A precision forging device and method for a spiral bevel gear

A gear precision and spiral bevel technology, which is applied in the field of spiral bevel gear precision forging and spiral bevel gear, can solve the problems of difficult demoulding, difficult mold filling, and large metal forming resistance, and achieve the effect of reducing the difficulty of mold filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

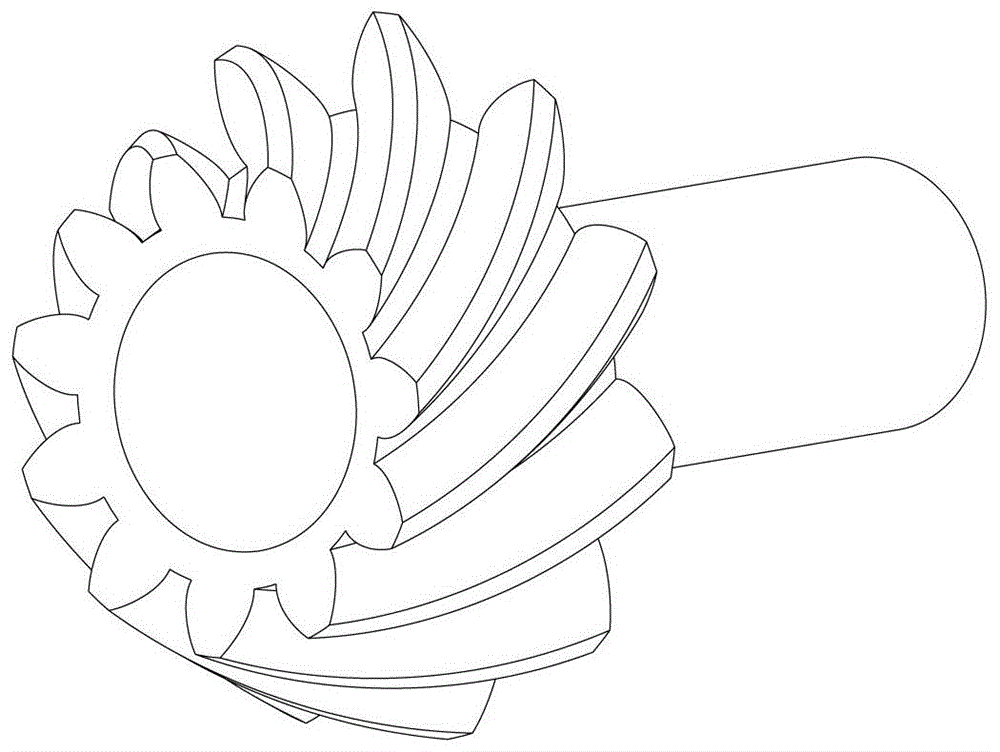

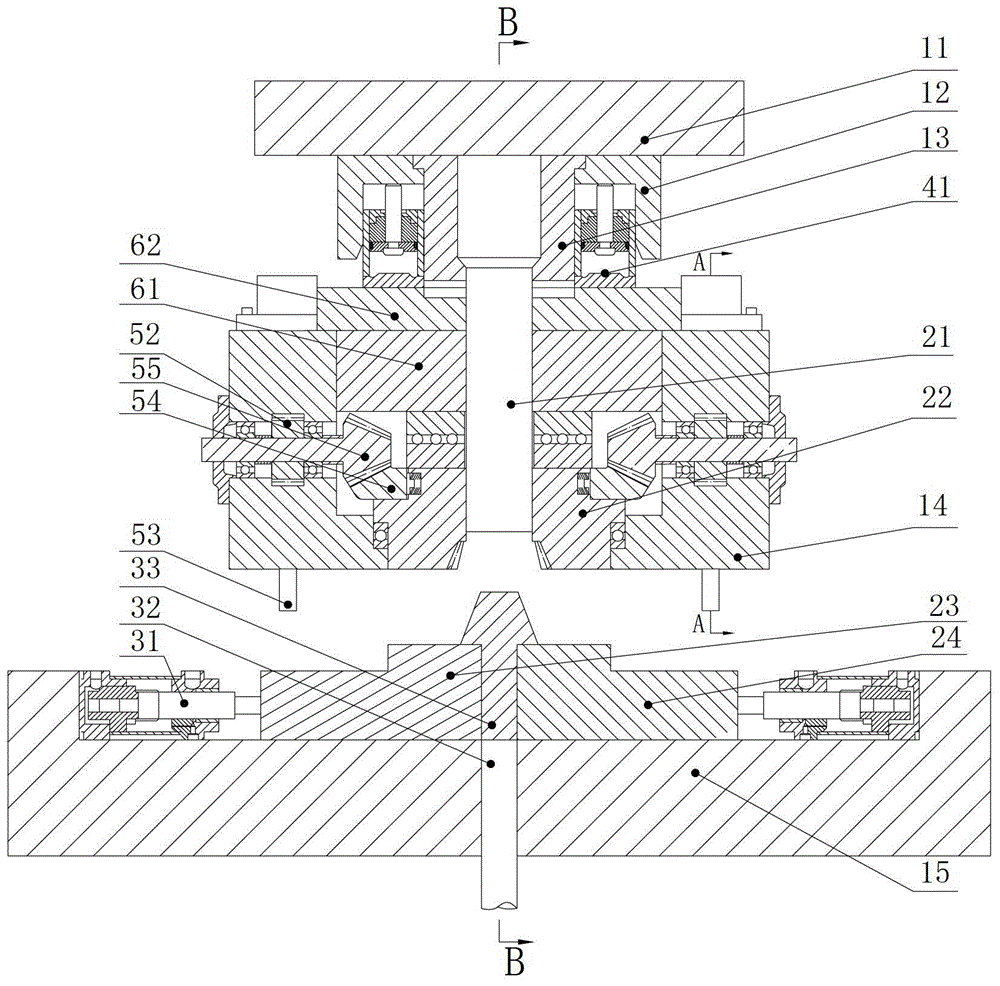

[0036] A precision forging device for spiral bevel gears of the present invention is mainly used for producing such as figure 1 The