Spoke casting mold, vacuum die-casting forming system and spoke manufacturing method

A mold and spoke technology, applied in the direction of rolling resistance optimization, road transportation emission reduction, etc., can solve the problems of gas involved in castings, fast filling speed, porosity defects, etc., to reduce gas content, reduce possibility, and improve vacuum degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

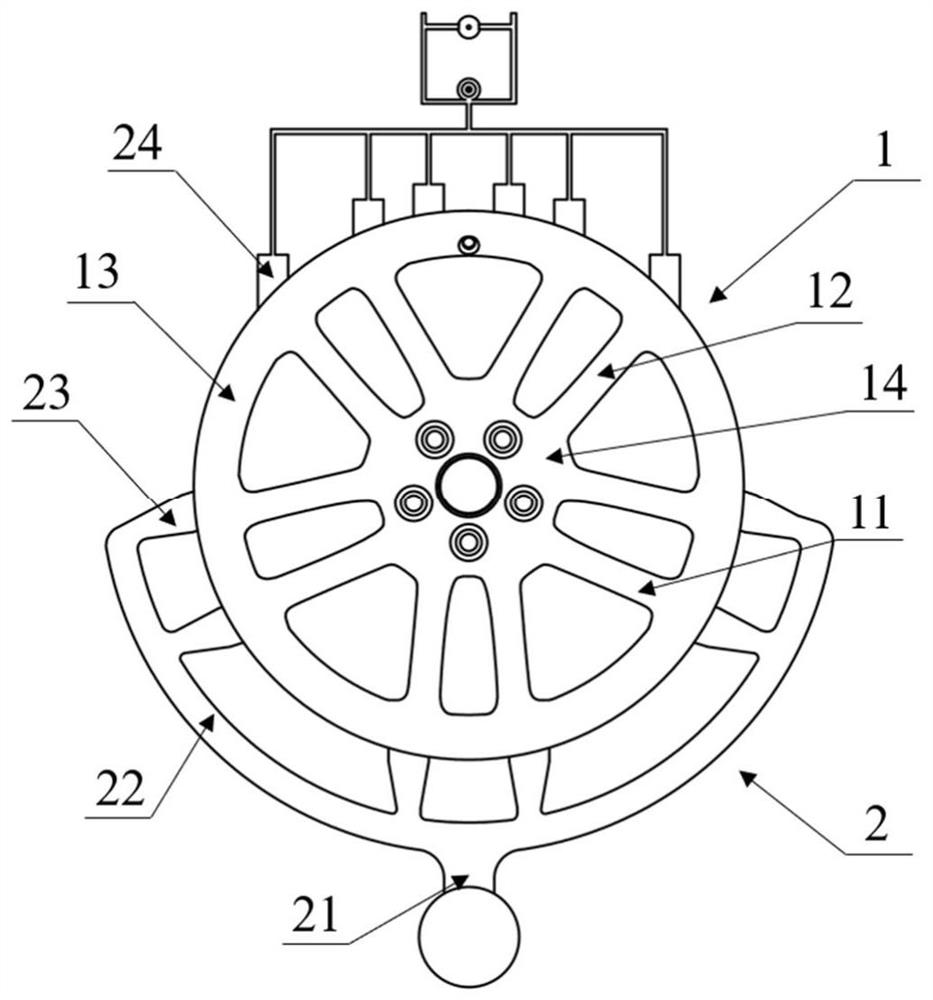

[0057] This embodiment provides a spoke with 10 spokes, such as Image 6 Show. The aluminum alloy spoke alloy ingredients are Al-SI-MG system pressure cast aluminum alloy. The specific manufacturing method is:

[0058] S101: Design die -casting pouring system, such as figure 1 Show, place the wheel -transmitted casting mold vertically, set the pouring system at the outer edge of the lower semi -semi -semi -semi -semi -semi -semi -semi -semi -semicircular bars. One spoke tinching cavity 11, aluminum liquid can enter the mold -type cavity 1 through 6 internal watering tract 23. The outer end of the inner pouring road is connected to the 22 of the horizontal pouring road. The crossway 22 passes through the main watering road 21 and the ingredients on the ingredients on the 31st of the Shipping Room 31. The aluminum liquid "from bottom to top" is a unidirectional flow, and the vacuum valve 41 at the top through the overflow slot 24 is passed through the splittering cavity 13. The thick...

