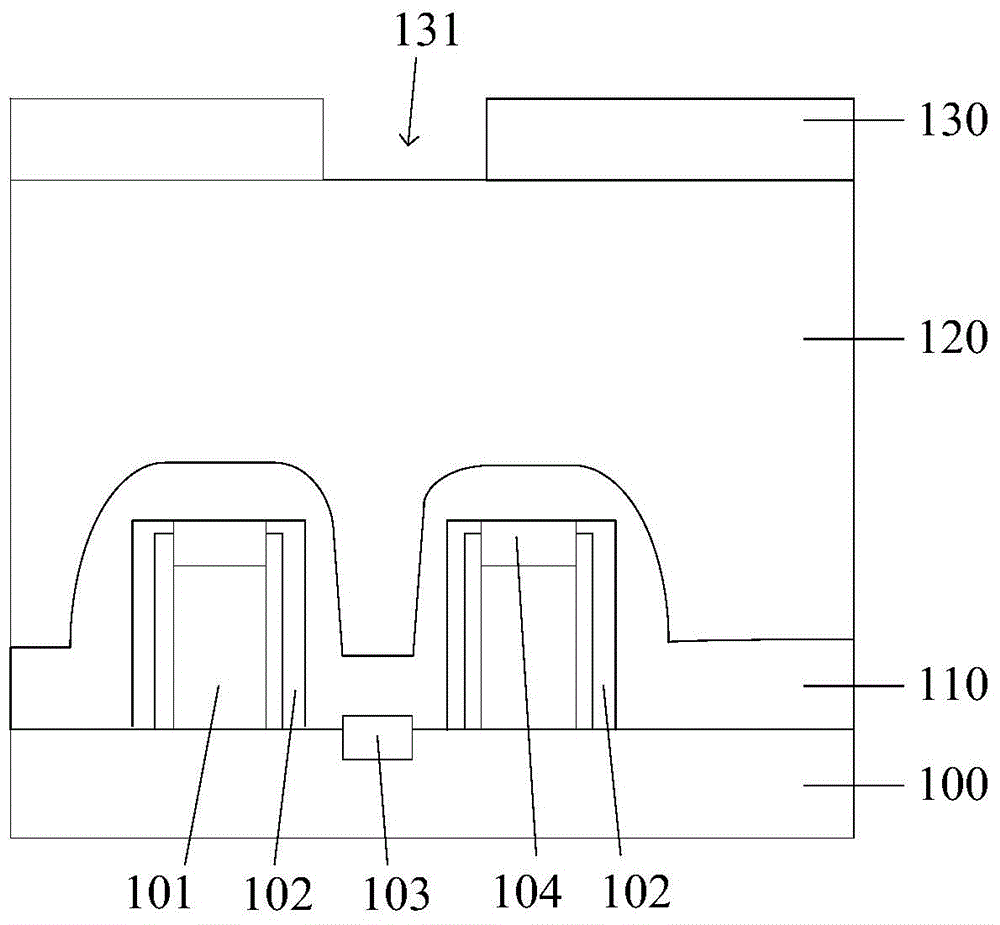

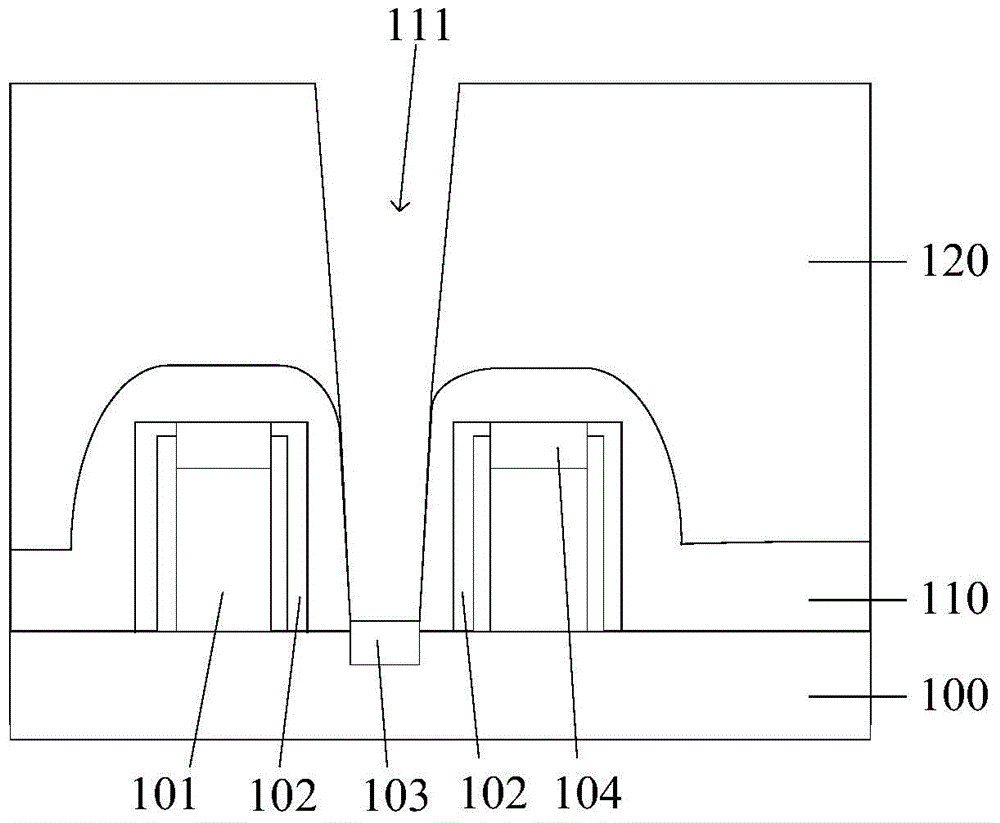

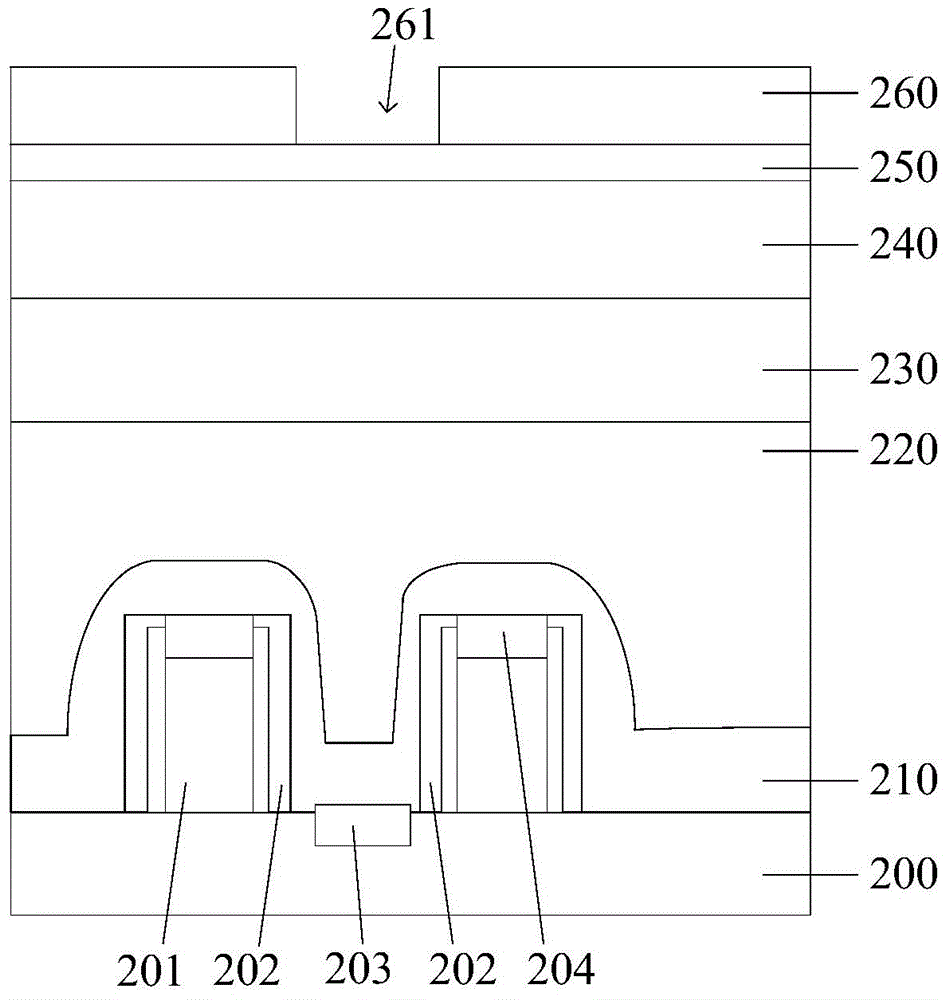

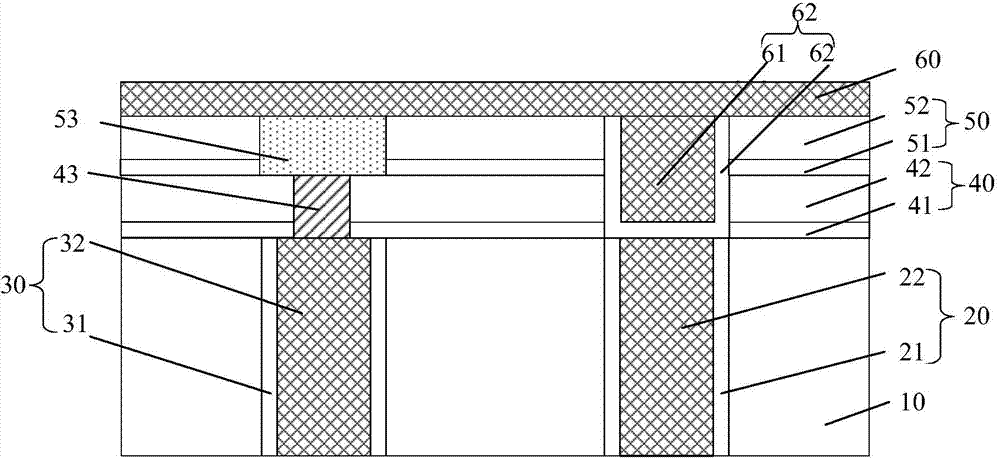

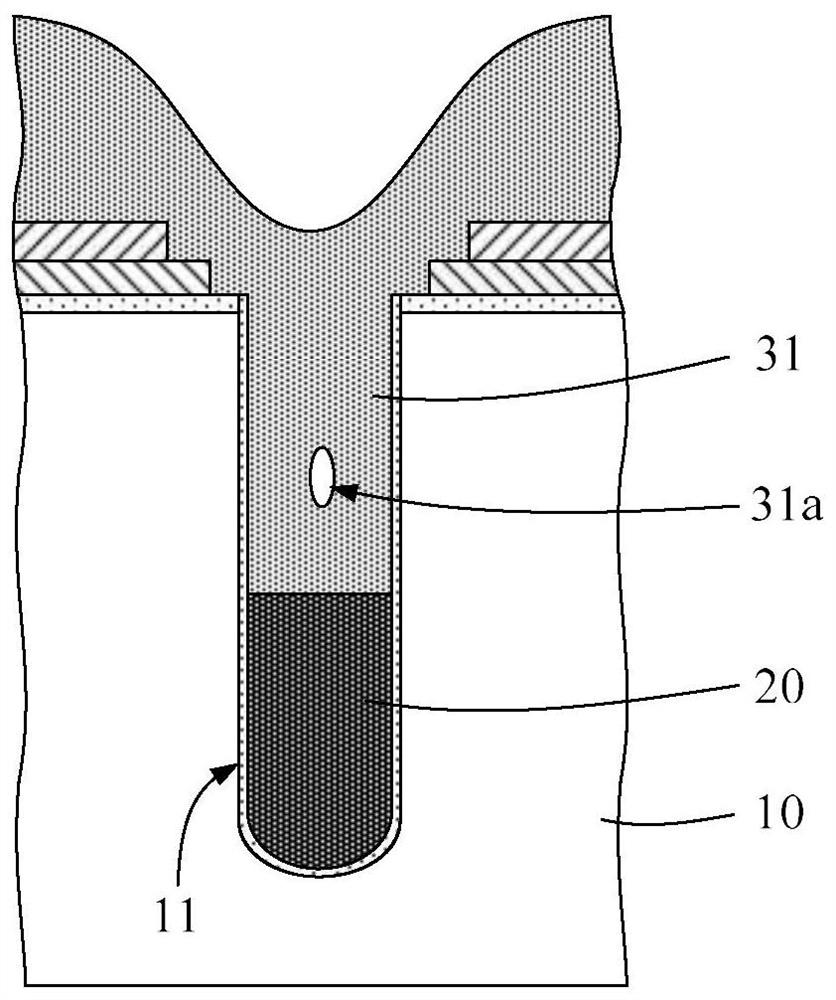

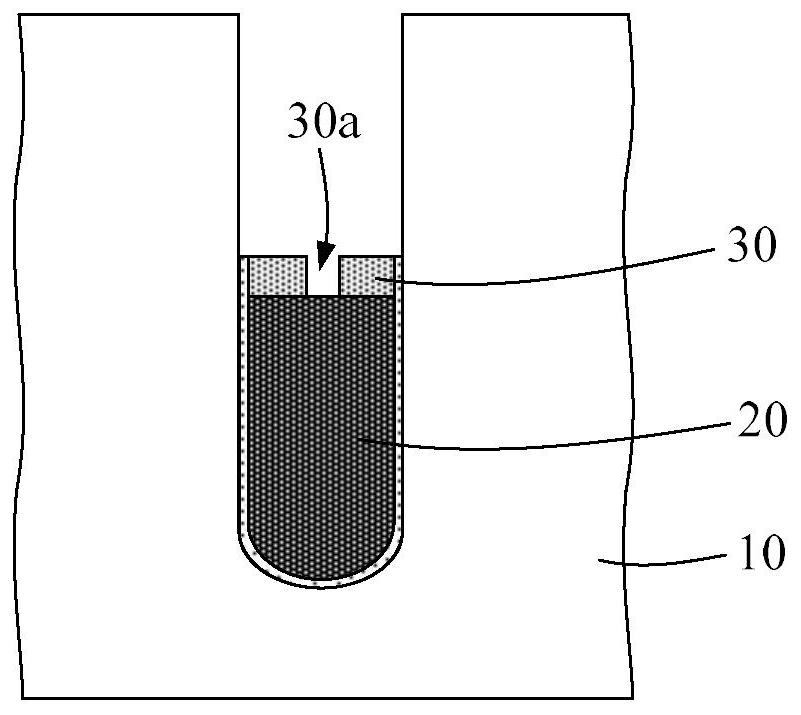

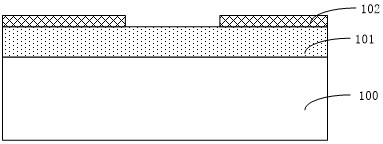

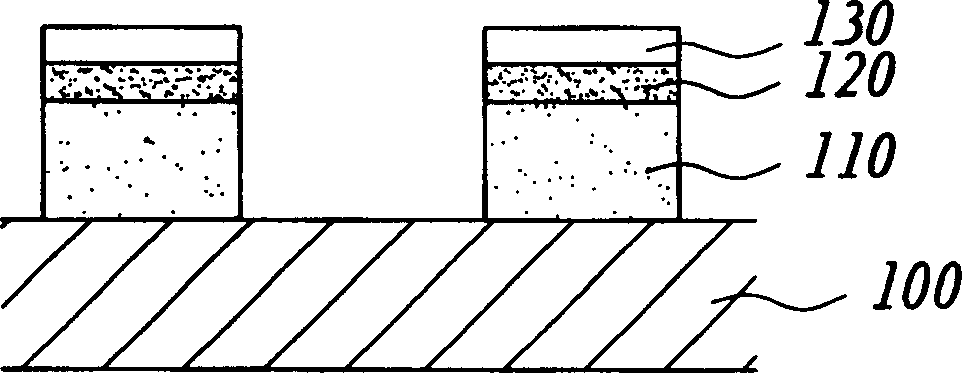

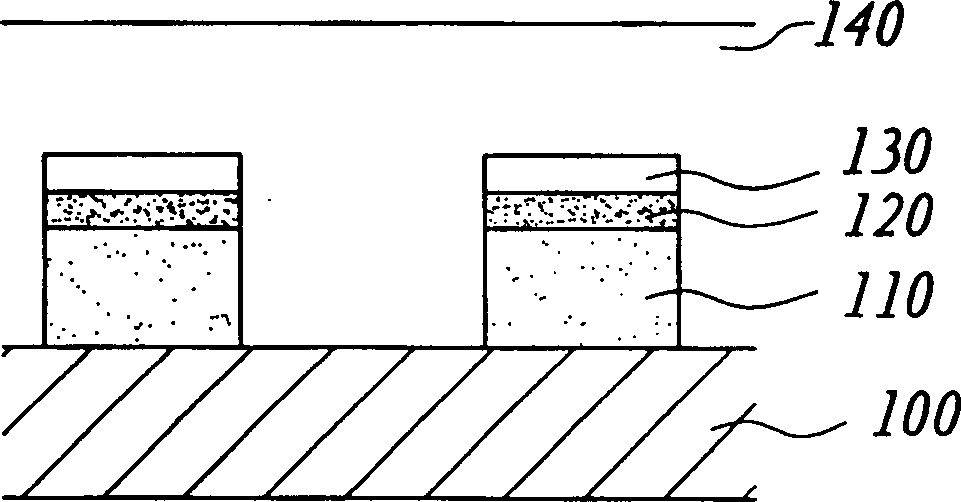

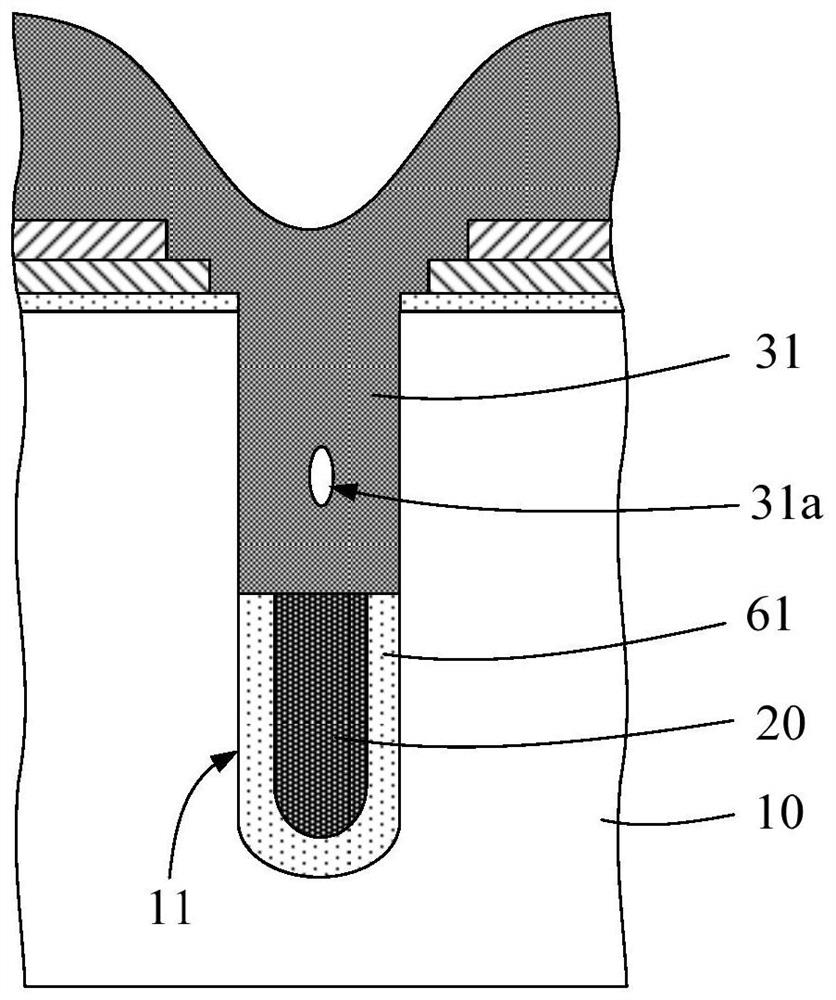

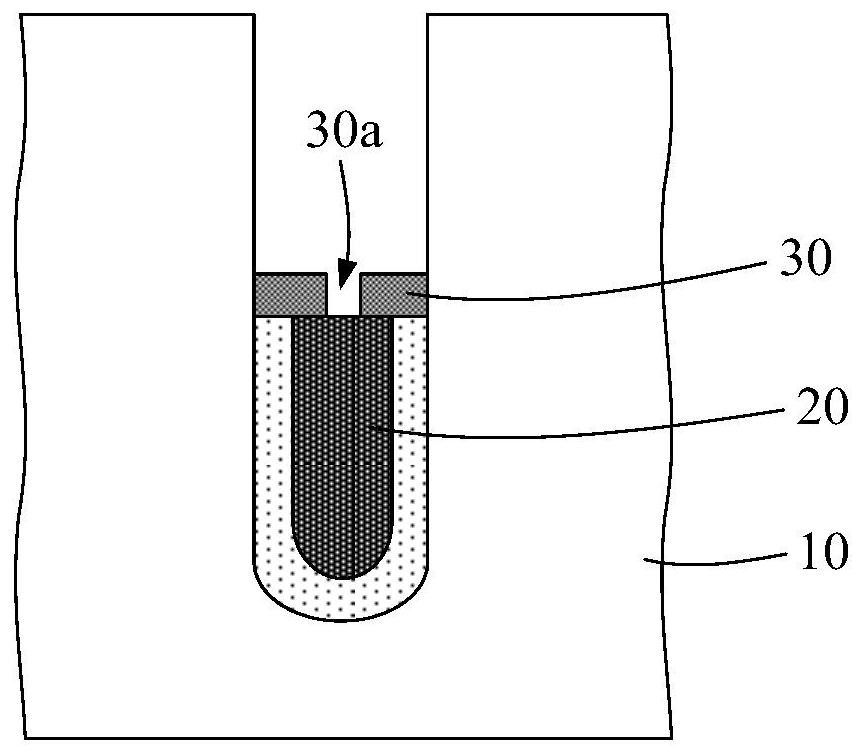

Phase change memory and fabrication method

ActiveUS20150090954A1Reduce the difficulty of fillingImprove molding qualitySemiconductor/solid-state device manufacturingBulk negative resistance effect devicesPhase-change memoryEngineering physics

