Safe method applicable to shaft furnace soft coal preparation and jetting

A bituminous and safe technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve problems such as difficulty in coal blending adjustment, rising prices, and reduced efficiency of blast furnace coal injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

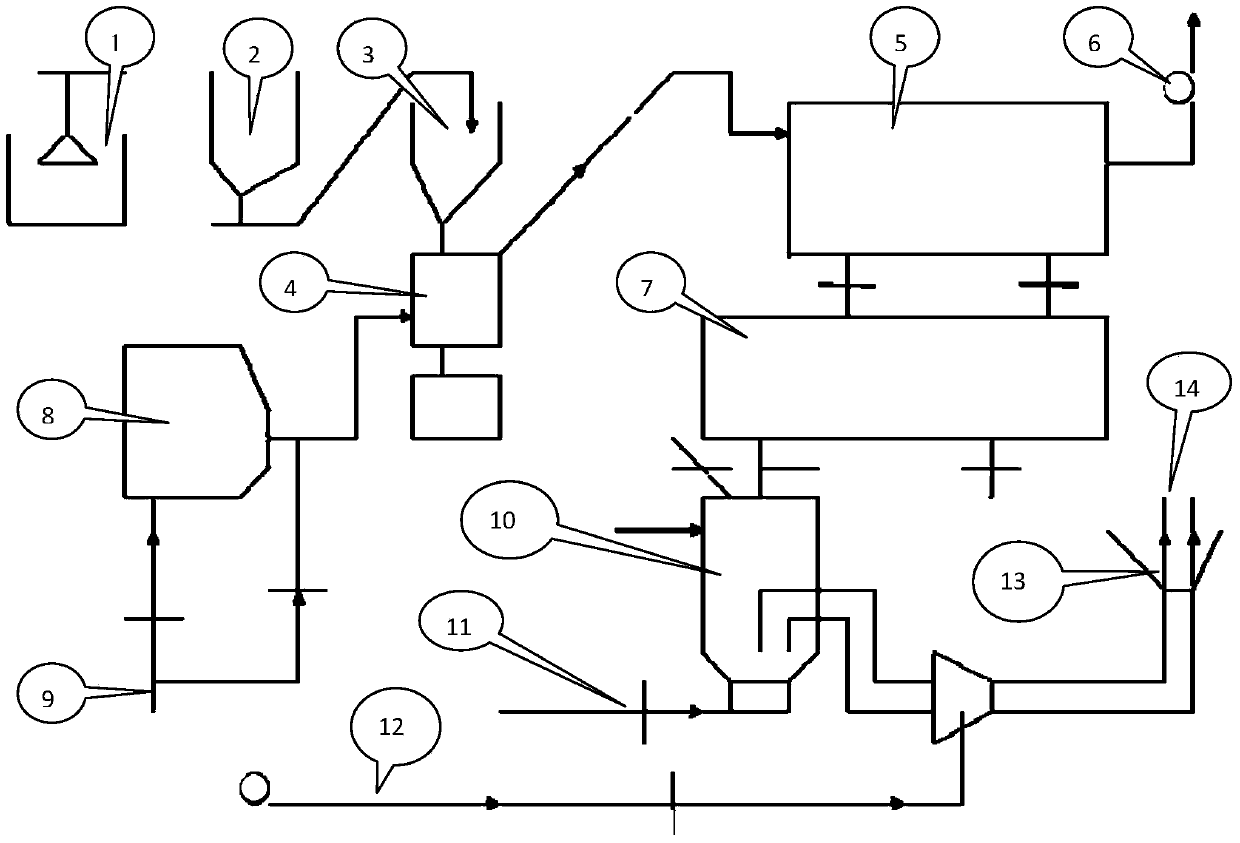

[0019] The blast furnace coal injection process of this method: transport the bituminous coal to the coal injection drying coal shed 1 for storage by vehicles from other places, stack it by driving, perform preliminary mixing and removal of debris, and then lay it flat and directly take it into the raw material warehouse 2 by driving Through the belt scale at the lower part of the raw material bin, the material is evenly proportioned to the 1#-5# belt according to the specified ratio, and transported to different raw coal bunkers 3; the pulverizing machine is turned on, and the main exhaust fan 6 generates the main force (pumping force), The exhaust gas from the hot blast stove 9 and the flue gas from the flue gas stove 8 are drawn into the coal mill 4 as a drying medium, and the coal mill rotates to crush the raw coal falling from the raw coal bunker, and the exhaust gas from the high temperature hot blast stove and the flue gas stove dries the pulverized coal and removes it. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com