Embodiment 2

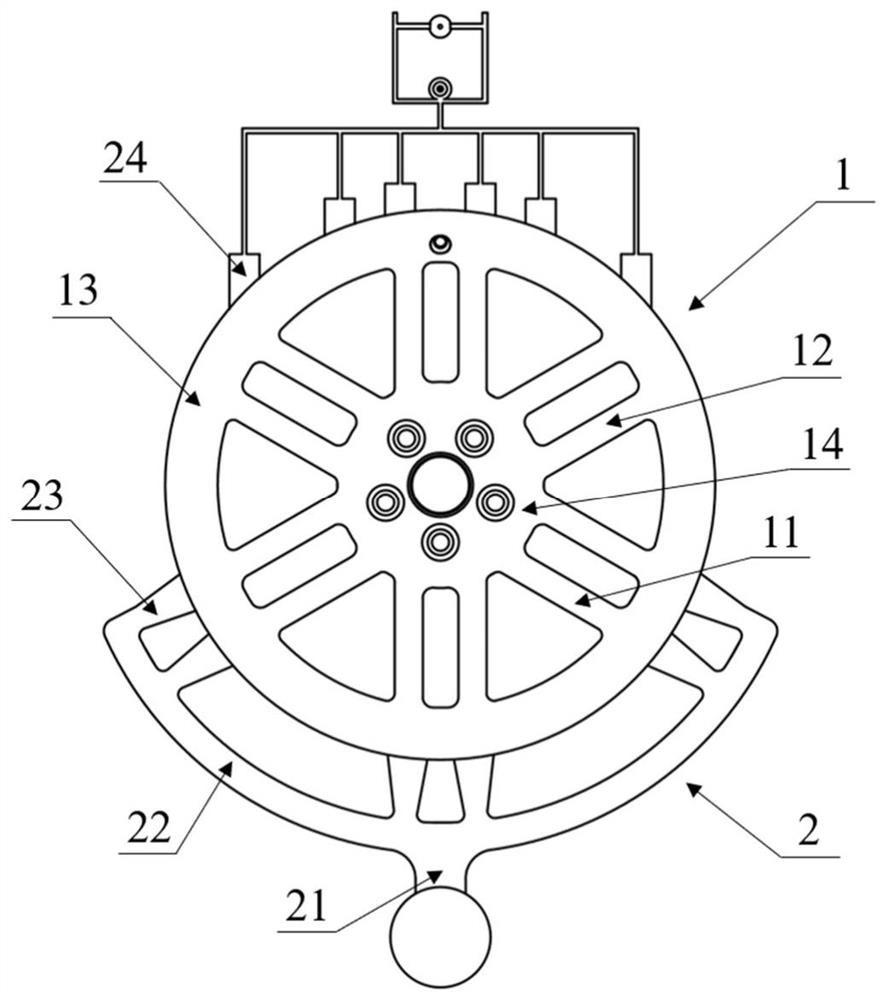

[0064] This embodiment provides a spoke with 12 spokes. The aluminum alloy spoke alloy composition is Al-SI-MG system pressure cast aluminum alloy. The specific manufacturing method is:

[0065] S201: Design die -casting pouring system, such as figure 2 Show, place the wheel -transmitted casting mold vertically, and set the pouring system at the outer edge of the lower semicircle of the lower semicircle. For casting cavity, aluminum liquid can enter the mold -shaped cavity of the wheel spoke through 6 internal lanes. The outer end of the inner watering trail is connected to the horizontal lane. The aluminum liquid "from bottom to top" is a unidirectional flow, and the vacuum valve at the top through the overflow slot is passed on the top of the spokes. The thickness of the design of the internal lane is 1.2mm, and the total cross -sectional area of the internal water tract meets the maximum flow rate of the aluminum fluid of the inner watering tract is 40m / s; the number of overf...