A phase change memory and its fabrication method are provided. A bottom electrode structure is provided through a substrate. A mask layer is formed on the substrate and the bottom electrode structure. A first opening is formed in the mask layer to expose the bottom electrode structure. A spacer is formed on sidewalls and bottom surface portions of the first opening to expose a surface portion of the bottom electrode structure. The first opening including the spacer therein has a bottom width less than a top width. A heating layer is formed at least on the surface portion of the bottom electrode structure exposed by the spacer. A phase change layer is formed on the heating layer to completely fill the first opening. A top electrode is formed on the phase change layer and the mask layer.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

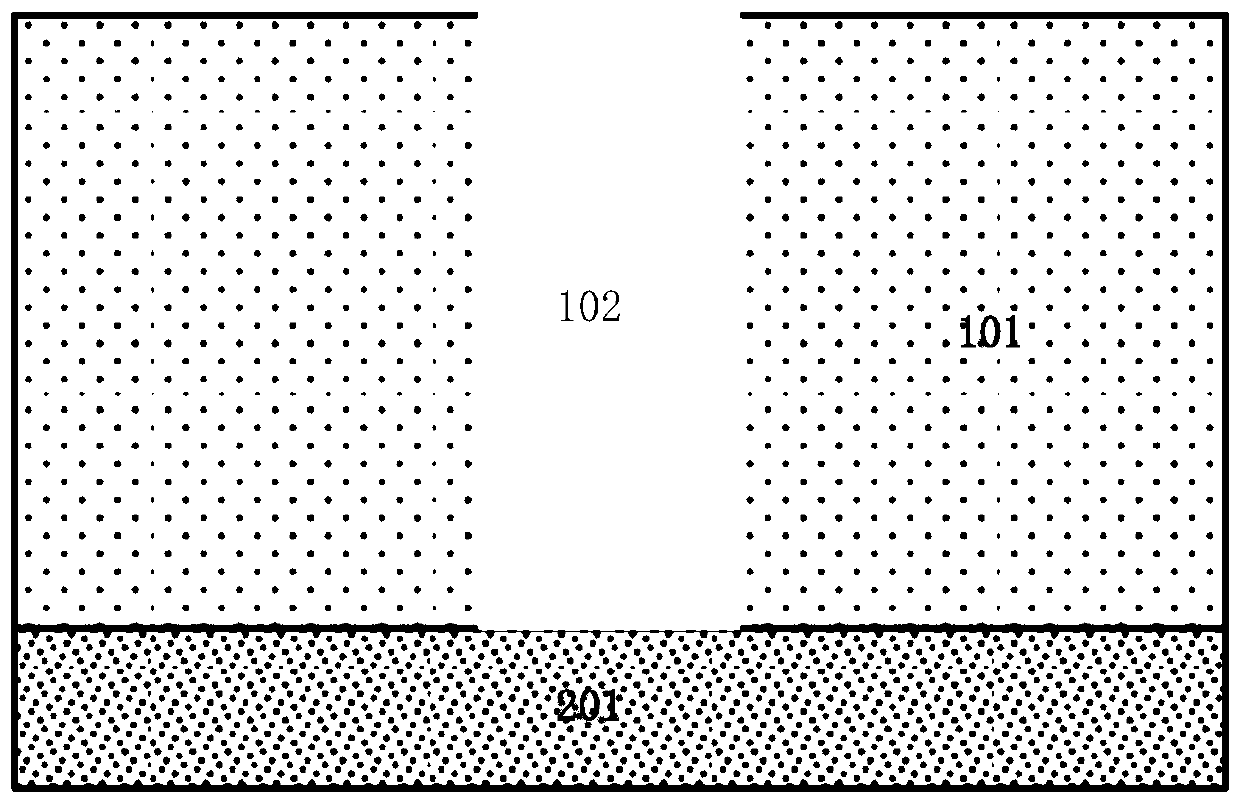

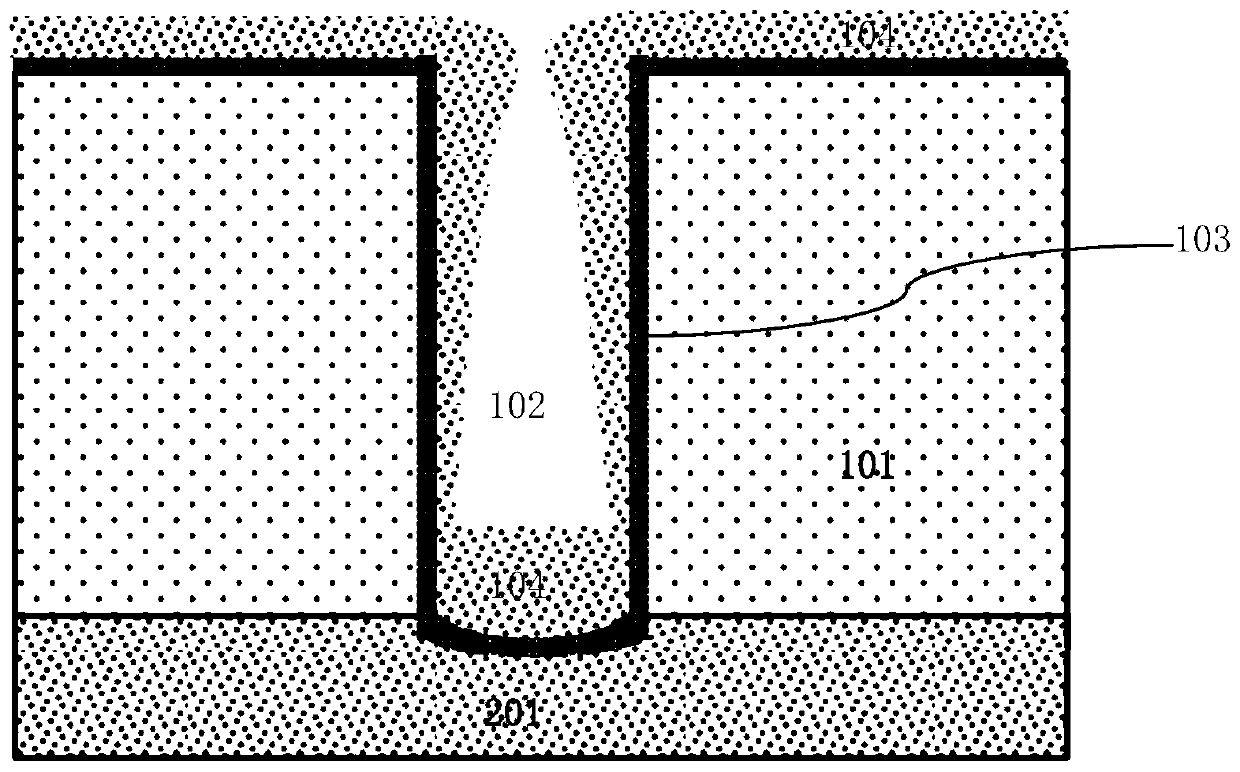

Formation method of contact plug

ActiveCN105097650AEasy to fillReduce the difficulty of formationSemiconductor/solid-state device manufacturingConductive materialsDielectric layer

A formation method of a contact plug comprises the steps of providing a substrate; forming an interlayer dielectric layer on the substrate; forming a high K dielectric layer on the interlayer dielectric layer; etching the high K dielectric layer and the interlayer dielectric layer orderly until the substrate is exposed to form a contact hole; continuously etching the high K dielectric layer along the contact hole until the diameter of the contact hole located at the high K dielectric layer is increased; adopting a conductive material to fill the contact hole. The formation method of the contact plug enables the formation difficulty of the contact plug to be reduced and also the quality of the formed contact plug to be improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Manufacturing method of LTCC substrate double-face cavity structure

ActiveCN111312596ARealize processingReduce the difficulty of fillingSemiconductor/solid-state device detailsSolid-state devicesHemt circuitsEngineering

The invention relates to the field of LTCC circuit substrate processing, and discloses a manufacturing method of a LTCC substrate double-face cavity structure. Rigid supporting pieces at the top and the bottom are used for providing rigid supporting during product lamination, and pressure transmission to the interiors of cavities in the front face and the back face in the lamination process is achieved by opening cavities in the rigid supporting pieces. Meanwhile, the planar soft silica gel sheets are used for replacing filling protection objects such as filling embedded blocks and silicone rubber male dies on the front face and the back face, all that is needed is to spread the whole face, operation is extremely easy, alignment and embedding problems do not need to be considered, the filling difficulty of the filling protection objects is greatly reduced, and good process stability is achieved. According to the forming method, a traditional LTCC lamination technology is not changed, high interlayer alignment precision of the product can be obtained while good double-face cavity quality and high flatness of the substrate are guaranteed, and manufacturing of the high-performance LTCC substrate is achieved.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

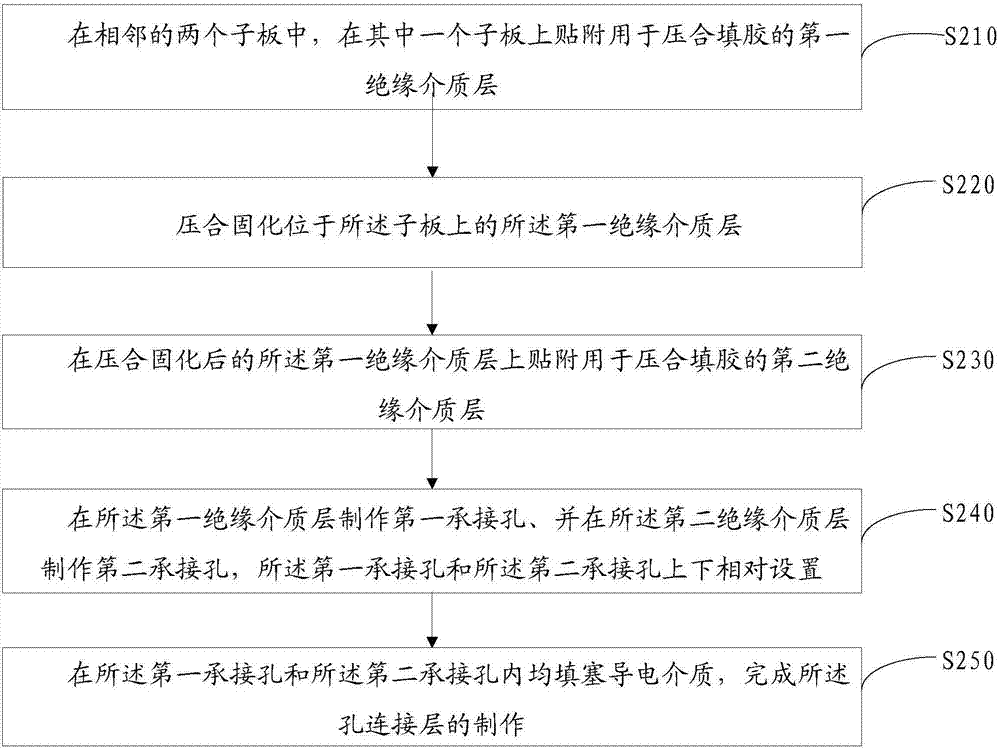

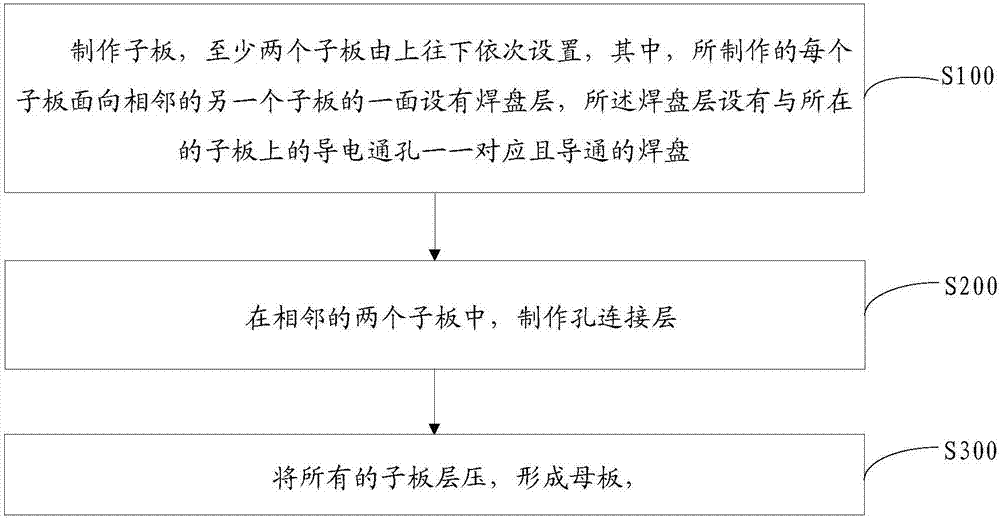

Method for manufacturing hole connecting layer, method for manufacturing circuit board and circuit board

ActiveCN107257603AHigh bonding strengthReduce bond strengthPrinted circuit aspectsElectrical connection printed elementsUltimate tensile strengthDielectric layer

The invention discloses a method for manufacturing a hole connecting layer, a method for manufacturing a circuit board and a circuit board. The method for manufacturing a hole connecting layer comprises: attaching one daughter board to a first insulating dielectric layer for pressing a filter; pressing and solidifying the first insulating dielectric layer arranged on the daughter board; pasting a second insulating dielectric layer for pressing a filler on the first insulating dielectric layer after pressing and solidifying; manufacturing a first carrying hole in the first insulating dielectric layer and manufacturing a second carrying hole opposite to the first carrying hole in an up-down manner in the second insulating dielectric layer; and filling the first carrying hole and the second carrying hole with conductive media to complete manufacturing of a hole connecting layer. Therefore, the dual-sided filler filing need can be met; the bonding strength of the adjacent daughter boards is enhanced; the fluidity of the hole connecting hole is controlled; a phenomenon that the carrying hole shape is damaged by too large flowing glue can be avoided; and the conducting media can be protected from being squeezed and dispersed.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

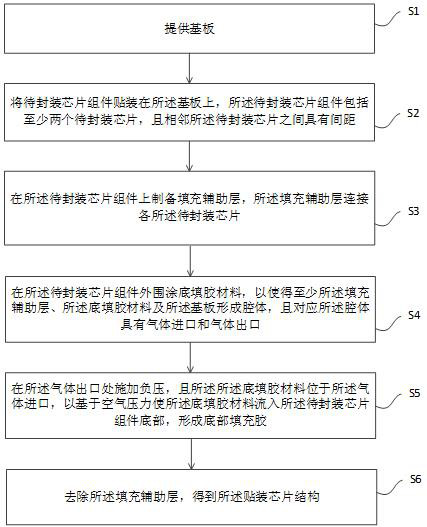

A microstructure packaging method and a packaging device

ActiveCN109928359AReduce the difficulty of fillingImprove yieldDecorative surface effectsSolid-state devicesBonding processElectrical connection

The invention provides a microstructure packaging method, which comprises the following steps that: a conductive silicon column and a silicon groove are etched on the upper surface of a monocrystalline silicon wafer, and a monocrystalline silicon material left between the bottom of the silicon groove and the back surface of the monocrystalline silicon wafer is a microstructure functional layer; asilicon groove is filled with the glass powder; the glass powder is sintered at a high temperature above the softening point of the glass powder to form a glass body; a microstructure containing a functional structure and an electrical connection structure and a frame are etched on the back surface of the monocrystalline silicon wafer; the cap and the frame are bonded through a bonding process, and the microstructure is sealed and packaged; And depositing a metal electrode on the conductive silicon column to realize ohmic contact with an external circuit.

Owner:INSTR TECH & ECONOMY INST P R CHINA

Multi-chip mounting structure and preparation method thereof

ActiveCN112701071ASolve the problem of difficult to fill on demandReduce the difficulty of fillingSemiconductor/solid-state device manufacturingMechanical engineeringGas bubble

The invention provides a multi-chip mounting structure and a preparation method, and the preparation method comprises the steps: mounting a plurality of chips on a substrate, preparing a filling auxiliary layer on the chips to form a cavity, forming a gas inlet and a gas outlet corresponding to the cavity, coating the gas inlet with a primer filling material, and applying a negative pressure at the gas outlet; enabling the primer filling material to flow into the bottoms of the chips based on the air pressure to form underfill. For a packaging structure of a plurality of chip modules, the cavity is constructed between a to-be-packaged chip and a substrate, the primer filling material is coated at the gas inlet, and negative pressure is applied at the gas outlet, so that the underfill is pressed into the bottoms of the chips under the action of gas pressure, the filling difficulty of the underfill of the multi-chip structure can be reduced, and the problem of filling bubbles is favorably solved. And the problems that in a multi-chip small-spacing structure, the glue filling head is difficult to place, the glue filling process is complex, and the influence on the structure of the previous step is large can be solved. The process is simple, and the problem that filling is performed as required when a plurality of chips are difficult to integrate can be solved.

