Process for making powder through stainless steel waste corner sheet metal

A technology of stainless steel and corners, which is applied in the process field of using stainless steel waste corners to make powders. It can solve the problems of increased labor costs and production costs, poor quality of metal powders, and failure to meet the requirements of 3D printing. The effect of low content, low processing cost and sufficient raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with specific examples.

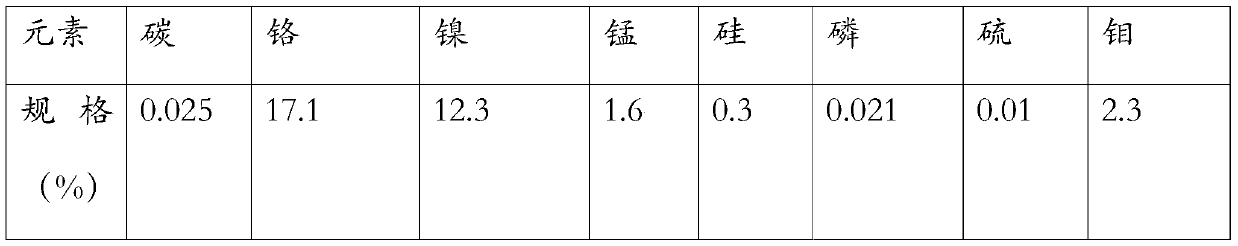

[0035] The invention relates to a process for preparing powder by using waste stainless steel scraps and scraps. The scraps produced by manufacturing enterprises producing complete sets of stainless steel equipment are recycled and used, and stainless steel scraps and scraps are used as raw materials to prepare stainless steel powder. The prepared stainless steel The powder is used for 3D printing, which improves the recycling rate of stainless steel scraps and scraps, reduces the production cost of stainless steel powder, and at the same time, the quality of stainless steel powder is controllable.

[0036] The above-mentioned process of making powder by using stainless steel scrap scraps uses an atomization method for powder preparation. The atomization method can be high-pressure water atomization or combined water-gas atomization, which can be selected according to actual ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com