Patents

Literature

38results about How to "Meet preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High temperature-resistant heat-bonding enamelled wire paint and preparation method thereof

InactiveCN101818023AImprove heat resistanceImprove application adaptabilityPolyamide coatingsInsulating bodiesWire rodFurnace temperature

The invention discloses high temperature-resistant heat-bonding enamelled wire paint and a preparation method thereof. The high temperature-resistant heat-bonding enamelled wire paint consists of patient base resin such as modified co-polymerized nylon and phenolic resin, mixing dissolvent and assistant. The high temperature-resistant heat-bonding enamelled wire paint meets the requirement of heat-resistant condition more than 180 DEG C, the appearance of the finished product is brown thick liquid, the weight solid part is 18-28%, and the rotating viscosity is 800-2000mPa.s at 25 DEG C. The patient is used for the outer layer of a high temperature-resistant coil wire material, and can be solidified with polyesterimide base paint at the same furnace temperature.

Owner:广东省石油化工研究院

Cephalosporin ester drug particle in non-gel state after meeting water, and preparation method and application of drug particle

ActiveCN103027899AGood dispersionImprove hydrophilicityAntibacterial agentsOrganic active ingredientsAdjuvantDrugs preparations

The invention relates to a cephalosporin ester drug particle in a non-gel state after meeting water, and a preparation method and an application of the drug particle, and belongs to the technical field of pharmaceutical preparations. The drug particle comprises the following raw and auxiliary materials: a cephalosporin ester drug with the bulk density of 0.1-0.3g / ml, and the following auxiliary materials accounting for the mass percentage of the cephalosporin ester drug as follows: 2-4.5% of micropowder silica gel, 2-4.5% of anti-gel adjuvant, and 12-16% of disintegrating agent, wherein the anti-gel adjuvant is a glidant and / or a lubricant with the bulk density greater than 0.50g / ml. According to the cephalosporin ester drug particle in the non-gel state after meeting the water, and the preparation method and the application of the drug particle, the problem that the dissolution rate is relatively low due to the fact that gelatinization is severe when the cephalosporin ester drug is dissolved out in the water in the prior art is solved, the dispersity and the hydrophilicity in a dissolution-out process are good, no gelatinization exists, and the dissolution rate is increased greatly.

Owner:SUZHOU CHUNGHWA CHEM & PHARMA IND

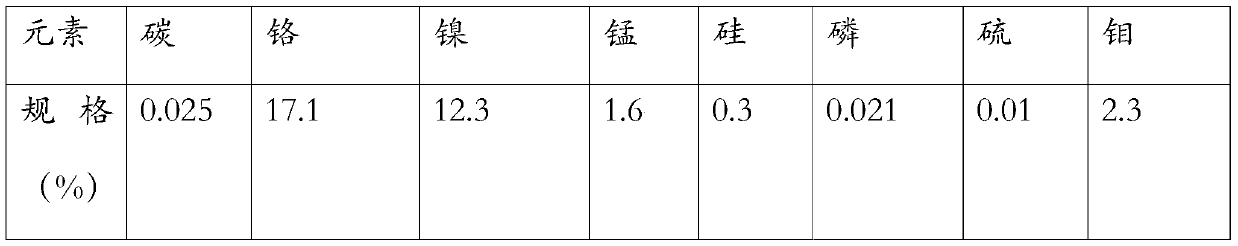

Process for making powder through stainless steel waste corner sheet metal

ActiveCN109865842AIncrease profitReduce wasteAdditive manufacturing apparatusRecycling and recovery technologiesMetal alloyMetal powder

The invention provides a process for making powder through a stainless steel waste corner sheet metal. The powder is prepared by using an atomization method. The process comprises the following stepsthat S1, raw materials are sorted and graded; S2, cleaning and dewatering are conducted; S3, the technology ratio is formulated, smelting is conducted, and ingredients are added; S4, atomization for powder making is conducted; S5, dewatering and drying are conducted; and S6, screening and detection are conducted. The process has the beneficial effects that stainless steel edge corner waste materials are recycled, waste of the materials is reduced, the using ratio of stainless steel edge corner waste materials is increased, the metal powder is prepared by using the stainless steel waste cornersheet metal, so that the processing cost is low, and the raw materials are sufficient; and the metal powder is prepared by using the atomization method, so that the production efficiency is high, mostmetal and metal alloy powder thereof can be prepared, the metal powder quality is controllable, and using requirements of 3D printing and additive manufacturing are met.

Owner:普瑞特机械制造股份有限公司

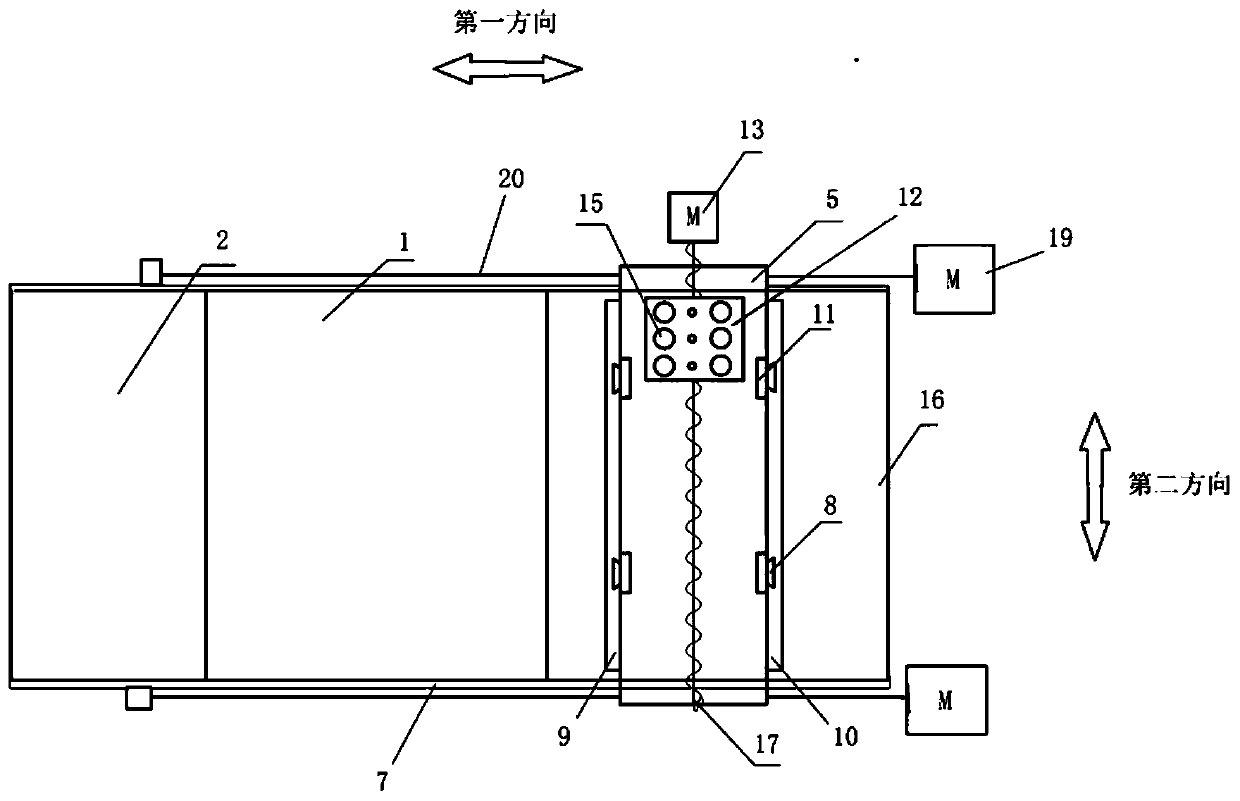

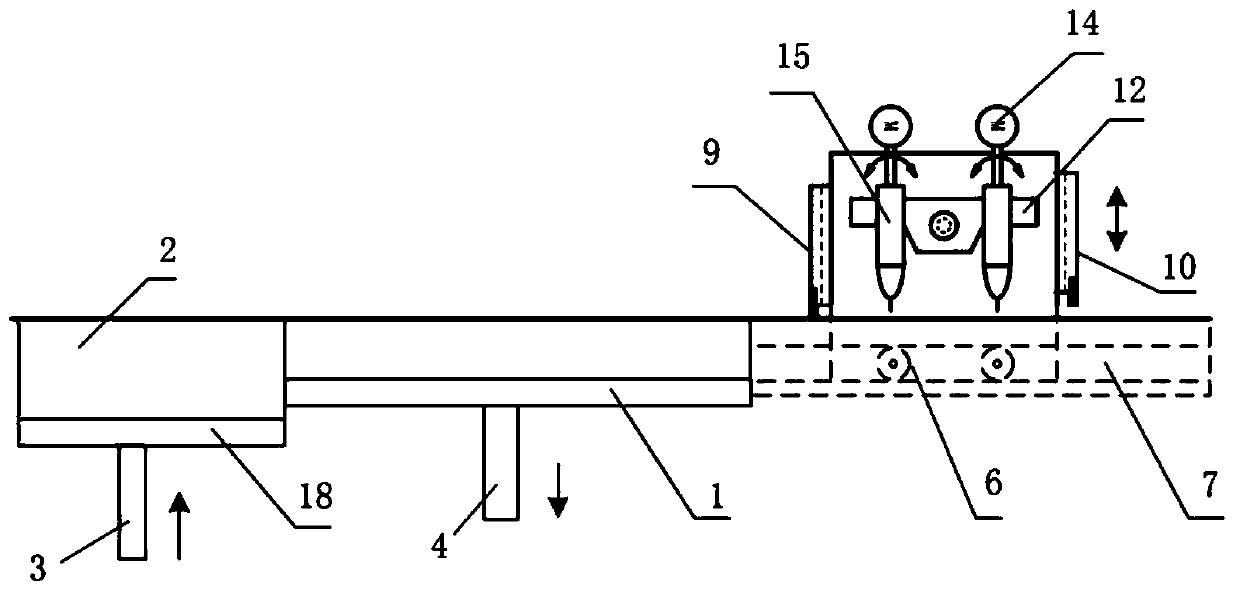

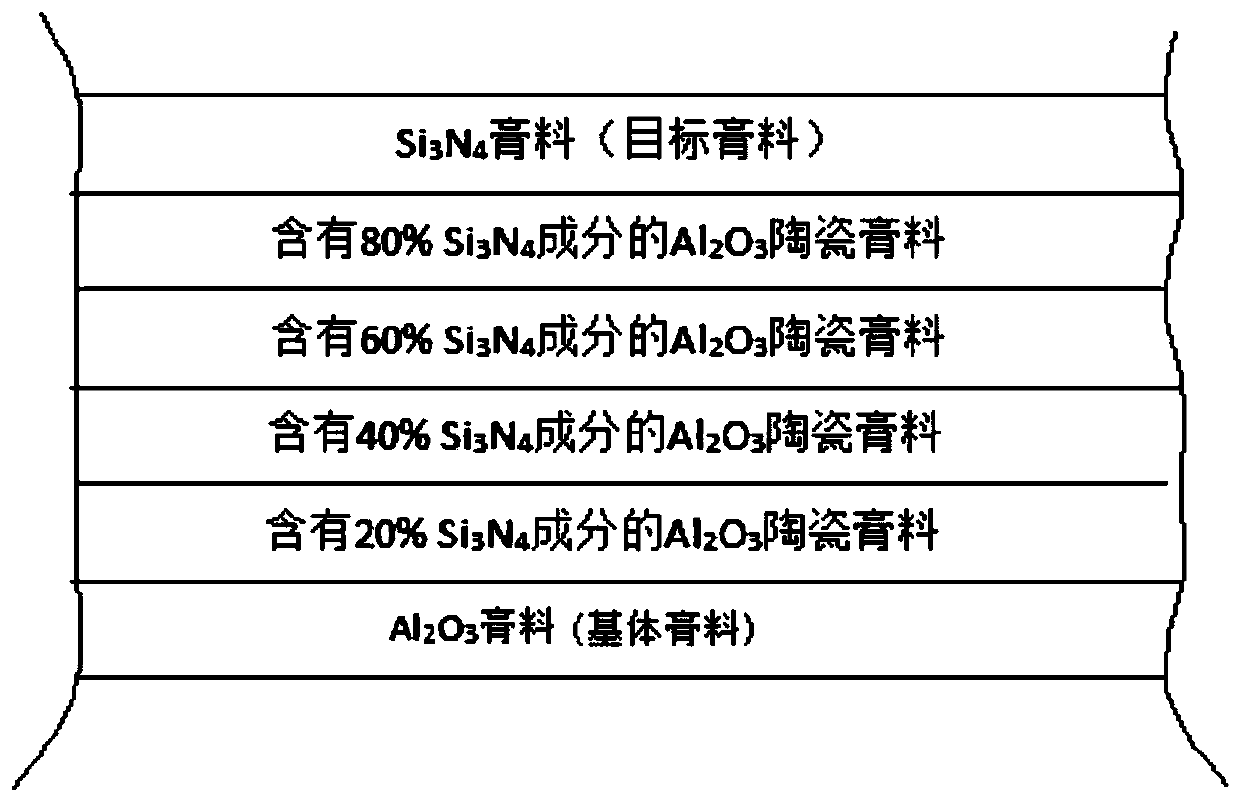

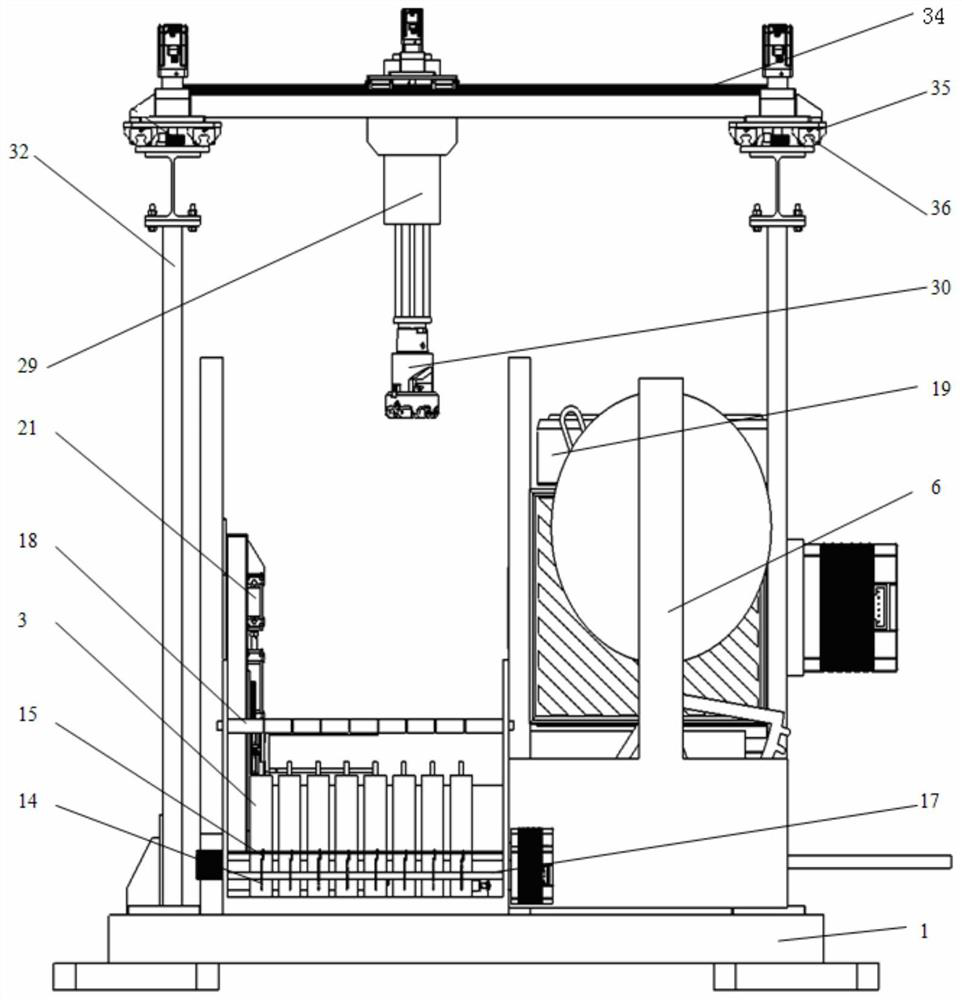

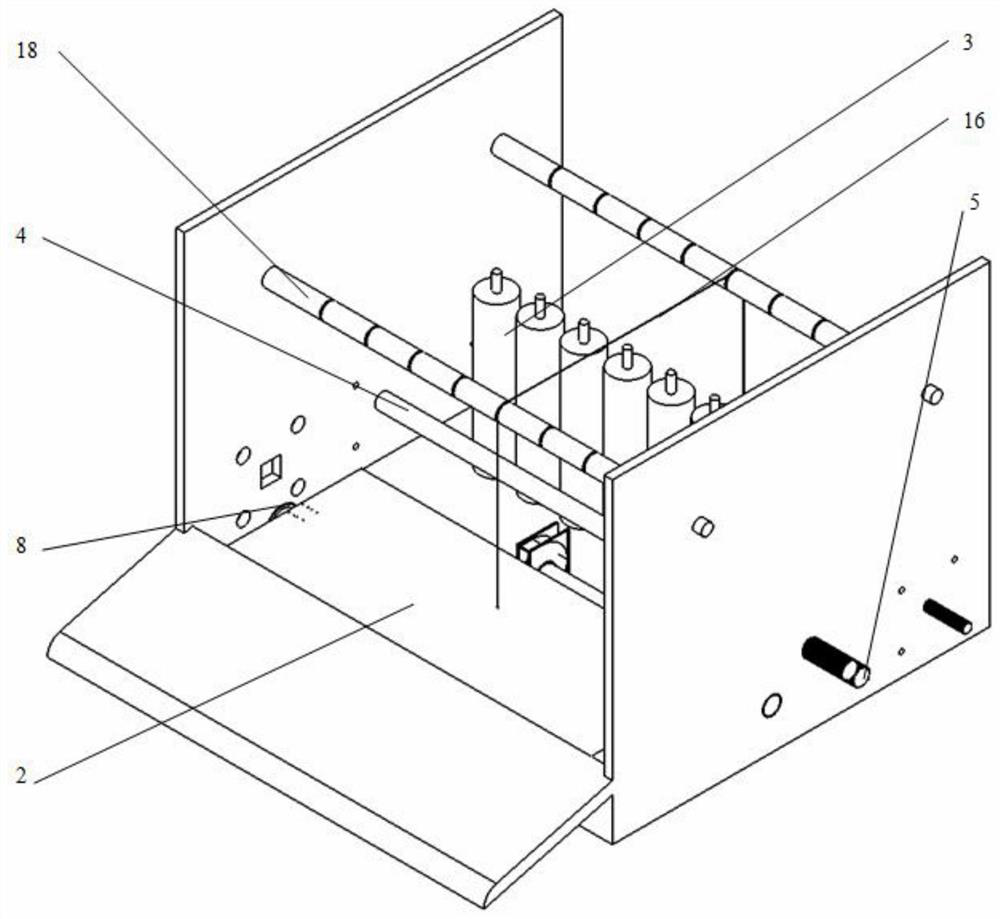

Gradient functional material 3D printing device and working method

InactiveCN110091413AHigh dimensional accuracyHigh densityAdditive manufacturing apparatusCeramic shaping apparatusGradient materialPiston

The invention relates to a gradient functional material 3D printing device and a working method. The gradient functional material 3D printing device comprises a raw material bin, a forming platform, atool reset, a plurality of charging barrels, and a laser curing mechanism, wherein a piston connected with a first lifting mechanism is arranged in the raw material bin; the forming platform is located one side of the raw material bin and connected with a second lifting mechanism; the tool rest is in sliding connection with first guide rails on two sides of the forming platform and connected witha second drive mechanism, the second drive mechanism can drive the tool rest to slide in the first direction, two end faces, perpendicular to the first direction, of the tool rest are in sliding connection with a scraper which is connected with a third lifting mechanism; the charging barrels are connected with a first drive mechanism fixed to the tool rest, the first drive mechanism is used for driving the charging barrels to move in the second direction perpendicular to the first direction, and the charging barrels are connected with a material extruding mechanism; and the laser curing mechanism is used for generating laser rays. The 3D printing device can realize 3D printing of functional gradient materials based on the SL technology.

