Patents

Literature

31results about How to "Improve axial uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

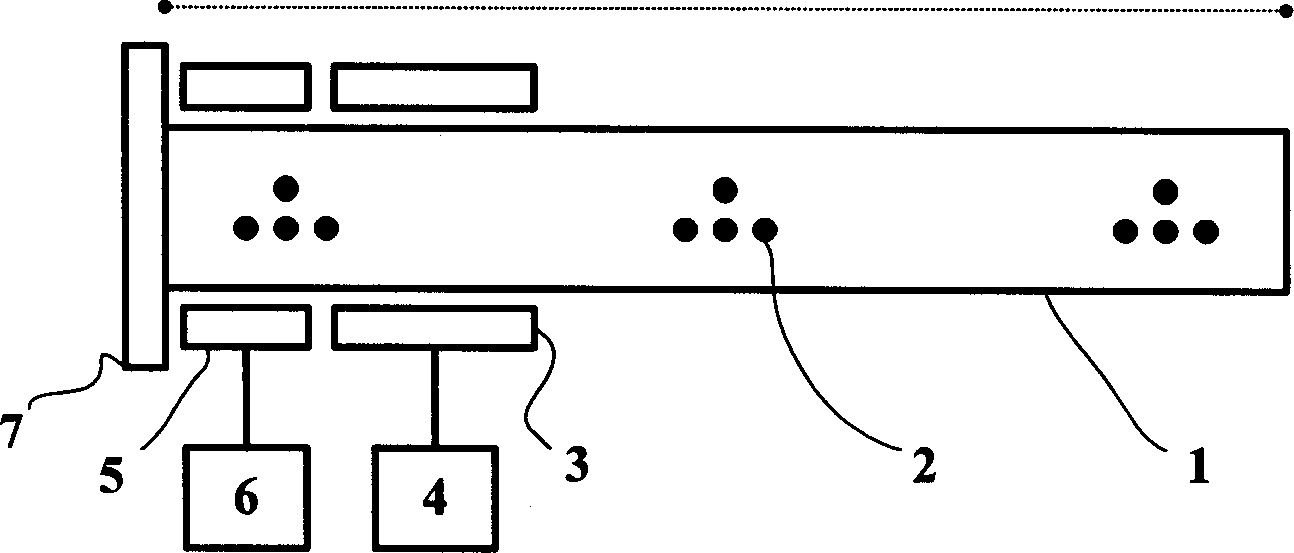