Owner:浙江集迈科微电子有限公司

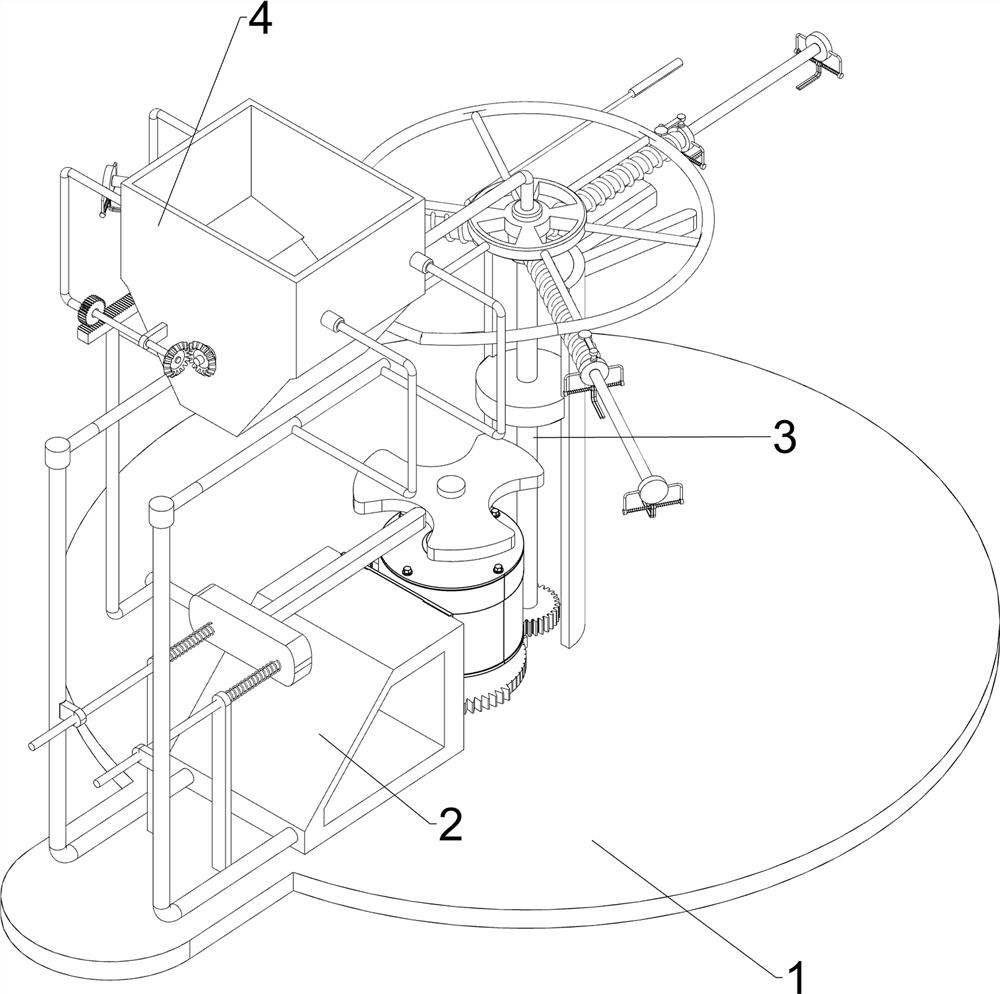

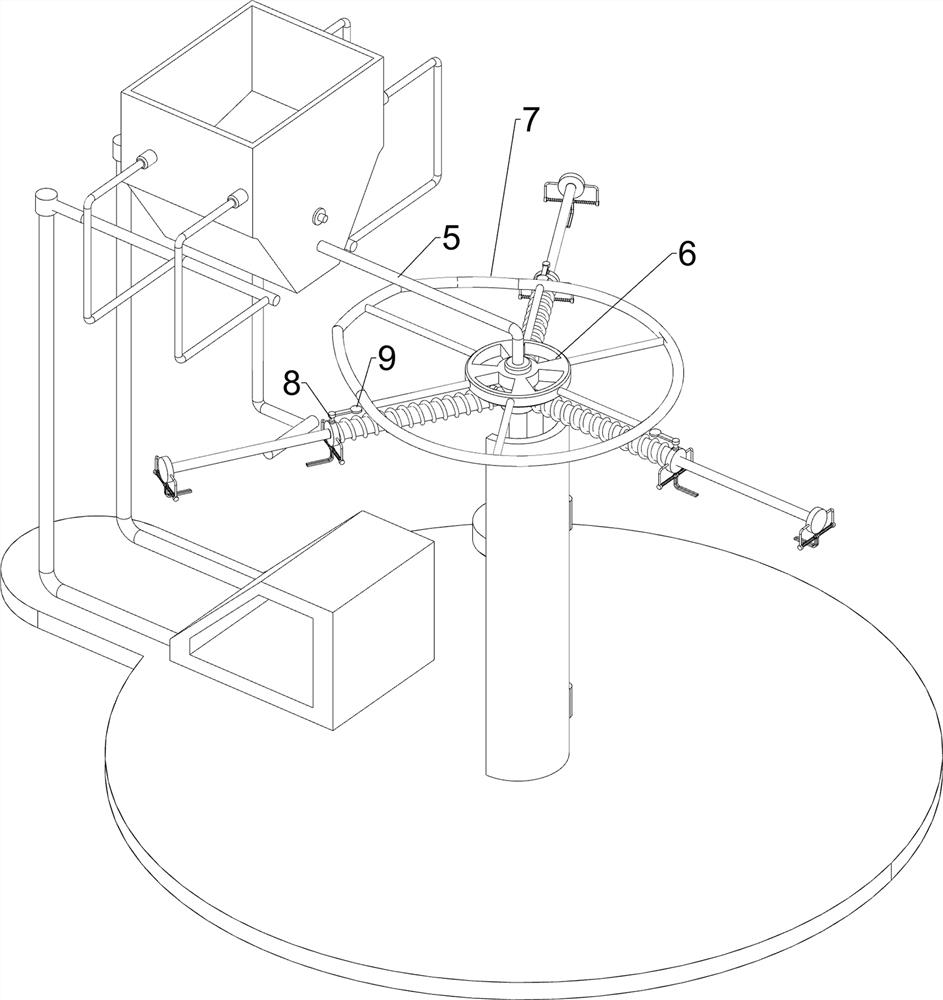

Bagged washing powder filling, sealing and packaging device

ActiveCN112078877ARealize intermittent transmissionRealize intermittent fillingPackage recyclingWrapper twisting/gatheringEngineeringMechanical engineering

The invention relates to a filling device, in particular to a bagged washing powder filling, sealing and packaging device. The bagged washing powder filling, sealing and packaging device is high in working efficiency, consistent in filling amount and capable of avoiding waste. The provided bagged washing powder filling, sealing and packaging device comprises a base plate, a conveying mechanism anda filling mechanism, wherein a fixing seat is arranged on one side of the top of the base plate, the conveying mechanism is arranged at the center of the top of the base plate, and the filling mechanism is arranged on the side, away from the conveying mechanism, of the fixing seat. An incomplete tooth gear and a first circular gear are meshed with each other to achieve intermittent conveyance ofwashing powder packaging bags. A fan-shaped material-discharging barrel rotates and cooperates with a funnel material-discharging opening to achieve intermittent filling of washing powder.

