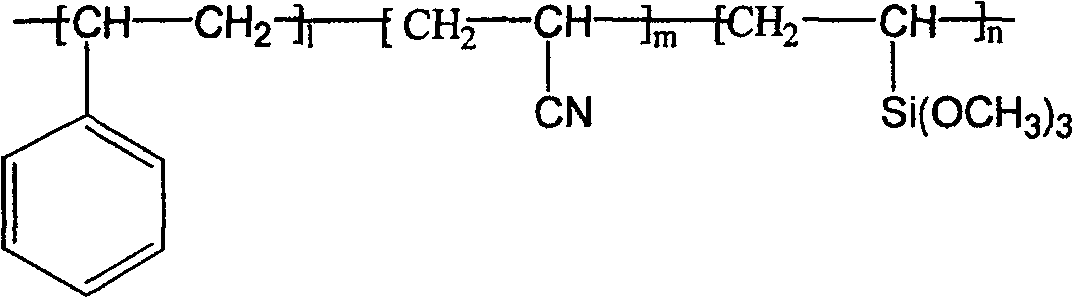

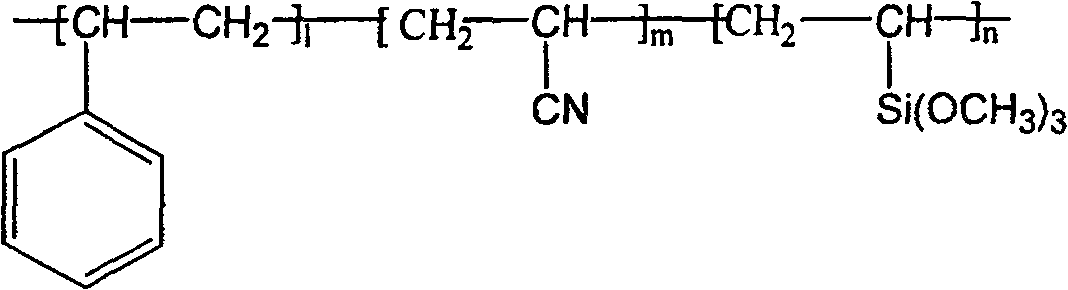

Macromolecule coupling agent containing active cyano group and preparing method thereof

A technology of macromolecular coupling agent and cyano group, applied in the field of active cyano group-containing macromolecular coupling agent and its preparation, can solve the problems of unfavorable industrial production, complicated preparation process, and high purity requirements of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

