A kind of preparation method of al4cu9 single crystal particles

A single crystal particle, al4cu9 technology, applied in the field of metal materials, can solve complex and cumbersome problems, and achieve the effect of simple process, good quality, and feasible operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

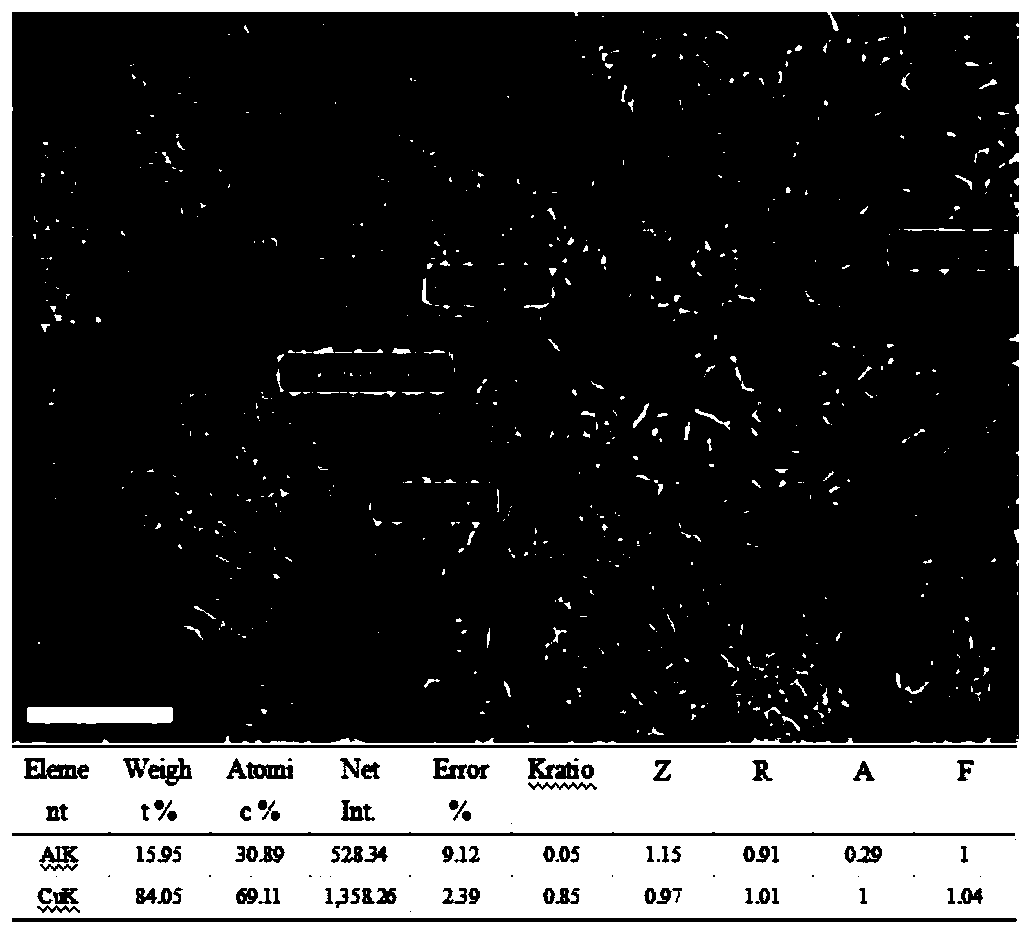

[0016] (1) Weigh 0.56422g of high-purity Al powder and 3.00850g of Cu powder according to the atomic ratio (Al:Cu=30:70), mix the two powders evenly and put them into a cemented carbide mold with an inner diameter of Φ9.6mm , use a powder tablet press to press 3MPa and keep it for 180s to obtain a prefabricated block with a diameter of Φ9.6mm and a height of 10mm;

[0017] (2) The graphite furnace is a tubular furnace body with a height of 16.6mm and an outer diameter of Φ14mm and an inner diameter of Φ12mm. Both ends are sealed with a boron nitride sheet of Φ12mm and a thickness of 3.3mm. The graphite furnace is equipped with a boron nitride crucible with a height of 10mm and an outer diameter of Φ12mm and an inner diameter of Φ9.6mm. , both ends are sealed with boron nitride sheets with a diameter of Φ9.6mm and a thickness of 1.2mm. Together with the pyrophyllite cubes and conductive steel rings used in the six-sided top press, put them in a drying oven at 180°C for 3 hours ...

Embodiment 2

[0023] (1) Weigh 0.50738g of high-purity Al powder and 3.09259g of Cu powder according to the atomic ratio (Al:Cu=28:72), mix the two powders evenly and put them into a cemented carbide mold with an inner diameter of Φ9.6mm , use a powder tablet press to press 3MPa and keep it for 180s to obtain a prefabricated block with a diameter of Φ9.6mm and a height of 10mm;

[0024] (2) The graphite furnace is a tubular furnace body with a height of 16.6mm and an outer diameter of Φ14mm and an inner diameter of Φ12mm. Both ends are sealed with a boron nitride sheet of Φ12mm and a thickness of 3.3mm. The graphite furnace is equipped with a boron nitride crucible with a height of 10mm and an outer diameter of Φ12mm and an inner diameter of Φ9.6mm. , Both ends are sealed with boron nitride sheets with a diameter of Φ9.6mm and a thickness of 1.2mm. Put the graphite furnace, boron nitride crucible, boron nitride sheet, pyrophyllite square and conductive steel ring used together with the six-...

Embodiment 3

[0029] (1) Weigh 0.55768g of high-purity Al powder and 2.94231g of Cu powder according to the atomic ratio (Al:Cu=31:69), mix the two powders evenly and put them into a cemented carbide mold with an inner diameter of Φ9.6mm , use a powder tablet press to press 3MPa and keep it for 180s to obtain a prefabricated block with a diameter of Φ9.6mm and a height of 10mm;

[0030] (2) The graphite furnace is a tubular furnace body with a height of 16.6mm and an outer diameter of Φ14mm and an inner diameter of Φ12mm. Both ends are sealed with a boron nitride sheet of Φ12mm and a thickness of 3.3mm. The graphite furnace is equipped with a boron nitride crucible with a height of 10mm and an outer diameter of Φ12mm and an inner diameter of Φ9.6mm. , both ends are sealed with boron nitride sheets with a diameter of Φ9.6mm and a thickness of 1.2mm. Together with the pyrophyllite squares and conductive steel rings used in the six-sided top press, put them in a drying oven at a temperature of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com