Owner:SHANDONG UNIV

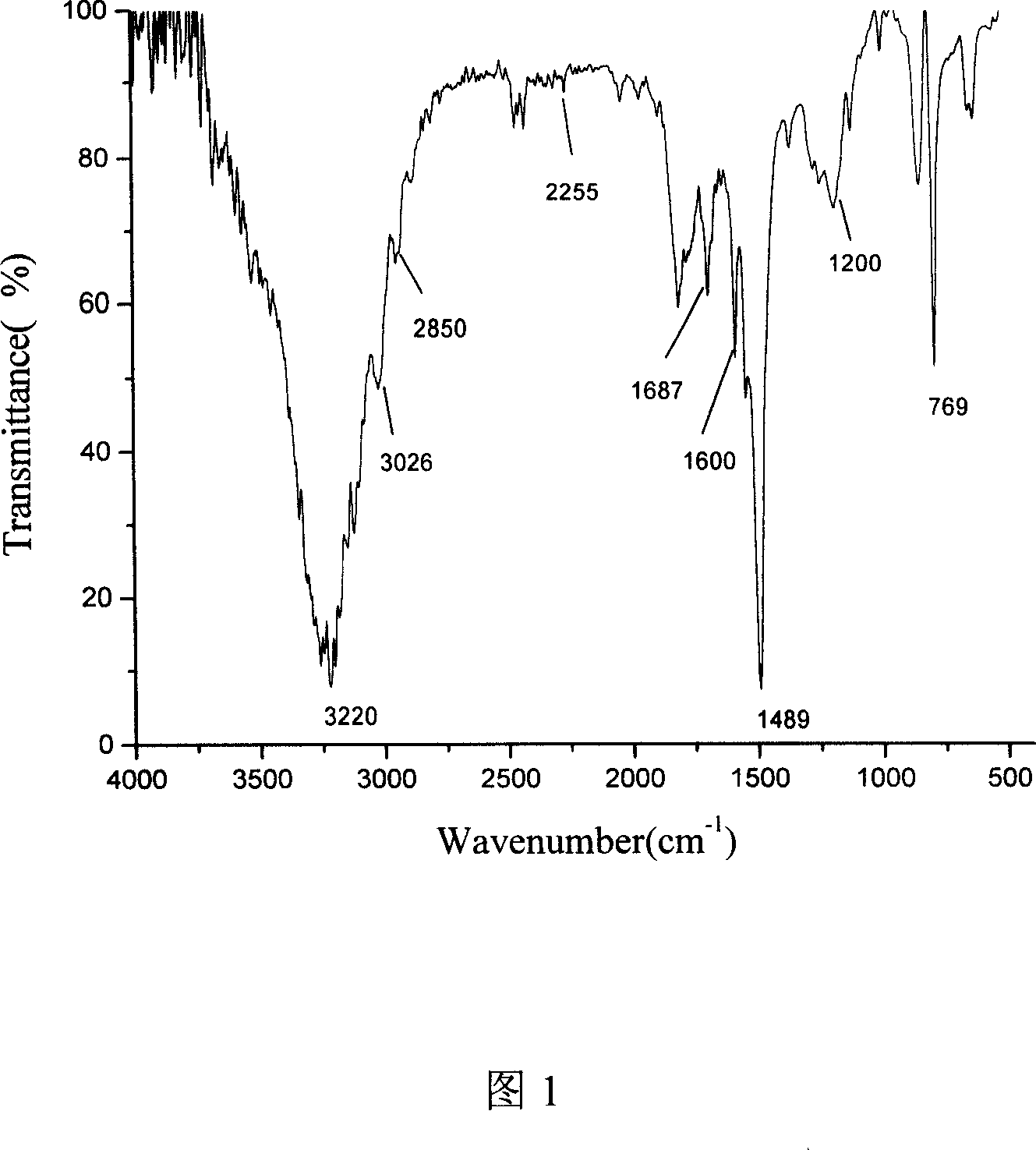

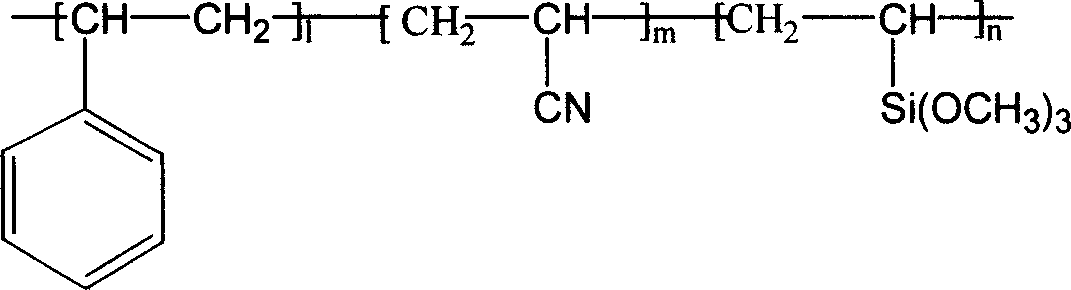

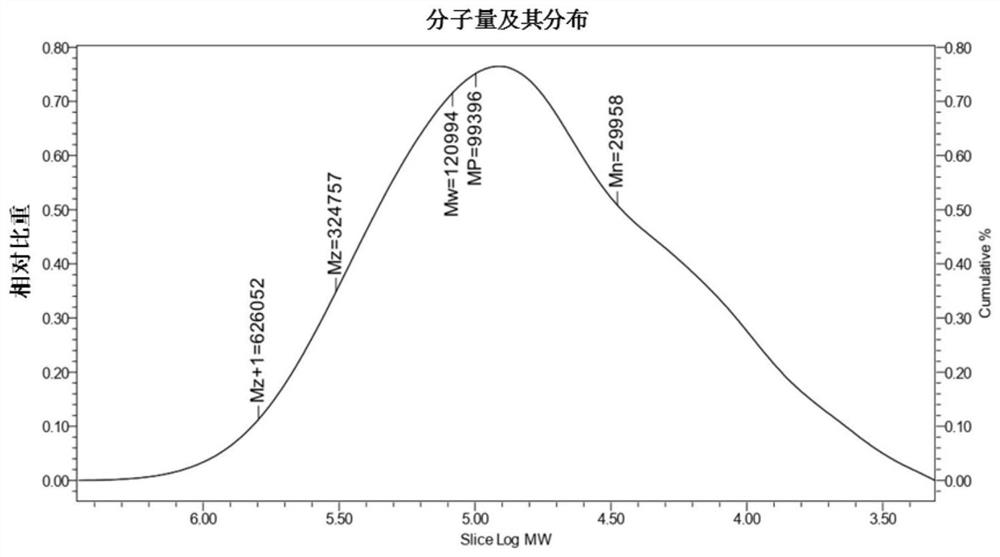

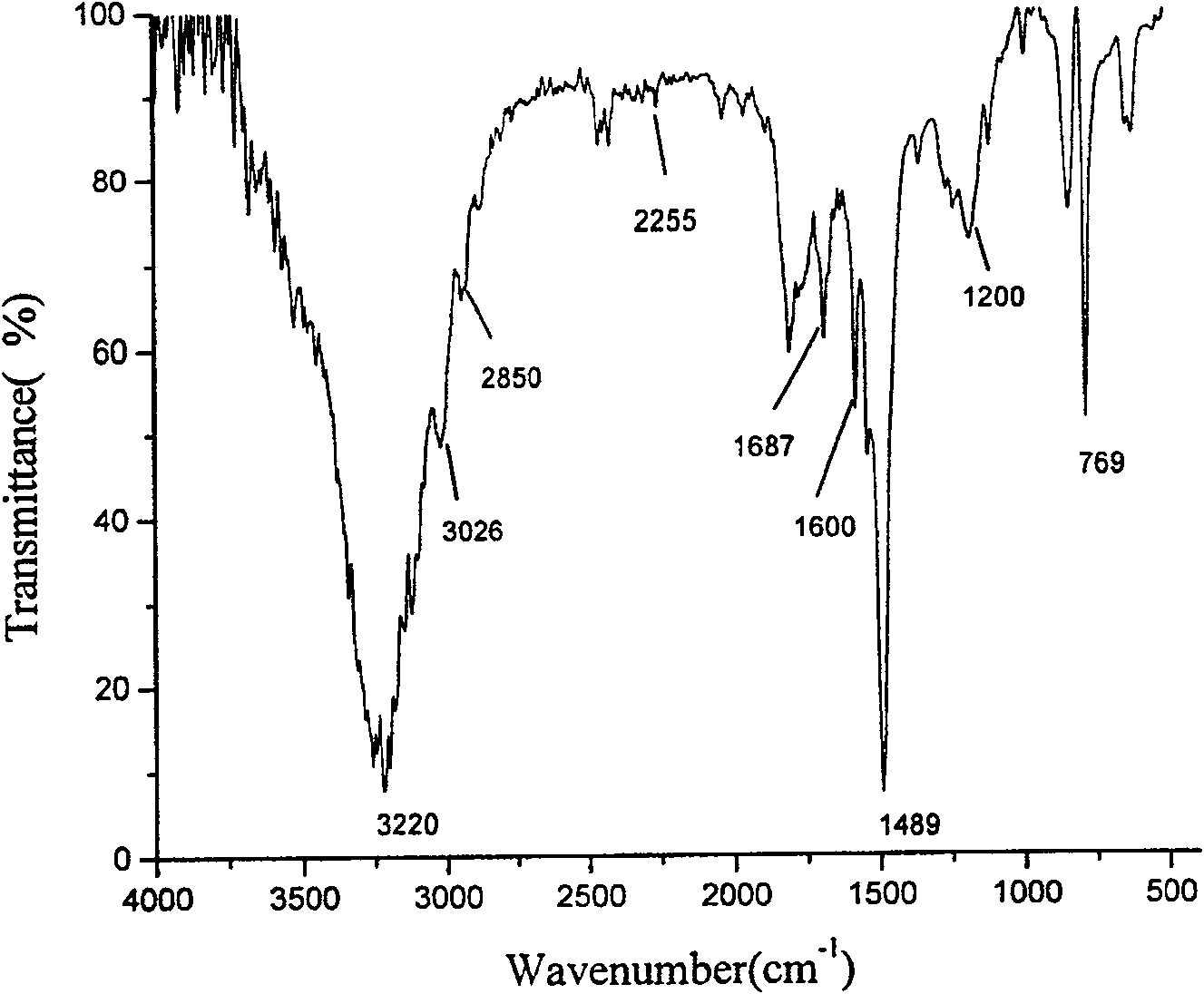

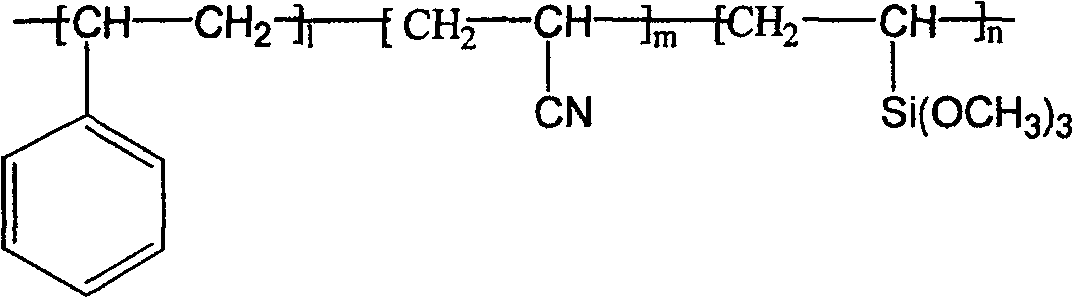

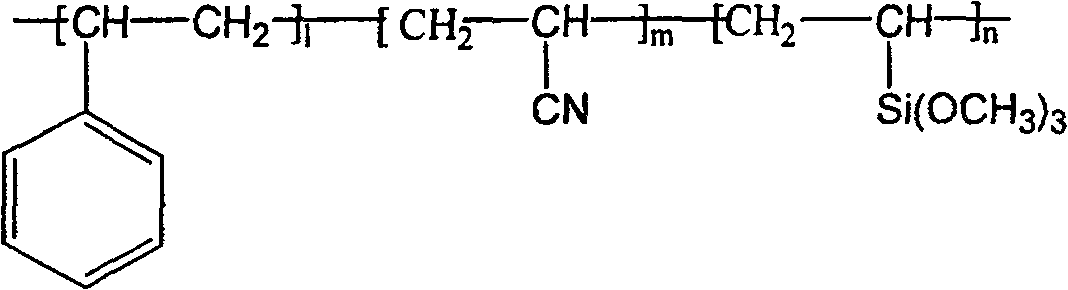

Macromolecule coupling agent containing active cyano group and preparing method thereof

The invention relates to a macromolecular coupling agent containing active cayno and a preparation method of the macromolecular coupling agent containing active cayno. The technology of the invention is characterized in that a ternary random copolymer is synthesized by means of free radical polymerization reaction with styrene, acrylonitrile and vinyl trimethoxy silane as monomers, dibenzoyl peroxide and azobisisobutyronitrile as an initiator, and one of xylene, toluene, benzene or dimethylformamide as a solvent. The preparation steps are as follow: the solvent, the monomers and the initiator are put into a three-mouth flask sequentially and mixed, nitrogen is input, and then the flask is heated slowly until thermal insulation, the heating is stopped after the reaction. A quantity of the acrylonitrile is put into the three-mouth flask after the flask is cooled, then the solution is vacuum distilled after being heated and thermal insulated. At last, the ternary copolymer macromolecular coupling agent is obtained with the solution being dissolved with tetrahydrofuran, precipitated in methanol and dried in vacuum. The coupling agent is suitable for the composite material system with cyanate ester resin as matrix, glass fiber or inorganic particles as reinforcing material with simple preparation process and short reaction time, which lays a foundation for industrialized production.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Safe method applicable to shaft furnace soft coal preparation and jetting

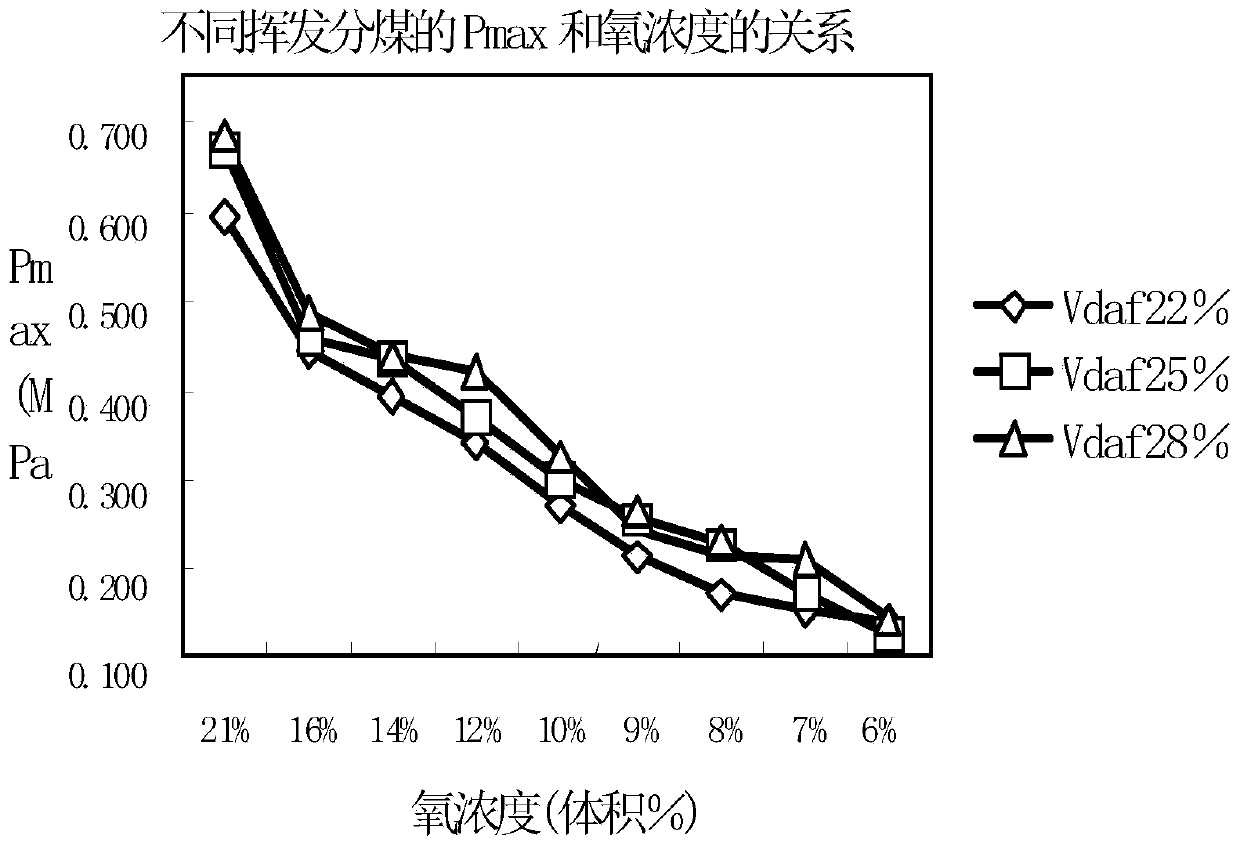

InactiveCN103468837AMeet preparationReduce smelting costBlast furnace detailsEngineeringNitrogen gas

The invention provides a safe method applicable to blast furnace soft coal preparation and jetting. The safe method comprises the steps: 1) an exhaust pipe is mounted on a hot blast furnace and extends to a chimney, and the oxygen content of hot blast furnace waste gas is controlled to be not more than 2.0%; 2) the hot blast furnace waste gas or nitrogen is utilized to replace natural wind for preparing pulverized coal and back blowing a cloth bag, the oxygen content at an inlet of a mill of a coal jetting system is not more than 4.0%, and the oxygen content at an outlet of the cloth bag is not more than 6.0%; 3) effective sealing and leaking stoppage of the waste gas pipeline of the hot blast furnace, a flue gas furnace, the mill and the cloth bag are implemented, and the system wind leakage rate is reduced to be not more than 10%; and 4) full nitrogen stamping and fluidization are adopted for a jetting blowing tank, and full nitrogen is also adopted in powdering. The method is suitable for safe preparation and jetting blowing production of raw coal with the volatile component content of not less than 25%.

