A kind of manufacturing device and manufacturing method of polarization maintaining optical fiber preform rod

A polarization-maintaining fiber and manufacturing device technology, which is applied to manufacturing tools, glass manufacturing equipment, etc., can solve the problems of adverse effects of polarization-maintaining fiber strength and optical performance, high surface roughness of processing holes, and difficulty in satisfying drill strength. Easy to implement operation, high fiber production efficiency, long draw length effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

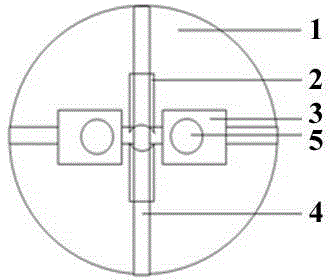

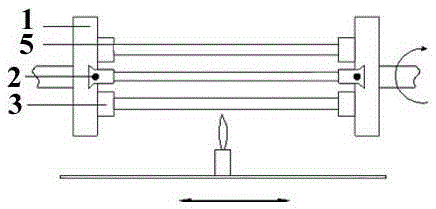

[0038] The specific example is as follows: first select a mandrel 1 with a diameter of 20mm manufactured by the VAD process, and a doped B rod with a diameter of 26 mm manufactured by the MCVD process. 2 o 3Two polarization-maintaining stress rods 4, fix the prepared glass core rod in the middle of the claw 2 of the disc body 1, fix the stress rod in the two slots on the claw 3, adjust the center of the stress rod and the core rod The distance between the centers is 29 mm, and the centers of the two grooved sections are on the same straight line as the center of the cross-section of the glass core rod, and then the above-mentioned assembly is fixed on the OVD deposition lathe, and the above-mentioned glass core rod and stress rod assembly are deposited Pure SiO 2 Porcelain cladding, so that the glass core rod and stress rod are wrapped in the cladding. In the process of depositing the cladding, the angular velocity of the rotation is designed to ensure that the final sintere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com