Owner:山东卓辰科技服务有限公司

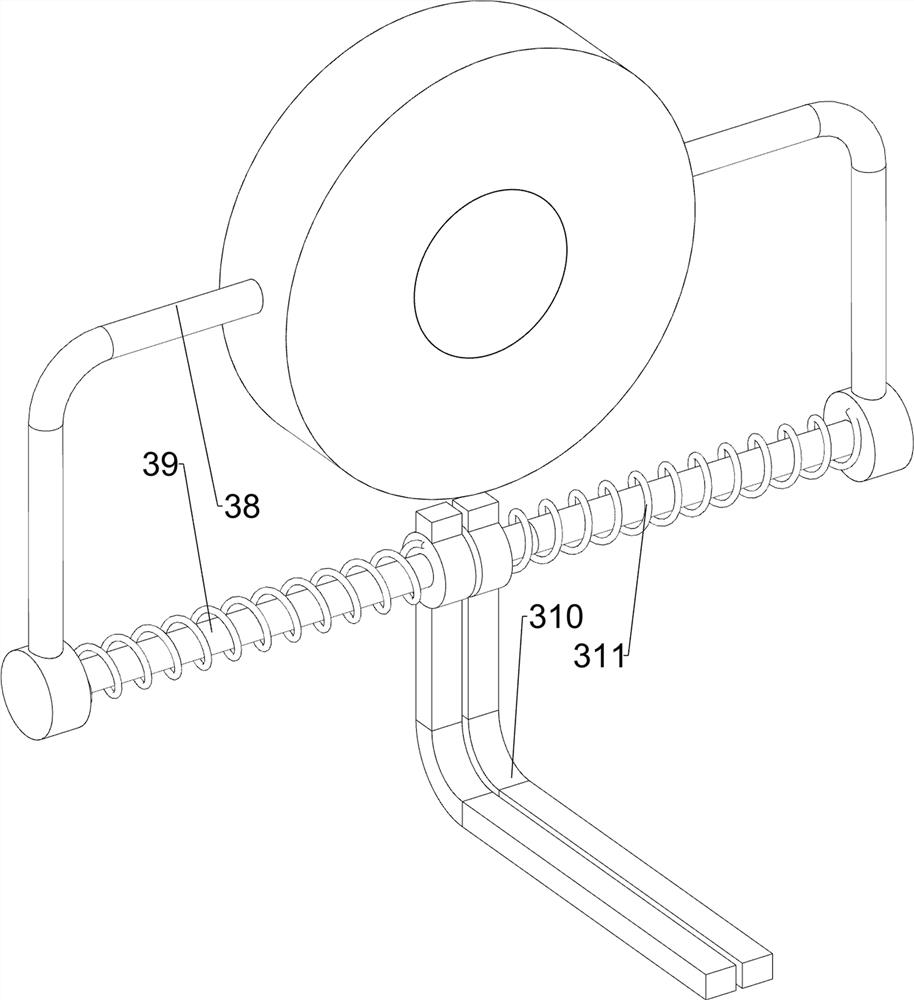

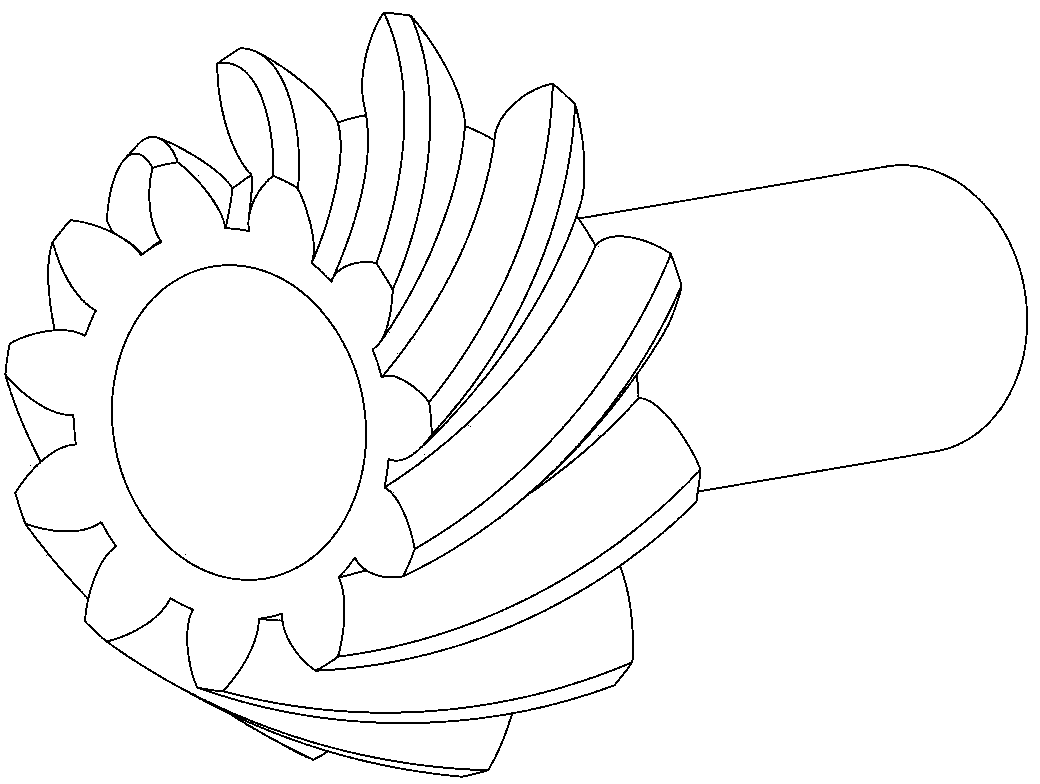

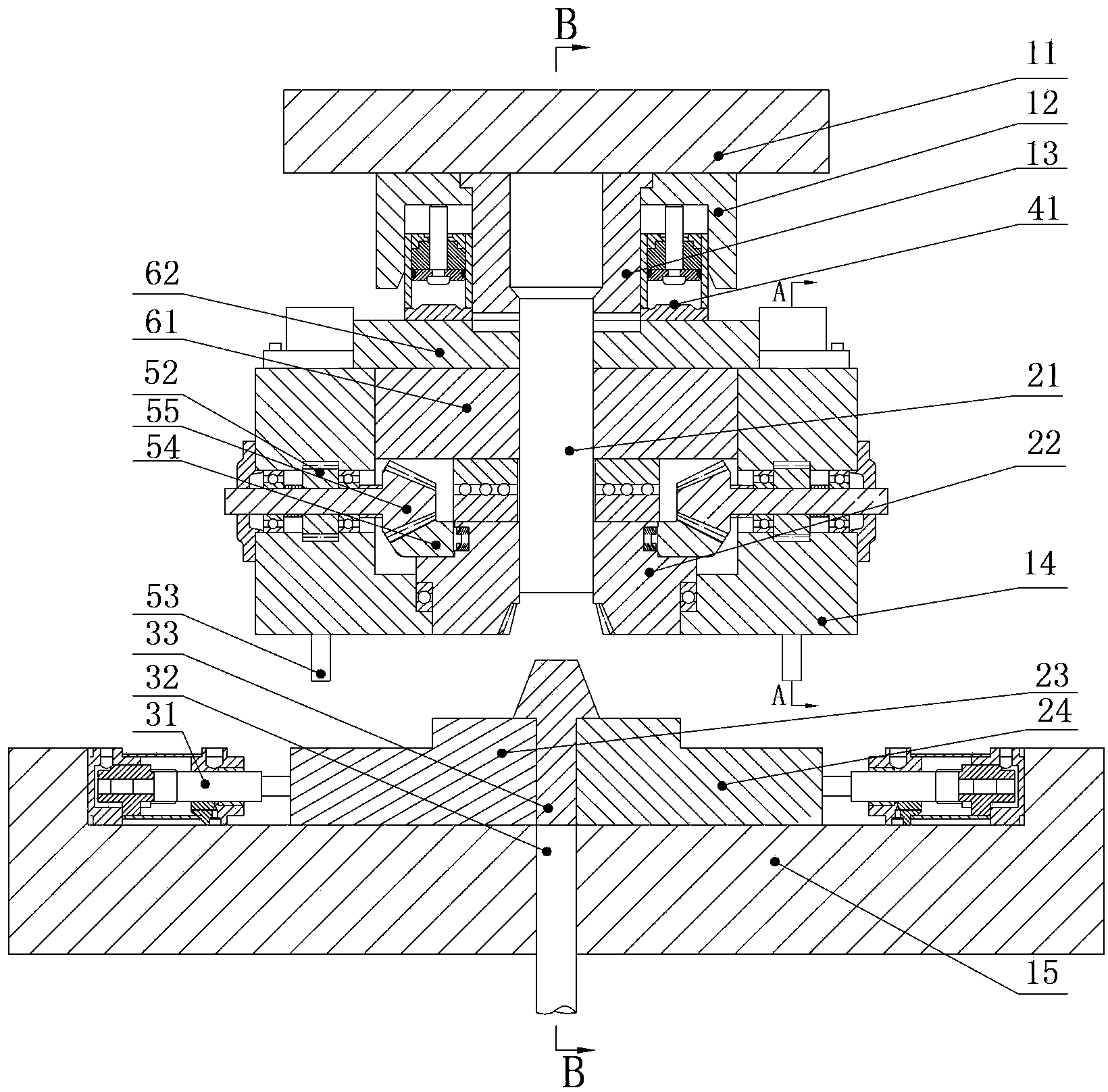

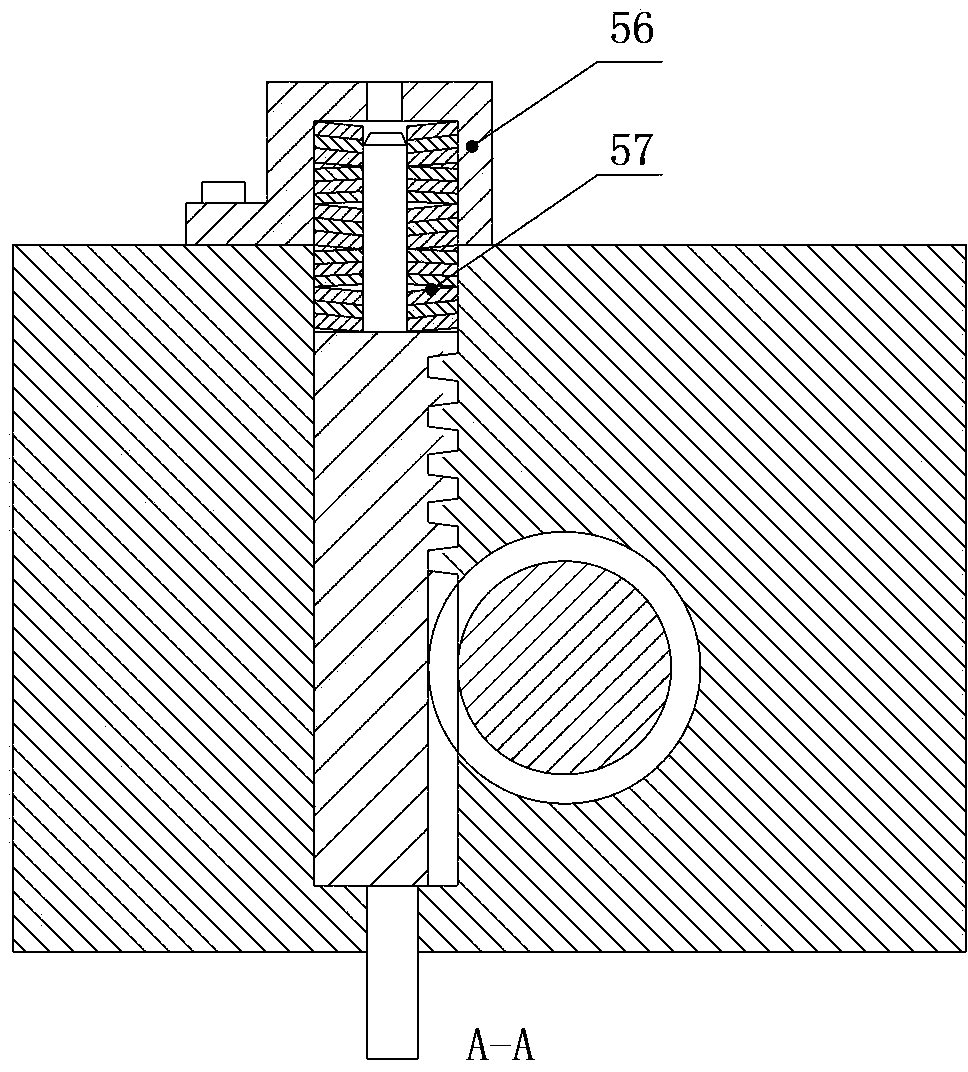

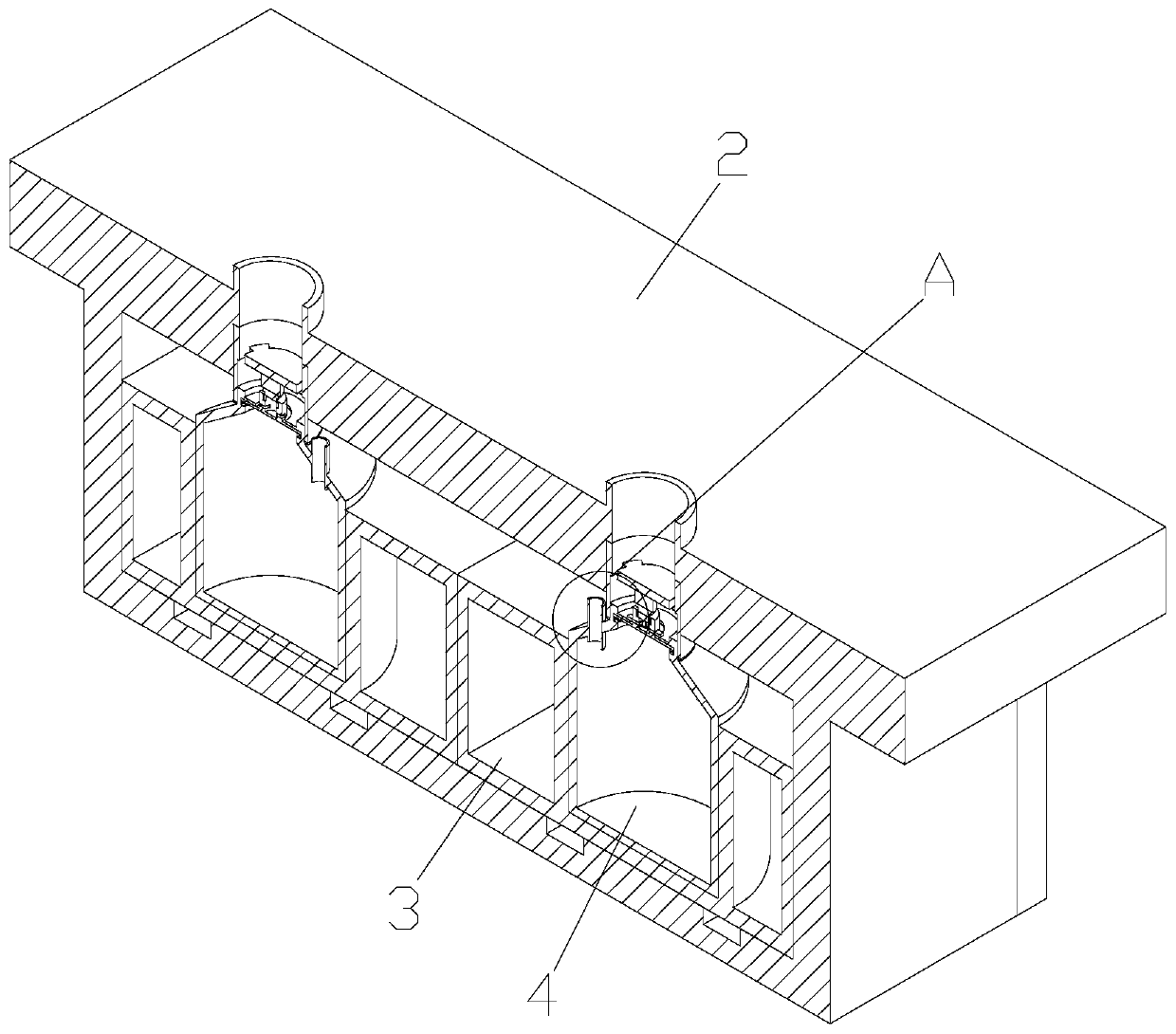

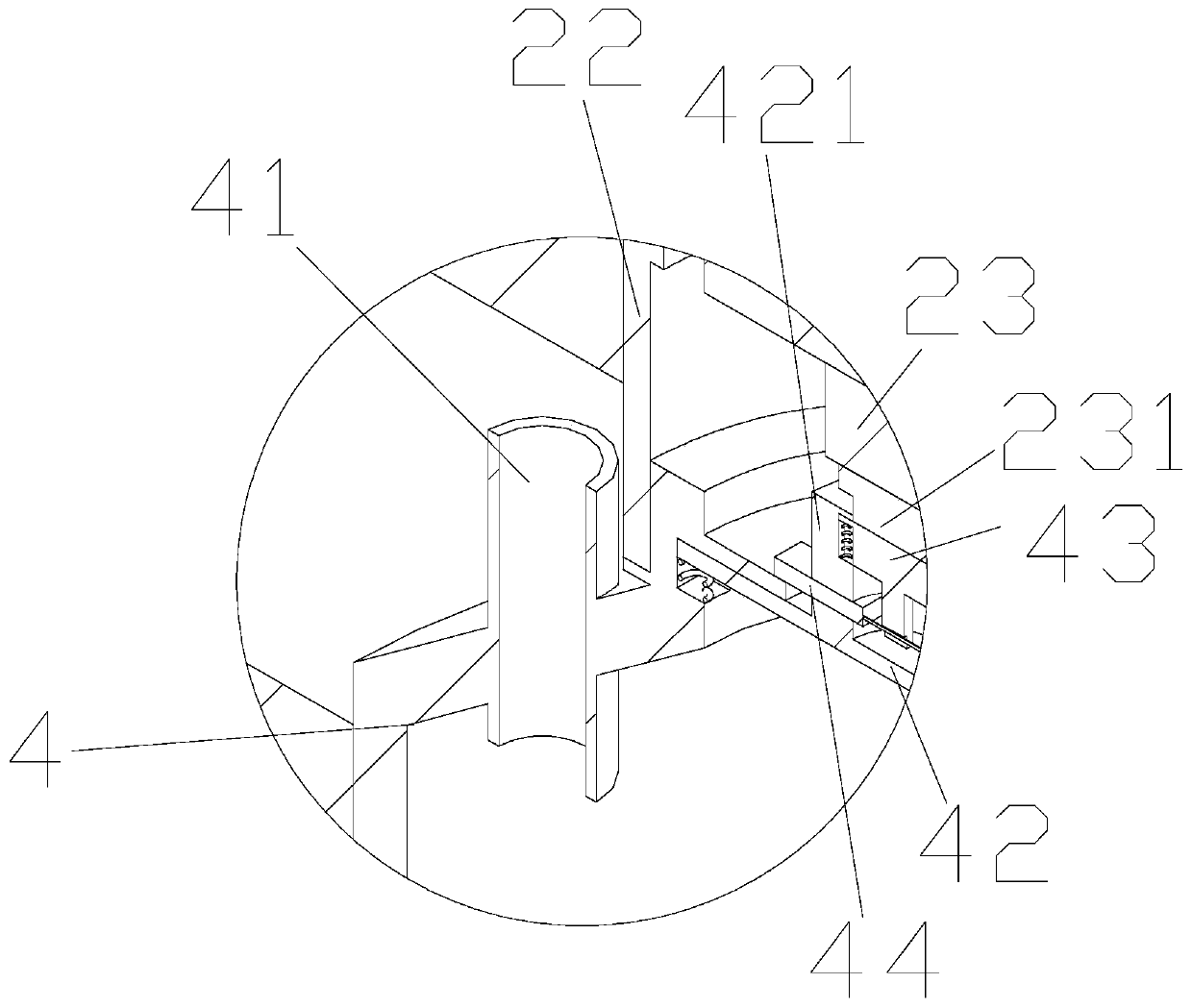

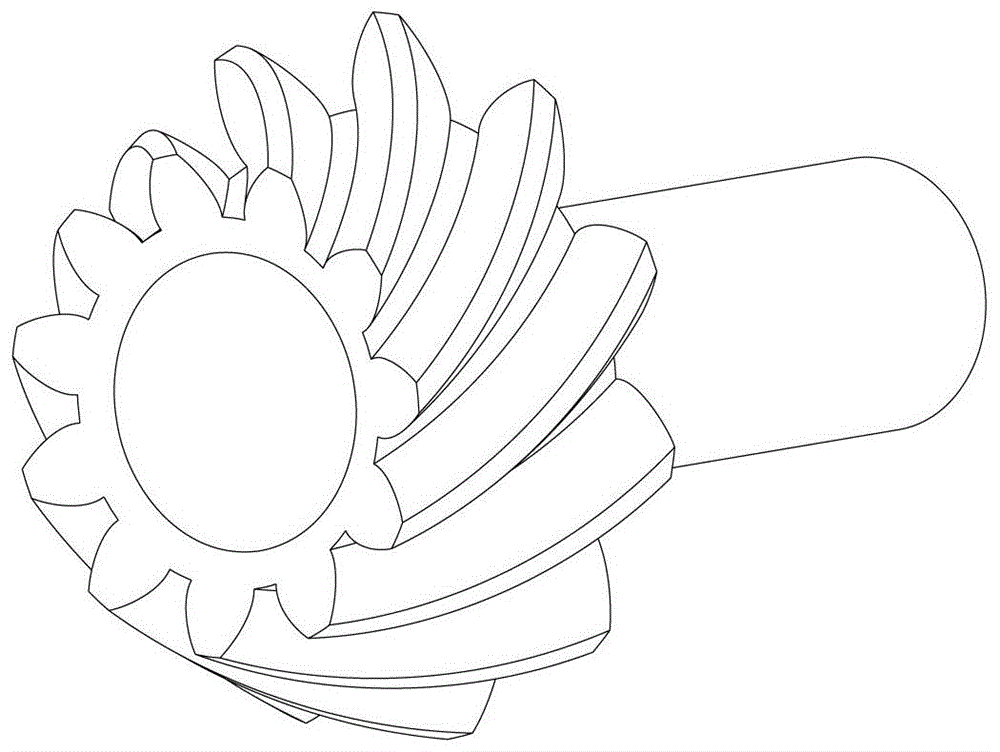

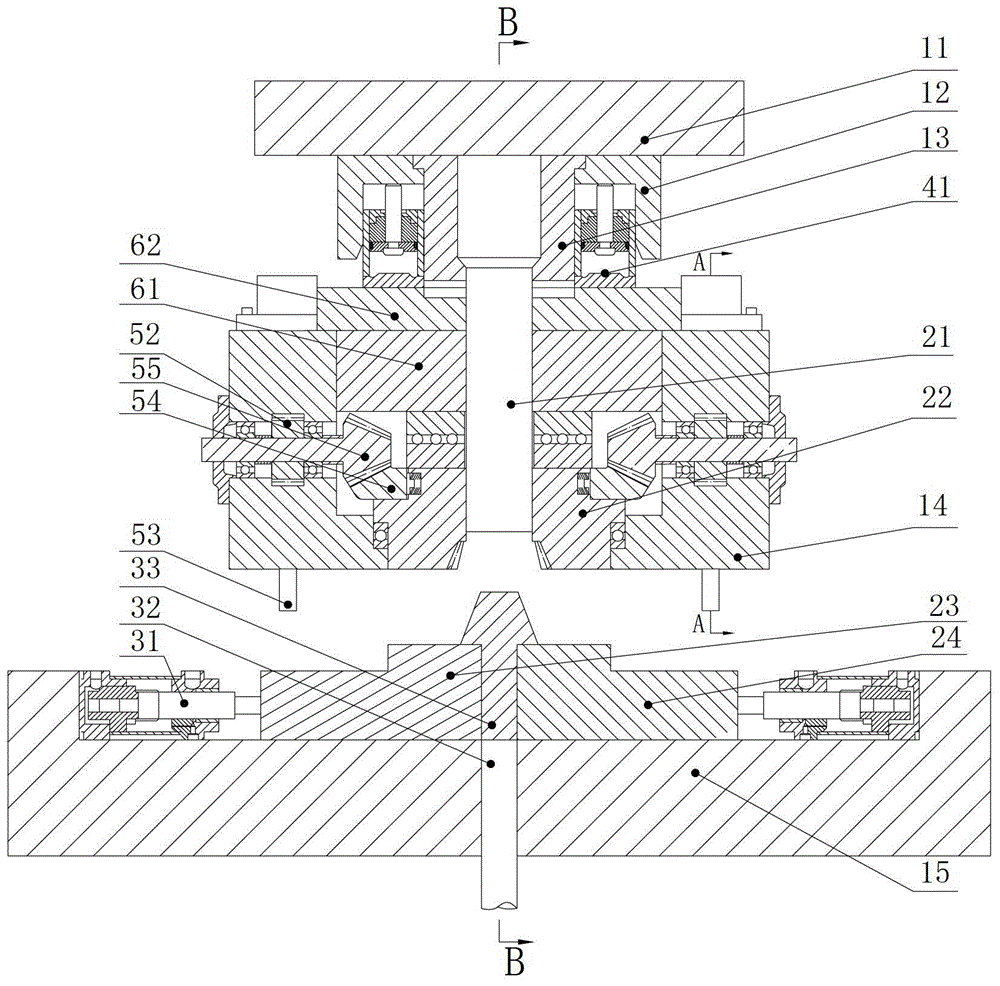

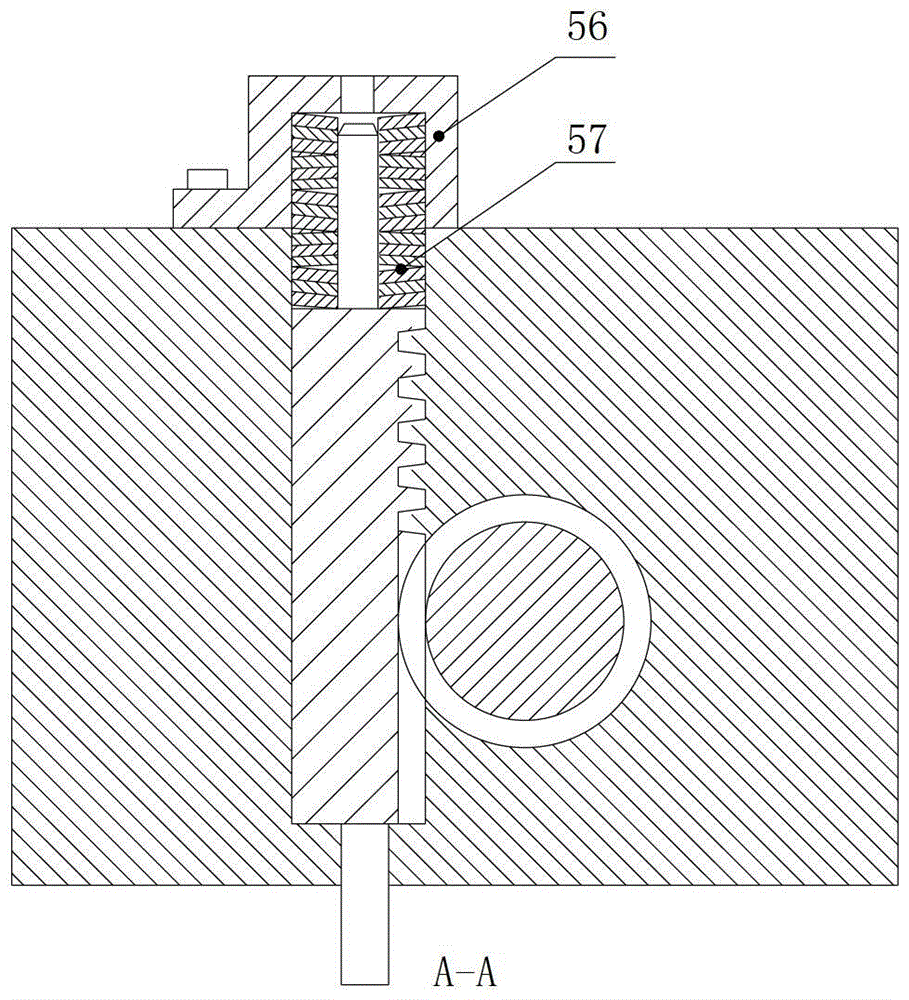

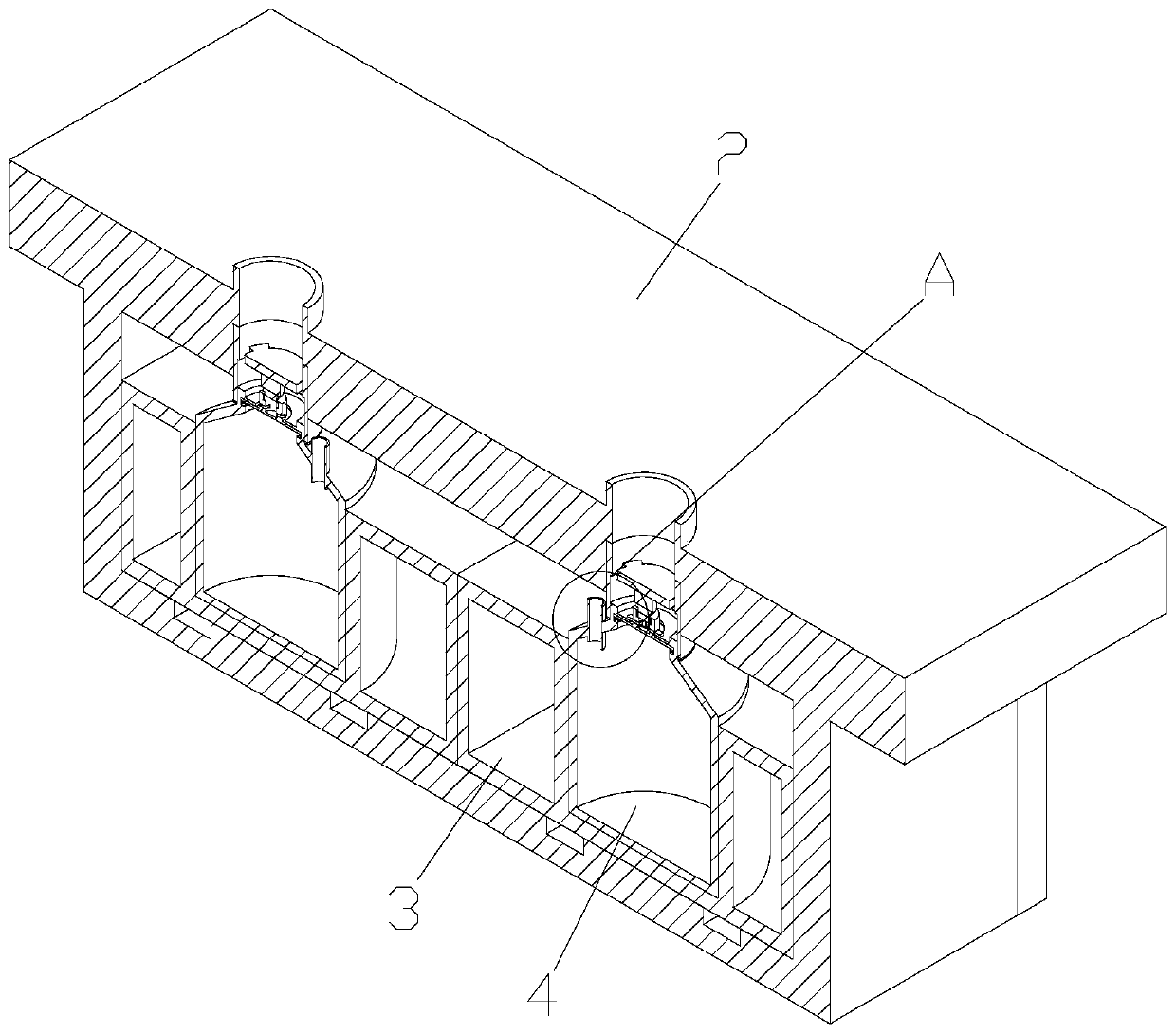

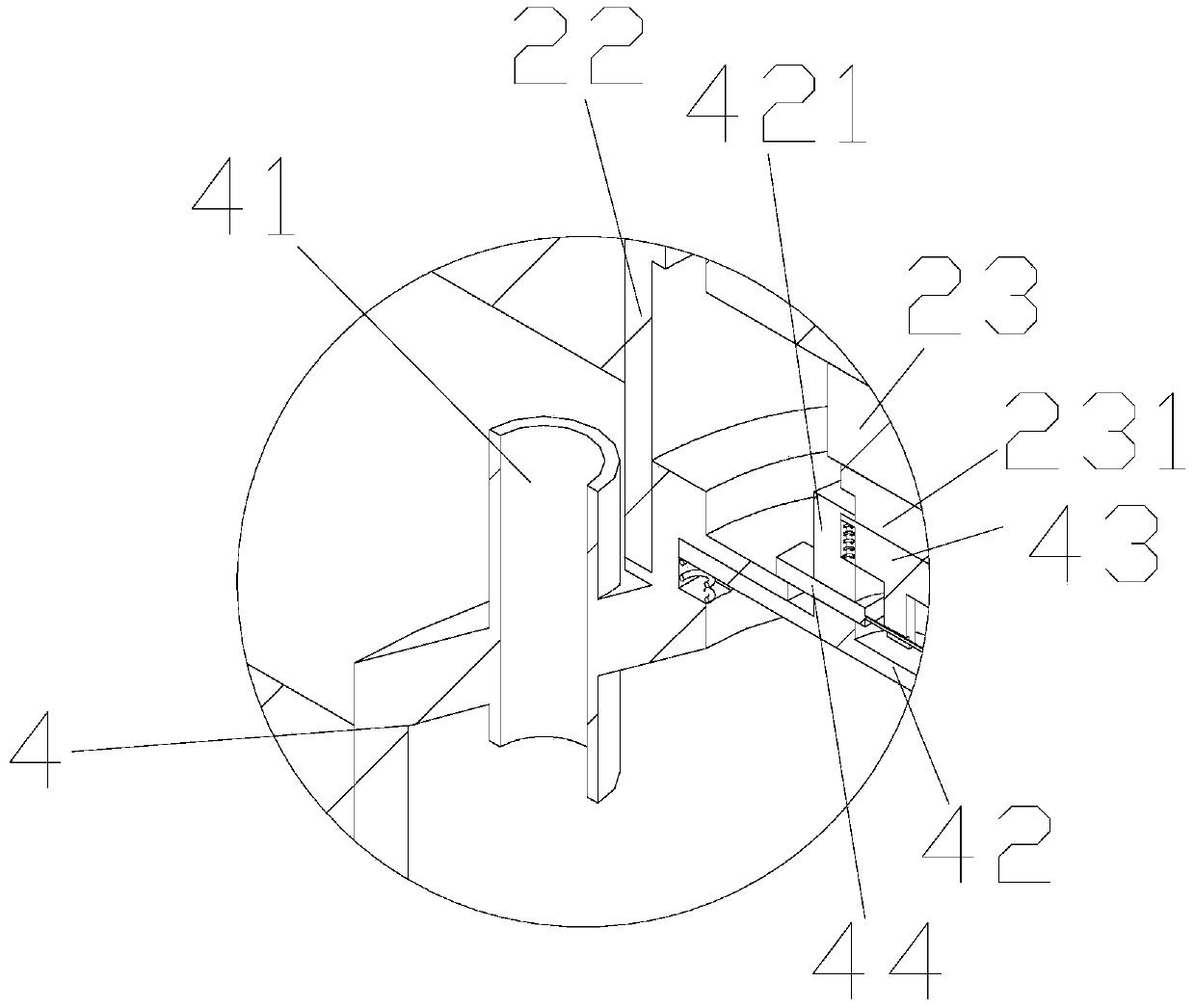

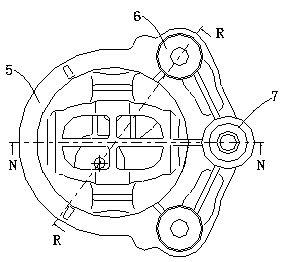

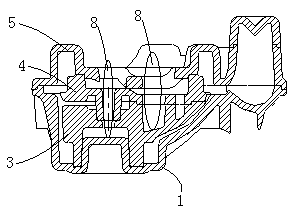

Precision forging device and method for spiral bevel gear

InactiveCN103433418AReduce the difficulty of fillingRealize positioning and lockingForging/hammering/pressing machinesWheelsEngineeringBevel gear

The invention relates to the field of spiral bevel gears, in particular to the field of precision forging of spiral bevel gears. The precision forging device comprises a die set, a convex die, a toothed die, a lower die, an elastic part, a rack, a straight toothed spur gear, a driving straight toothed bevel gear and a driven straight toothed bevel gear, wherein the die set serves as the main body for connecting the parts, the lower die is arranged under the toothed die, the convex die is arranged on the upper part of the toothed die, the lower die, the convex die and the toothed die are closed to form a hermetic cavity, a retaining mechanism is arranged between the driven straight toothed bevel gear and the toothed die to enable the driven straight toothed bevel gear to only drive the toothed die to rotate in one direction, the driving straight toothed bevel gear is meshed with the driven straight toothed bevel gear and is coaxially connected with the straight toothed spur gear, the straight toothed spur gear is meshed with the rack, and the elastic part is arranged above the rack. The precision forging device and the precision forging method realize that the toothed die only rotates during demolding and does not rotate during die assembling and forge piece forming, so that the die filling difficulty and demolding difficulty after forming of a spiral bevel gear in the precision forging process are reduced; the purposes that a preformed blank is located and locked during die assembling, and a finished forged piece does not rotate along with the toothed die during die splitting are realized.