Owner:BAOSTEEL GROUP XINJIANG BAYI IRON & STEEL

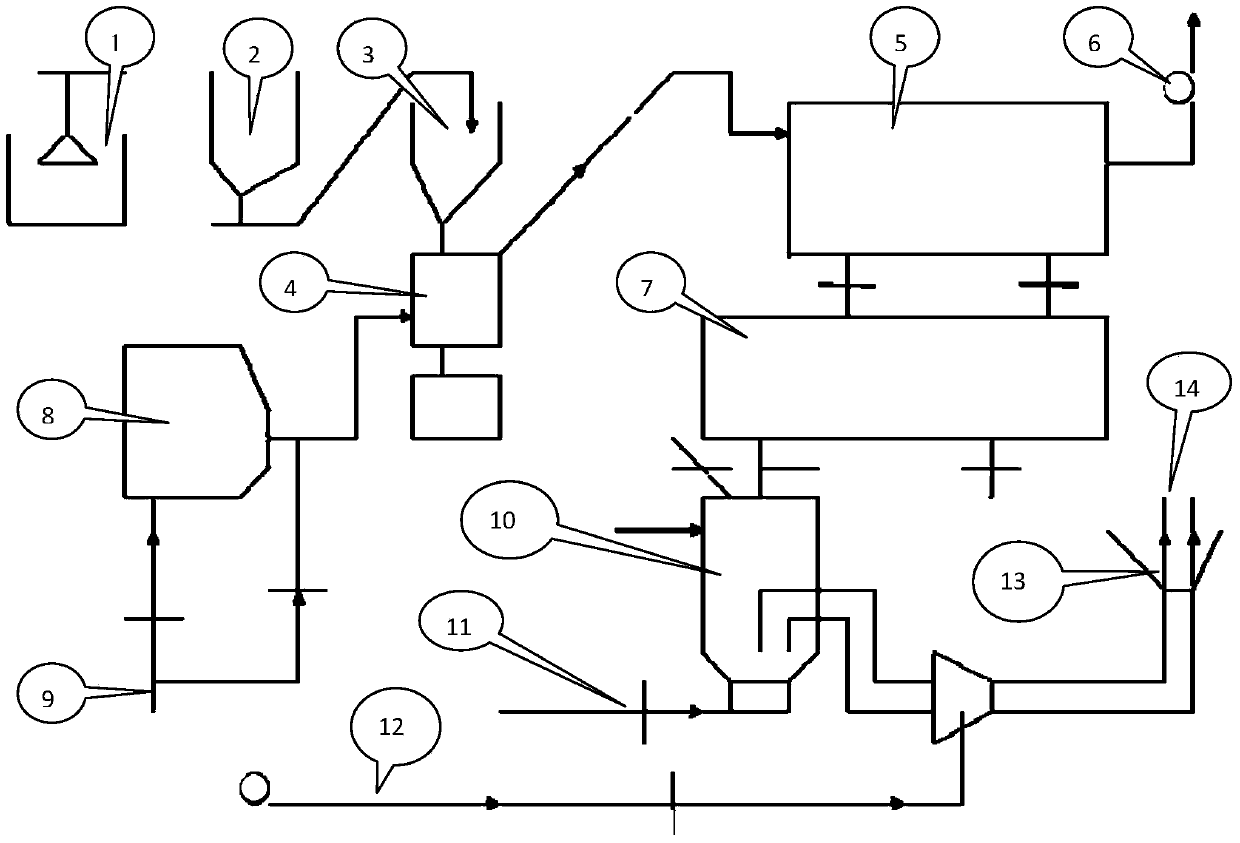

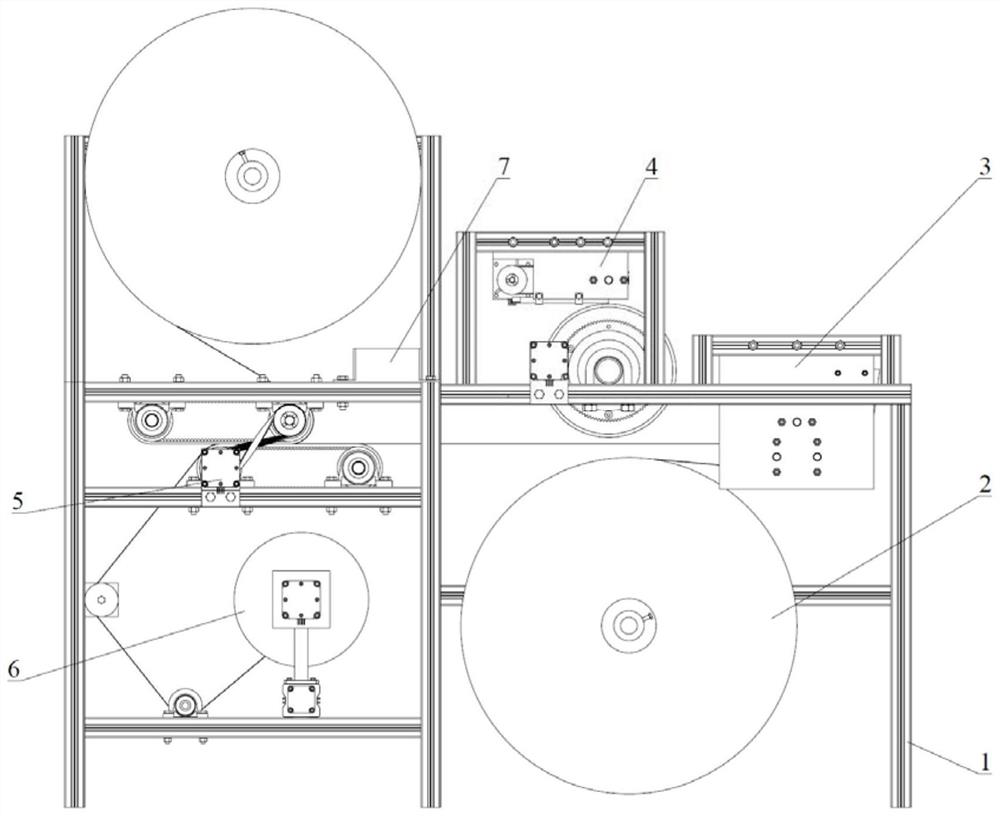

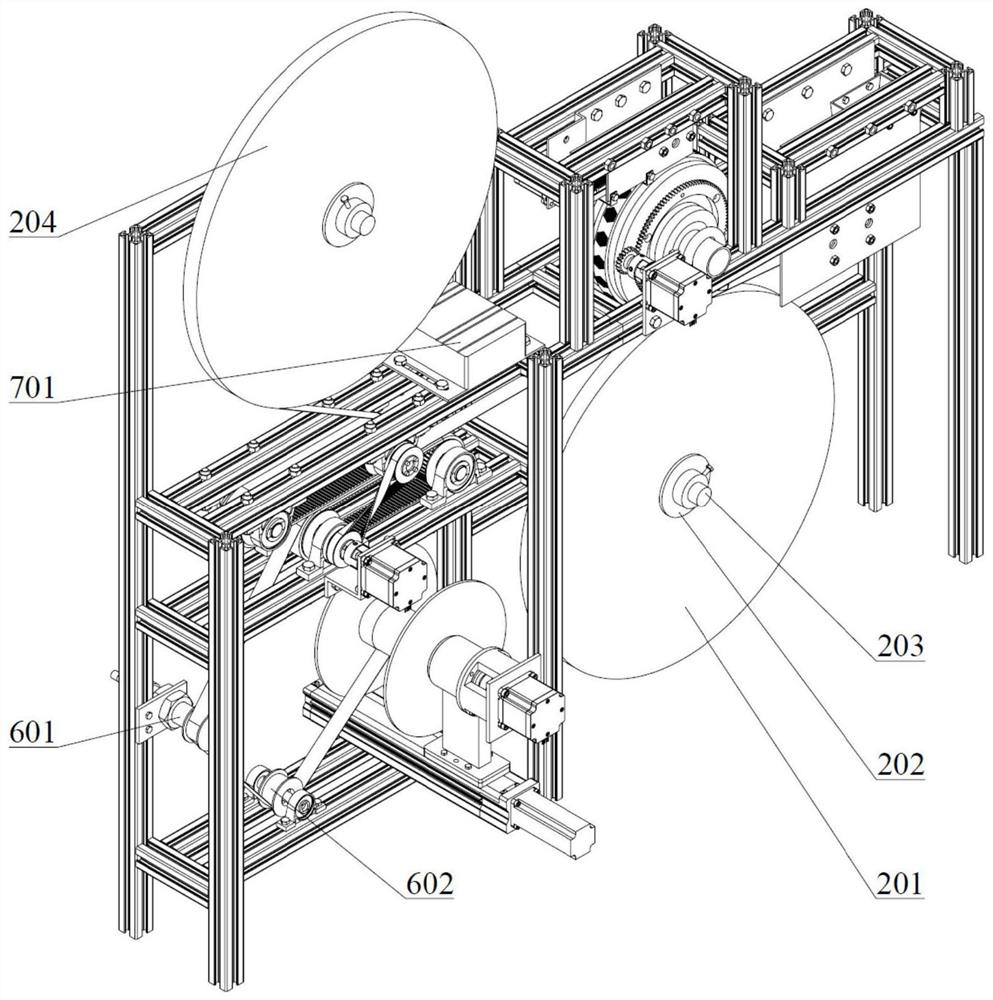

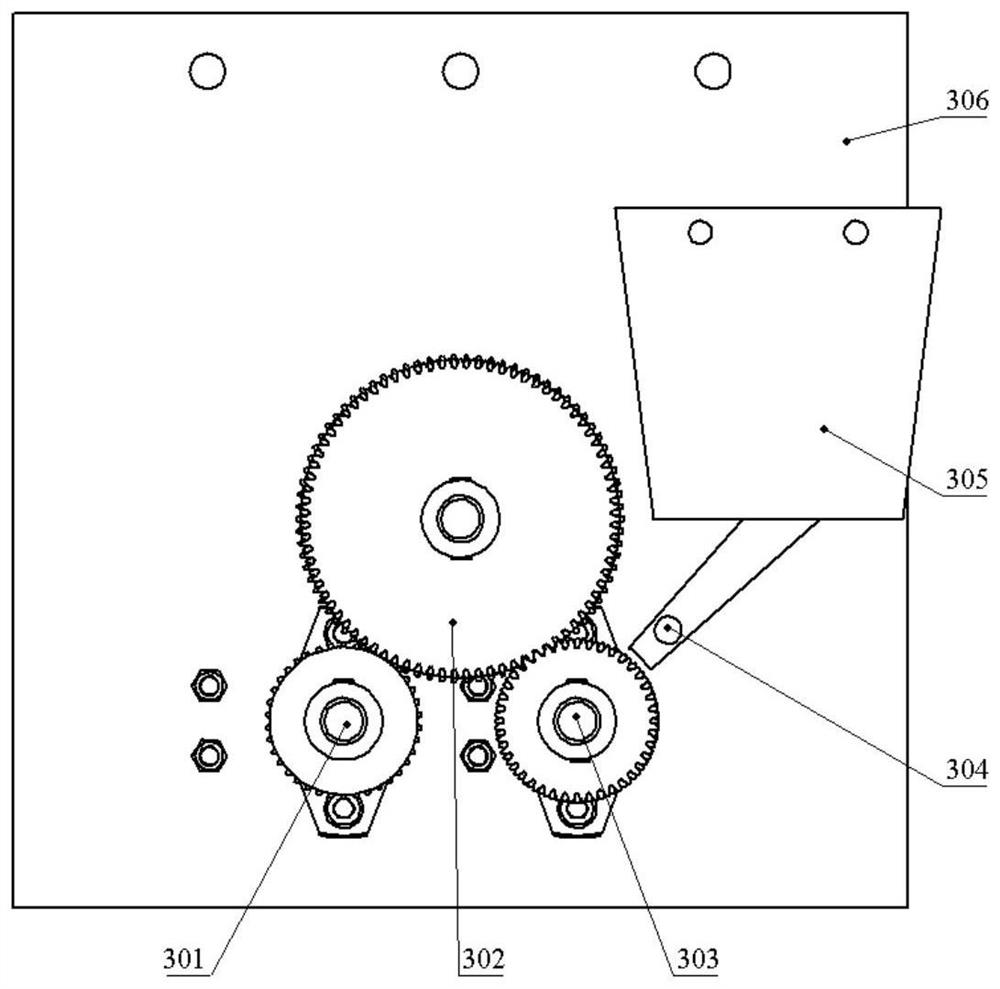

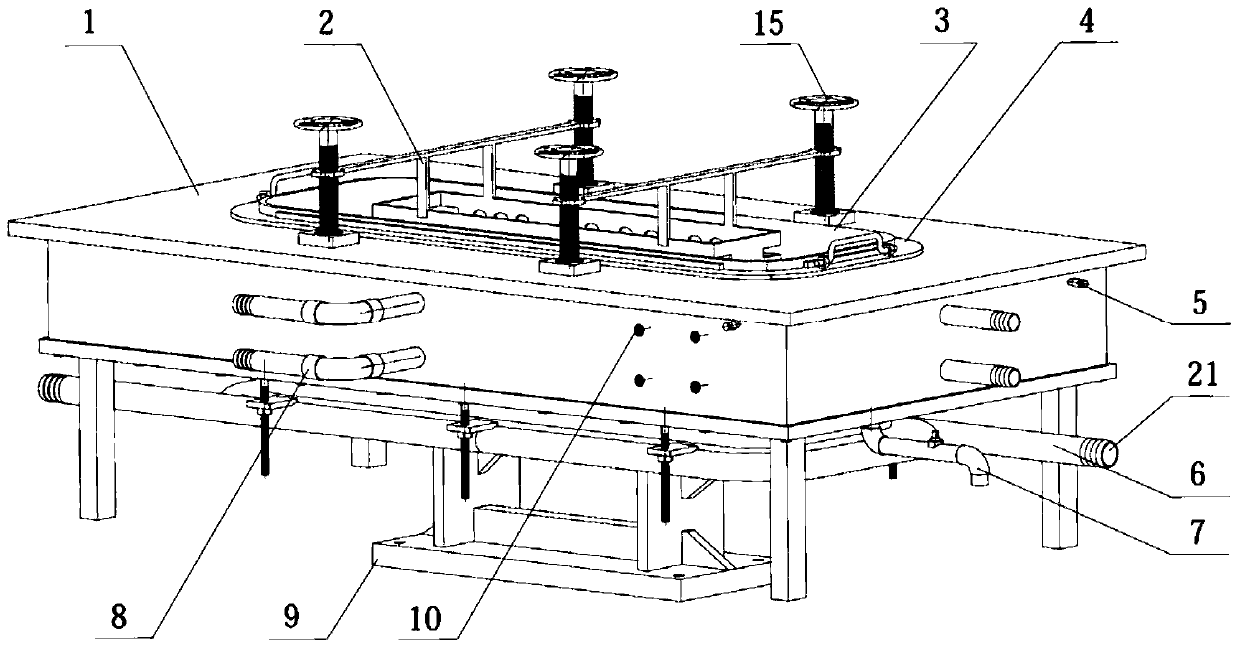

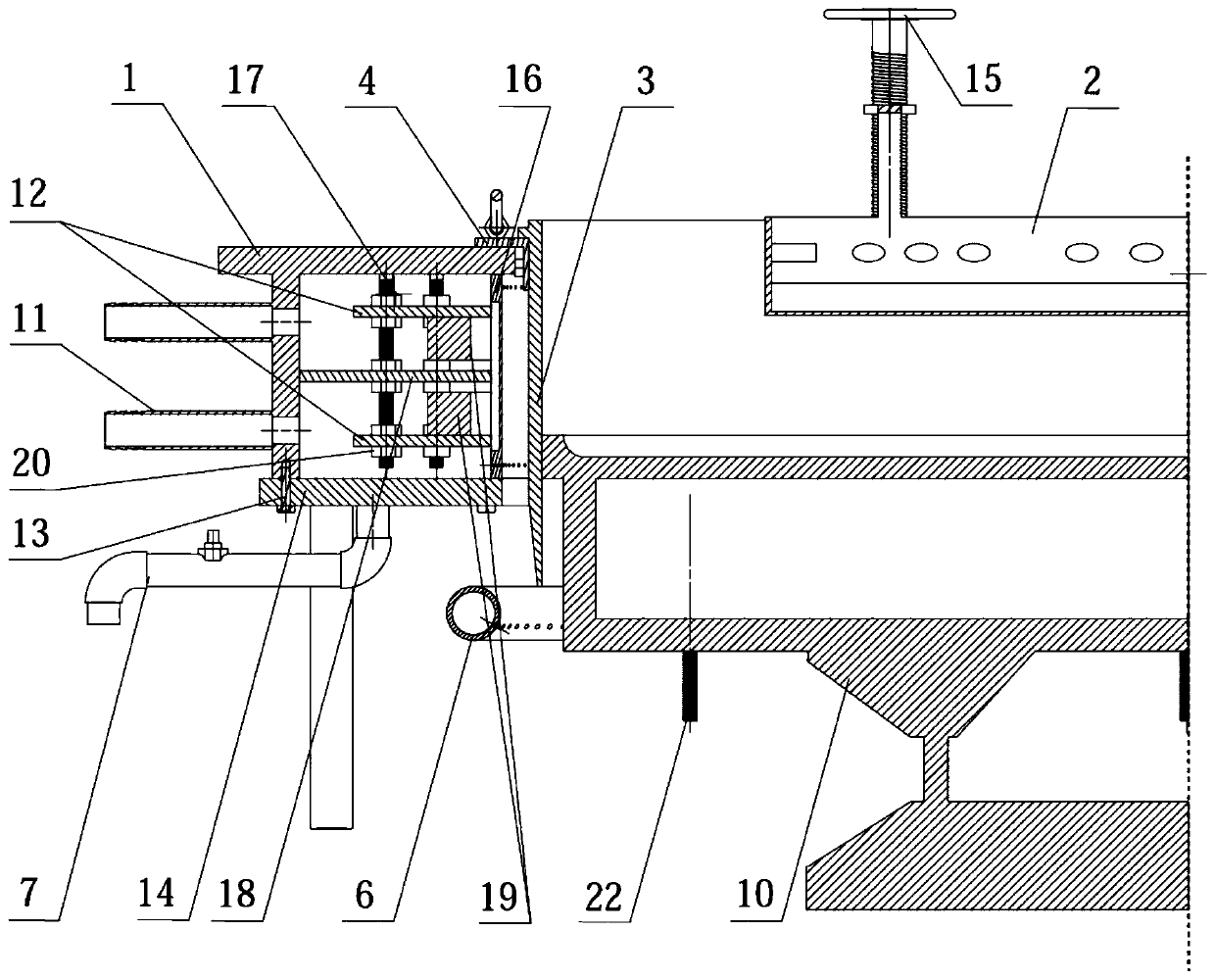

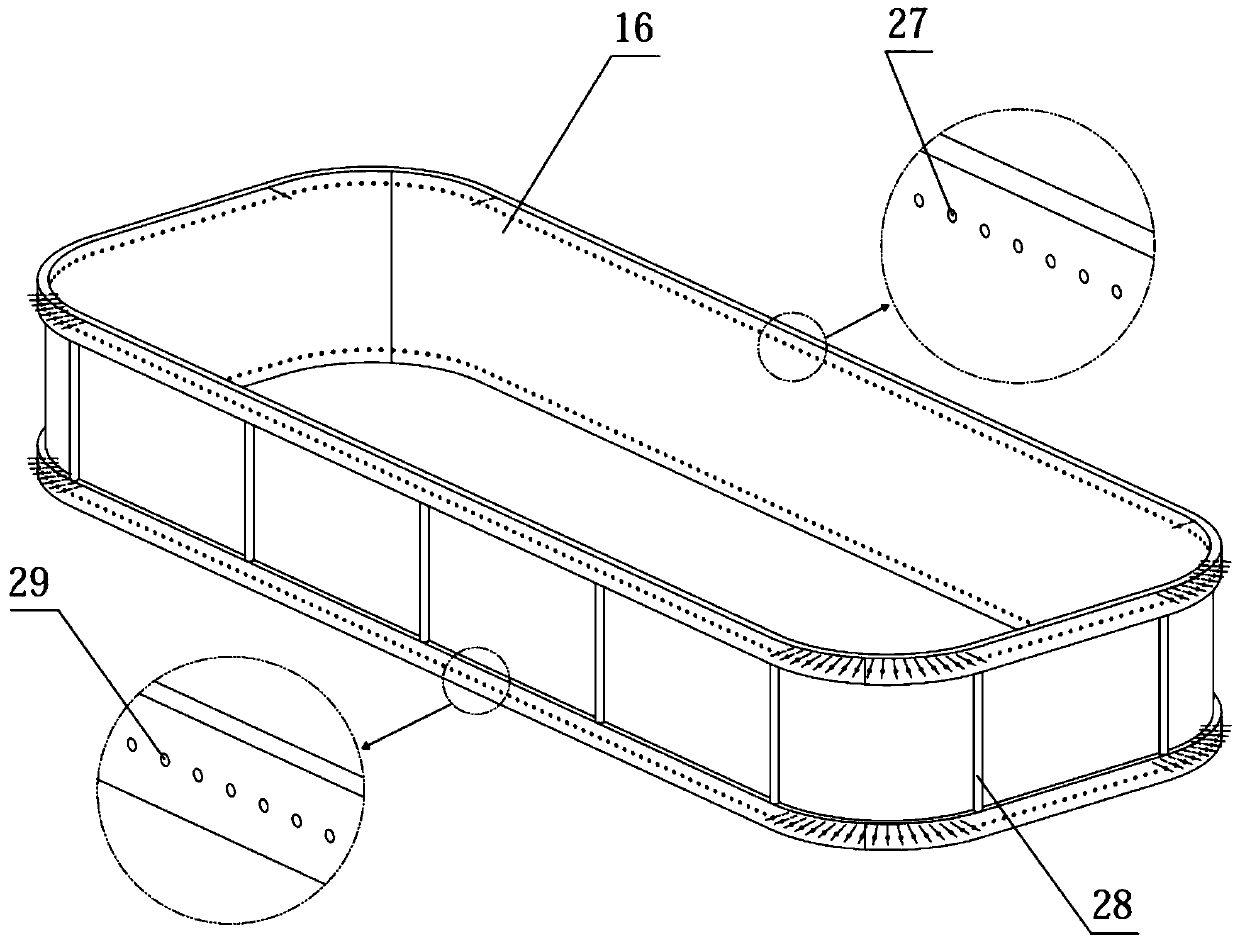

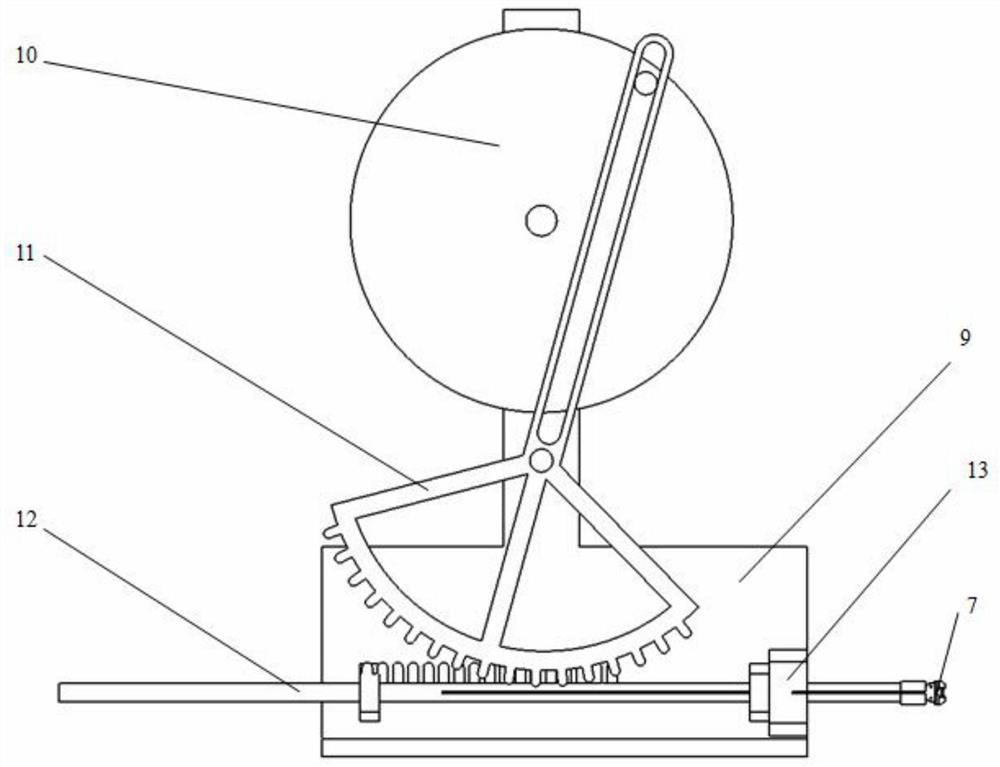

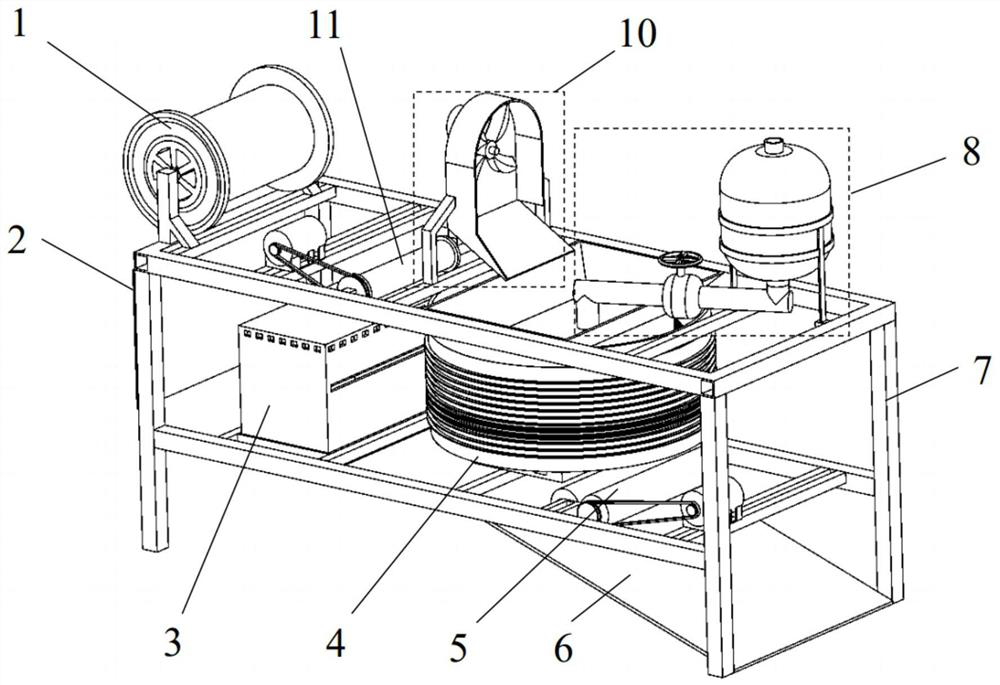

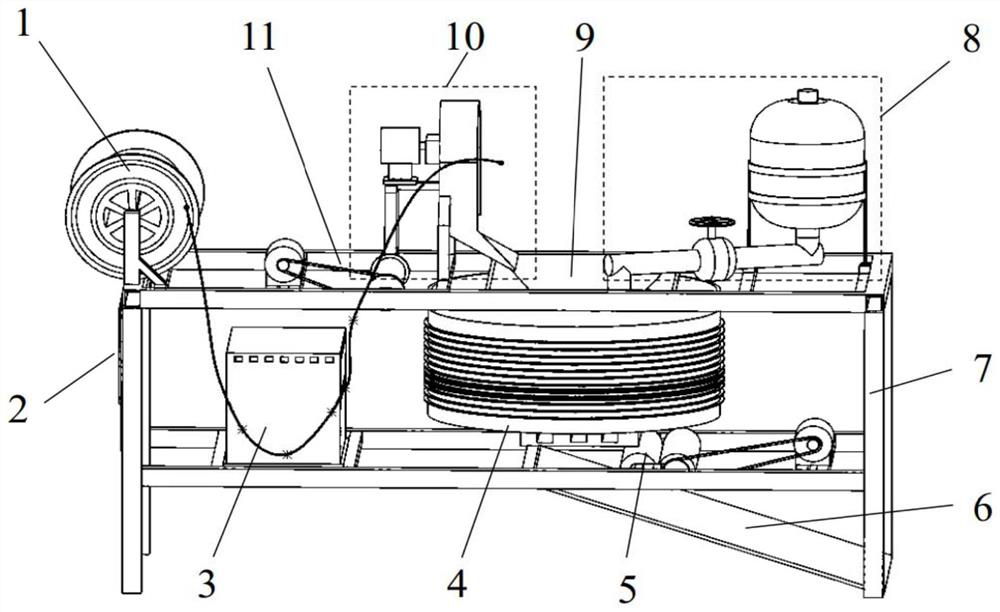

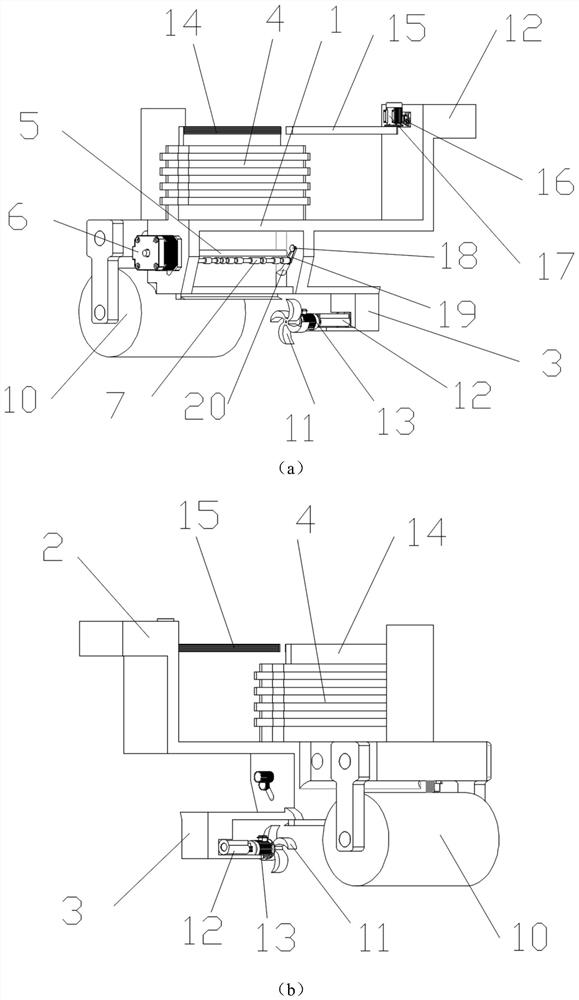

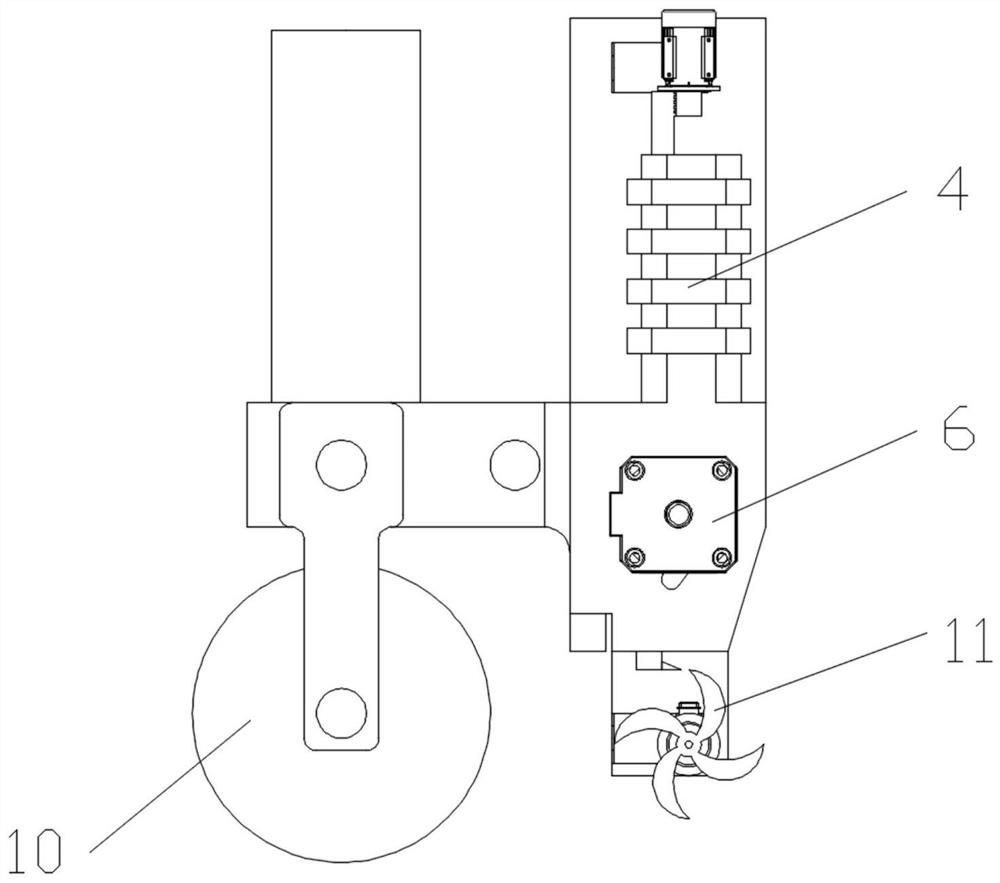

Seed tape preparation device for directional seeding corns

The invention discloses a seed tape preparation device for directional seeding corns. The seed tape preparation device for directional seeding corns comprises a working rack, a paper tape unwinding mechanism, a gluing mechanism, a directional zero-speed seed feeding mechanism, an upper and lower paper tape bonding mechanism, a winding mechanism and a control system; the working rack is formed by splicing a plurality of aluminum profiles; The paper tape unwinding mechanism comprises a lower paper tape, two material blocking disks, two optical shafts I and an upper paper tape; the upper paper tape is concentrically arranged on one optical shaft I through the material blocking disk, one optical shaft I is arranged on an upper left side of the working rack, the lower paper tape is concentrically arranged on the other optical shaft I through the material blocking disk, and the other optical shaft I is arranged on a lower right side of the working rack; and the gluing mechanism is arranged on an upper right side of the working rack, the directional zero-speed seed feeding mechanism is arranged on an upper middle part of the working rack, the upper and lower paper tape bonding mechanism is arranged on a middle part of a left side of the working rack, the winding mechanism is arranged on a lower part of the left side of the working rack and located below the upper and lower paper tape bonding mechanism, and the control system is arranged on an upper middle part of the working rack.

Owner:CHINA AGRI UNIV

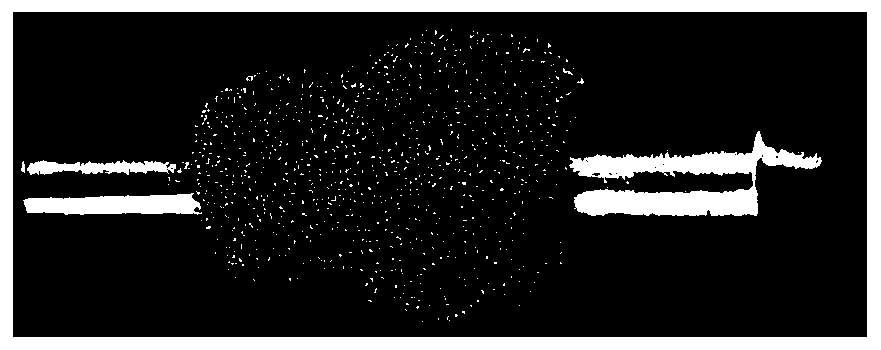

Device and method for low-cold electromagnetic semi-continuous casting

The invention provides a device and method for low-cold electromagnetic semi-continuous casting. The device comprises a crystallizer, wherein an upper dielectric plate is disposed between an outer sleeve top plate and an inner sleeve; clearance between the inner edge of an baseplate of the crystallizer and the outer wall of the inner sleeve is taken as a cooling water channel; the inner sleeve issurrounded by a water stop plate; and space between the water stop plate and an outer sleeve side plate is taken as a cooling water cavity. The method comprises the steps that (1) cooling water is fedinto the cooling water cavity via a cooling water inlet pipe, and then first cooling water and secondary cooling water are formed and sprayed to the outer wall of the inner sleeve; (2) an magnetic exciting coil is powered on by a power source, and a magnetic field is generated; (3) an alloy melt is poured into the inner sleeve, and a dummy bar head is started for continuous casting; and (4) thirdcooling water is sprayed to an ingot casting surface via a third cooling water pipe. The device provided by the invention has the beneficial effects that the structure is simple; maintenance is easy;production efficiency can be increased; cooling intensity can be controlled and regulated easily; and surfaces of large-size ingot castings prepared are of good quality.

Owner:NORTHEASTERN UNIV LIAONING

