A composite material 3D printing porous nozzle and method integrating filament laying, forming and cutting

A technology of 3D printing and wire laying head, which is applied in the direction of 3D object support structure, additive processing, coating device, etc. Insufficient tension, avoiding material waste, and saving processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to better explain the present invention and facilitate understanding, the technical solutions and effects of the present invention will be described in detail below through specific implementation manners in conjunction with the accompanying drawings.

[0044] A composite material 3D printing porous nozzle integrated with laying, forming and cutting, including a fiber resin porous wire feeding nozzle, a carbon fiber filament cutting mechanism, and a fiber filament laying stop mechanism;

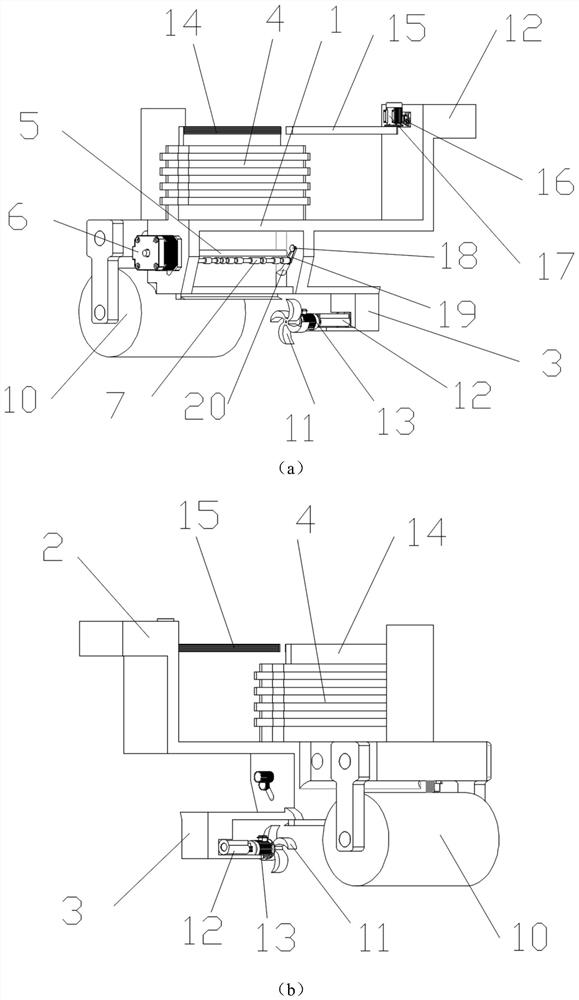

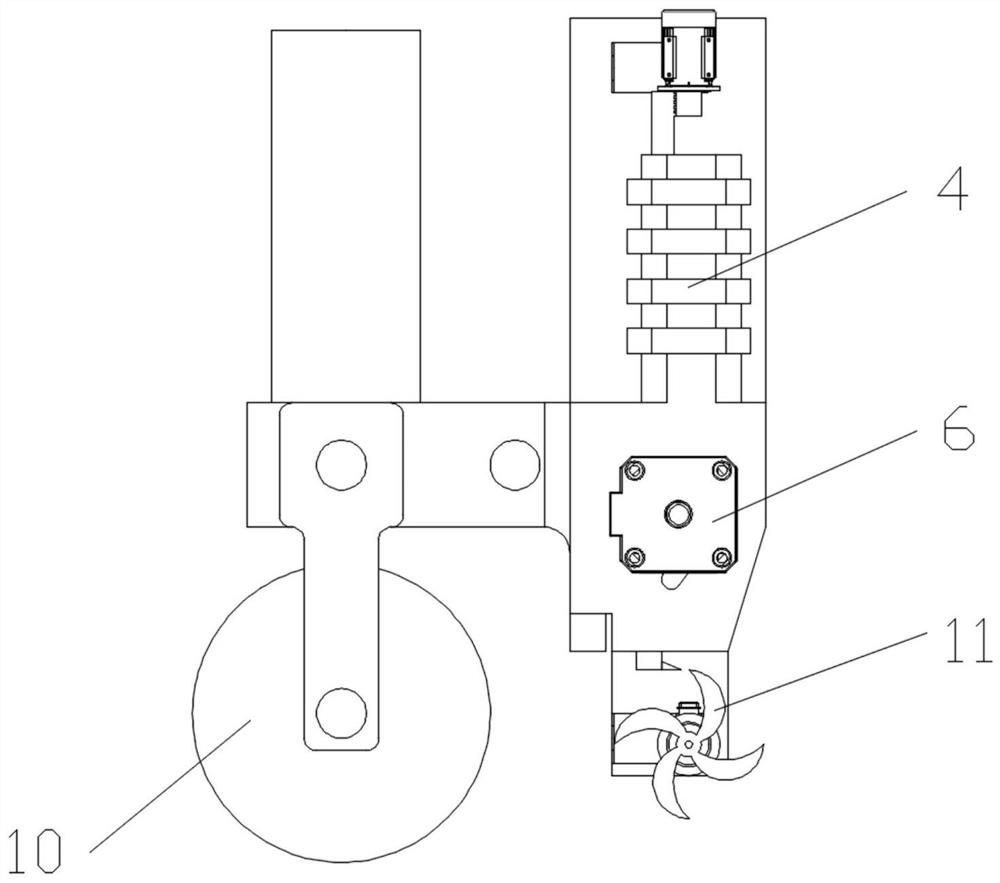

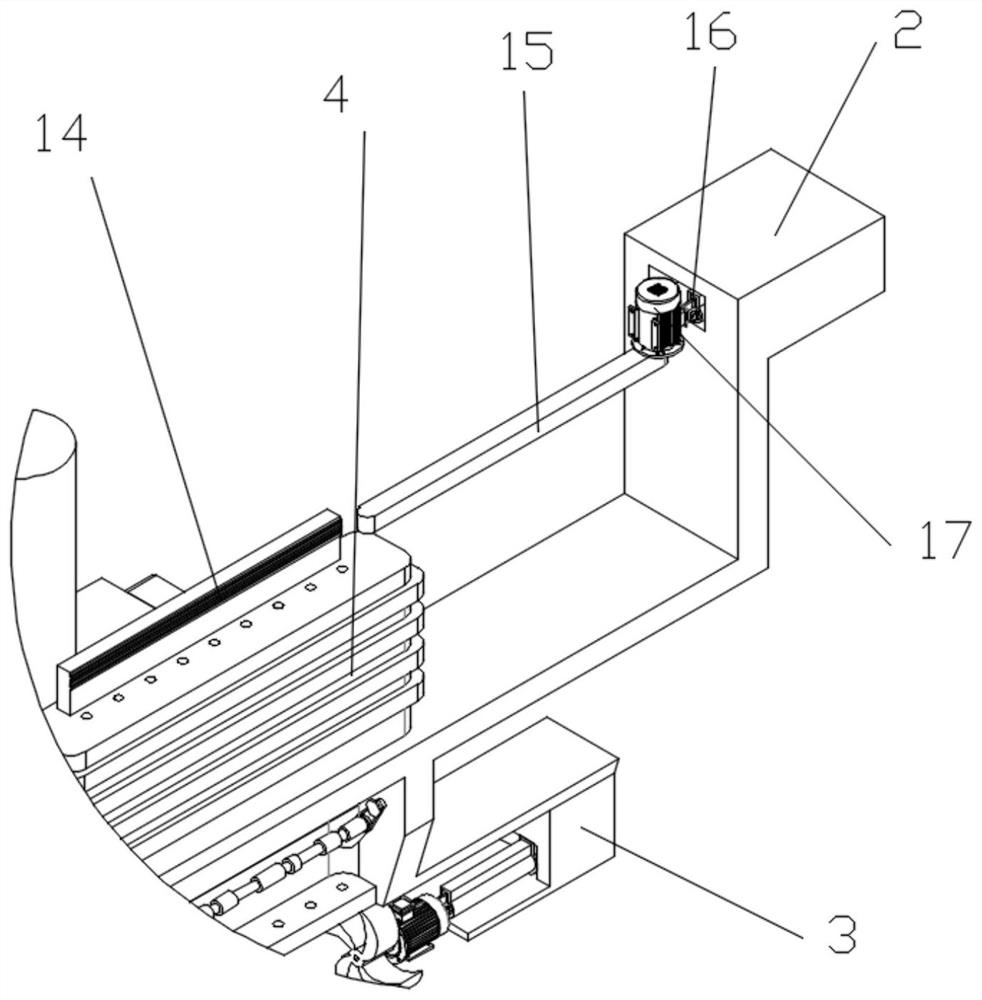

[0045] Such as Figure 1-2 shown (where figure 1 (a) and (b) are the overall structural schematic diagrams of the two angles of the porous nozzle), the fiber resin porous wire feeding nozzle includes a nozzle base frame 1, a porous wire feeding nozzle 4, and the porous wire feeding nozzle 4 is fixedly installed on the On the nozzle base frame 1, the upper surface of the porous wire feeding nozzle 4 is provided with a threading hole, and the porous wire feeding nozzle 4 extend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com