Owner:CHINA AGRI UNIV

Metal rubber fabricated part and preparation thereof, and preparation method of metal rubber ring

PendingCN110345185AMeet preparationIncrease dampingElastic dampersShock absorbersPolymer scienceMetal rubber

The invention discloses a metal rubber fabricated part and a method thereof, and a preparation method of a metal rubber ring. The metal rubber fabricated part comprises a core body and a coating body,wherein the core body comprises a plurality of O-type weaving layers; each O-type weaving layer comprises a plurality of O-type structures formed by winding metal wires; the adjacent O-type structures of the adjacent layers incompletely coincide; the coating body coats the outer part of the core body, and comprises a plurality of first diagonal type weaving layers; each first diagonal type weaving layer is formed by winding metal wires in the same inclining direction; and the metal wires between the adjacent first diagonal type weaving layers form a first X-type structure. The metal rubber fabricated part is not filled with a die or a weaving process ruler, so that the preparation of the large metal rubber fabricated part is met. The invention also provides the preparation of the metal rubber ring. A metal rubber blank part is formed by winding the meal rubber fabricated part on a core shaft and weaving the metal rubber fabricated part, and is subjected to compression moulding to formthe metal rubber ring. Through the adoption of the method, layering and cracking of metal rubber can be avoided.

Owner:BEIJING XINGJI RONGYAO SPACE TECH CO LTD

Phase-change memory and method for manufacturing same

ActiveCN104518084AThermal insulationReduce processing costsElectrical apparatusPhase-change memoryMask layer

Owner:SEMICON MFG INT (SHANGHAI) CORP

Method for filling electroplated copper

InactiveCN110473828AGuaranteed thicknessReduce solubilitySemiconductor/solid-state device manufacturingCopper oxideSeed crystal

The invention discloses a method for filling electroplated copper, comprising the steps of 1, forming a trench or a through hole; 2, forming a copper seed crystal layer on the inner surface of the trench or the via hole; 3, oxidizing the surface of the copper seed crystal layer to form copper oxide during the waiting time between the formation of the copper seed crystal layer and the copper electroplating process in the next step; 4, performing a reduction process before the copper electroplating process, and then performing the copper electroplating process to fill the trench or the through hole with the copper layer. The method, by performing the reduction process before the copper electroplating process, can eliminate the copper oxide on the surface of the copper seed crystal layer during the copper electroplating process and keep the thickness of the copper seed crystal layer at various positions on the inner surface of the trench or the through hole, thereby reducing the difficulty of the electroplated copper filling process and improving the electroplated copper filling ability.

Owner:SHANGHAI HUALI INTEGRATED CIRCUTE MFG CO LTD

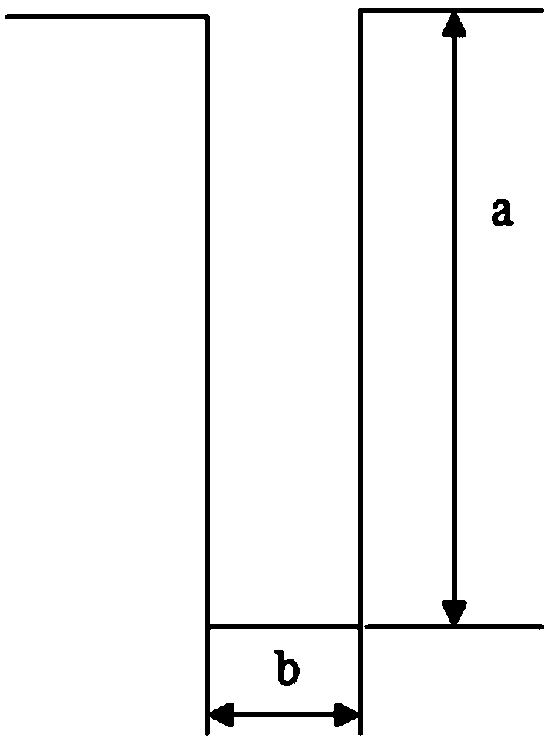

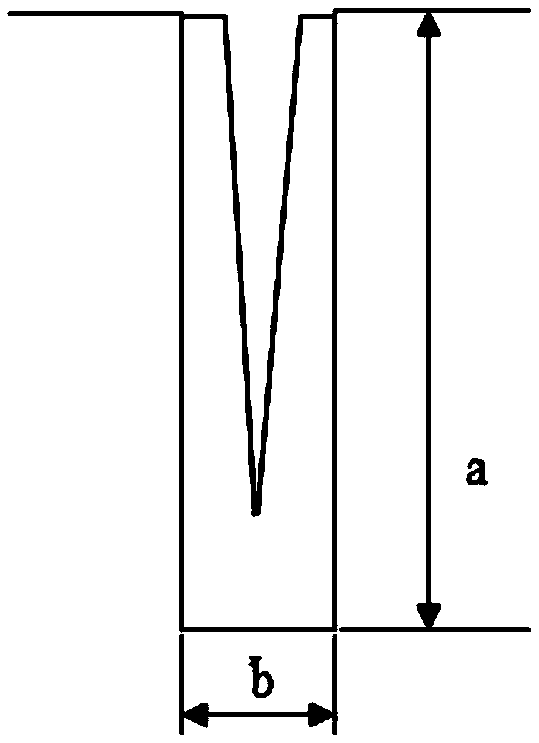

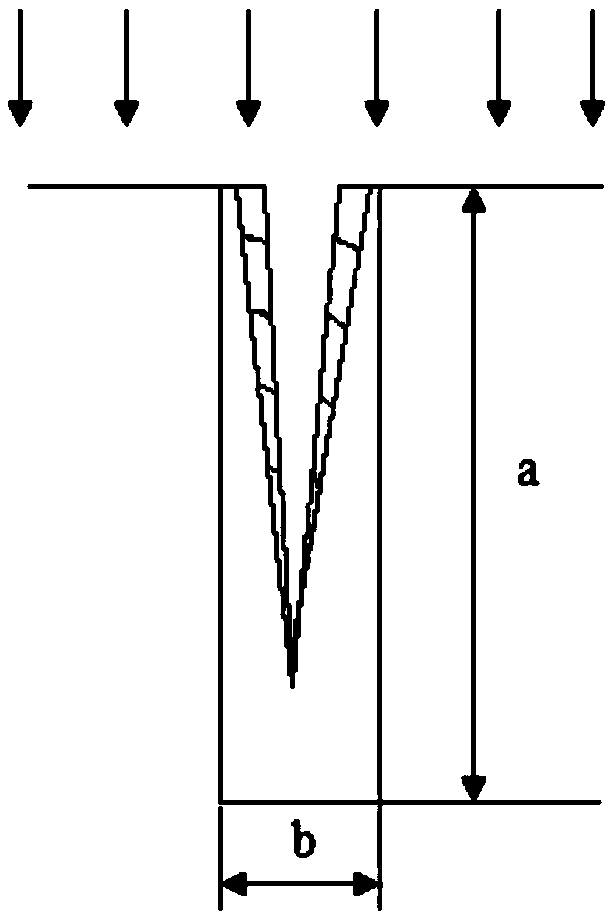

Through hole manufacturing method beneficial to filling

InactiveCN107170708AReduce the difficulty of fillingReduce negative impactSemiconductor/solid-state device manufacturingProcess windowSilicon dioxide

The invention provides a through hole manufacturing method beneficial to filling. An etch stop layer, an inner layer dielectric layer and an antireflection layer are deposited on the surface of a semiconductor device in sequence; a first through hole is etched in the antireflection layer, the inner layer dielectric layer and a part of etch stop layer; the bottom of the first through hole is etched to reach a silicon dioxide layer to form second through hole; the second through hole is filled with an antireflection material; a third through hole, the outlet caliber of which is greater than that of the second through hole, is photo-etched; the bottom of the third through hole is etched to reach the silicon dioxide layer of the semiconductor device to form a fourth through hole; the residual antireflection material in the fourth through hole is removed to form a fifth through hole; and the fifth through holes is continuously etched. According to the through hole manufacturing method provided by the invention, the key dimensions of the upper part through holes are enlarged to form a through hole appearance with a relatively large opening, thereby reducing negative influences to the subsequent process caused by high-aspect ratio, further lowering through hole filling difficulty caused by subsequent metal tungsten, and enlarging the subsequent process window.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

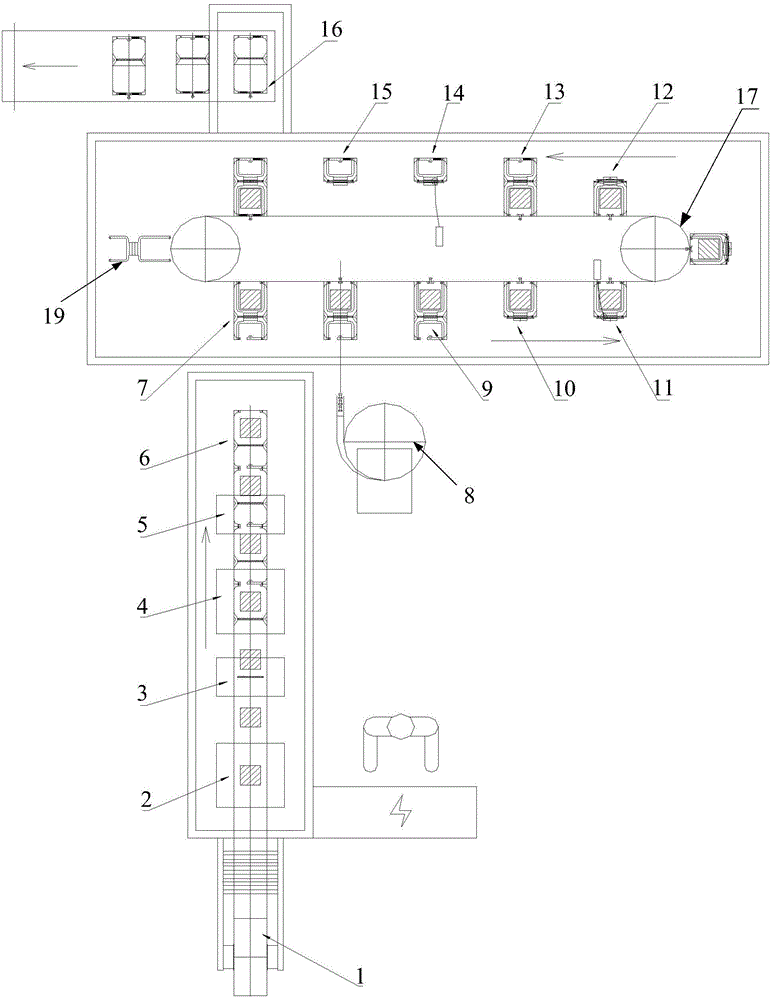

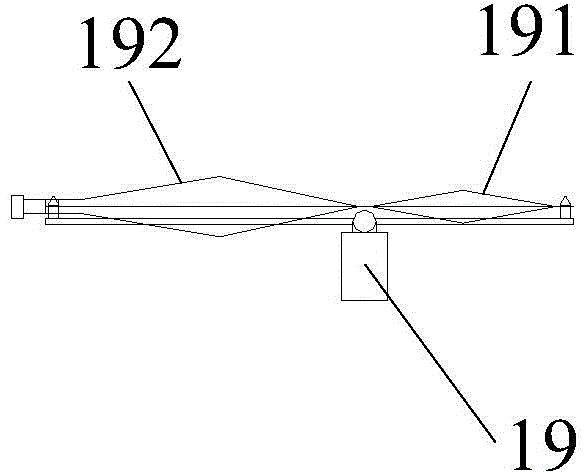

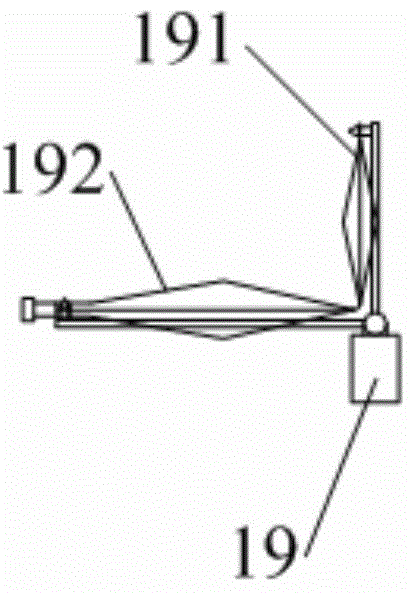

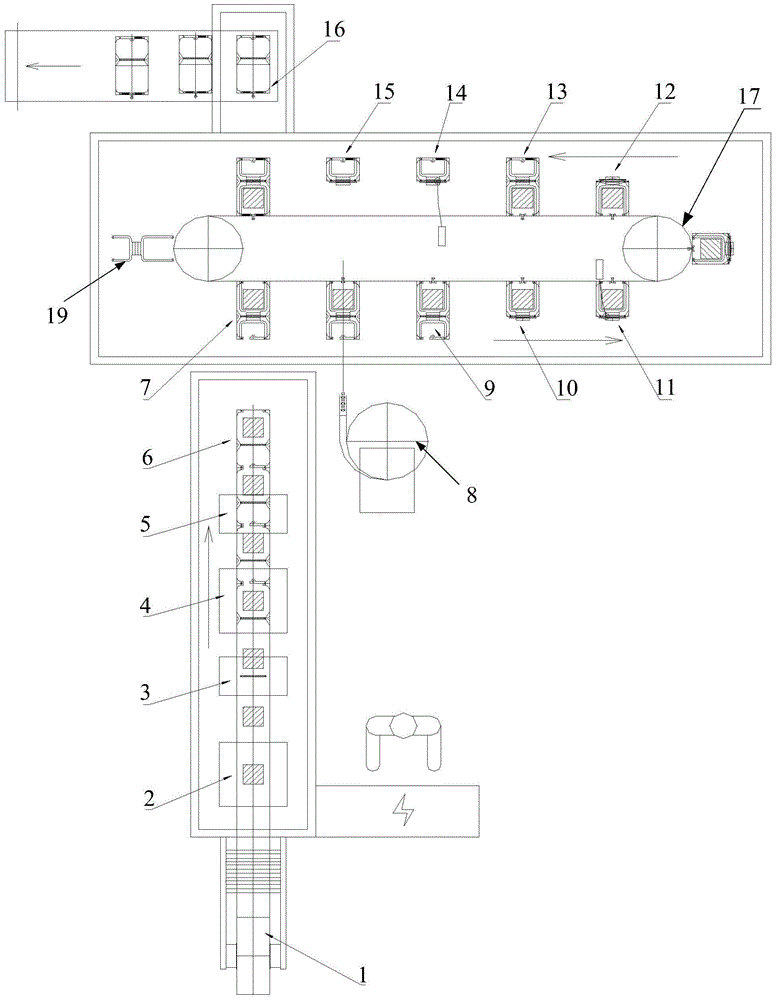

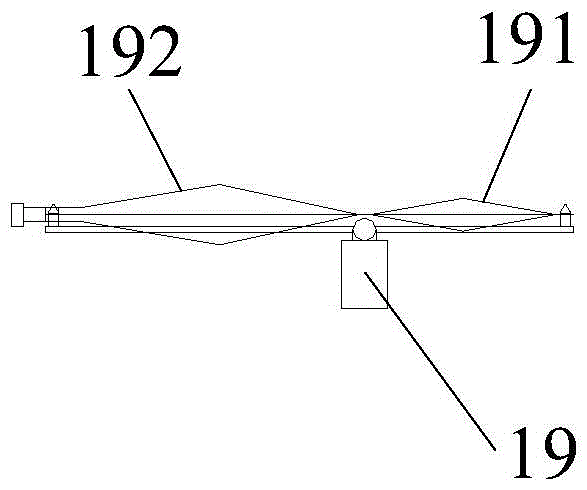

Multi-chamber soft infusion bag production line

ActiveCN104443467AReduce the difficulty of fillingShorten the lengthLiquid materialProduction lineEngineering

The invention provides a multi-chamber soft infusion bag production line. A film material is conveyed and formed through a bag making machine so as to be filled. The middle of a soft infusion bag is welded to a weld joint through a weld joint welding device, wherein the weld joint is arranged in the width direction. The soft infusion bag is divided into two parts in the length direction and horizontally clamped through a filling and sealing machine, a first bag body and a second bag body of the soft infusion bag are turned over to filling positions in the vertical direction through filling and sealing clamps, the first bag body is welded and sealed through a first filling device and a first sealing mold after being filled, and similarly, the second bag body is filled and sealed through a second filling device and a second sealing mold after the second bag body of the soft infusion bag is turned over. Due to the fact that the soft infusion bag is divided into the two parts in the length direction and clamped through the filling and sealing clamps, the two bag bodies are filled and sealed respectively, the length of the weld joint is decreased, cold joint quality is improved, the filling difficulty of the soft infusion bag is lowered, the structure is simple, and operation is stable.

Owner:SHINVA MEDICAL INSTR CO LTD

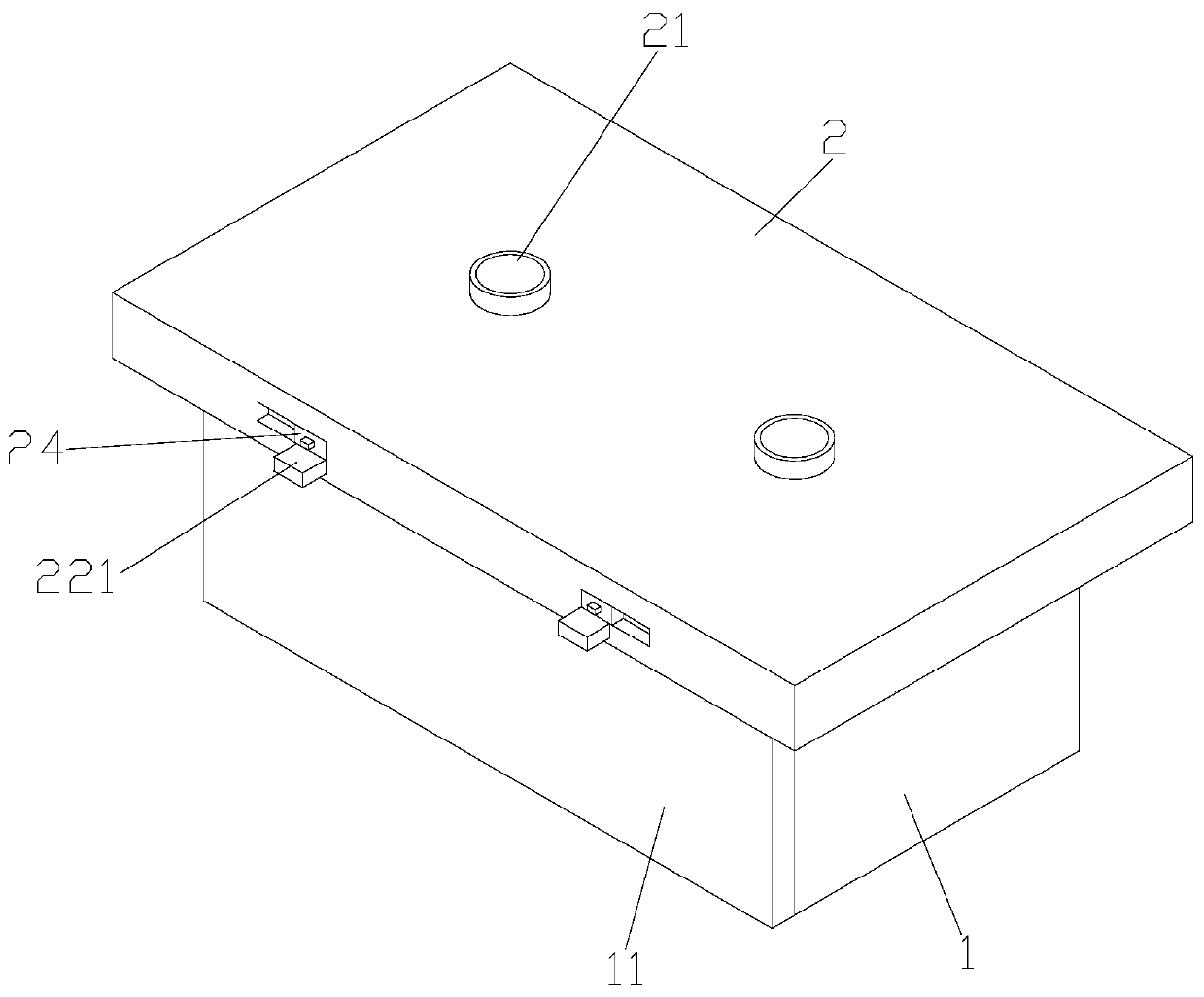

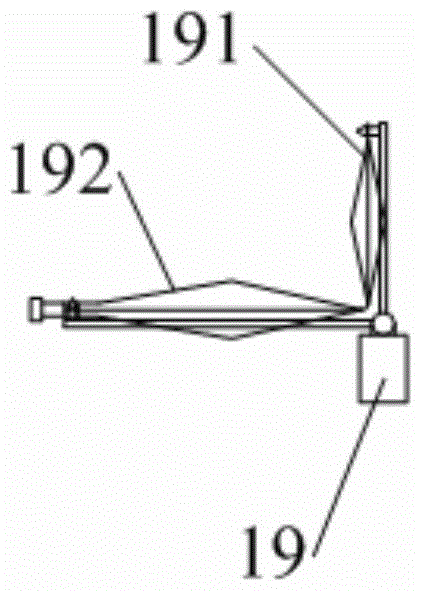

Operating table of laboratory incubator for placing embryos of flocks and herds

ActiveCN110639634AReduce the difficulty of fillingBiochemistry apparatusLaboratory benches/tablesExperimental laboratoryHerd

The invention discloses an operating table of a laboratory incubator for placing embryos of flocks and herds. The operating table comprises a base and a platform arranged on the base, wherein the baseis provided with a cavity, a gas storage cylinder is arranged in the cavity, a door plate is rotatably connected onto the sidewall of the cavity, a carrier block is arranged in the cavity, a mountinggroove matched with the gas storage cylinder is formed in the carrier block, roller wheels are arranged at the bottom of the carrier block, first movement grooves matched with the roller wheels are formed in the bottom of the cavity, a bevel face is formed at one end of each first movement groove, and a first connecting pipe communicating with the gas storage cylinder is arranged on the platform.The gas storage cylinder is directly placed in the cavity, pipelines are not required to be specially laid for the gas storage cylinder, influence on utilization of space in a laboratory caused by the pipelines is avoided, the gas storage cylinder can be directly drawn out from the cavity so as to clean a cylinder body, and thus, the difficulty of cleaning of the gas storage cylinder is lowered.