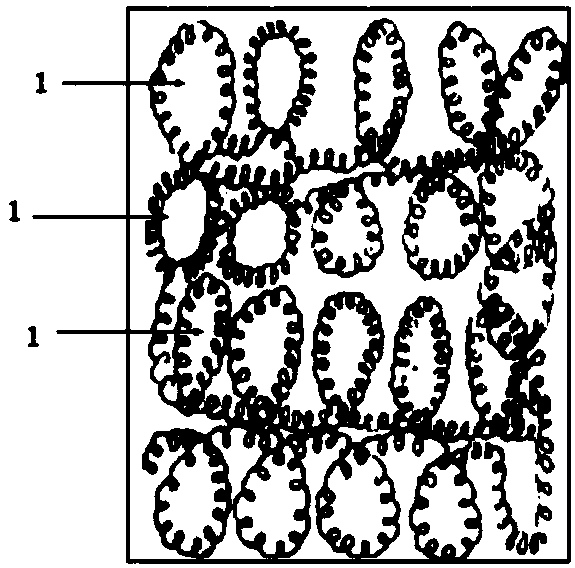

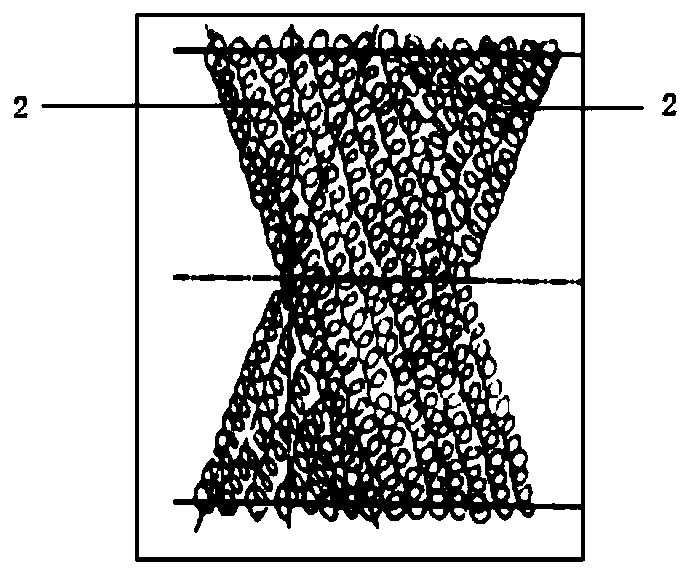

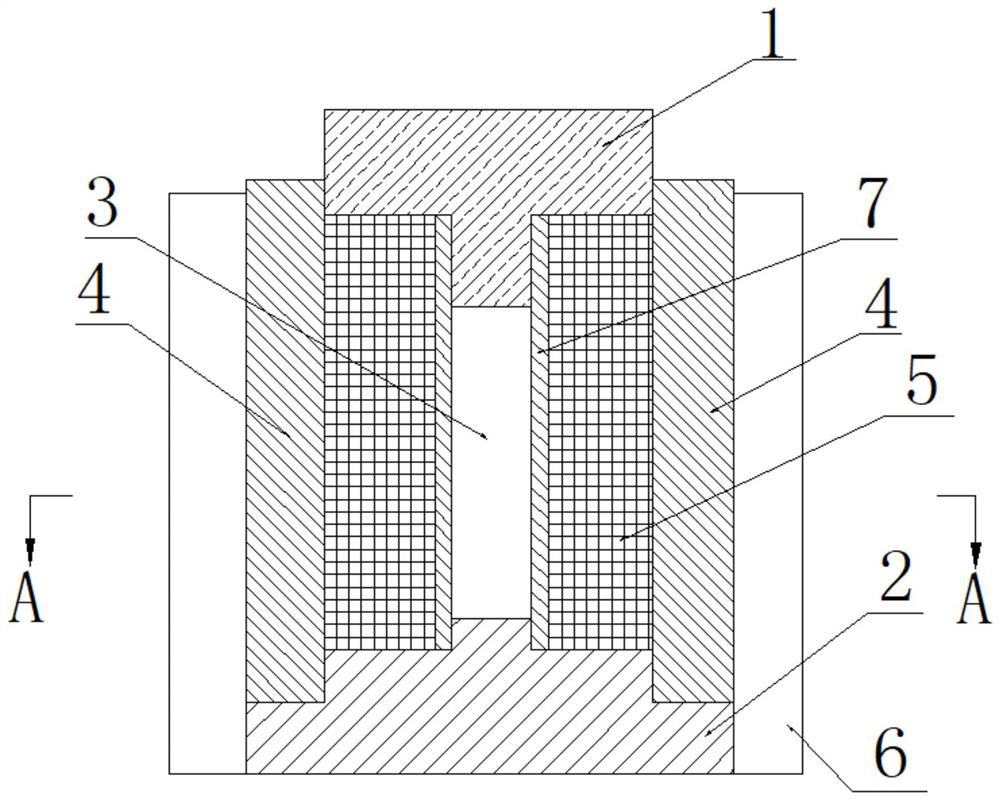

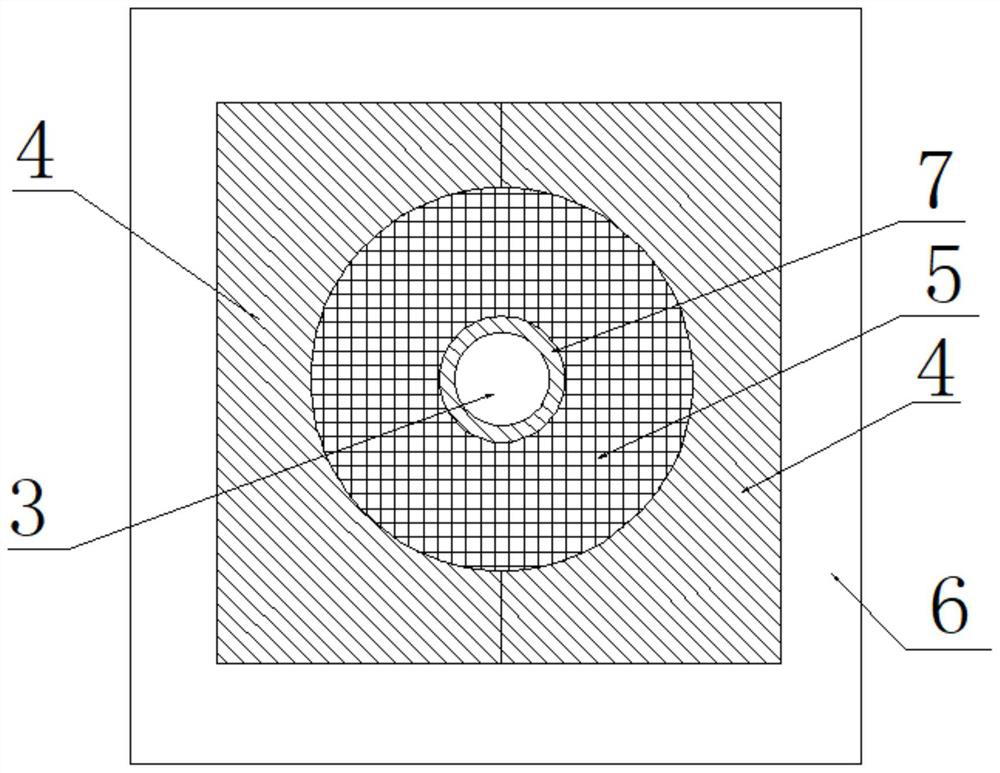

Metal rubber fabricated part and preparation thereof, and preparation method of metal rubber ring

PendingCN110345185AMeet preparationIncrease dampingElastic dampersShock absorbersPolymer scienceMetal rubber

The invention discloses a metal rubber fabricated part and a method thereof, and a preparation method of a metal rubber ring. The metal rubber fabricated part comprises a core body and a coating body,wherein the core body comprises a plurality of O-type weaving layers; each O-type weaving layer comprises a plurality of O-type structures formed by winding metal wires; the adjacent O-type structures of the adjacent layers incompletely coincide; the coating body coats the outer part of the core body, and comprises a plurality of first diagonal type weaving layers; each first diagonal type weaving layer is formed by winding metal wires in the same inclining direction; and the metal wires between the adjacent first diagonal type weaving layers form a first X-type structure. The metal rubber fabricated part is not filled with a die or a weaving process ruler, so that the preparation of the large metal rubber fabricated part is met. The invention also provides the preparation of the metal rubber ring. A metal rubber blank part is formed by winding the meal rubber fabricated part on a core shaft and weaving the metal rubber fabricated part, and is subjected to compression moulding to formthe metal rubber ring. Through the adoption of the method, layering and cracking of metal rubber can be avoided.

Owner:BEIJING XINGJI RONGYAO SPACE TECH CO LTD

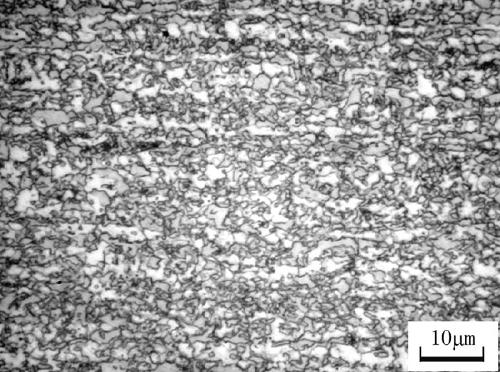

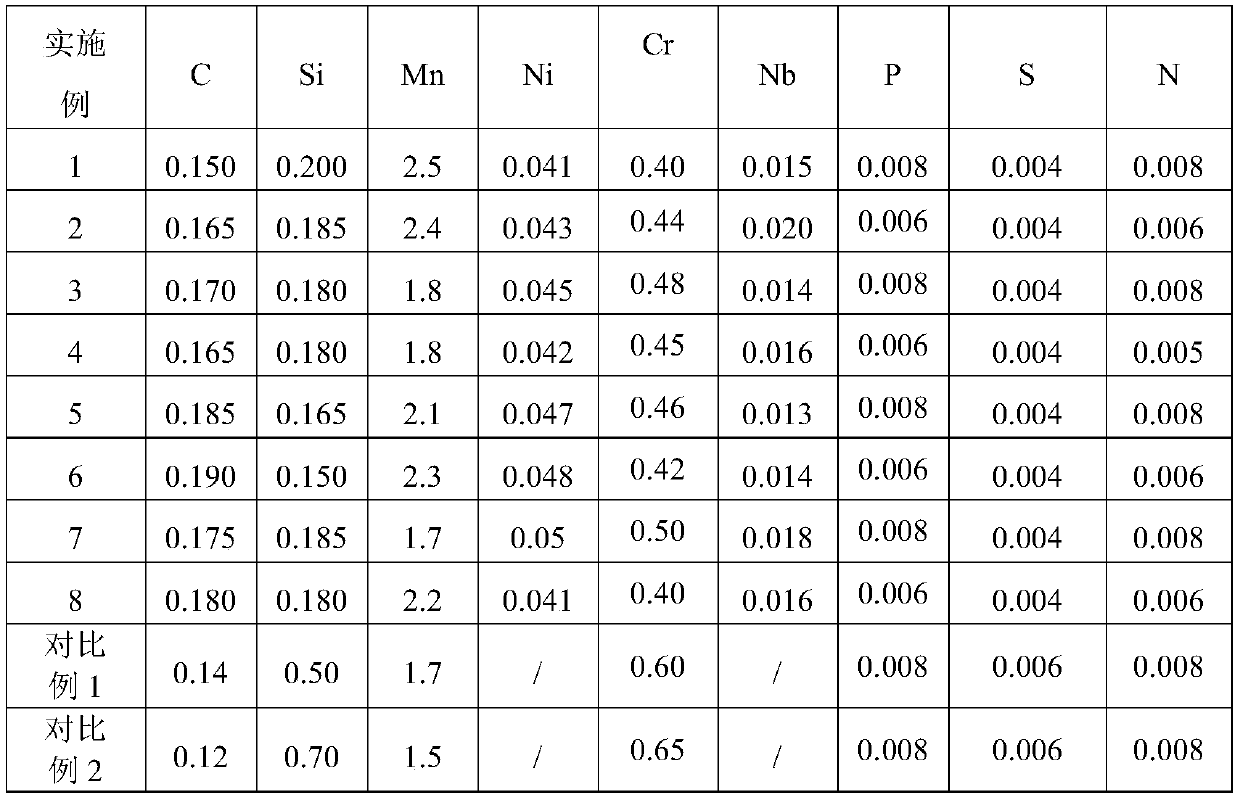

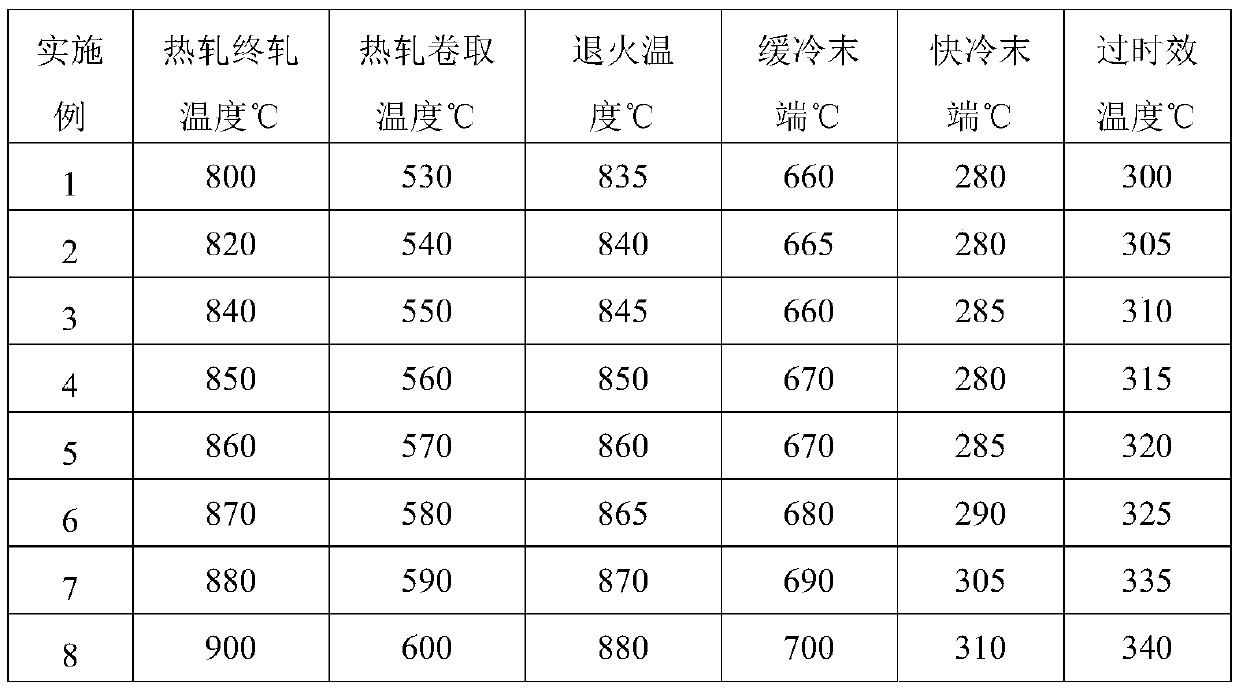

800 MPa-level cold rolled steel with hardening index value n larger than or equal to 0.155 and production method

The invention provides 800 MPa-level cold rolled steel with a hardening index value n larger than or equal to 0.155. The cold rolled steel comprises components in percentage by weight as follows: 0.16%-0.19% of C, 0.15%-0.20% of Si, 1.5%-2.5% of Mn, 0.40%-0.50% of Cr, 0.040%-0.05% of Ni, 0.010%-0.020% of Nb, smaller than 0.005% of S, smaller than 0.008% of P and smaller than 0.006% of N. A technology comprises steps as follows: hot rolling of a casting blank; coiling; cold rolling; continuous annealing; slow cooling; fast cooling; overaging treatment; natural cooling to room temperature. The yield strength Rp0.2 of 540 MPa-670 MPa and the tensile strength Rm of 870 MPa-895 MPa are guaranteed, the hardening index n is enabled to be larger than or equal to 0.155, the elongation A80mm is enabled to be larger than or equal to 17%, so that the grain size of the metallographic structure reaches level 15.5, and the preparation demand of more complicated parts can be completely met.

Owner:武汉钢铁有限公司

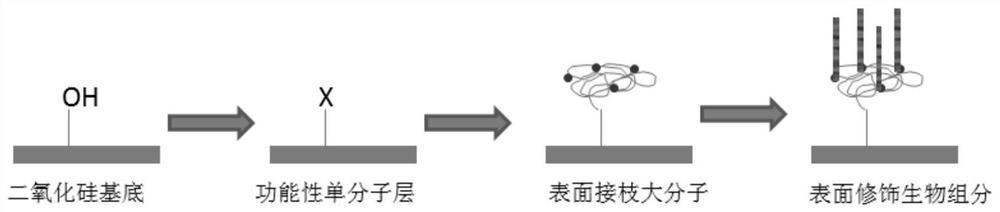

Polymer, chip and preparation method and application thereof

ActiveCN114573764AImprove stabilityOvercome the technical defects of relatively limited manufacturing processMicrobiological testing/measurementLaboratory glasswaresBio moleculesHigh density

The invention relates to a polymer, a chip and a preparation method and application thereof. The polymer comprises a repeating unit A and a repeating unit B with specific structural characteristics. The biochip can load biological components with higher density, meets the requirements of continuously developing biomolecule preparation and / or analysis, and is good in stability.