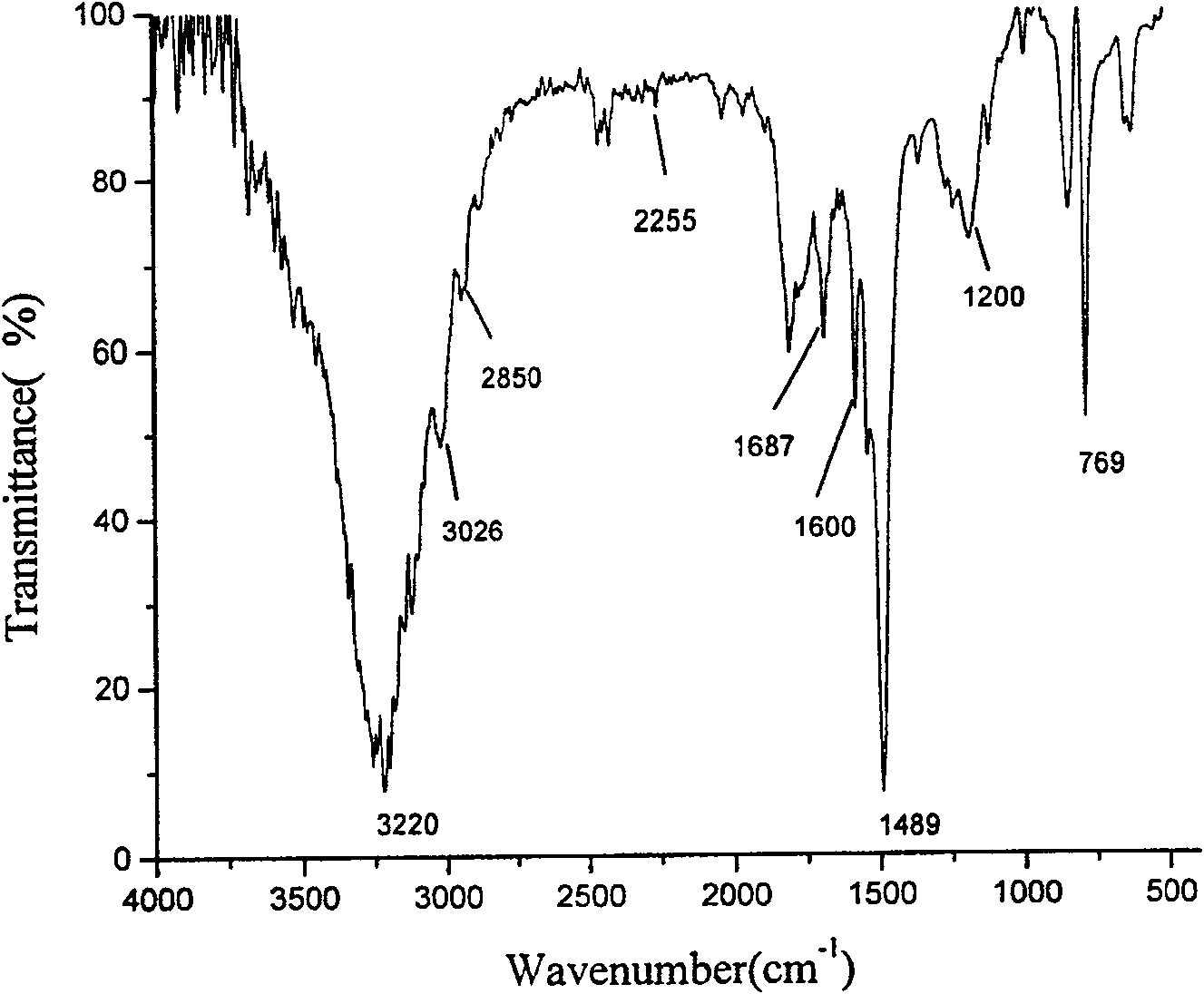

Embodiment 1

[0033] After the instruments to be used in the reaction process were placed in an oven and fully dried, 70ml of xylene, 40.0ml of styrene, 10.3ml of vinyltrimethoxysilane, and 0.54g of BPO were successively added to the three-necked flask, stirred and nitrogen gas was introduced. Slowly heated to 110°C, after 3.5 hours of reaction, the temperature was raised to 120°C, and after 1.5 hours of reaction at this temperature, the heating was stopped. After cooling down to 70°C, add 9.2ml of acrylonitrile into the three-necked flask, heat and keep it at 75-80°C for 3.5h, then distill under reduced pressure. Finally, it was dissolved in tetrahydrofuran, precipitated in 200ml of methanol, and finally vacuum-dried at 65°C for 4 hours to obtain a white solid powder. . The number-average molecular weight of the synthesized terpolymer macromolecular coupling agent was determined to be 11,600 by gel permeation chromatography (GPC), and the molecular weight distribution width was 1.73.

Embodiment 2

[0035] After the instruments to be used in the reaction process were placed in an oven and fully dried, 70ml of xylene, 40.0ml of styrene, 10.3ml of vinyltrimethoxysilane, and 0.27g of BPO were successively added to the three-necked flask, stirred and nitrogen gas was introduced. Slowly heated to 110°C, after 3.5 hours of reaction, the temperature was raised to 120°C, and after 1.5 hours of reaction at this temperature, the heating was stopped. After cooling down to 70°C, add 9.2ml of acrylonitrile into the three-necked flask, heat and keep it at 75-80°C for 3.5h, then distill under reduced pressure. Finally, it was dissolved in tetrahydrofuran, precipitated in 200ml of methanol, and finally vacuum-dried at 65°C for 4 hours to obtain a white solid powder. The number-average molecular weight of the synthesized terpolymer macromolecular coupling agent was determined to be 25,300 by gel permeation chromatography (GPC), and the molecular weight distribution width was 2.82.

Embodiment 3

[0037] After placing the instruments used in the reaction process in an oven and fully drying them, add 70ml of xylene, 40ml of styrene, 20.6ml of vinyltrimethoxysilane, and 0.54g of BPO into the three-necked flask in sequence, stir and introduce nitrogen gas, slowly Heat to 110°C, react for 3.5 hours, then raise the temperature to 120°C, and react at this temperature for 1.5 hours, then stop heating. After cooling down to 70°C, add 9.2ml of acrylonitrile into the three-necked flask, heat and keep it at 75-80°C for 3.5h, then distill under reduced pressure. Finally, it was dissolved in tetrahydrofuran, precipitated in 200ml of methanol, and finally vacuum-dried at 65°C for 4 hours to obtain a white solid powder. The number-average molecular weight of the synthesized terpolymer macromolecular coupling agent was determined to be 14,700 by gel permeation chromatography (GPC), and the molecular weight distribution width was 1.86.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com