Owner:ZHEJIANG UNIV

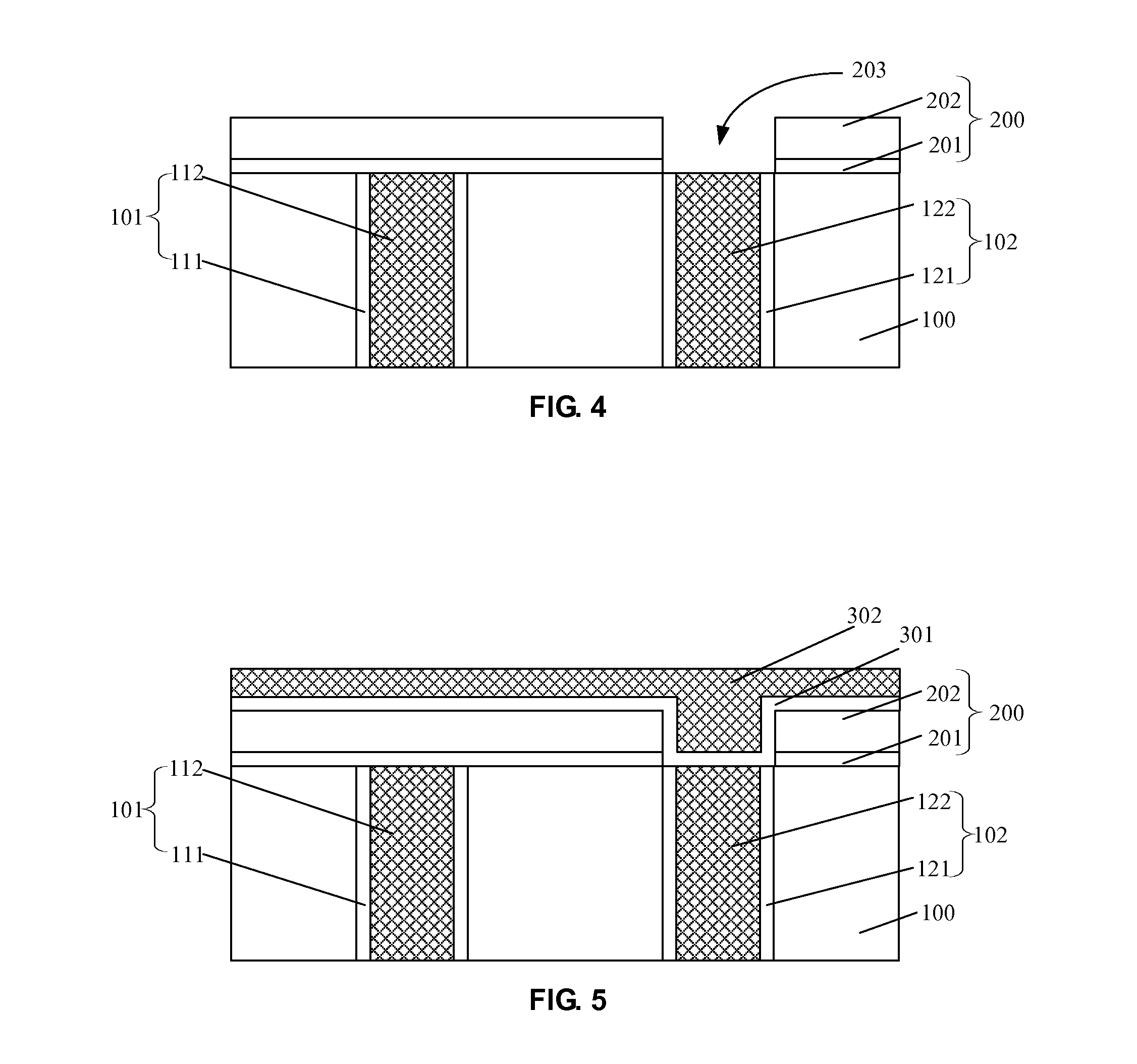

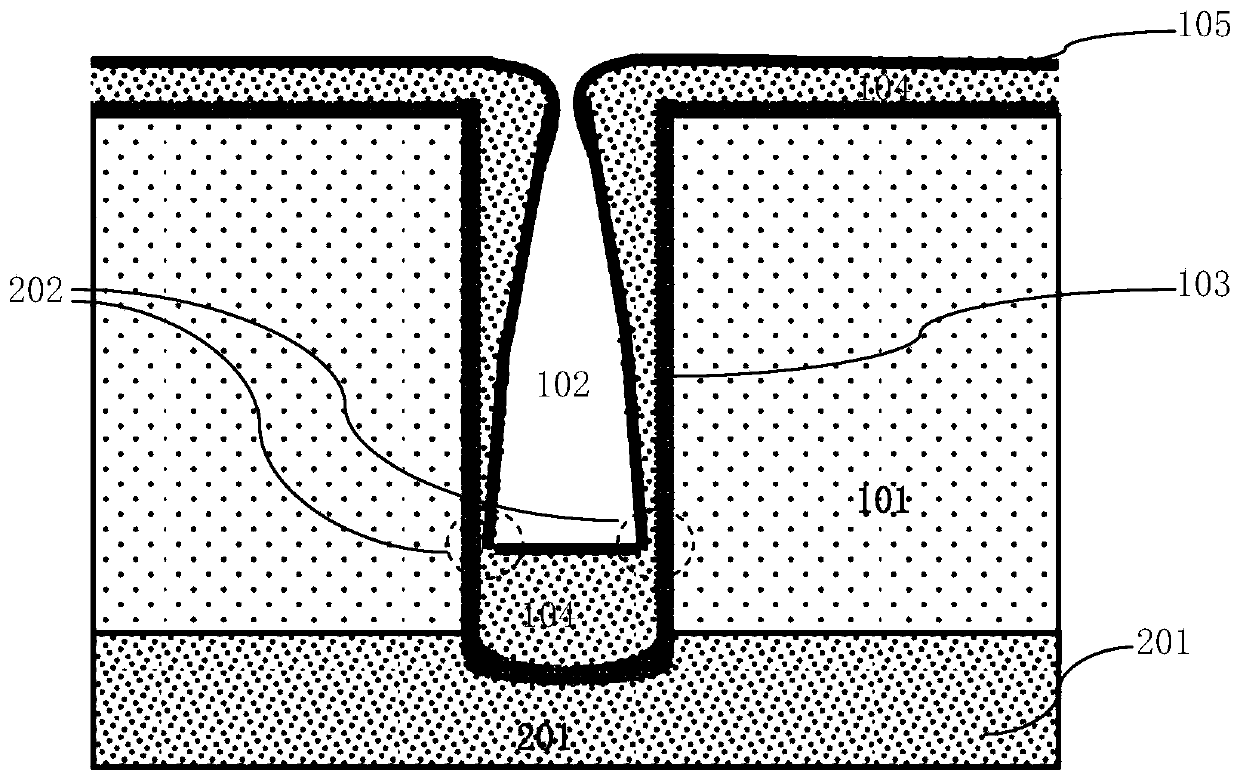

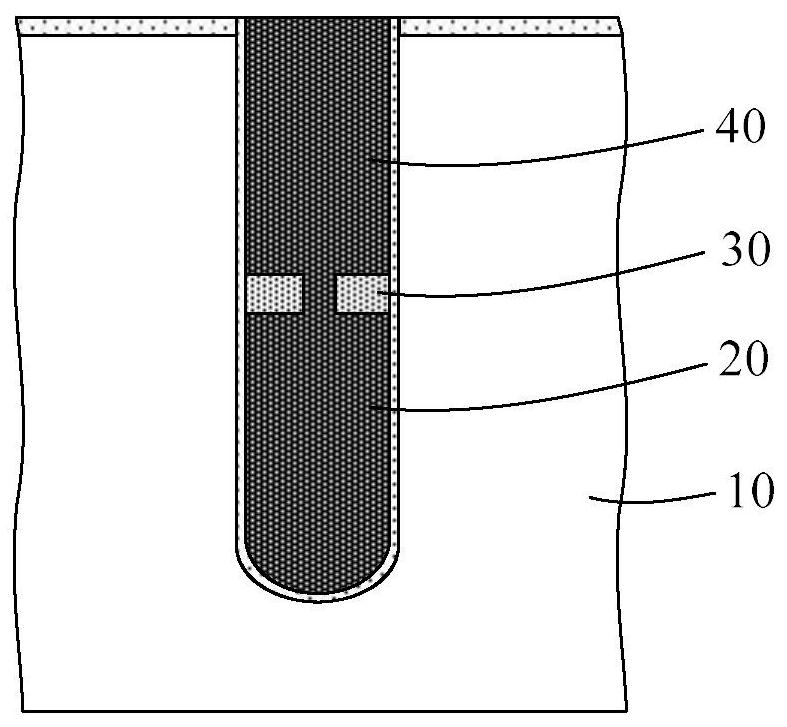

Shielded gate field effect transistor and method of forming the same

ActiveCN111180341BReduce the difficulty of fillingEasy to fillSemiconductor/solid-state device manufacturingSemiconductor devicesIsolation layerEngineering

The present invention provides a shielded gate field effect transistor and a method for forming the same. After the shielding electrode is formed, an isolation spacer with decreasing thickness from bottom to top is formed on the sidewall of the gate trench higher than the shielding electrode, so that the topography of the upper trench located above the shielding electrode is modified by the isolation spacer. In this way, the filling difficulty of the insulating filling layer can be reduced, and the filling performance of the insulating filling layer in the upper trench can be improved to avoid the occurrence of voids, and further, when the insulating filling layer is subsequently etched to form the isolation layer, a gap-free isolation layer can be formed to ensure the gate. Mutual isolation between electrode and shield electrode.

Owner:SEMICON MFG ELECTRONICS (SHAOXING) CORP

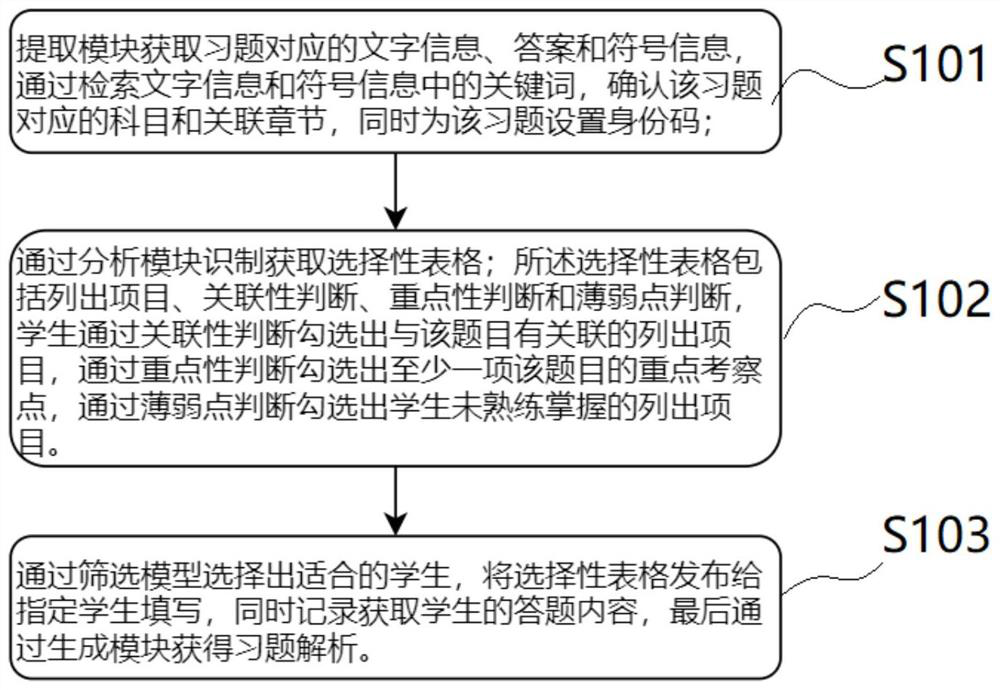

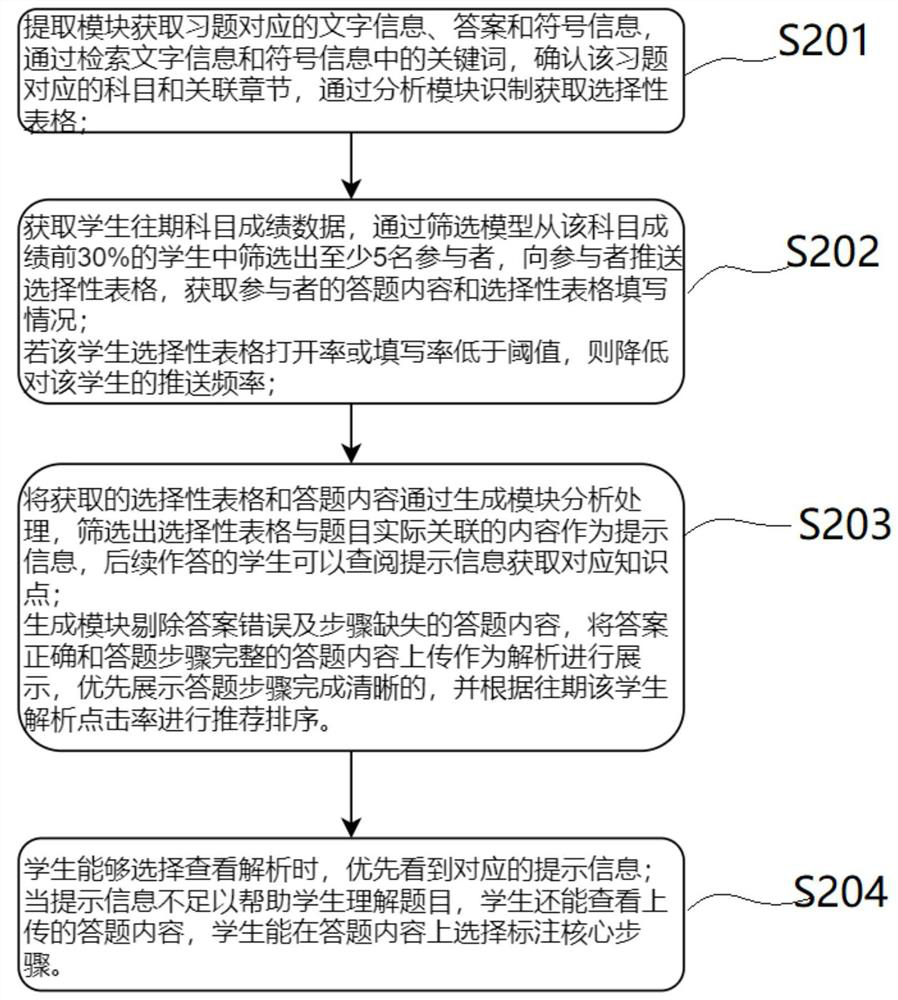

Exercise analysis processing method and device and storage medium

PendingCN114692586AReduce the difficulty of fillingImprove filling efficiencyNatural language data processingResourcesEngineeringTextual information

The invention discloses an exercise analysis processing method, which comprises the following steps that: an extraction module obtains character information, answers and symbol information corresponding to exercises, and confirms subjects and associated chapters corresponding to the exercises by searching keywords in the character information and the symbol information; making a selective table through an analysis module; proper students are selected through the pushing module, a selective table is published to the designated students to fill in, meanwhile, the answer content of the students is recorded and obtained, and finally exercise analysis is obtained through the generation module. According to the method, students can be actively invited to participate, the system confirms chapters and subjects corresponding to exercises and sets identity codes IDs, matching retrieval of other students next time is facilitated, and repeated analysis processing is not needed; the analysis module recognizes the character information and the symbol information to automatically generate the selective table, and the table form is adopted, so that the filling difficulty of participated students is low, the filling efficiency is high, and the students can participate in the table form only by increasing little time additionally.

Owner:广州宏途数字科技有限公司

Semiconductor isolation structure and manufacturing method thereof

ActiveCN112071900BImprove performanceQuick removalSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialDielectric layer

The invention provides a semiconductor isolation structure and a manufacturing method thereof. According to the manufacturing method, a plurality of grooves are formed in the semiconductor substrate,then a pull-back process is executed to enable the side walls of a pad oxide layer and a hard mask layer on the semiconductor substrate to shrink inwards, the grooves are filled with the first isolation dielectric layer, and then an ion implantation process is executed to enable the upper portion of the first isolation dielectric layer to form a modified area. The depth of the modified area is greater than or equal to the total thickness of the pad oxide layer and the hard mask layer, a part of the first isolation dielectric layer in the modified area is removed by soaking with an etching solution, holes in the first isolation dielectric layer are opened or even removed, and the second isolation dielectric layer is filled in the grooves, so that the holes in the isolation dielectric in thegrooves can be reduced, and the performance of the semiconductor device is improved. The groove filling quality and the performance of the semiconductor isolation structure are improved. The semiconductor isolation structure is obtained by using the manufacturing method.