Owner:GENEMIND BIOSCIENCES CO LTD

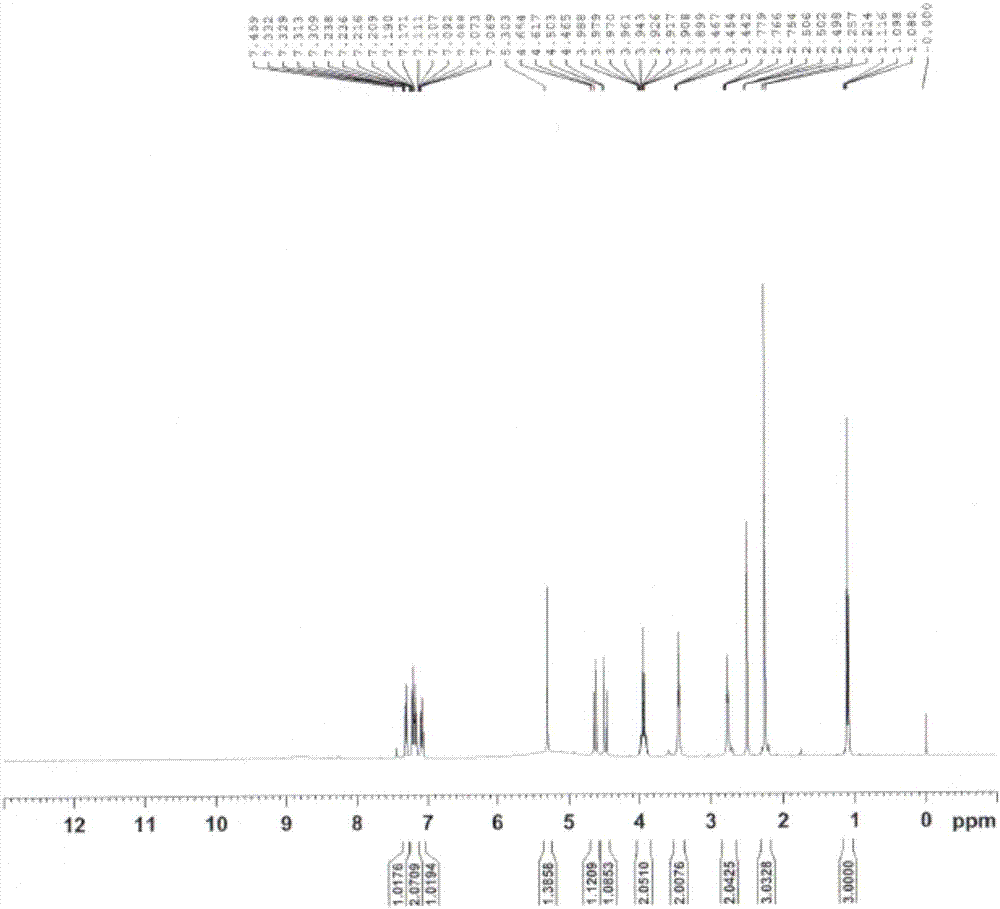

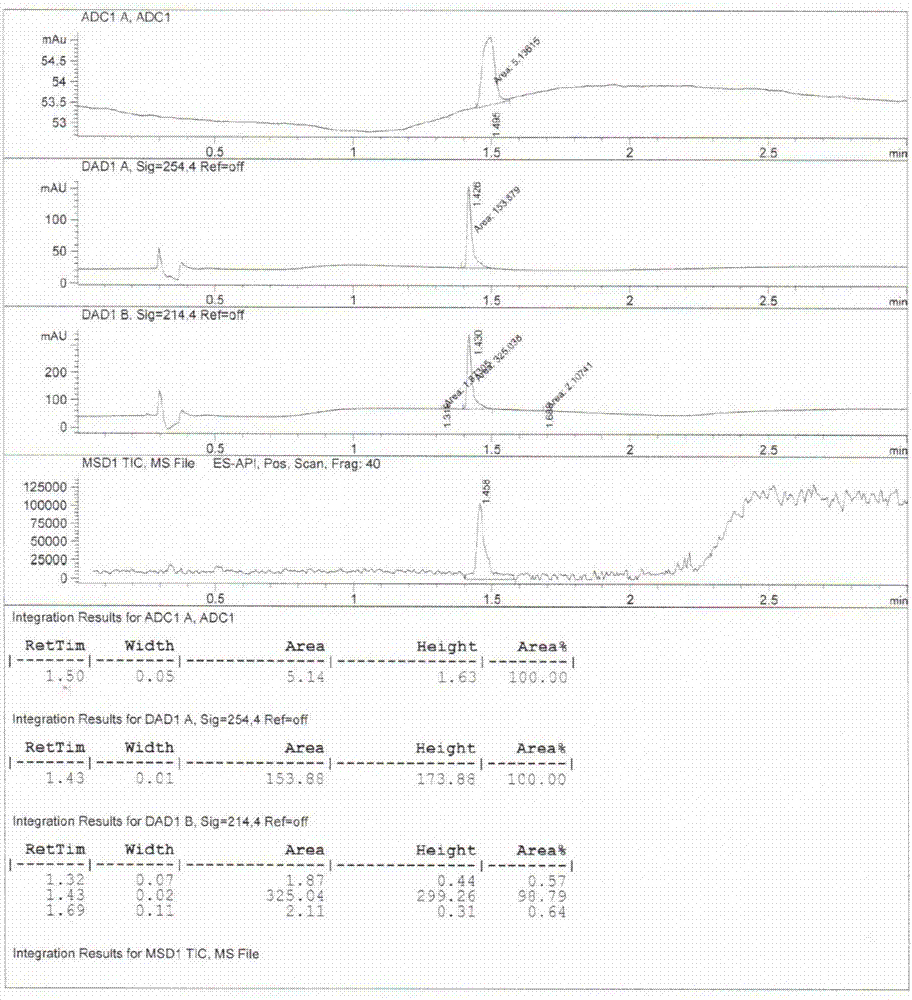

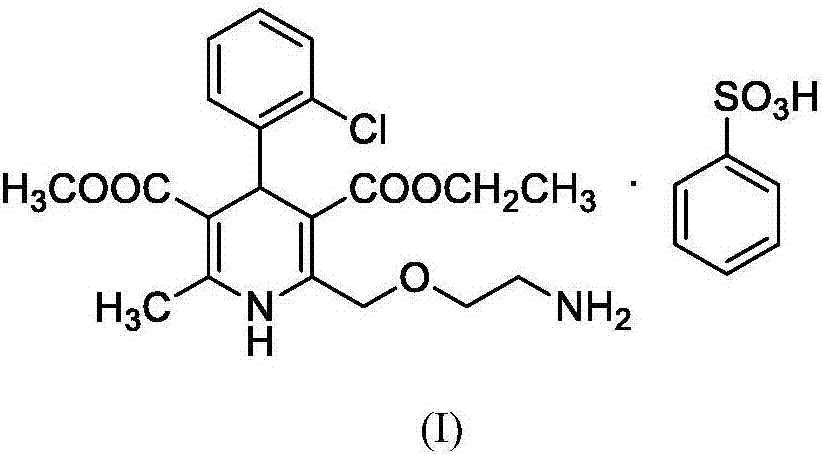

Synthesis method of amlodipine besylate degradant impurities

The invention provides a preparation method of amlodipine besylate degradant impurities. The method comprises the following steps: a) preparation of a compound 1: generating corresponding imine, namely, the compound 1 by using an acetylacetic ester compound SM1 as a raw material and using lower alcohol as a solvent under the condition of an ammonia source; b) preparation of a compound 2: performing a Hantzsch reaction on a compound SM2, the compound 1 and o-chlorobenzaldehyde SM3 as raw materials, so as to obtain the compound 2; c) preparation of a compound 3: removing R-base protection from the compound 2, so as to obtain the compound 3; d) preparation of a compound TM: removing R' from the compound 3, so as to obtain the compound TM. The invention provides a synthesis method of the amlodipine besylate degradant impurities and provides the preparation method of a reference substance for the study on the quality of amlodipine besylate, so that the important guiding significance is provided for safe medication of the amlodipine besylate.

Owner:JIANGSU HAICI BIOLOGICAL PHARMA CO LTD OF YANGTZE RIVER PHARMA GRP +1

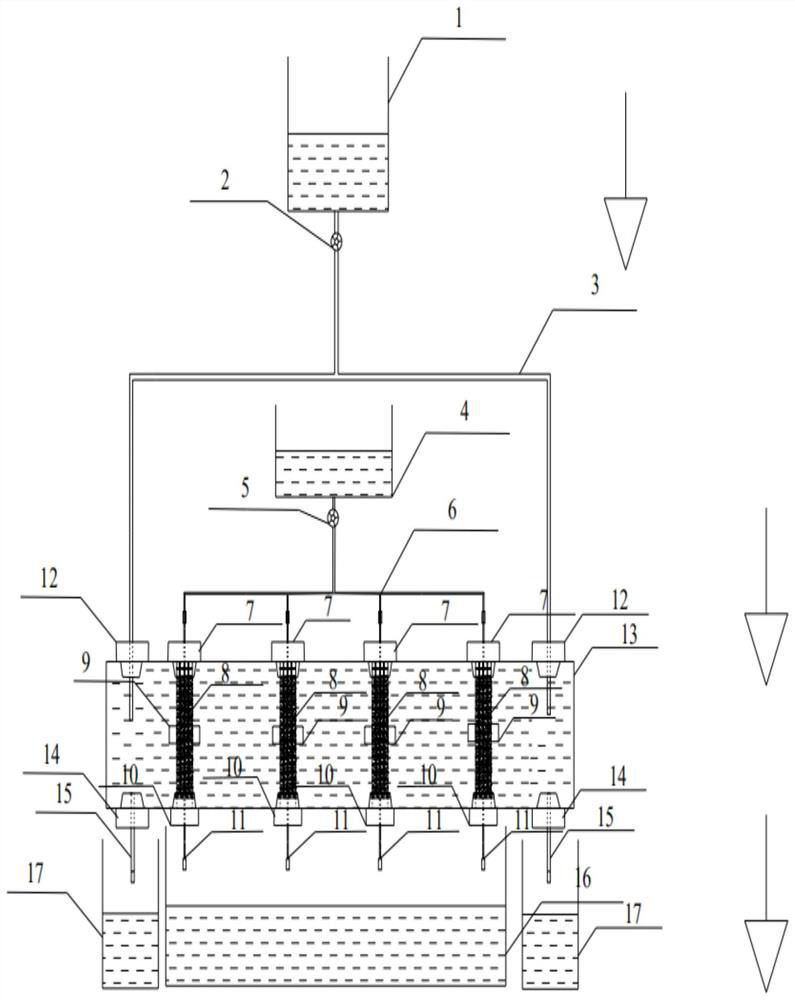

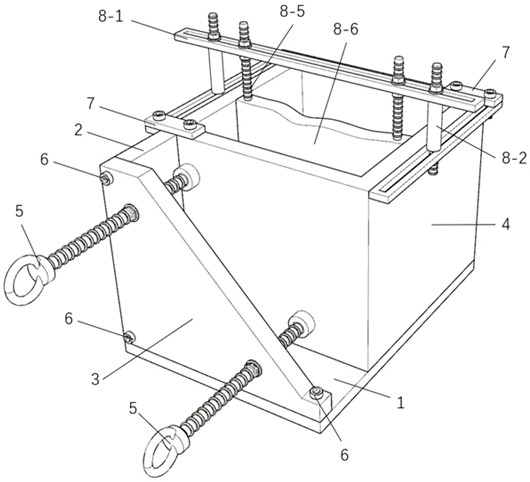

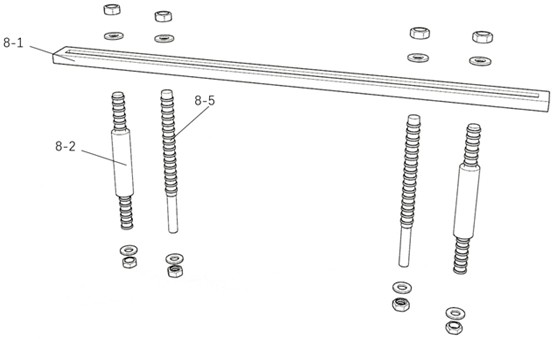

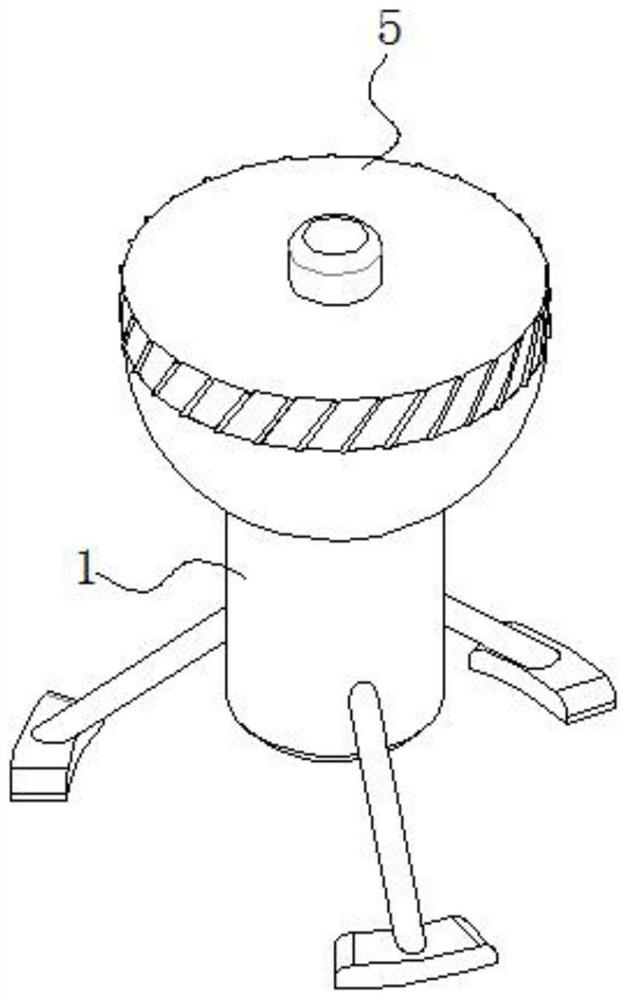

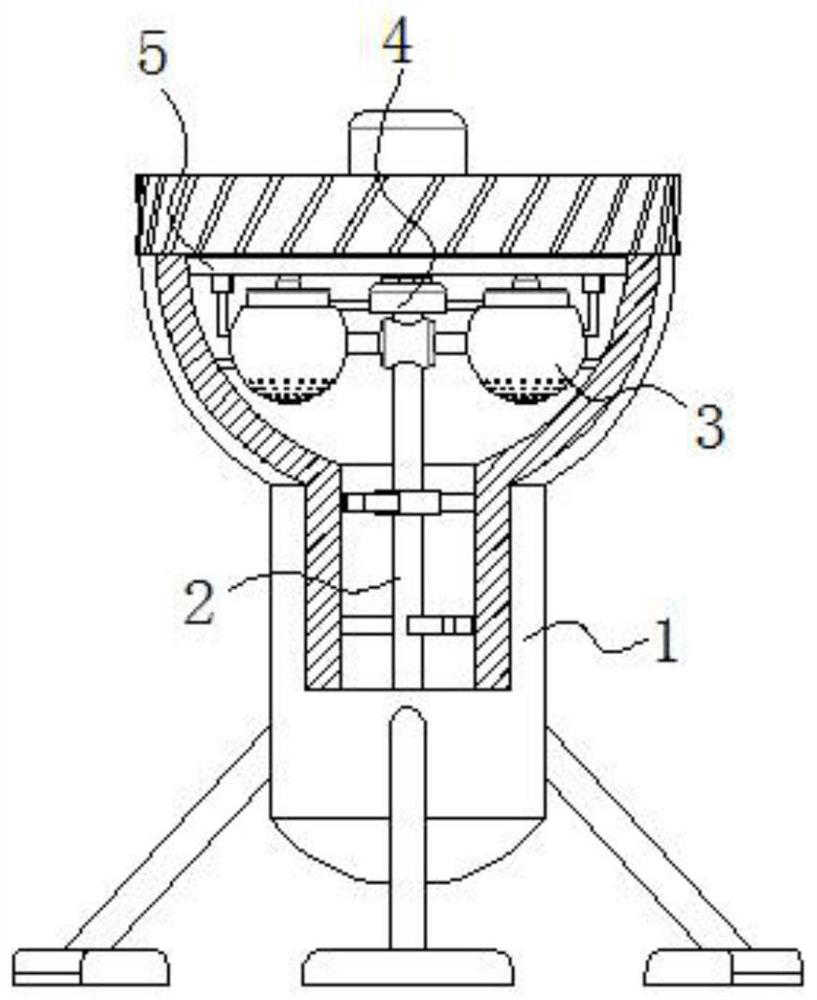

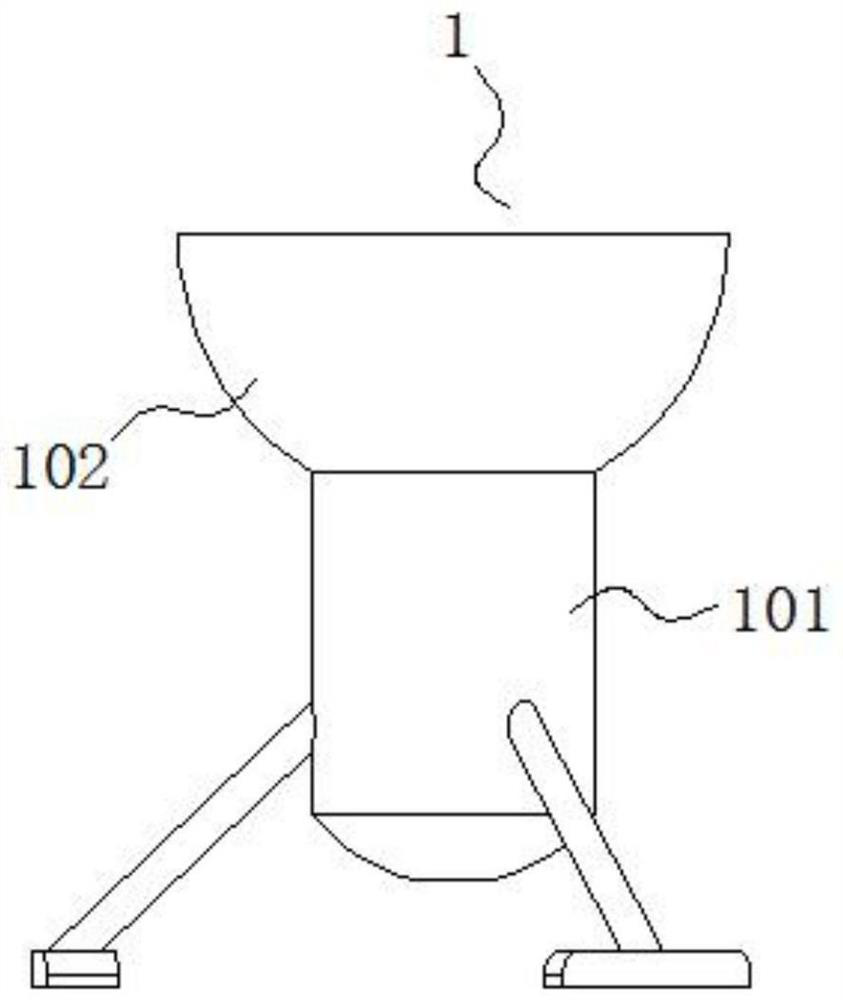

Linkage type liquefiable sandy soil triaxial sample in-situ solidification sample preparation instrument and method

ActiveCN112525649ARealize in-situ grouting reinforcementImprove curing effectPreparing sample for investigationPeristaltic pumpSoil science

The invention discloses a linkage type liquefiable sandy soil triaxial sample in-situ solidification sample preparation instrument. The instrument comprises a No.1 slurry storage box, a No.1 peristaltic pump, a No.1 grouting pipe, a No.2 slurry storage box, a No.2 peristaltic pump, a No.2 grouting pipe, a No.1 rubber plug, a sand sample compaction cylinder, a compaction cylinder pipe hoop, a composite plug, a percolate outlet pipe, a No.2 rubber plug, an organic glass dish, a No.3 rubber plug, a surplus slurry outlet pipe, a percolate collection dish and a surplus slurry collection dish. The linkage type liquefiable sandy soil triaxial sample in-situ solidification sample preparation method comprises the steps that sandy soil with the soil particle size ranging from 0.075 mm to 4 mm is putinto all sand sample compaction cylinders, a cylindrical sample with the set diameter range and the adjustable height range is formed after layered compaction, grouting is conducted through the peristaltic pumps according to related requirements, and therefore, a solidified sandy soil cylindrical sample meeting the standard requirements is obtained. The solidification effect and integrity of theprepared sample are improved, the sample preparation efficiency is improved, the sample preparation precision is improved, and the application range is widened.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Preparation method of MoNiB metal ceramic thread element

PendingCN112893843AHas tensile strengthWith bending strengthTurbinesOther manufacturing equipments/toolsRound barMetal mold

The invention discloses a preparation method of a MoNiB metal ceramic thread element. The preparation method comprises the following steps that Mo-Ni-B metal mixed powder is prepared; a steel tubular core rod is machined; a metal mold is prepared; the steel tubular core rod is placed in the mold, and the space among a outer mold, a core mold and a lower mold is filled with the Mo-Ni-B metal mixed powder; the metal mold filled with the powder is placed into a pressure chamber of press equipment, static pressure molding is performed, and demolding is performed to form a composite molding body with the steel core hollow round rod inside and the Mo-Ni-B metal mixed powder on the outer layer; the composite forming body is machined into a thread element blank; the blank is subjected to vacuum sintering, and a finished blank is obtained; and the finished blank is subjected to finish machining, and the steel-based MoNiB composite metal ceramic product thread element finished product is obtained. The MoNiB metal ceramic thread element has ultrahigh corrosion resistance and wear resistance at the same time.