Embodiment 3

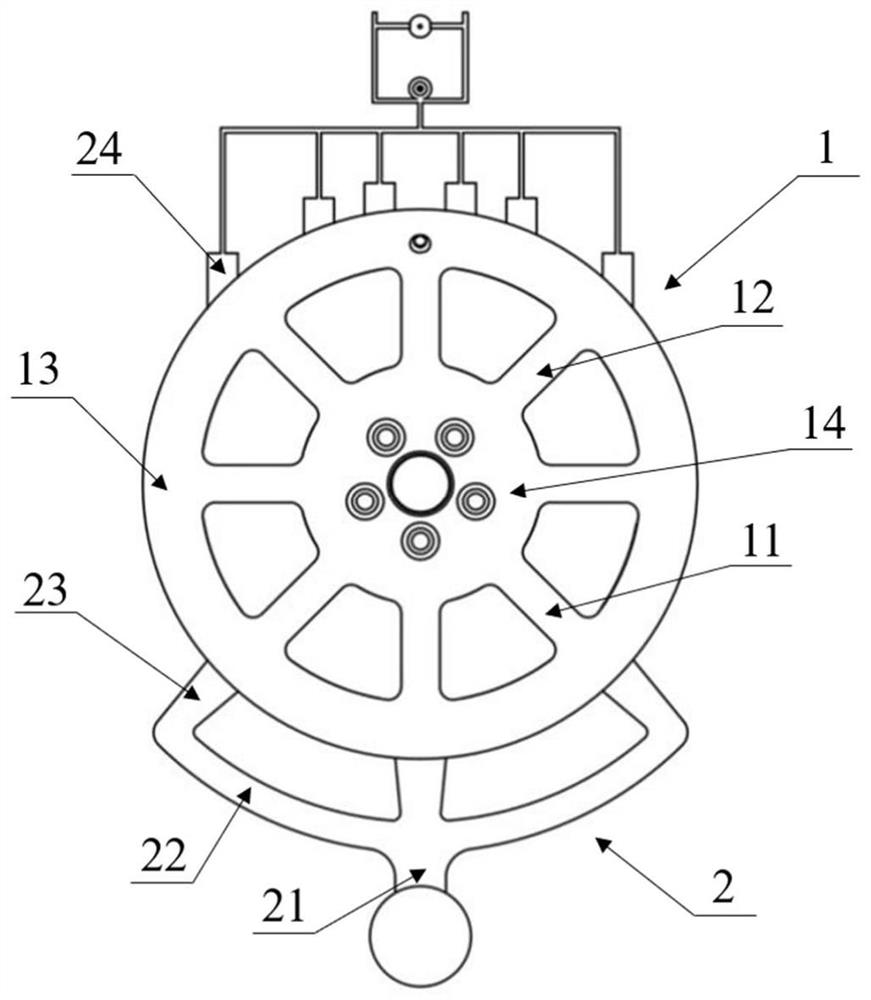

[0071] The wheel spoke of this embodiment is a spoke with 8 spokes. Aluminum alloy wheel spoke alloy composition is Al-Mg-SI system pressure cast aluminum alloy. The specific manufacturing method is:

[0072] S301: Design die -casting pouring system, such as image 3Show, the wheel -transmitted casting mold is placed vertically, and the pouring system is set on the outer edge of the lower semicircle of the lower semicircle. In the casting cavity, aluminum liquid can enter the mold -shaped cavity of the wheel spoke through 4 internal lanes. The outer end of the inner watering trail is connected to the horizontal lane. The aluminum liquid "from bottom to top" is a unidirectional flow, and the vacuum valve at the top through the overflow slot is passed on the top of the spokes. The thickness of the design of the internal lane is 1.4mm, and the total cross -sectional area of the internal water track meets the maximum flow rate of the aluminum fluid of the inner watering tract is 25m / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com