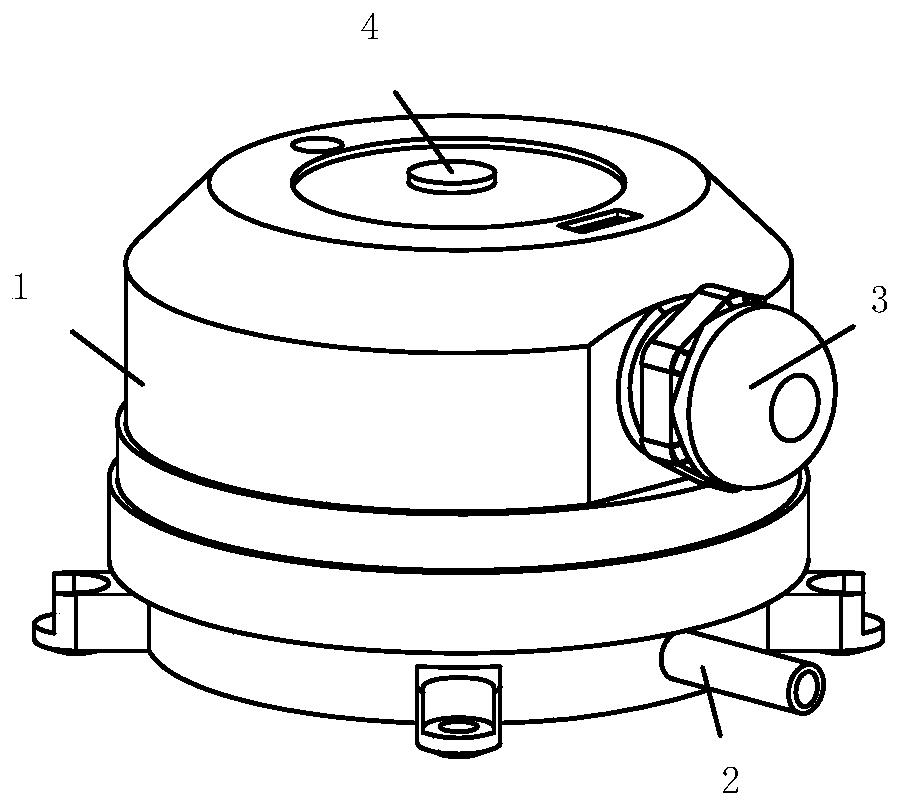

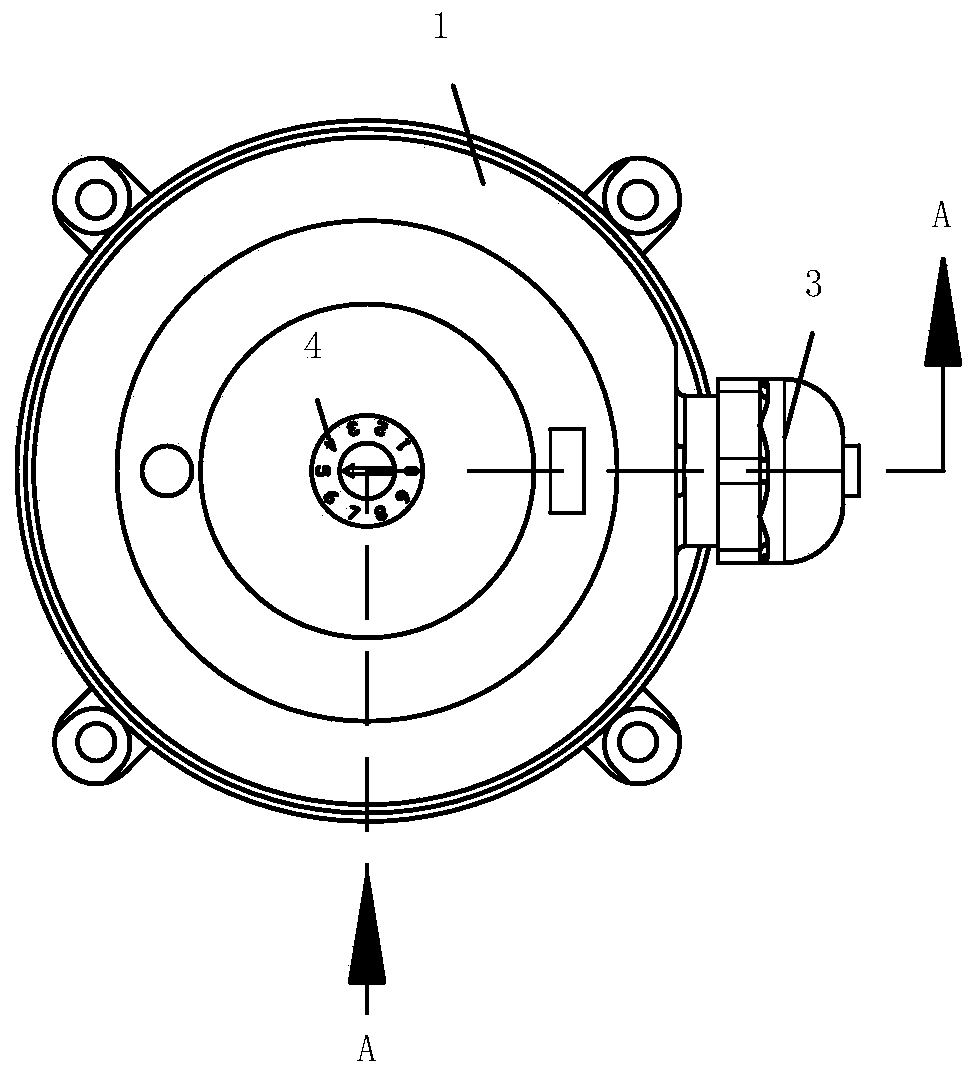

Pressure sensor module

A pressure sensor, pressure technology, applied in the measurement of fluid pressure, instruments, fluid pressure measurement using piezoelectric devices, etc., can solve the problems of high range, low piezoelectric performance, etc., to simplify the structure, improve sealing performance, and improve stability. The effect of sex and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

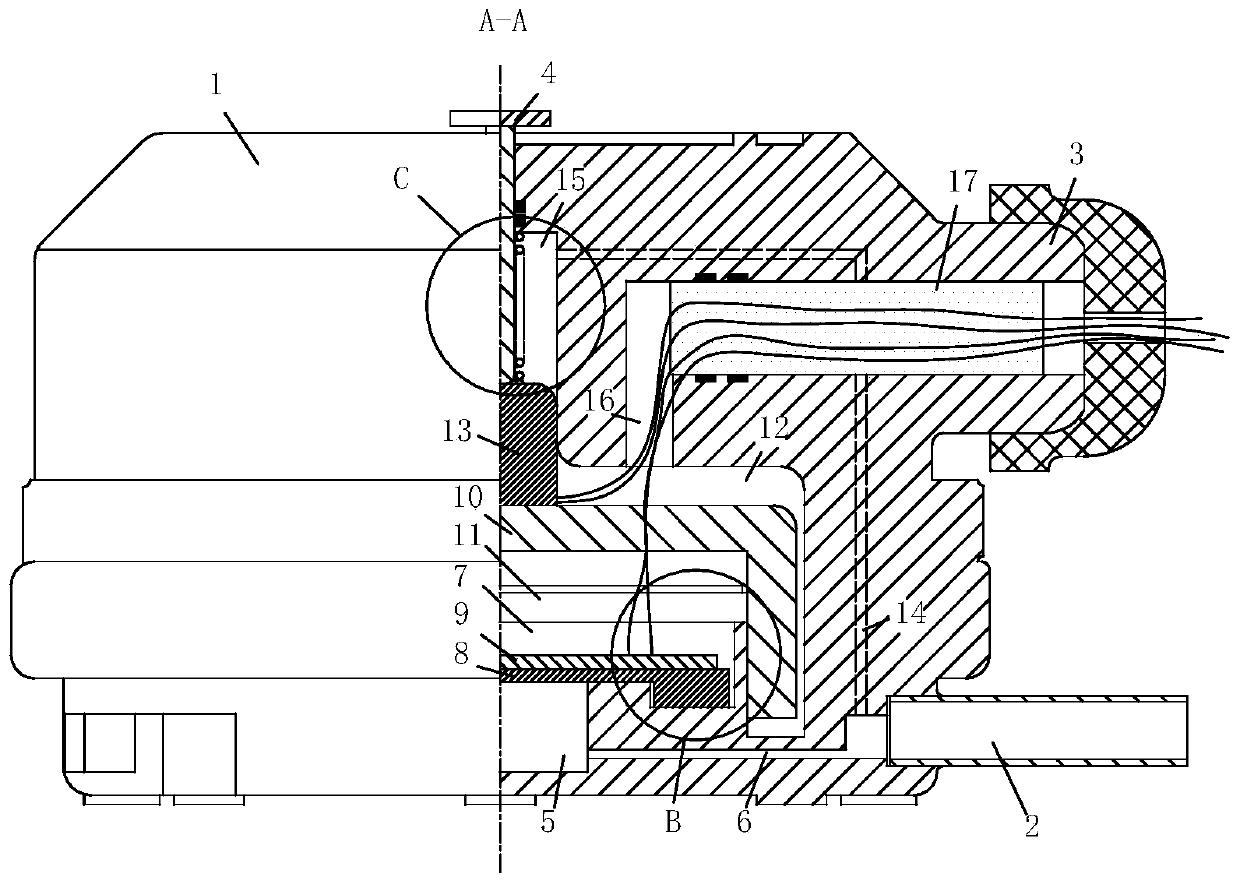

[0032] As an embodiment of the present invention, the cross-sectional area of the second cavity 11 is larger than the cross-sectional area of the third cavity 15, and the middle part of the upper end of the sealing cover 10 is fixedly provided with a sealing column 13, and the sealing column 13 The upper end extends into the third cavity 15 and is slidably sealed with the third cavity 15; the sealing column 13 and the third cavity 15 are set, mainly through the structure to change K 0 constant, to adjust the deformation speed of the pressure chip 9 in the first stage, that is, to adjust the corresponding sensitivity; at the same time, the sealing column 13 and the third cavity 15 can also play a guiding role, so that the sealing cover 10 is better vertically Move down to avoid tilting stuck.

[0033] As an embodiment of the present invention, the sealing column 13 is connected to the top end of the third cavity 15 by a spring 19; and the self-weight of the sealing cover 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com