Owner:晶芯成(北京)科技有限公司

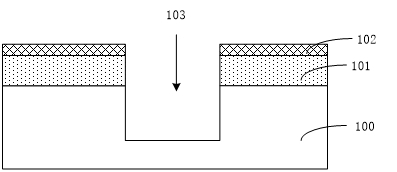

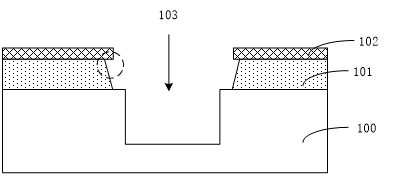

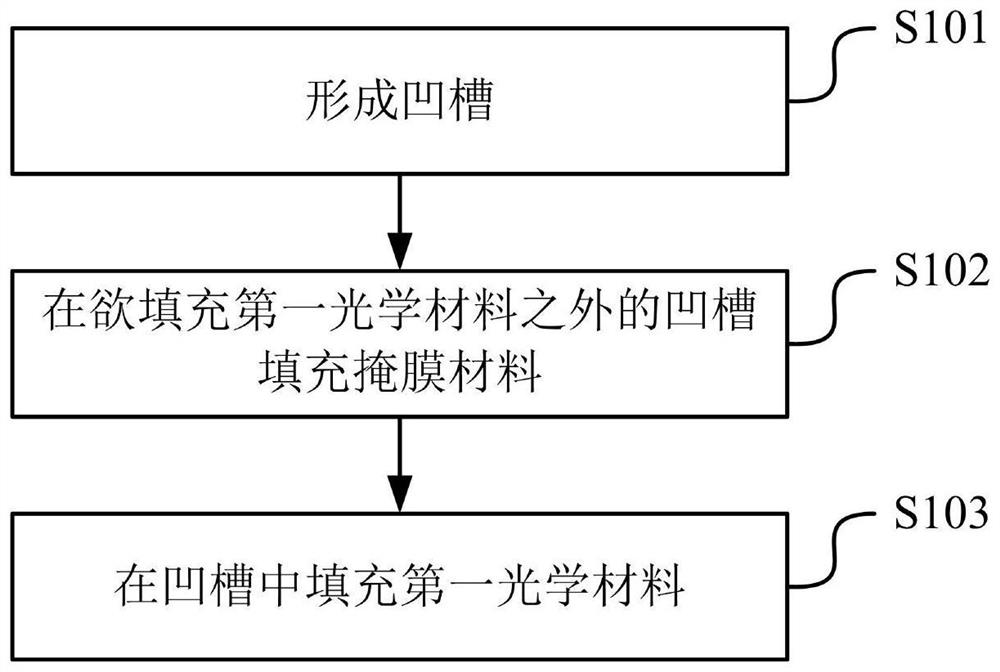

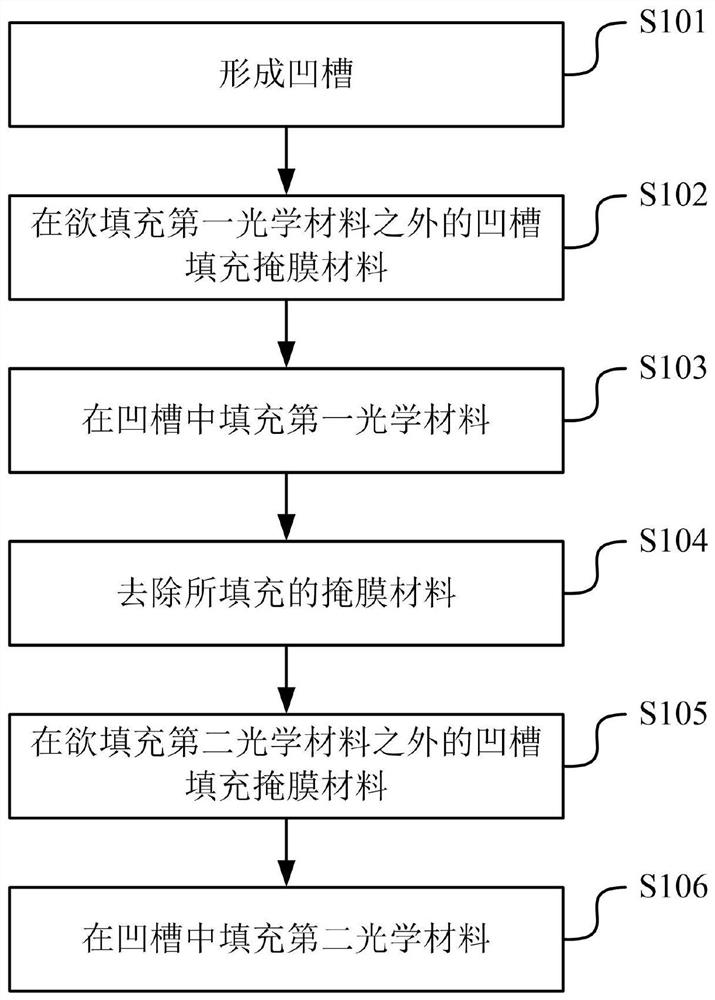

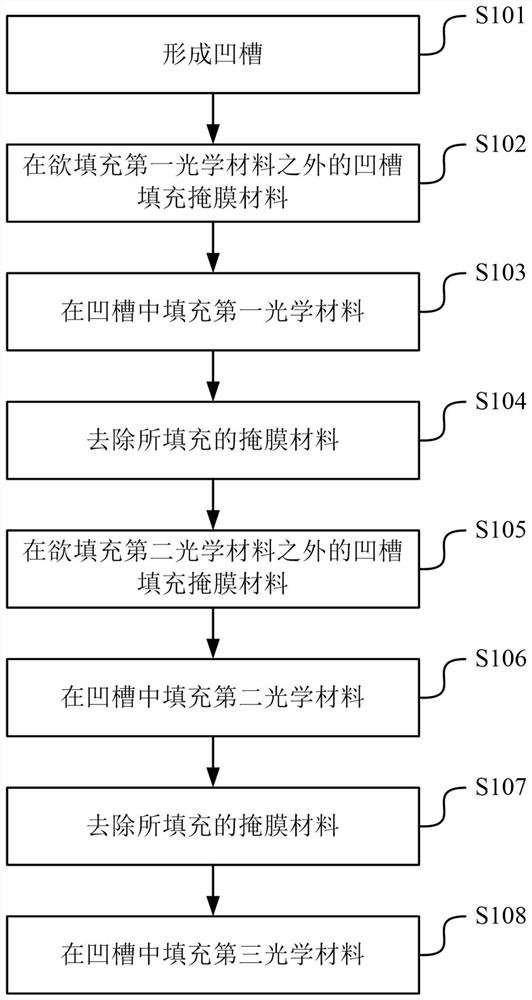

Optical material filling method and device

PendingCN114093986AReduce the difficulty of fillingSolid-state devicesSemiconductor devicesMaterials scienceOptical materials

The invention discloses an optical material filling method and device. The method comprises the steps of forming grooves; filling grooves except grooves to be filled with first optical materials with mask materials; and filling the grooves with the first optical materials . According to the scheme provided by the invention, the filling difficulty of the optical material is reduced to a certain extent.

Owner:BEIJING IVISUAL 3D TECH CO LTD

A precision forging device and method for a spiral bevel gear

InactiveCN103433418BReduce the difficulty of fillingRealize positioning and lockingForging/hammering/pressing machinesWheelsEngineeringBevel gear

The invention relates to the field of spiral bevel gears, in particular to the field of precision forging of spiral bevel gears. The precision forging device comprises a die set, a convex die, a toothed die, a lower die, an elastic part, a rack, a straight toothed spur gear, a driving straight toothed bevel gear and a driven straight toothed bevel gear, wherein the die set serves as the main body for connecting the parts, the lower die is arranged under the toothed die, the convex die is arranged on the upper part of the toothed die, the lower die, the convex die and the toothed die are closed to form a hermetic cavity, a retaining mechanism is arranged between the driven straight toothed bevel gear and the toothed die to enable the driven straight toothed bevel gear to only drive the toothed die to rotate in one direction, the driving straight toothed bevel gear is meshed with the driven straight toothed bevel gear and is coaxially connected with the straight toothed spur gear, the straight toothed spur gear is meshed with the rack, and the elastic part is arranged above the rack. The precision forging device and the precision forging method realize that the toothed die only rotates during demolding and does not rotate during die assembling and forge piece forming, so that the die filling difficulty and demolding difficulty after forming of a spiral bevel gear in the precision forging process are reduced; the purposes that a preformed blank is located and locked during die assembling, and a finished forged piece does not rotate along with the toothed die during die splitting are realized.

Owner:CHINA AGRI UNIV

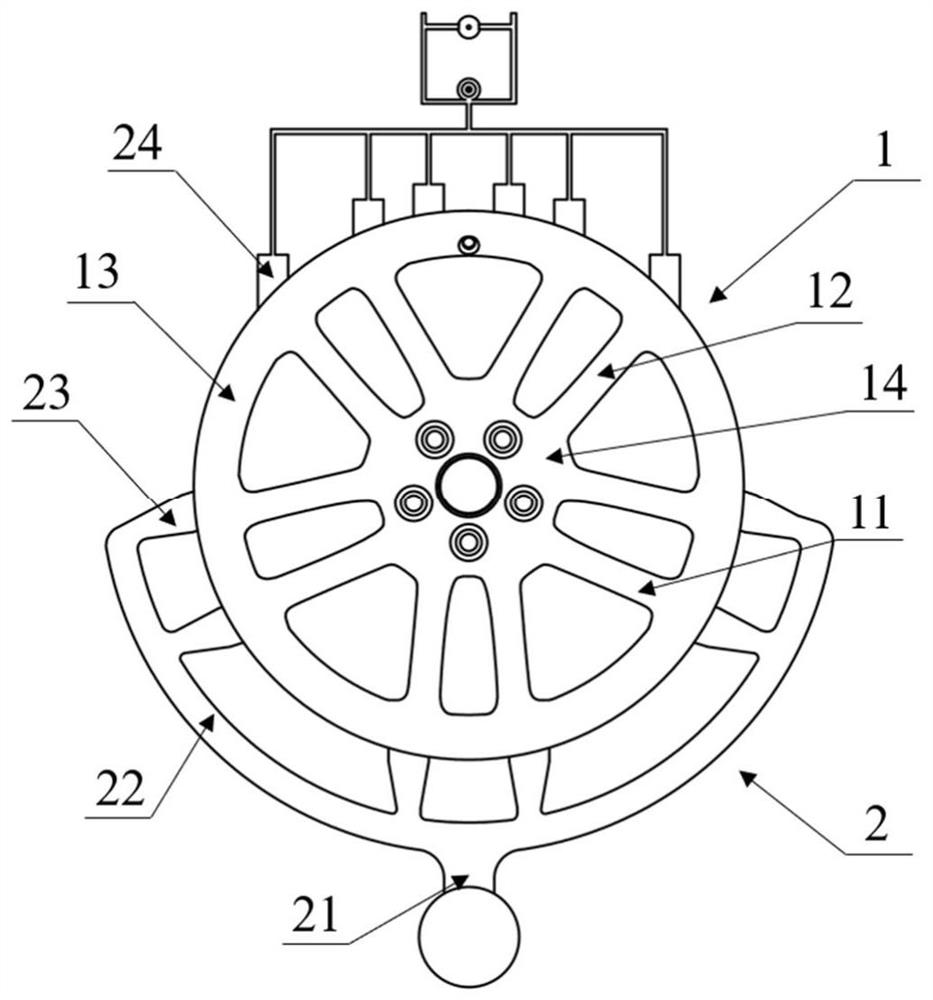

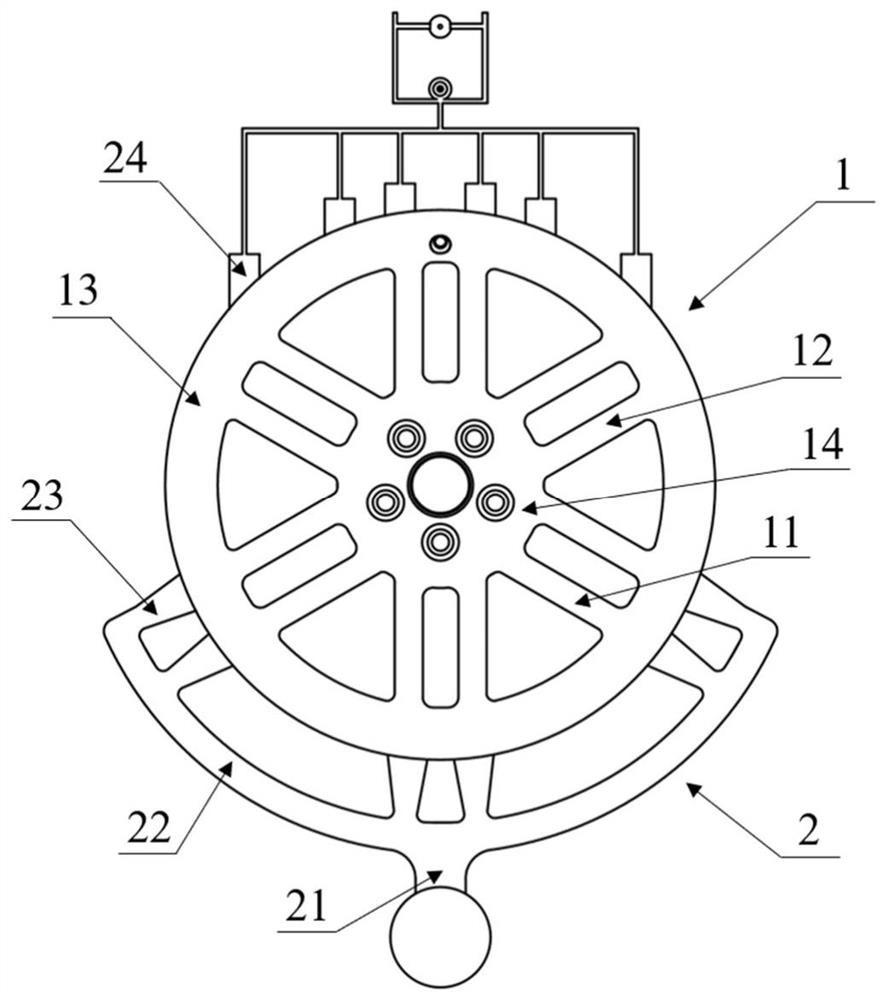

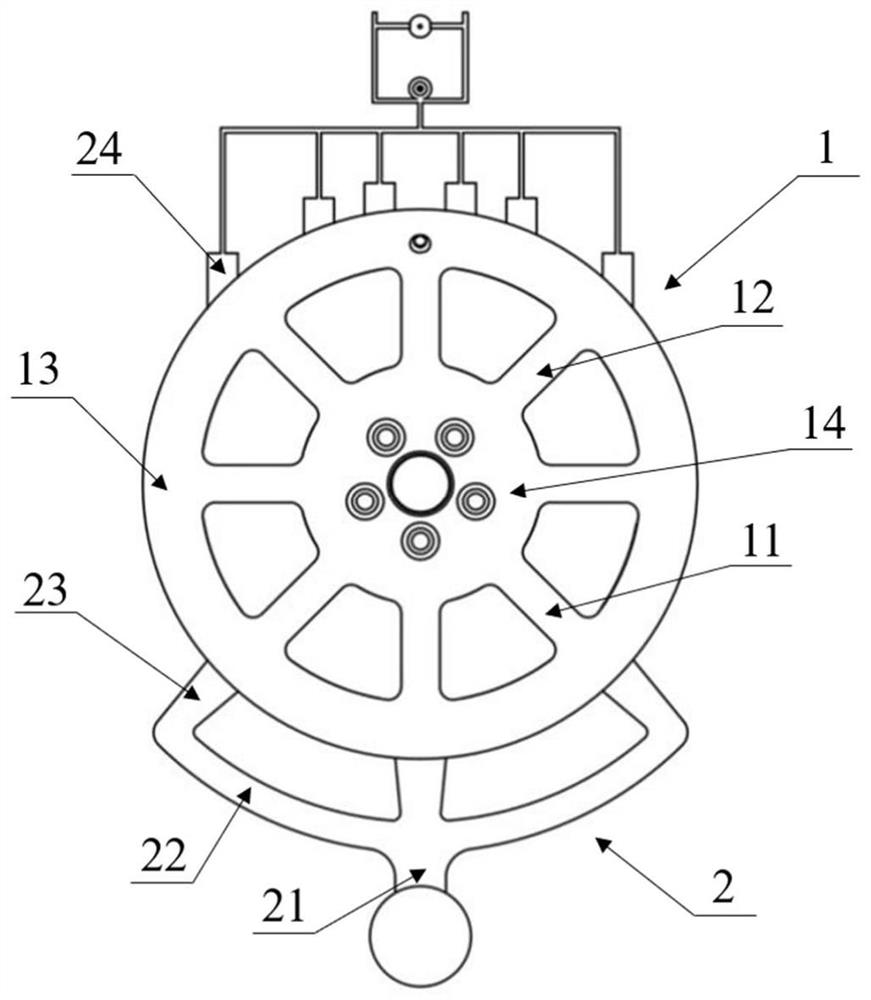

Spoke casting mold, vacuum die-casting forming system and spoke manufacturing method

ActiveCN114850440AEasy to drive awayIncrease vacuumRolling resistance optimizationMold fillingEngineering

The invention belongs to the field of metal casting machining, and discloses a spoke casting mold, a vacuum die-casting forming system and a spoke manufacturing method.The spoke casting mold comprises a mold cavity and a pouring system; the mold cavity is matched with the spoke in shape and comprises a first spoke casting cavity, a second spoke casting cavity and an annular spoke edge casting cavity; the pouring system comprises a main pouring gate, a transverse pouring gate communicated with the main pouring gate, inner pouring gates communicated with the transverse pouring gate and the spoke edge casting cavity and an overflow groove, the transverse pouring gate is in an inferior arc shape and arranged on the periphery of the spoke edge casting cavity, the number of the inner pouring gates is equal to that of the first spoke casting cavities, each inner pouring gate directly faces one first spoke casting cavity, and the overflow groove is communicated with the transverse pouring gate. The overflow groove is formed in the outer edge of the side, away from the cross gate, of the spoke edge casting cavity. The invention provides a pouring system for unidirectionally flowing from one end of a spoke to the other end of the spoke, so that gas in a cavity can be conveniently expelled and pumped away in the mold filling process of molten metal, the vacuum degree in the cavity is improved, the defect of casting air holes is eliminated, and the subsequent welding process with a rim is facilitated.

Owner:HUAZHONG UNIV OF SCI & TECH +1

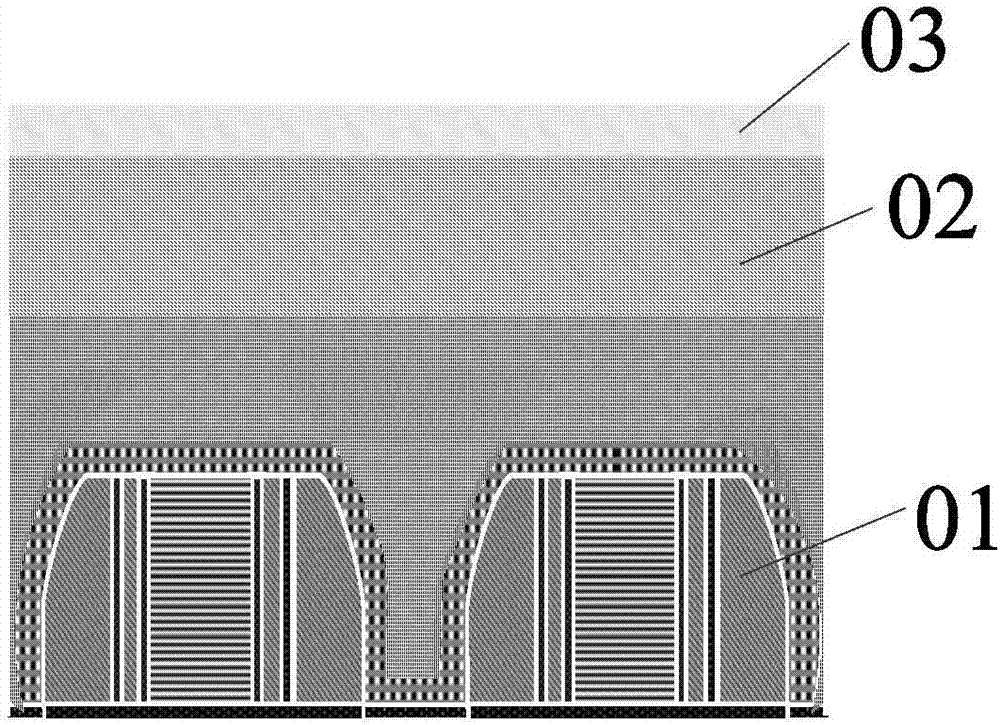

Method of forming embolism and hole

InactiveCN1453846AReduce the difficulty of fillingReduce thicknessSemiconductor/solid-state device manufacturingSemiconductor devicesOptoelectronicsMetal

The present invention discloses one manufacture process capable of avoiding un-landed phenomenon caused by error aligning. The process includes providing one substrate with formed metal layer and anti-reflecting layer; forming one spin-on glass layer on the anti-reflecting layer; defining several metal wires produced through etching the metal layer, the anti-reflecting layer and the spin-on glass layer; depositing oxide layer on the substrate to cover the metal wires; and defining several embolism hole via etching the oxide layer. The spin-on glass layer may be replaced with one dye spin-onglass layer, and in this case the step of forming anti-reflecting layer may be omitted.