Owner:CHINA UNIV OF MINING & TECH +1

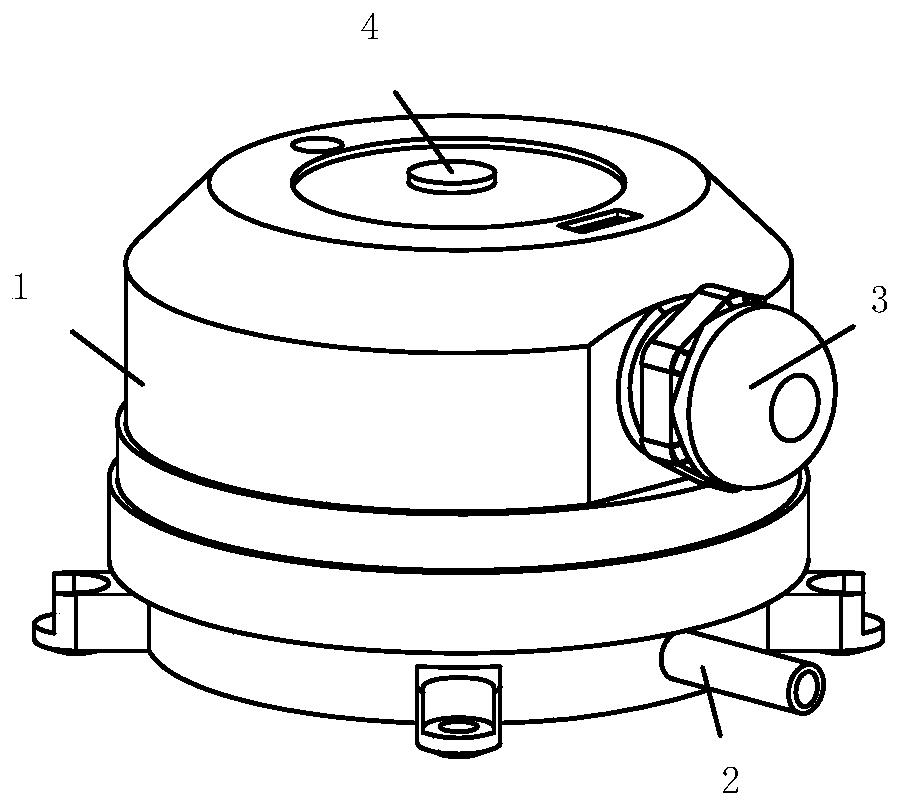

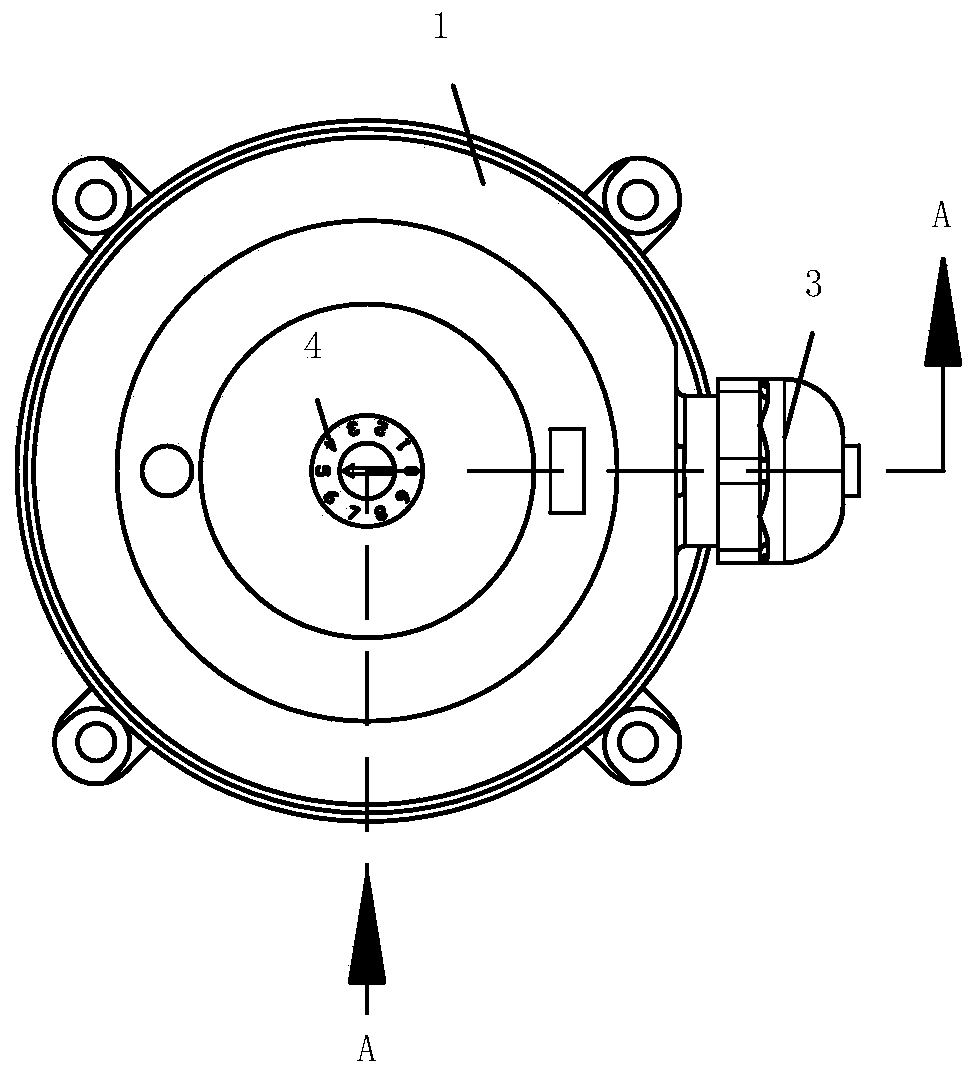

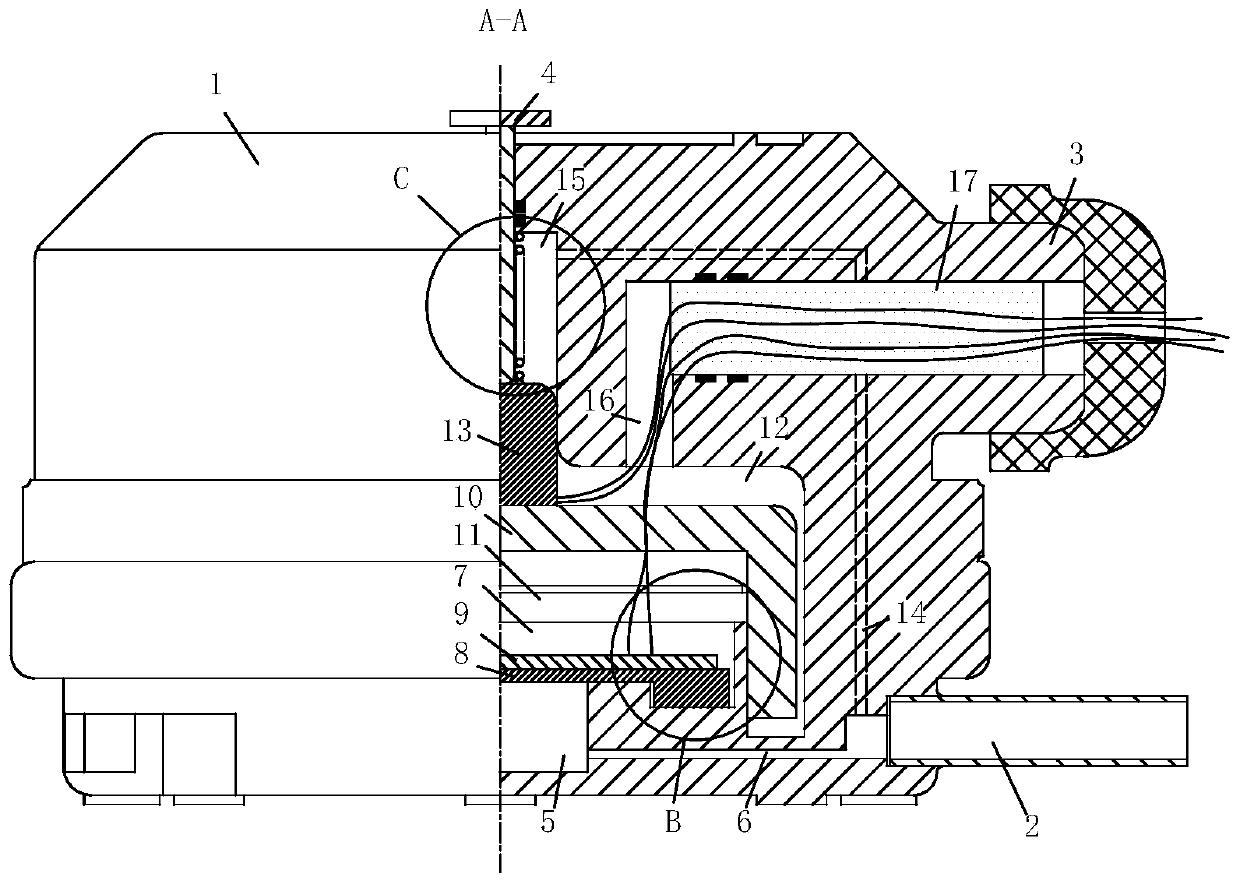

Pressure sensor module

InactiveCN111595507AAvoid leaning stuckSimple structureFluid pressure measurement using piezo-electric devicesPhysicsEngineering

The invention relates to the technical field of pressure sensor modules, and in particular, relates to a pressure sensor module which comprises a shell; an air inlet pipe is arranged on the right sideof the lower end of the shell, and a wire outlet pipe is arranged on the right side of the upper end of the shell; a first cavity, an installation cavity and a third cavity are sequentially formed inthe shell from bottom to top, the first cavity is communicated with the air inlet pipe through an airflow channel, the installation cavity is communicated with the wire outlet pipe through a wiring hole, and a sealing plug is arranged in the wire outlet pipe. Under the condition that the maximum deformation of a pressure chip is not changed, through the arrangement of a second cavity and the first cavity, the pressure chip deforms downwards in the reverse direction under the small pressure and deforms upwards in the forward direction under the large pressure, and the sensitivity and the measuring range of the pressure sensor module are improved in proportion under the condition of low cost.

Owner:岳保丽

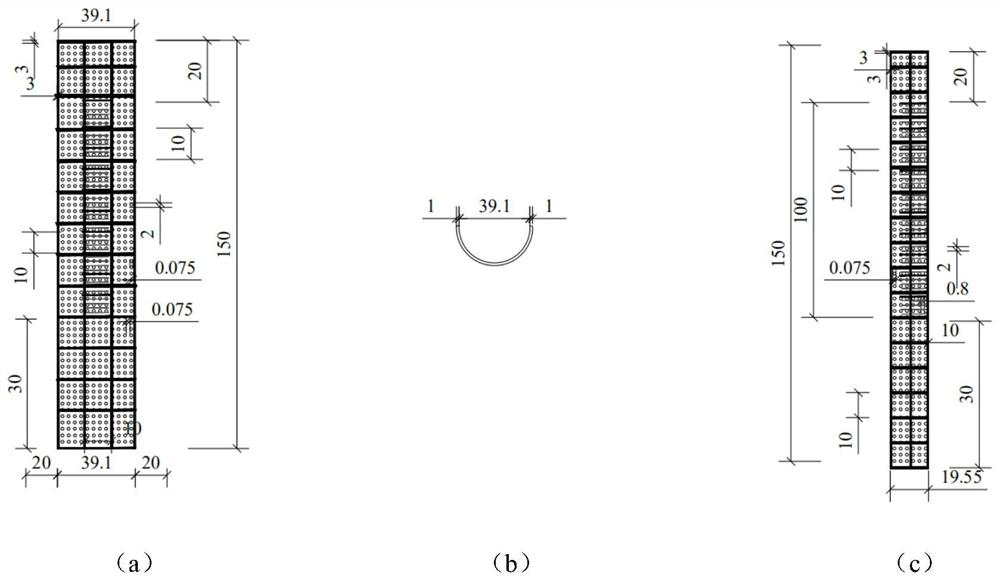

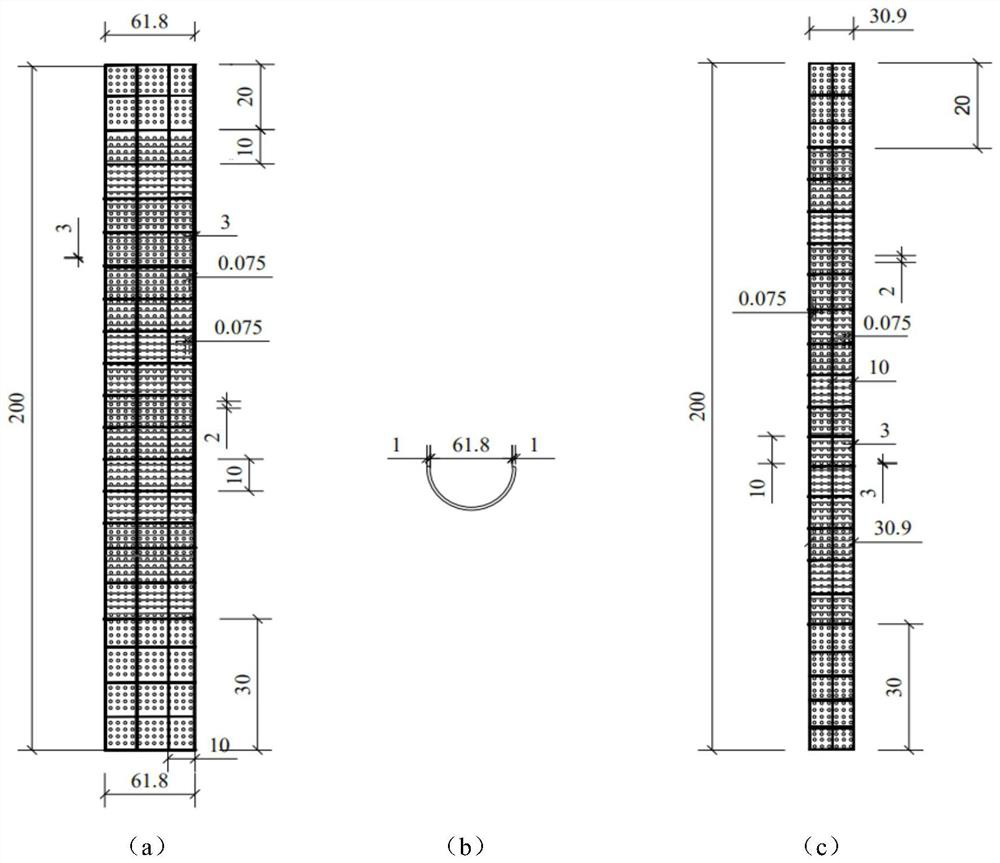

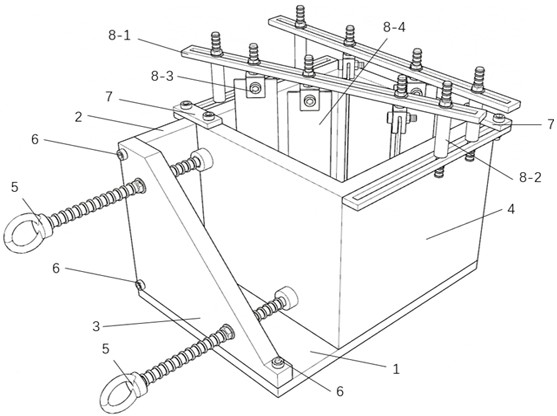

Crack-containing rock material preparation test device and use method

ActiveCN114858561AExtended service lifeFlexible model size control capabilityPreparing sample for investigationStructural engineeringTest rig

Owner:SOUTHWEST JIAOTONG UNIV +1

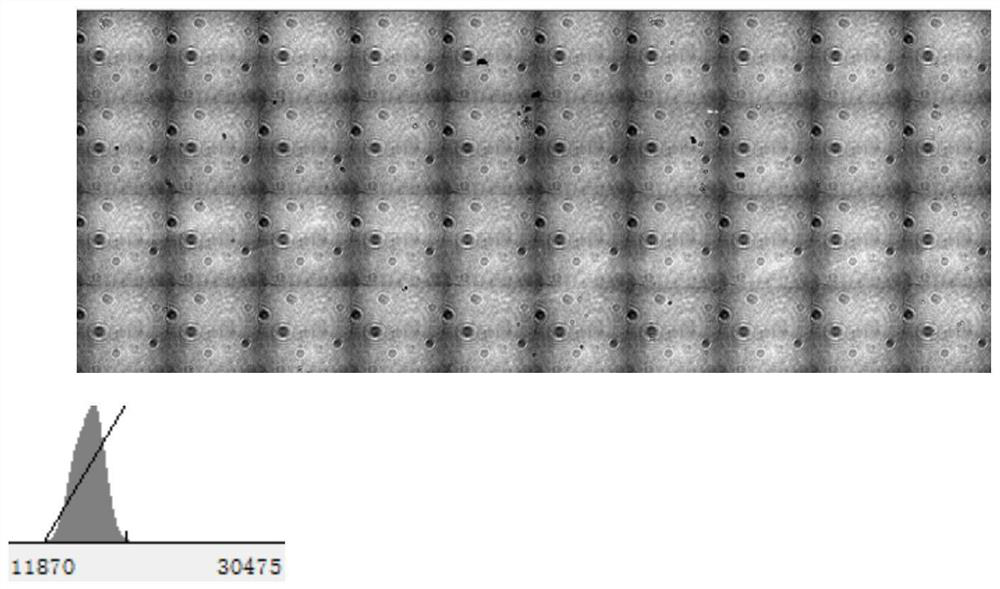

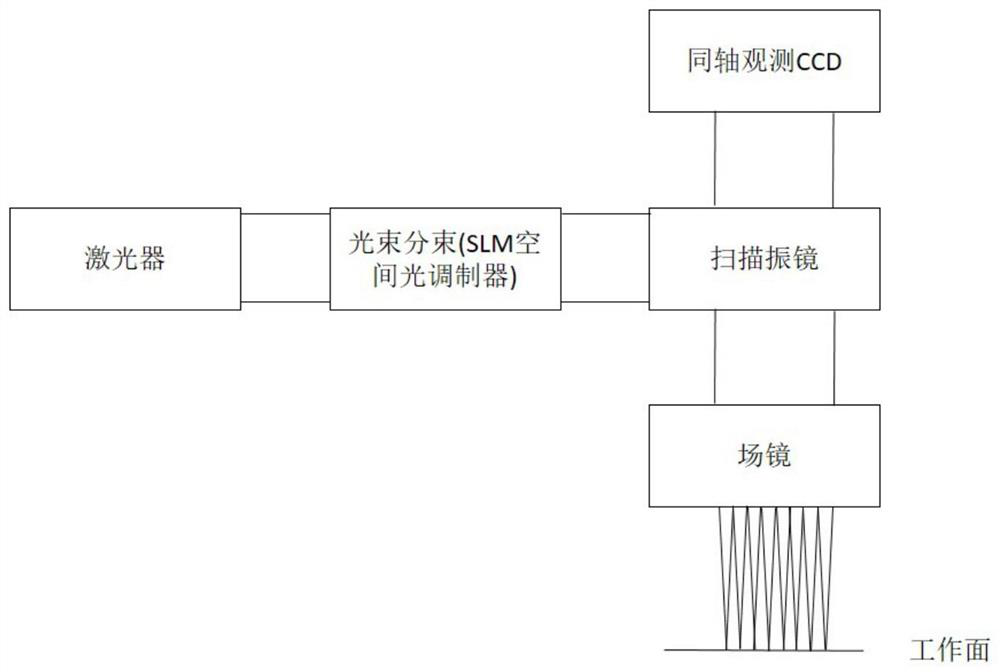

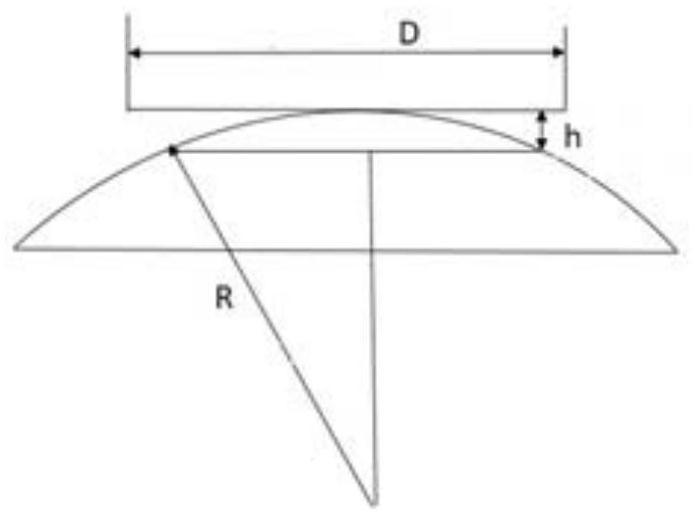

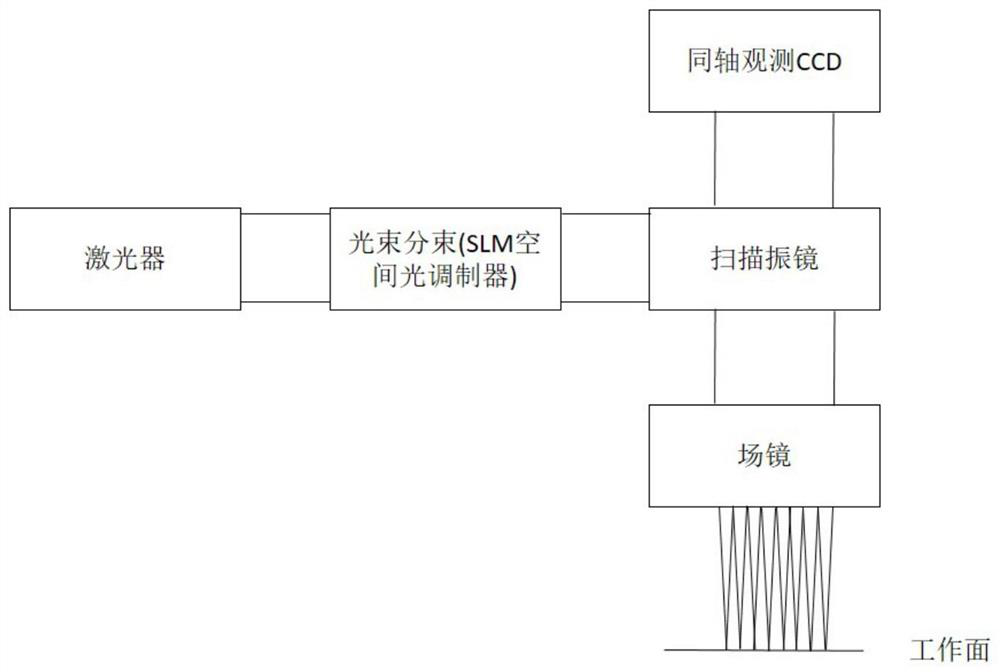

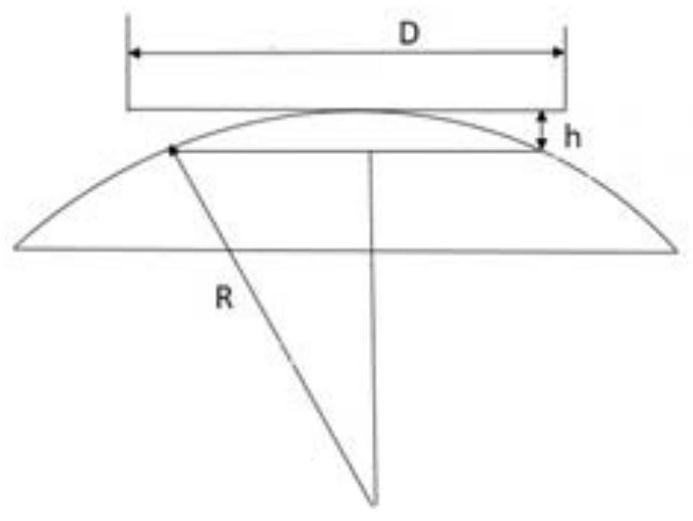

Method and system for machining micro-nano structure with array anti-reflection function