spiral bevel gear shown. It includes a mold base, a punch 21 , a tooth mold 22 , a lower mold, an elastic member, a rack 51 , a spur gear 52 , a driving spur gear 55 and a driven spur gear 54 .

[0037] Such as figure 2 Shown, in the embodiment of the present invention, wherein, formwork is the main body that connects each component, and it comprises upper template 11, lower template 15, pressing plate 62, upper mold supporting device 14, guide post 16 and guide sleeve 17.

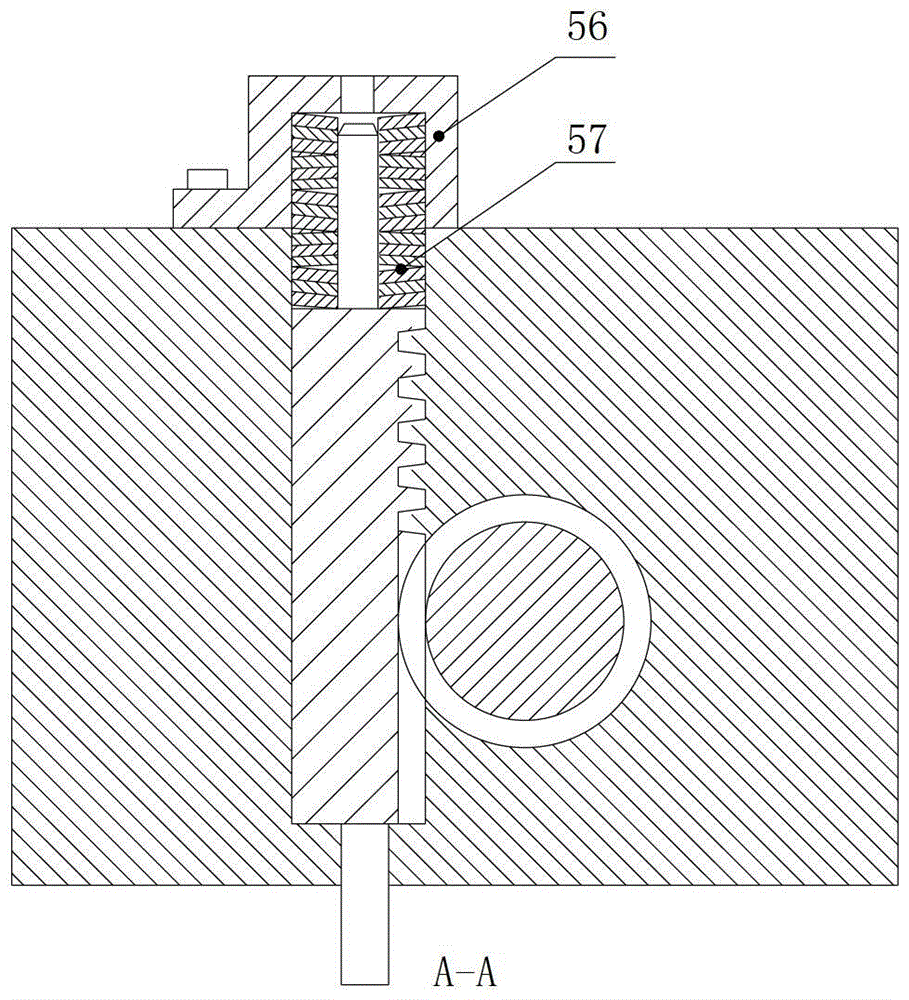

[0038] A preferred embodiment is that the inventive precision forgin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com