Owner:MACRONIX INT CO LTD

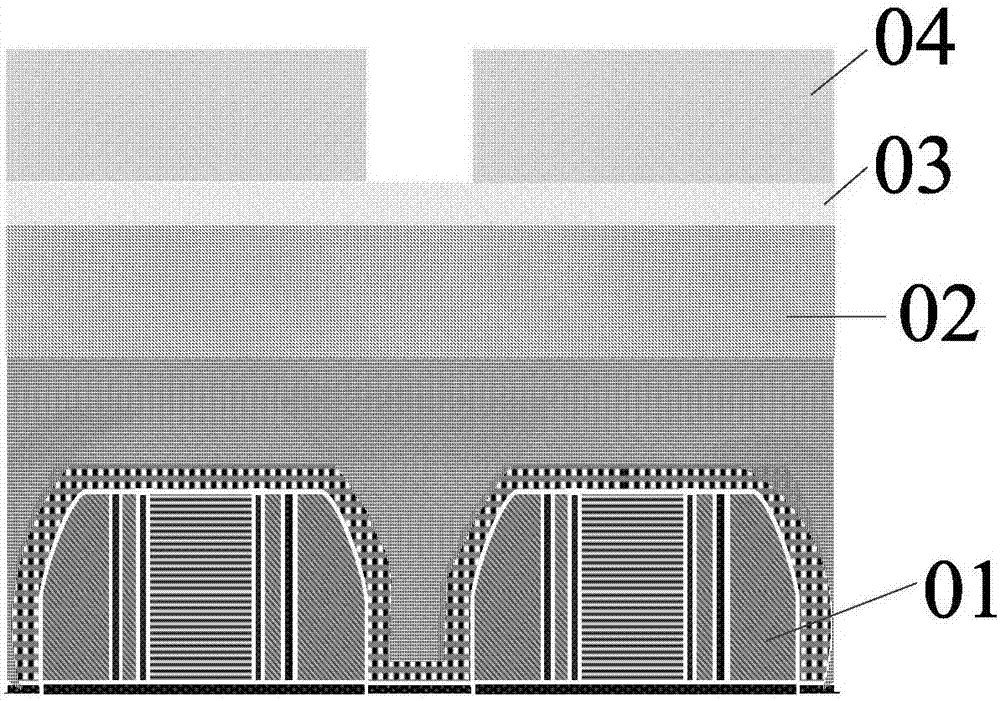

Method for Simultaneously Filling and Planarizing Deep Trenches of Different Sizes

ActiveCN103035486BReduce the difficulty of fillingGuaranteed not to be removedSemiconductor/solid-state device manufacturingLacquerNitride

The invention discloses a method for simultaneously filling and flattening deep trenches with different sizes, which comprises the following steps: (1)depositing a layer or a plurality layers of combination bodies of oxide film or nitride film on a silicon substrate as a barrier layer, (2)depositing light-sensitive lacquer, after development, etching the combination bodies of oxide film or nitride film and revealing a silicon base which needs to etch the deep trenches in follow-up processes,(3) removing the light-sensitive lacquer and producing images of the deep trenches with different depth-to-width ratios through etching with utilization of the combination bodies of oxide film or nitride film as a barrier layer, (4)depositing a layer of oxidation film which is good in steps covering power on a silicon slice, (5)removing the oxidation film above the barrier layer through the manner of chemical mechanical polish, and therefore, depth-to-width ratios of the deep trenches are reduced, (6) filling all the deep trenches with different sizes with a plurality of continuous rounds of oxide film deposition and chemical mechanical polish. Filling difficulty of the deep trenches which have large height-to-width ratios is reduced and at the same time fillers in the large opening deep trenches are not removed. Process is simple and effect is obvious.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

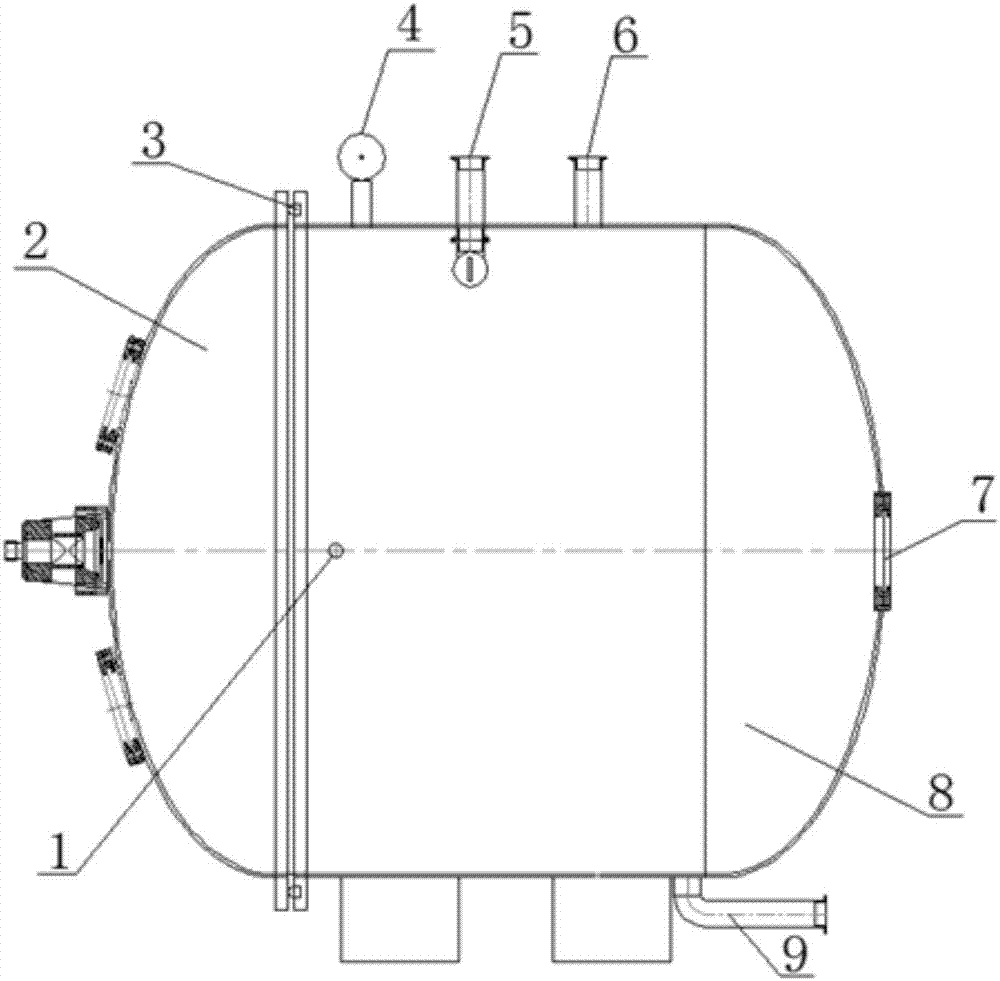

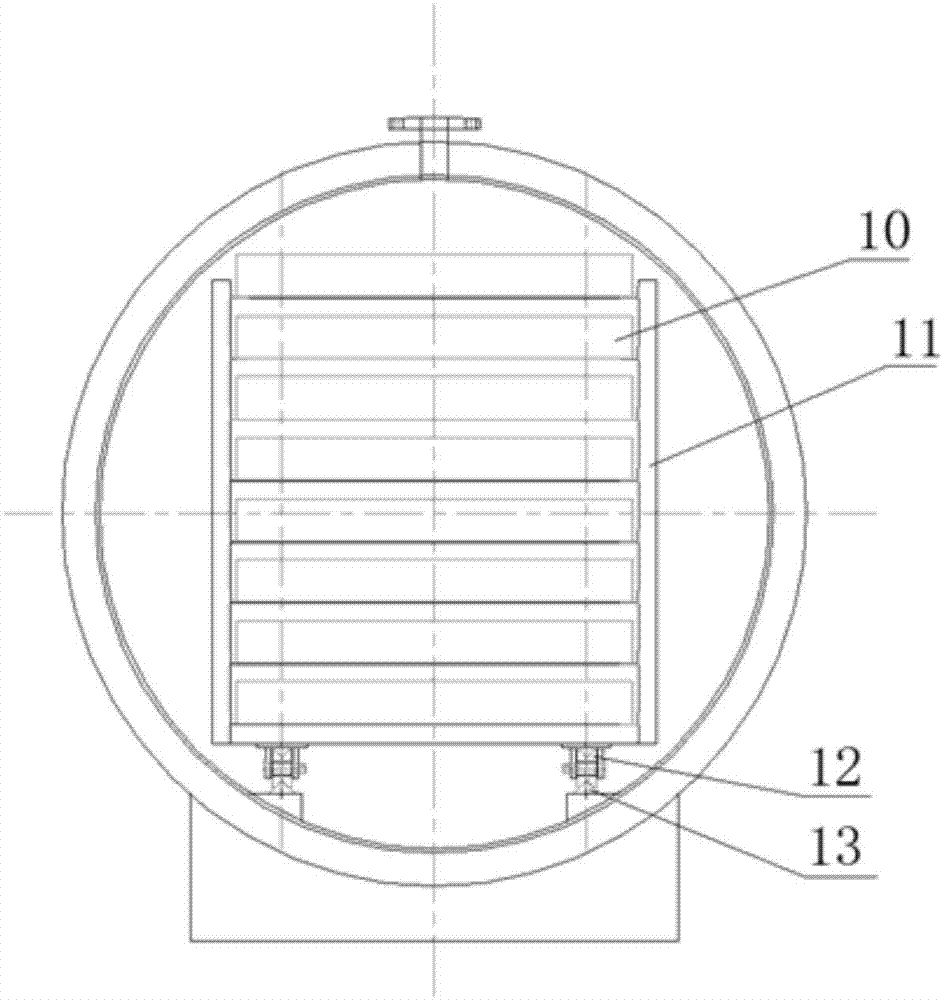

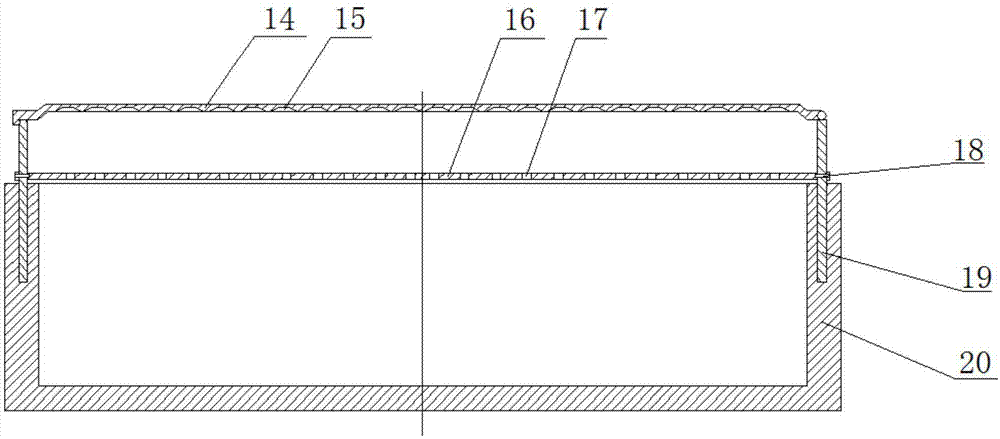

Liquid medicine vacuum negative-pressure filling tank

PendingCN107416372ASimple structureEasy filling and cleaningLarge containersLiquid materialPhysicsPumping vacuum

The invention relates to a liquid medicine vacuum negative-pressure filling tank. The liquid medicine vacuum negative-pressure filling tank comprises a horizontally-placed tank body, a vacuum negative-pressure meter, a washing interface pipe and a vacuumizing interface pipe are arranged at the upper portion of the tank body, a vent nozzle is arranged at the middle portion of the tank body, a drain outlet is formed in the bottom of the tank body, the tank body is of a cylindrical structure made of 304 stainless steel, one end of the two ends of the tank body is sealed, the other end of the tank body is a hemispheric cabinet door capable of being opened and closed, and observation sight glasses are arranged at the sealed end and the hemispheric cabinet door of the tank body; a movement support is arranged inside the tank body, a plurality of tray assemblies are arranged in the movement support in an up-and-down spaced manner, two sets of rollers are symmetrically connected to the lower end of the movement support, and a ring of taper guide groove is formed in the periphery of each roller; and a pair of taper sliding ways are arranged at the bottom of the tank body in the length direction. According to the liquid medicine vacuum negative-pressure filling tank, filling and cleaning are very convenient, filling is automatically completed, manual assisting is not needed, the filling difficulty is reduced, filling of multiple rubber pipes can be achieved at a time, and inclination, collision and extrusion of the rubber pipes in the carrying process are avoided.

Owner:绵阳一康制药有限公司

Multi-chamber infusion soft bag production line

ActiveCN104443467BReduce the difficulty of fillingShorten the lengthLiquid materialProduction lineEngineering

Owner:SHINVA MEDICAL INSTR CO LTD

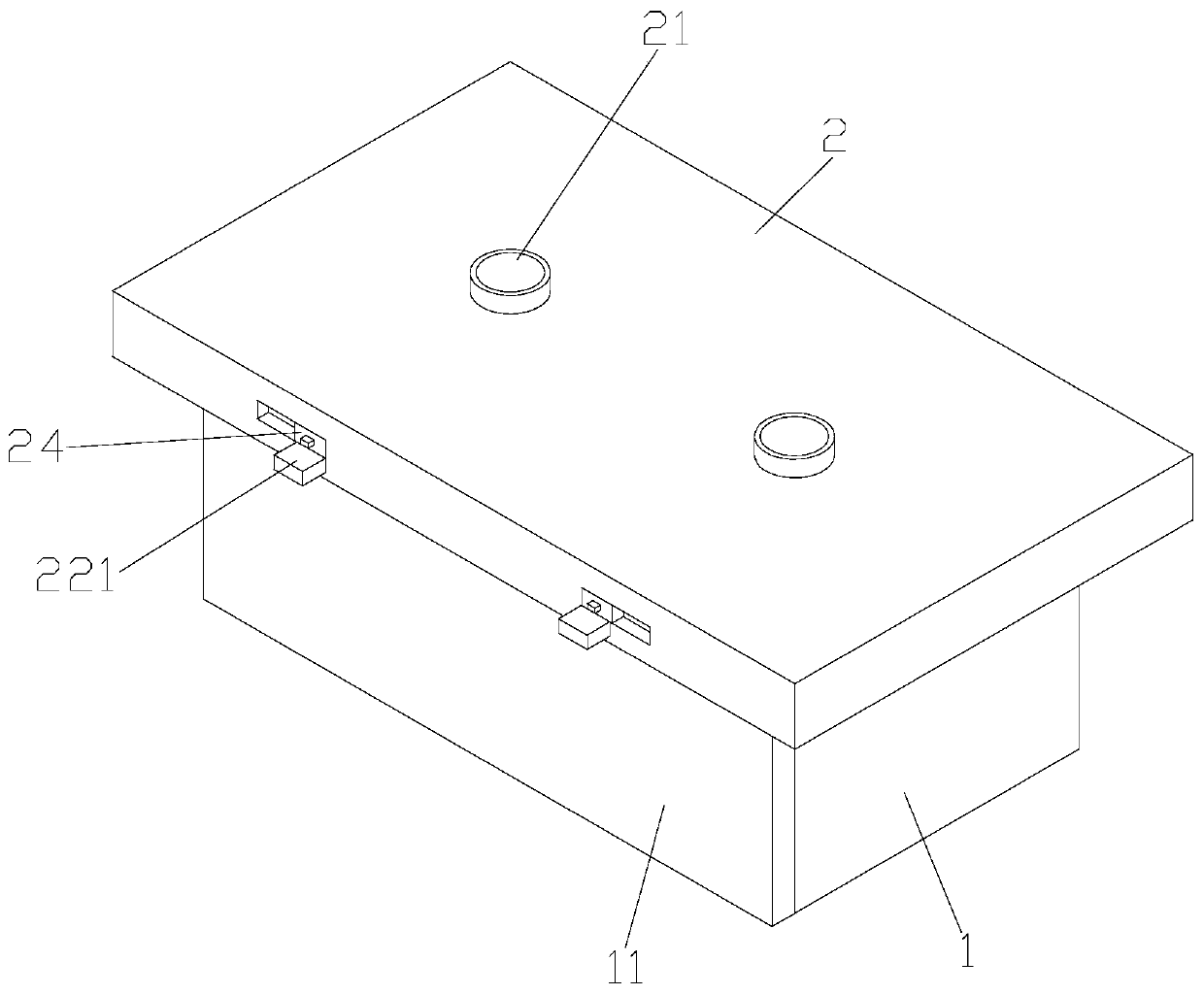

Operating table

ActiveCN111394249AReduce the difficulty of fillingBioreactor/fermenter combinationsBiological substance pretreatmentsGas cylinderBottle

The invention discloses an operating table. The operating table comprises a base and a platform arranged on the base, the base is provided with a cavity, a gas storage bottle is arranged in the cavity, a door plate is rotatably connected to the side wall of the cavity, a material carrying block is arranged in the cavity, a mounting groove matched with the gas storage bottle is formed in the material carrying block, idler wheels are arranged at the bottom of the material carrying block, a first movable groove matched with the idler wheels is formed in the bottom of the cavity, an inclined planeis arranged at one end of the first movable groove, and a first connecting pipe communicating with the gas storage bottle is arranged on the platform. The gas storage bottle is directly placed in thecavity, a pipeline does not need to be specially laid for the gas storage bottle, and the influence of the pipeline on space utilization in a laboratory is avoided. The gas storage bottle can be directly pulled out of the cavity to clean the bottle body, so that the cleaning difficulty of the gas storage bottle is reduced.

Owner:WUHU CHAOYUANLI IND DESIGN CO LTD

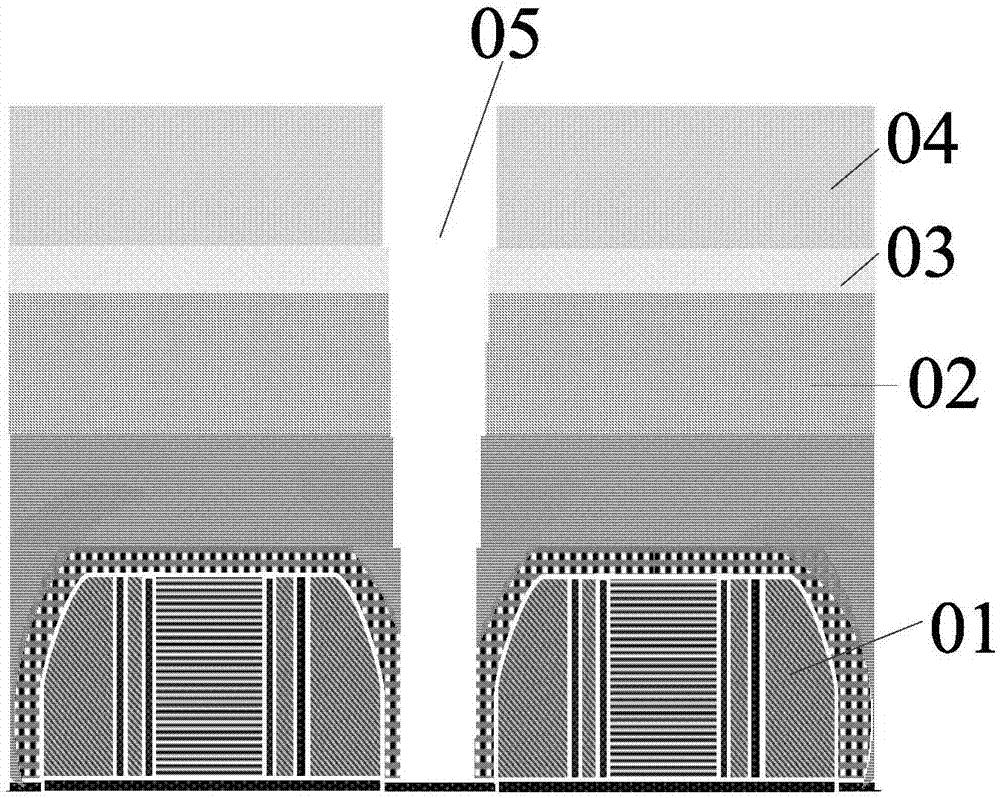

Shielded gate field effect transistor and method of forming the same

ActiveCN111180342BReduce the difficulty of fillingEasy to fillSemiconductor/solid-state device manufacturingSemiconductor devicesIsolation layerField effect

The present invention provides a shielded gate field effect transistor and a method for forming the same. After the first dielectric layer and the shielding electrode are formed in sequence, the part of the first dielectric layer higher than the shielding electrode is directly etched, so that the thickness of the etched first dielectric layer at the part higher than the shielding electrode decreases sequentially from bottom to top , so that the morphology of the upper trench above the shielding electrode can be modified, so that the filling difficulty of the insulating filling layer can be reduced, the filling performance of the insulating filling layer in the upper trench can be improved to avoid voids, and the insulating filling layer can be subsequently etched. When the isolation layer is formed, a gapless isolation layer can be formed to ensure mutual isolation between the gate electrode and the shield electrode.

Owner:中芯先锋集成电路制造(绍兴)有限公司

Casting method of a main reducer housing

ActiveCN106825438BHigh dimensional accuracyHigh surface finishGearboxesFoundry mouldsSurface finishPorosity

The invention relates to a casting method of a main reducer housing. The casting method includes: a precoated sand core forming process, a smelting ball iron process and a casting process, the precoated sand core forming process includes core-making of precoated sand, coated sand type assembly and sand-type steel shot filling; the smelting ball iron process includes electric-furnace smelting and charging of molten iron and treatment; the casting method is characterized by including casting, unboxing, de-gating, one-step shot blasting, grinding, secondary shot blasting and detecting. With the method, exhaust smoothness is guaranteed, generation of hole defects in the casting is avoided from the sand core exhaust process, sand hole and pore defective reject rate is controlled within 1%, shrinkage or porosity defect is avoided, the casting is stable in size and high in surface smoothness, the yield is higher as compared with that with a traditional casting method of the main reducer housing, the production process is easier to control, and production competitiveness has higher advantages.

Owner:抚州市羊易铸业有限公司

A method for improving the filling capacity of a deep trench

InactiveCN109148276AReduce difficultyEasy to fillSemiconductor/solid-state device manufacturingFilling materialsEngineering

The invention discloses a method for improving the filling capacity of a deep trench. Step 1, filling the formed deep trench; 2, when filling to half of the filling time required to fill the deep trench, stopping the filling first; 3, carrying out vertical implantation on the surface of the deep trench; 4, etching the surface of the injected filling material to increase the opening angle of the deep trench; and Step 5: continuing filling the deep trench in the reworked opening to complete the trench filling. The invention can realize the integrity of deep trench filling.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com