ActiveCN112192030AImprove manufacturing efficiencyImprove preparation efficiencyLaser beam welding apparatusOptical pathManufacturing efficiency

The invention relates to a method and a system for machining a micro-nano structure with an array anti-reflection function. According to the method and system, the problems that the efficiency is lowand the precision and consistency are poor in the anti-reflection micro-nano structure of a large-breadth transparent curved surface component achieved through laser single-point machining are solved.The method comprises the steps of determining the manufacturing focal depth h of each micro-nano structure; segmenting the surface of a to-be-machined curved surface part into a plurality of sub-regions; determining the number of machining light beams in the array machining light beams when each sub-region is machined; laser beam splitting shaping; and machining each sub-region in sequence, and machining an edge region. The system comprises a laser, and an SLM spatial light modulator, a Fresnel lens group, a scanning galvanometer and a field lens which are sequentially arranged in an emergentlight path of the laser. By utilizing the system and the method provided by the invention, the manufacturing efficiency of the array microstructure can be greatly improved.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

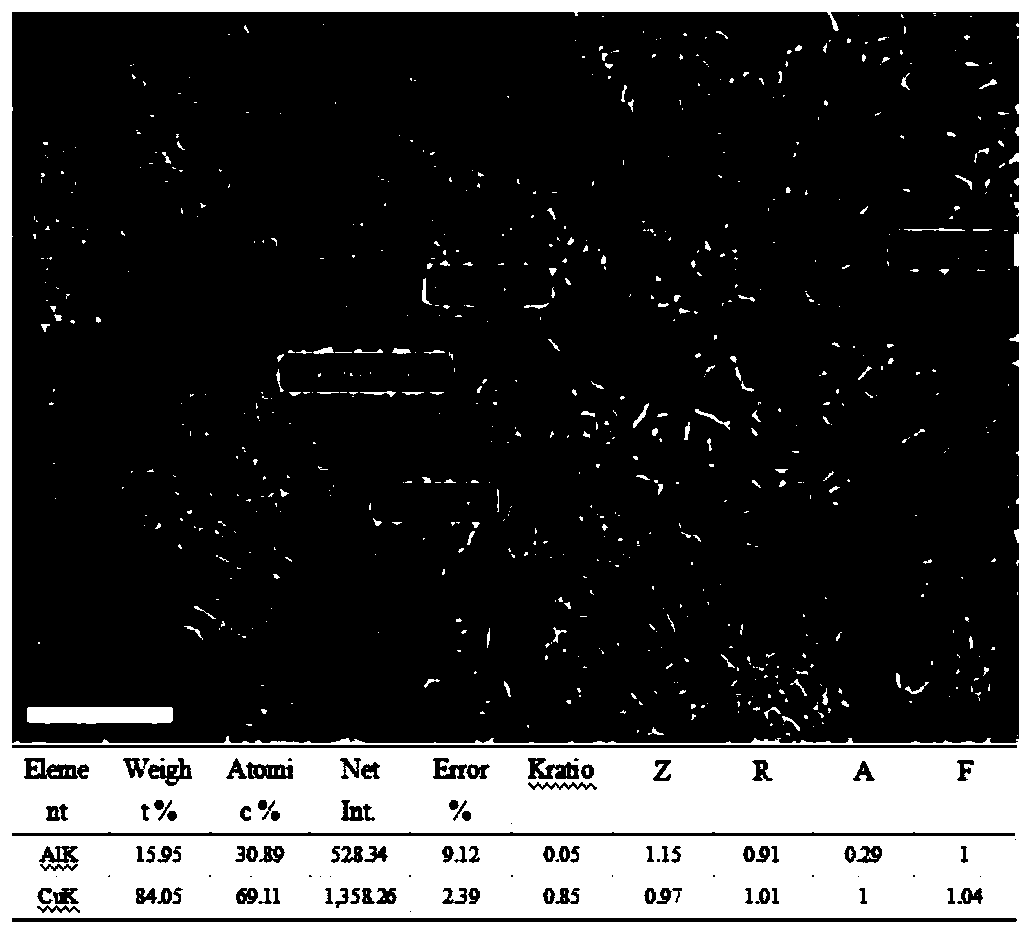

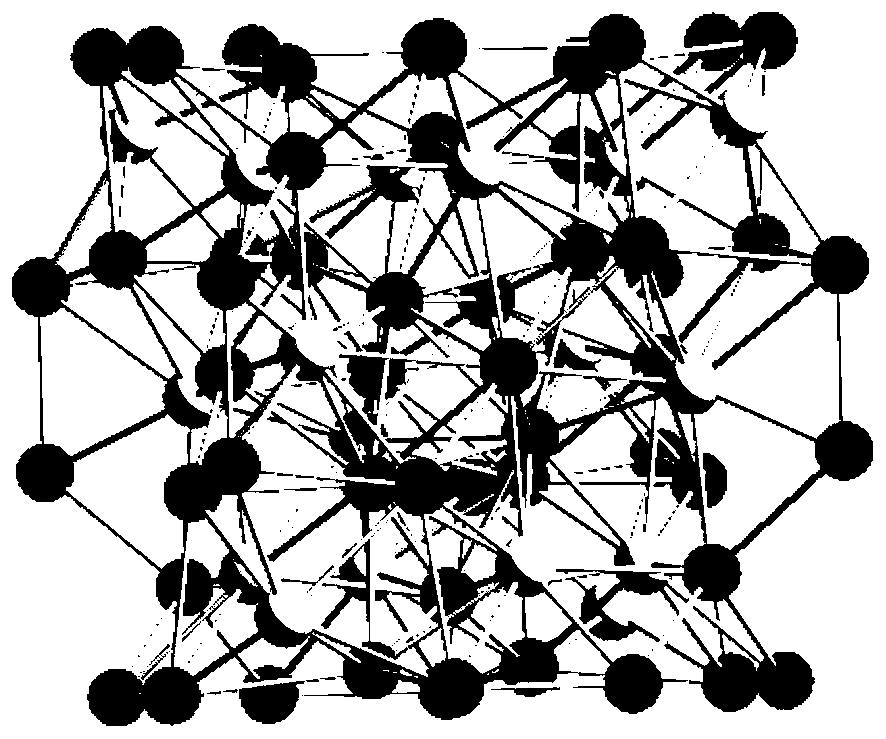

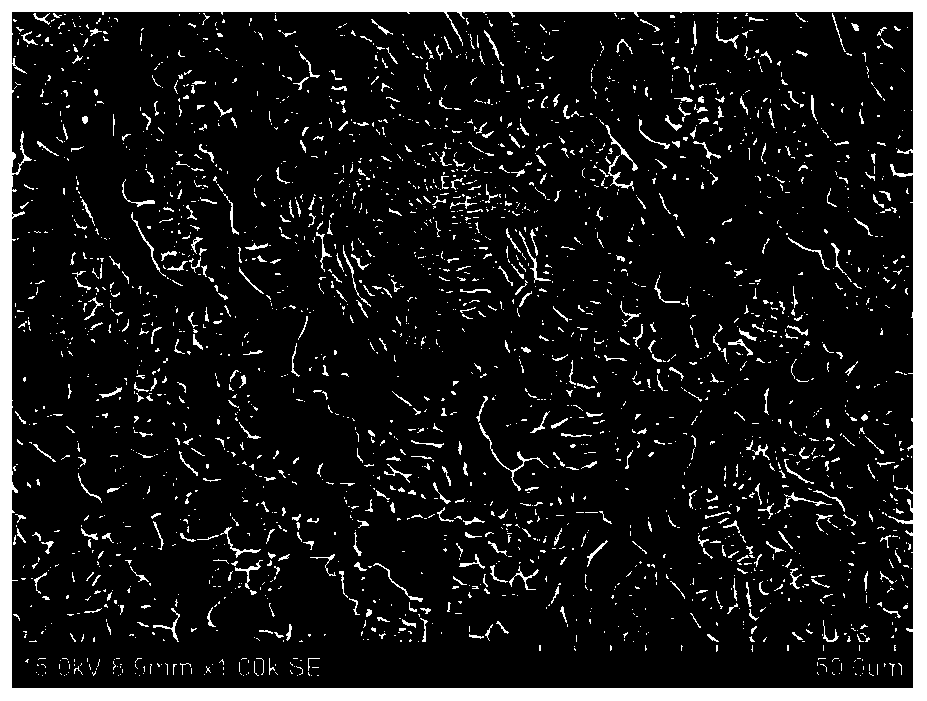

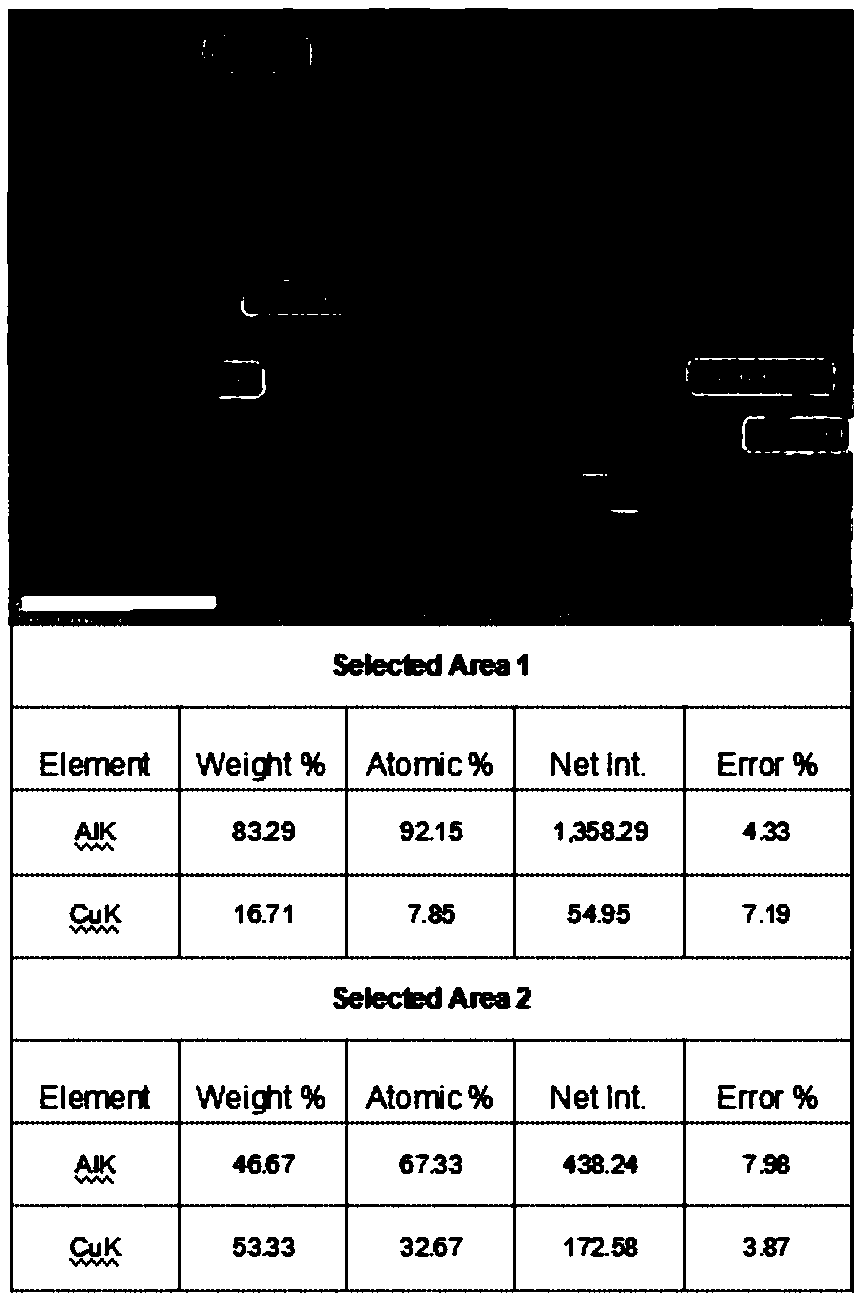

A kind of preparation method of al4cu9 single crystal particles

ActiveCN107185459BQuality improvementMeet preparationUltra-high pressure processesTemperature controlChemical composition

The invention provides a preparation method of an Al4Cu9 single-crystal particle. The atom ratio of the chemical components of AAl4Cu9 single crystal is as follows: 28-31% of Al and 69-72% of Cu; the preparation method of the Al4Cu9 single-crystal particle mainly comprises the steps of after evenly mixing high-purity aluminum powder and copper powder, putting the mixture into a hard alloy die, and using a powder compressing machine to apply 3MPa pressure and maintaining the pressure for 180 s to obtain a prefabricated block; putting the prepared prefabricated block into a boron nitride crucible, after assembling the boron nitride crucible, a tubular graphite furnace, graphite sheets and boron nitride sheets in sequence, placing the assembly into a cubic press, and maintaining the temperature for 30 min, wherein the pressure is set in the range of 3-5 GPa and the peak temperature is controlled in the range of 1100-1150 DEG C; when the temperature is reduced to 800-950 DEG C, maintaining the temperature for 1-2 h. The preparation method of the Al4Cu9 single-crystal particle has the advantages of simple process, true feasibility, common experiment equipment and good generated-single-crystal quality.

Owner:YANSHAN UNIV

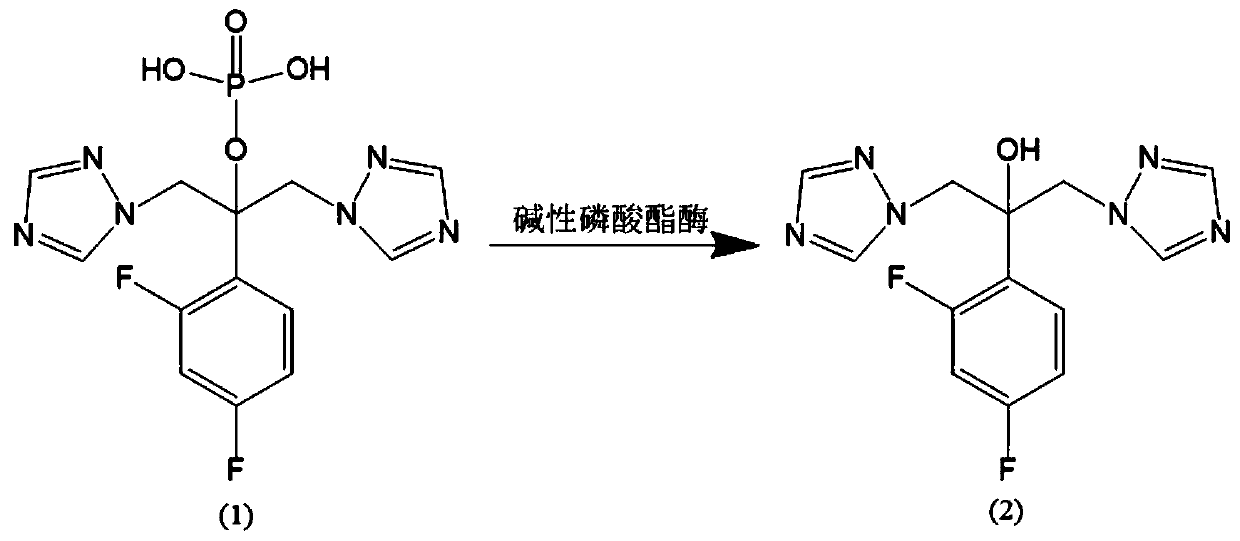

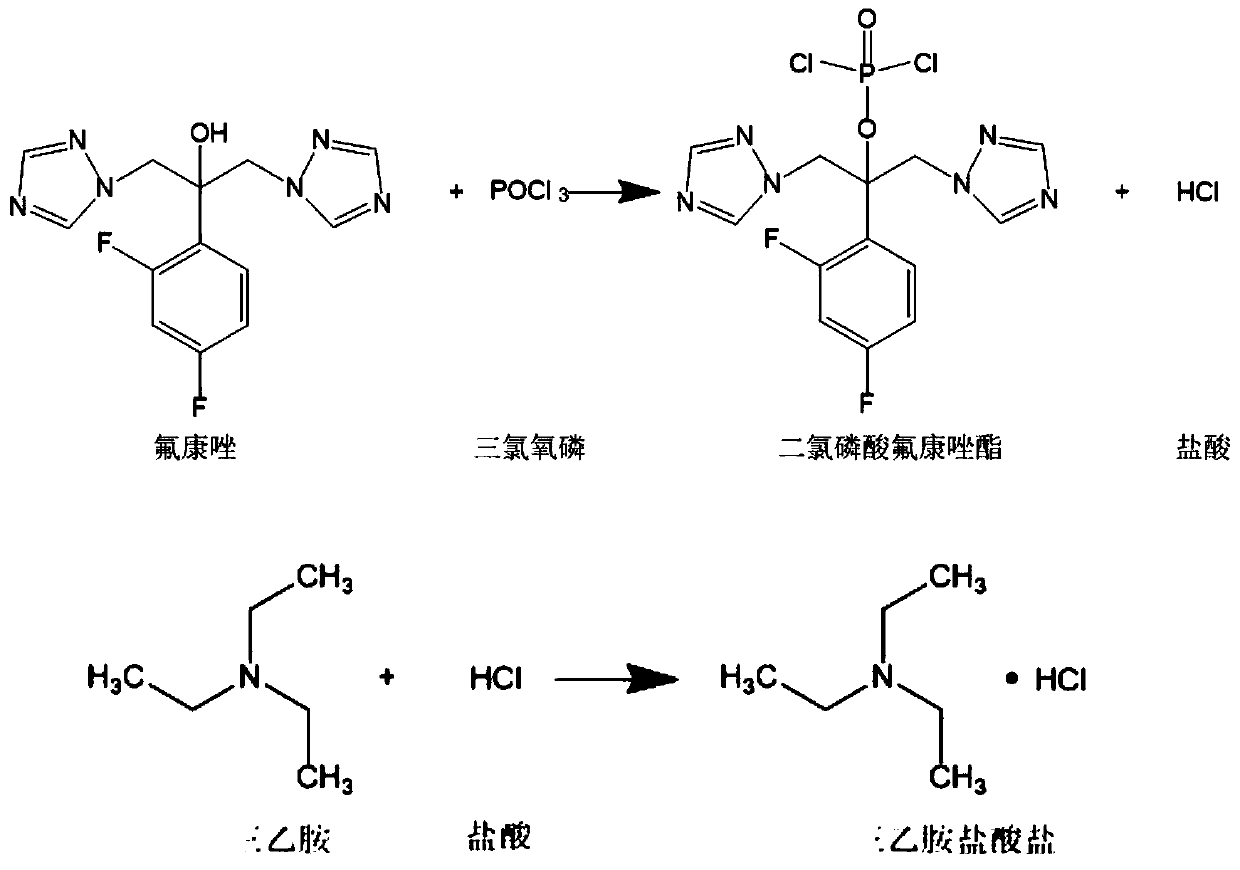

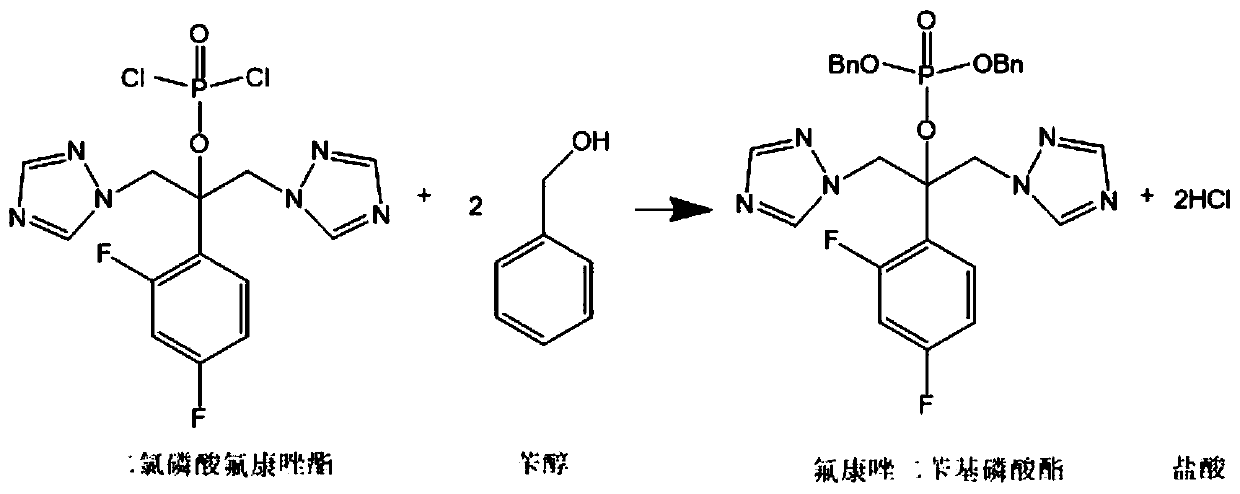

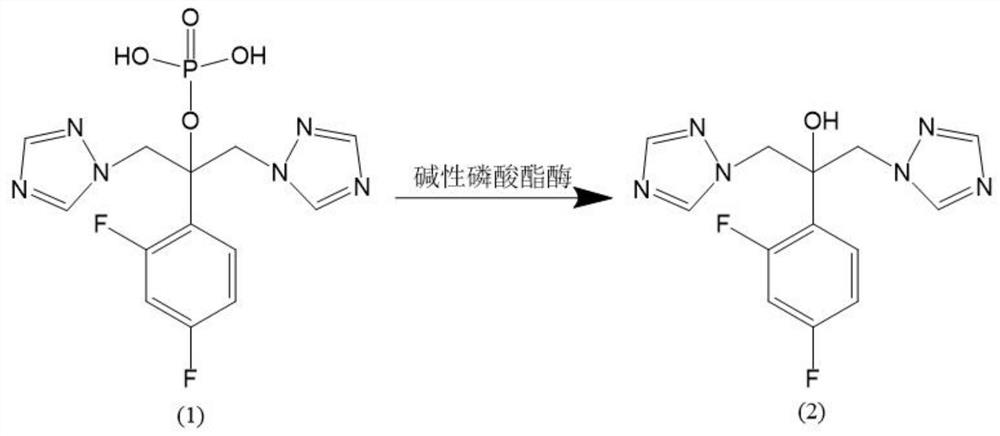

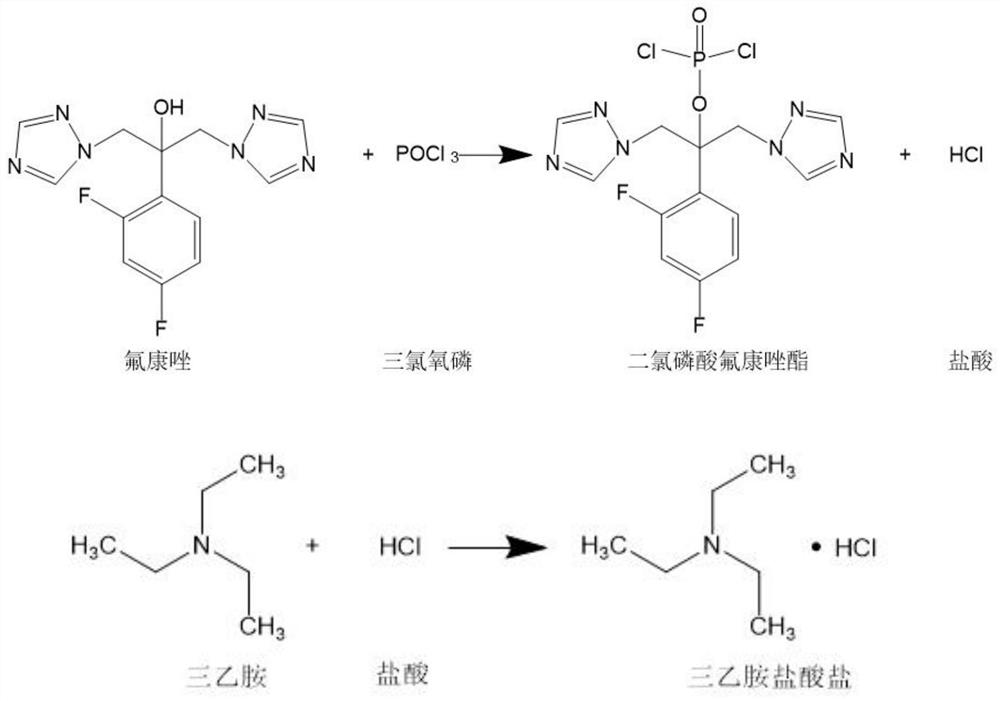

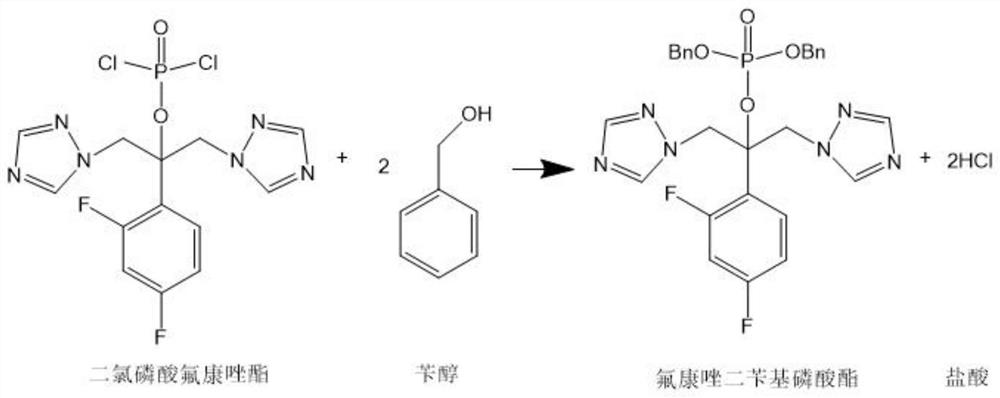

Preparation method of fosfluconazole

ActiveCN111171075AHigh yieldReduce dosageGroup 5/15 element organic compoundsAgainst vector-borne diseasesPhosphoric Acid EstersPhosphate

The invention provides a preparation method of fosfluconazole. The method comprises the following steps: preparing fluconazole dichlorophosphate: under the protection of nitrogen, controlling the temperature to be-10 DEG C to 0 DEG C, slowly dropwise adding phosphorus oxychloride into a dichloromethane solution of triethylamine, maintaining the temperature to be-10 DEG C to 0 DEG C, performing stirring for 1 hour, slowly dropwise adding a dichloromethane solution of fluconazole, and monitoring the completion of the reaction by TLC; maintaining temperature between-10 DEG C and 0 DEG C, adding water and stirring for 30 minutes, adding inorganic base until the pH value of the water phase is at least 8; and performing standing stratification, separating out the fluconazole, wherein the organicphase contains the fluconazole dichlorophosphate, the fluconazole is prepared through the fluconazole-fluconazole dichlorophosphate-fluconazole dibenzyl phosphate-fosfluconazole ammonium salt-fosfluconazole process, the yield is increased, all intermediates are controllably prepared, the raw materials can be recycled, and raw material waste and organic waste pollution are reduced.

Owner:BEIJING FOUR RINGS BIOPHARM

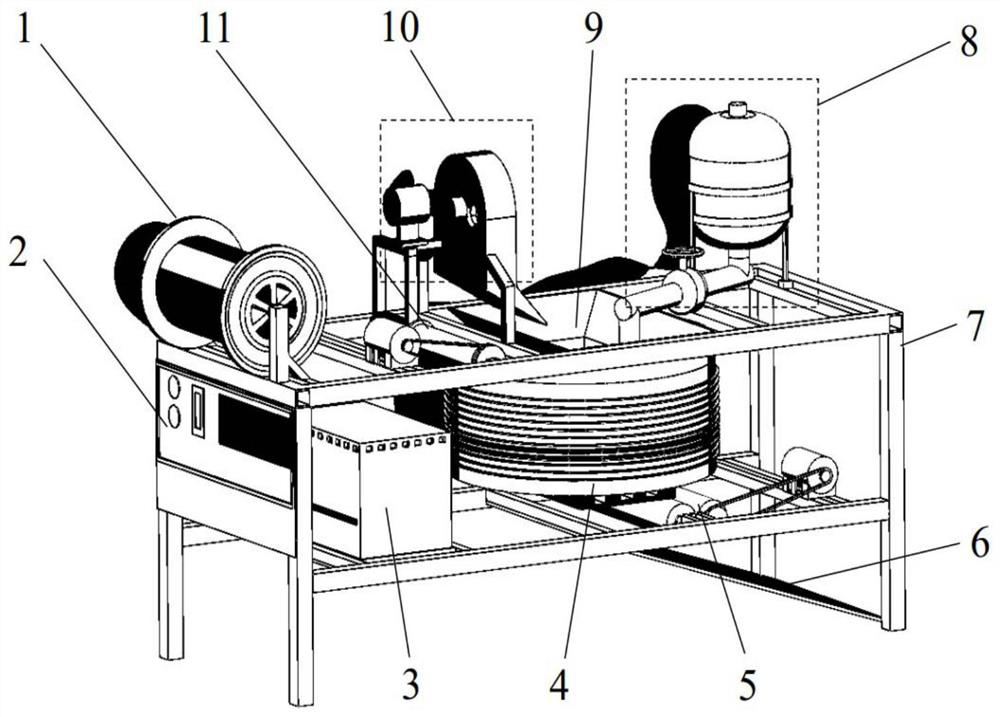

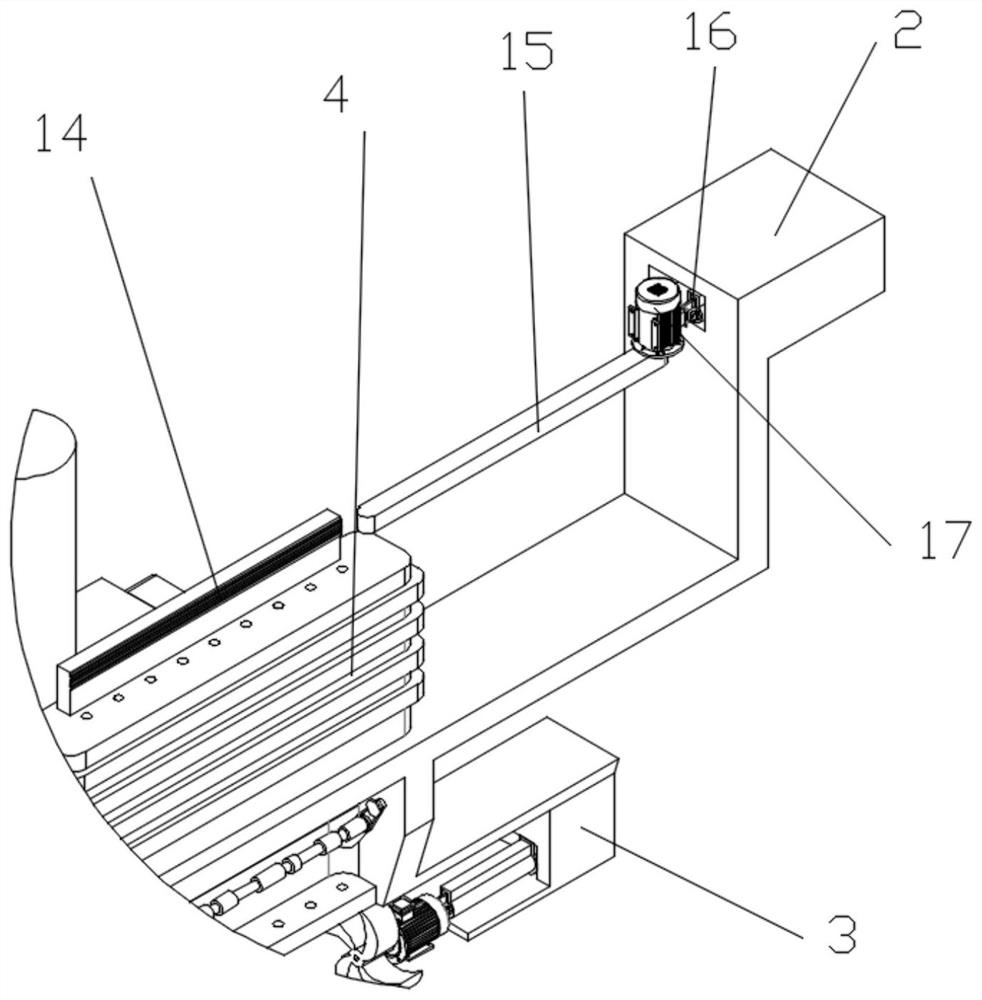

Carbon fiber felt pad weaving and extruding integrated forming machine for aero-engine clamps and method of using the same

The invention belongs to the field of fiber weaving and molding, and in particular relates to a carbon fiber felt mat weaving and extrusion integrated molding machine for aero-engine clamps and a method of using the same. The technical scheme of the present invention is as follows: a carbon fiber felt pad weaving and extrusion integrated forming machine for aero-engine clamps, including a braiding machine module, an extrusion forming and cutting module and a base, and the braiding machine module and the extrusion forming and cutting module are fixedly installed On the base, the knitting machine module is used for weaving the carbon fiber mat, and the extrusion molding and cutting module is used for the extrusion molding and cutting of the carbon fiber mat. The carbon fiber felt pad weaving and extrusion integrated molding machine for aero-engine clamps and its using method provided by the invention can realize the transportation and two-dimensional automatic weaving of carbon fiber filaments, and can realize the extrusion, molding and cutting of carbon fiber cloth. integrated processing.

Owner:NORTHEASTERN UNIV LIAONING +1

Micro-nano structure processing method and system with array anti-reflection and anti-reflection functions

ActiveCN112192030BImprove production efficiencyImprove efficiencyLaser beam welding apparatusSpatial light modulatorNano structuring

The invention relates to a micro-nano structure processing method and system for array anti-reflection and anti-reflection functions. Solve the problems of low efficiency, poor precision and poor consistency in the anti-reflection and anti-reflection micro-nano structure processing method of large-format transparent curved surface components realized by laser single-point processing. The method includes: determining the manufacturing focal depth h of each micro-nano structure; dividing the surface of the curved part to be processed into several sub-regions; determining the number of processing beams in the array processing beams when processing each sub-region; laser beam splitting and shaping; each sub-region Areas are machined sequentially: edge areas are machined. The system includes a laser, an SLM spatial light modulator, a Fresnel lens group, a scanning vibrating mirror and a field mirror which are sequentially arranged in the exit light path of the laser. The system and method of the invention can greatly improve the manufacturing efficiency of the array microstructure.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Method for preparing Al2Cu bi-phase single crystal particles

ActiveCN108866632ASimple processHow it worksPolycrystalline material growthFrom solid stateSingle crystalGraphite

The invention discloses a method for preparing Al2Cu bi-phase single crystal particles. The method mainly comprises the steps that according to an atom ratio of Al to Cu of (85 to 86) to (14 to 15), apowder compressing machine is used for applying 2-3-MPa pressure on high purity mixed powder of the Al and the Cu, and the pressure is maintained for 180 s, so that a prefabricated block is obtained;the prepared prefabricated block is placed in a boron nitride crucible, the boron nitride crucible, a tubular graphite furnace, graphite flakes and boron nitride flakes are placed in a 6-surface diamond presser after being assembled according to a corresponding sequence, the pressure is set to be 3-5 GPa, a peak temperature is controlled at 750-800 DEG C, and heat preservation is conducted for 30min; when the temperature is reduced to 450-500 DEG C, heat preservation is conducted for 1-2 h. The method for preparing the Al2Cu bi-phase single crystal particles has the advantages that a technology is simple, the operation method is feasible, equipment is simple, the generated single crystal particles are good in quality and large in particle, and the like, and application is wide.

Owner:YANSHAN UNIV

Macromolecule coupling agent containing active cyano group and preparing method thereof

Owner:NORTHWESTERN POLYTECHNICAL UNIV

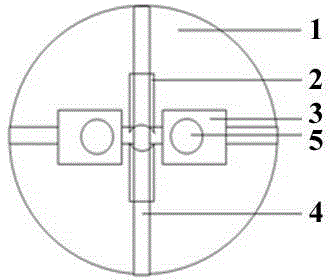

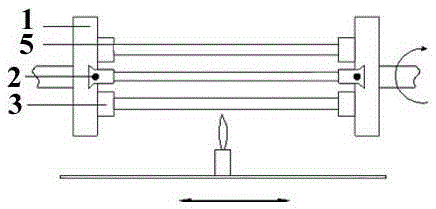

A kind of manufacturing device and manufacturing method of polarization maintaining optical fiber preform rod

ActiveCN103708721BMeet preparationIncrease productivityGlass making apparatusPolarization-maintaining optical fiberEngineering

The invention relates to a manufacturing device and a manufacturing method for a polarization maintaining optical fiber preform. The device comprises a disk with scaled calibration, four claws forming a cross shape and screws in one-to-one correspondence and meshing connection with the claws; and the rotating screw can control relative movement of the four claws. Two claws in the horizontal direction are respectively provided with a groove with adjustable diameter.

Owner:JIANGSU HENGTONG PHOTOELECTRIC +1

Special concrete based on waste resource utilization, and preparation process thereof

ActiveCN113816656AImprove performanceReduce manufacturing costSolid waste managementMixing operation control apparatusFiberEnvironmental engineering

The invention discloses a special concrete based on waste resource utilization, and a preparation process thereof, and relates to the technical field of buildings. The special concrete is prepared from, by weight, 100 to 120 parts of a tailing material, 200 to 300 parts of fly ash, 50 to 80 parts of cement, 5 to 10 parts of a water reducing agent, 500 to 700 parts of stone, 90 to 100 parts of reinforcing fiber and 200 to 350 parts of water. The tailing material containing quartz is ground, so that quartz molecules on the surface of the tailing material tend to be in disordered glass transition, and therefore, the tailing material has certain activity and interacts with a cementing material in cement, so the hardness and wear resistance of the concrete are improved; and meanwhile, a certain proportion of fly ash is doped in the concrete, so the properties of the produced special concrete are improved, the tailing and the fly ash are efficiently recycled, and the preparation cost of the special concrete is greatly reduced.

Owner:莱芜鲁碧商品混凝土有限公司

Metal-wrapped short fiber cloth forming device and using method thereof

ActiveCN113186657AImprove mechanical propertiesImprove adhesive performanceFibre mixingTextile treatment machine arrangementsPolymer chemistryFiber

The invention discloses a metal-wrapped short fiber cloth forming device and a using method thereof. The metal-wrapped short fiber cloth forming device comprises a vapor deposition device; a fiber raw material penetrates through the vapor deposition device; the vapor deposition device is used for depositing a metal layer on the surface of the fiber raw material; the fiber deposited with the metal layer penetrates into a fiber cutting device; a discharge hole of the fiber cutting device and a discharge hole of a resin injecting device are connected with the inlet end of a mixing device; a magnetic field generating device is arranged on the outer side of the mixing device; the outlet end of the mixing device is connected with a feeding hole of a cloth rolling device; and the cloth rolling device is used for rolling and forming to obtain finished short fiber cloth. According to the invention, the metal layer is deposited on the surface of the fiber raw material, so that the fiber has the conductivity; the short fiber and the resin are mixed in the mixing device; the orientation distribution of the fiber in a cloth mixture is adjusted by utilizing a magnetic field, so that the fiber is distributed according to controllable orientation, and the performance requirements of the short fiber cloth under different working conditions are met; and the structure and the process are simple, and the production cost is relatively low.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

A composite material 3D printing porous nozzle and method integrating filament laying, forming and cutting

ActiveCN111941836BRealize simultaneous layingImprove processing efficiency3D object support structuresApplying layer meansFiberCarbon fibers

The present invention relates to a multi-material 3D printing porous nozzle and method integrated with laying, forming and cutting. The nozzle includes a fiber resin porous wire feeding nozzle, a carbon fiber cutting mechanism, and a fiber filament laying stop mechanism. The fiber resin porous wire feeding nozzle includes The nozzle base frame, the porous wire feeding nozzle, the porous wire feeding nozzle extends downward through the nozzle base frame to extend the porous wire laying head and the resin heating nozzle; the carbon fiber cutting mechanism can realize the partial cutting and trimming of the fiber filament, and the fiber filament laying The stop mechanism can clamp the filaments before cutting. The invention can realize the simultaneous laying of multiple carbon fiber filaments and the synchronous curing and compaction, improve processing efficiency, and can realize carbon fiber laying and arbitrary cutting at any angle, saving materials and having a high degree of automation.

Owner:NORTHEASTERN UNIV LIAONING

A kind of preparation method of forsefluconazole

ActiveCN111171075BHigh yieldReduce dosageGroup 5/15 element organic compoundsAgainst vector-borne diseasesPhosphoric Acid EstersPhosphate

The invention provides a preparation method of forsifluconazole, comprising the following steps: preparing fluconazole dichlorophosphate: under nitrogen protection, at a temperature of ‑10 to 0 DEG C, adding a solution of triethylamine in dichloromethane Phosphorus oxychloride was slowly added dropwise, after the dropping was completed, the temperature was maintained at -10 to 0 °C and stirred for 1 hour, the dichloromethane solution of fluconazole was slowly added dropwise, and the reaction was monitored by TLC; the temperature was maintained at -10 to 0 °C, and water was added. Stir for 30 minutes, add an inorganic base until the pH of the aqueous phase is at least 8, stand for stratification, separate the upper aqueous phase, the organic phase contains fluconazole dichlorophosphate, pass through fluconazole-fluconazole dichlorophosphate ‑Fluconazole dibenzyl phosphate ‑ Forse fluconazole ammonium salt ‑ Forse fluconazole process to prepare forse fluconazole, improve yield, controllable preparation of intermediates, raw materials can be recycled and reused, reduce raw material waste and Organic waste pollution.

Owner:BEIJING FOUR RINGS BIOPHARM

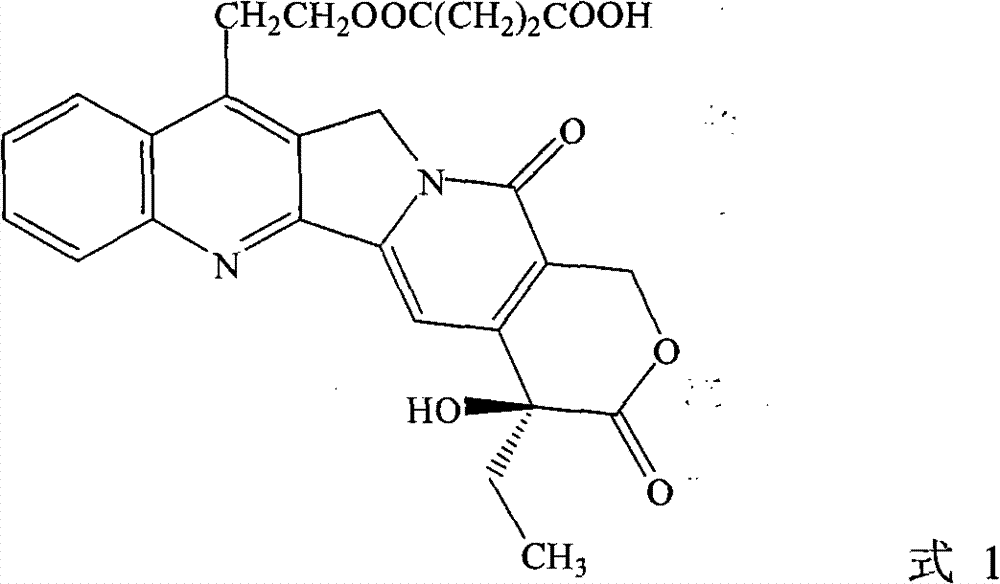

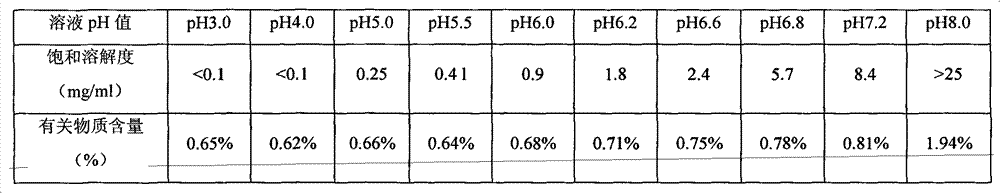

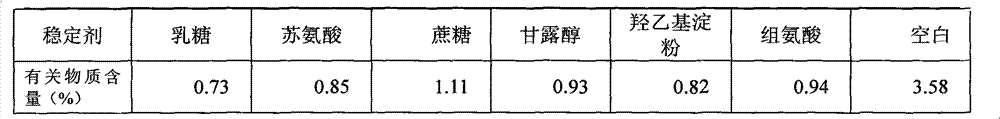

Pharmaceutical composition of camptothecin derivative and preparation method thereof

InactiveCN102764260ASolve solubilityIntegrity guaranteedPowder deliveryOrganic active ingredientsQuinolineKetone

The invention relates to a pharmaceutical composition, which comprises (+)-(4S)-11-succinyl oxyethyl-4-ethyl-4-hydroxy-1H pyran[3',4',6,7]indolizine[1,2-b]quinoline-3,14-(4H,12H)-dione or its pharmaceutically acceptable salt, a stabilizing agent and a pH conditioning agent, wherein the pH value is 6.0-7.2.

Owner:CHIA TAI TIANQING PHARMA GRP CO LTD

Organosilane crosslinked polyolefin elastic-body composition

The invention is silicon alkyl cross-linking polyolefin elastomer combination, adopting LLDPE (or ULDPE) and paraffin ot replace EPDM and using silicon grafting system to replace bakelite sulfuration system. It can meet different demands. The components of the compound: PP 2-10 phr; LDPE or ULDPE 50-80 phr; paraffin 50-500 phr; silicon hydride 2-10 phr; peroxide 0.5-2.5 phr; water 0.1-5.0 phr; and anti-oxidizing agent: 0.1-0.3%.

Owner:SINOPEC YANGZI PETROCHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com