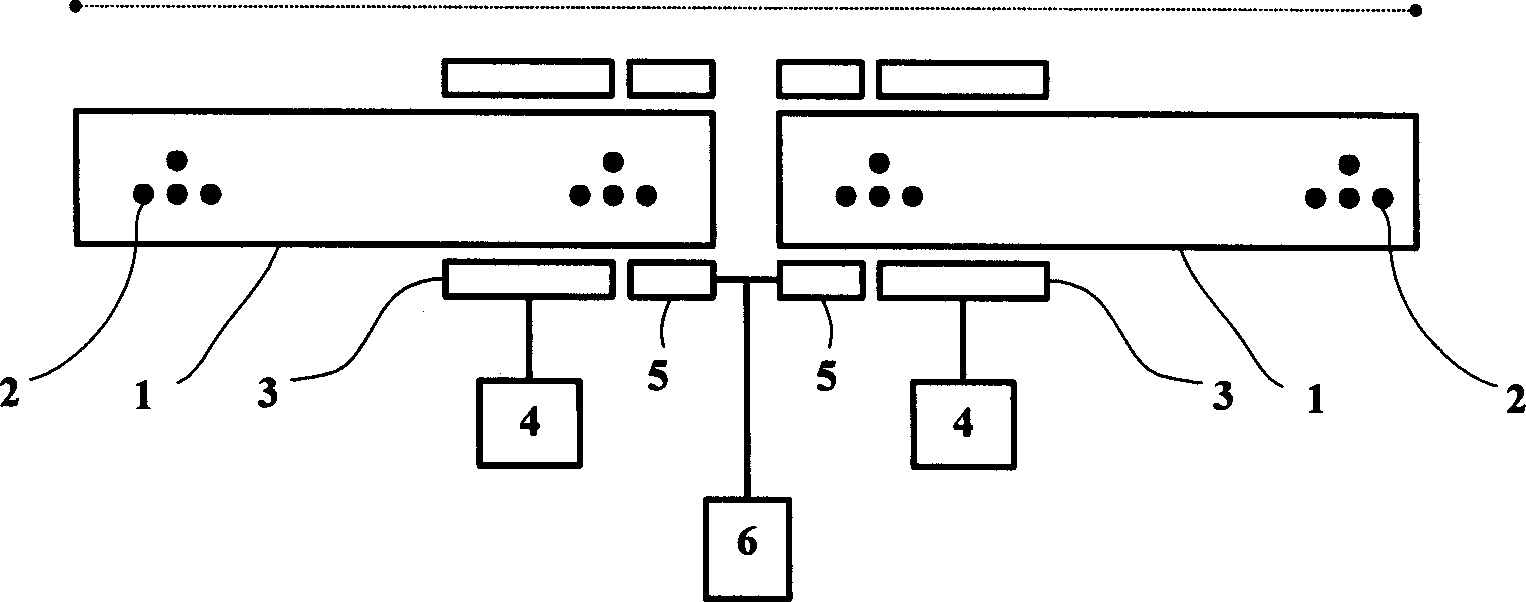

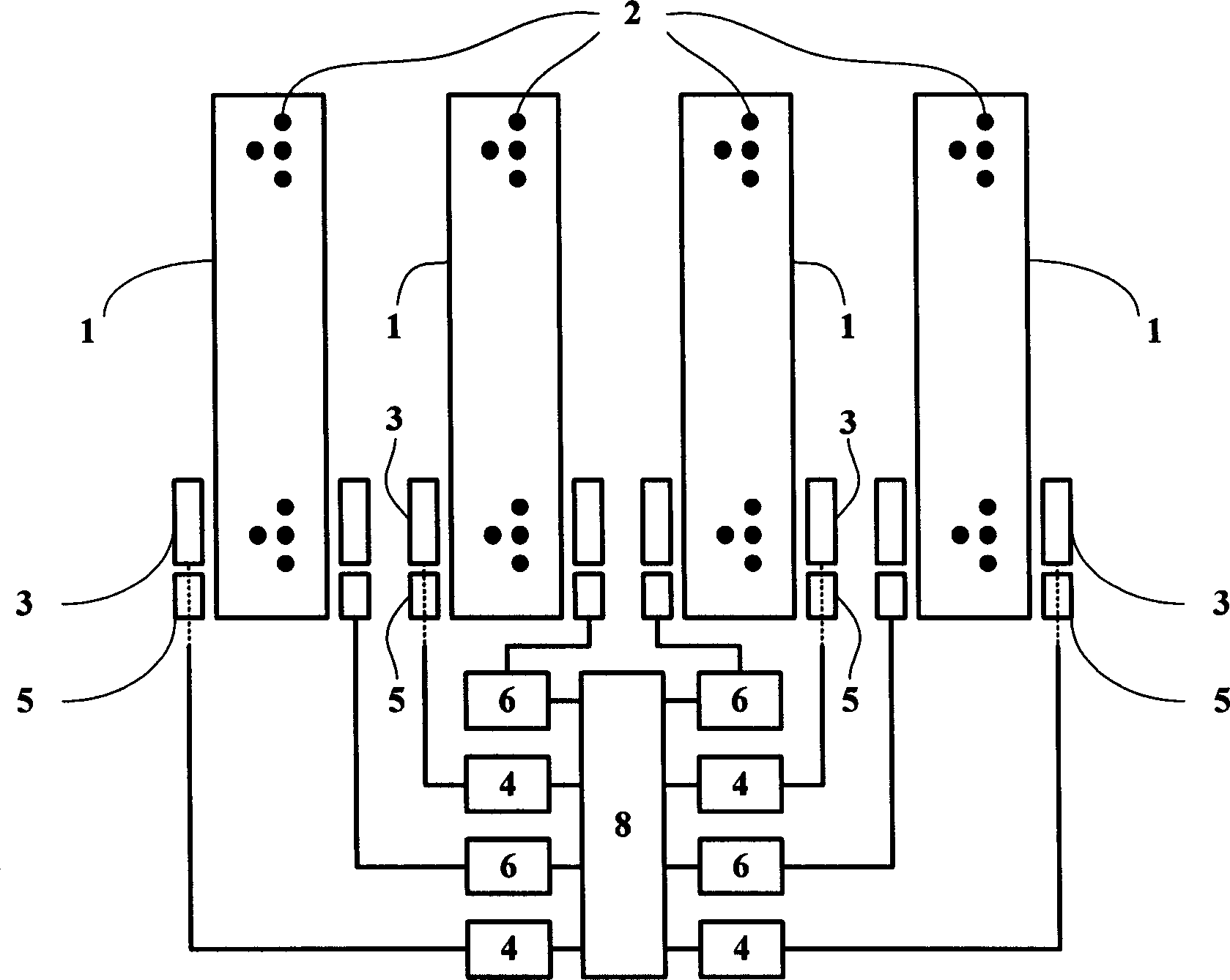

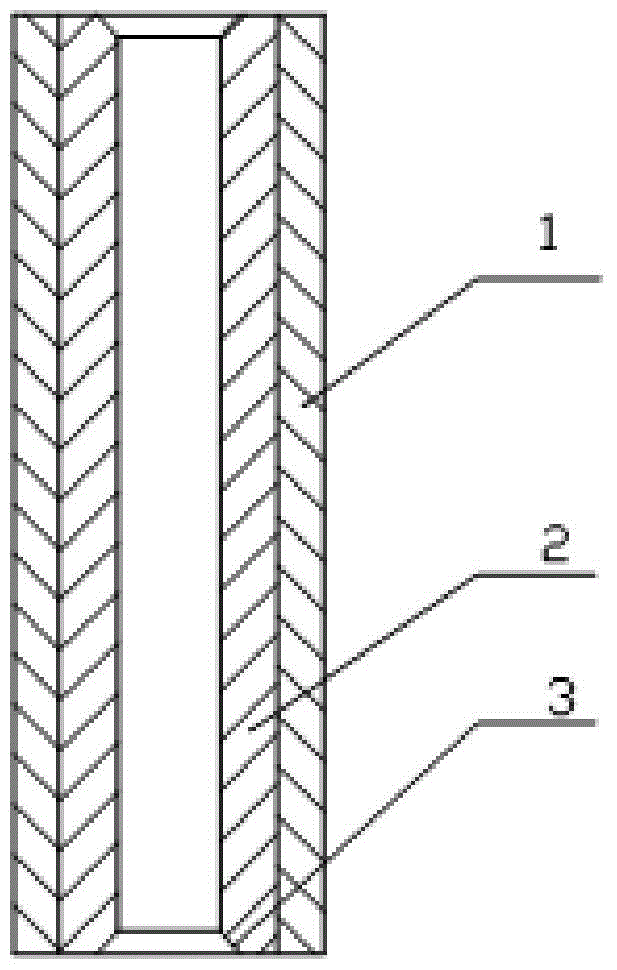

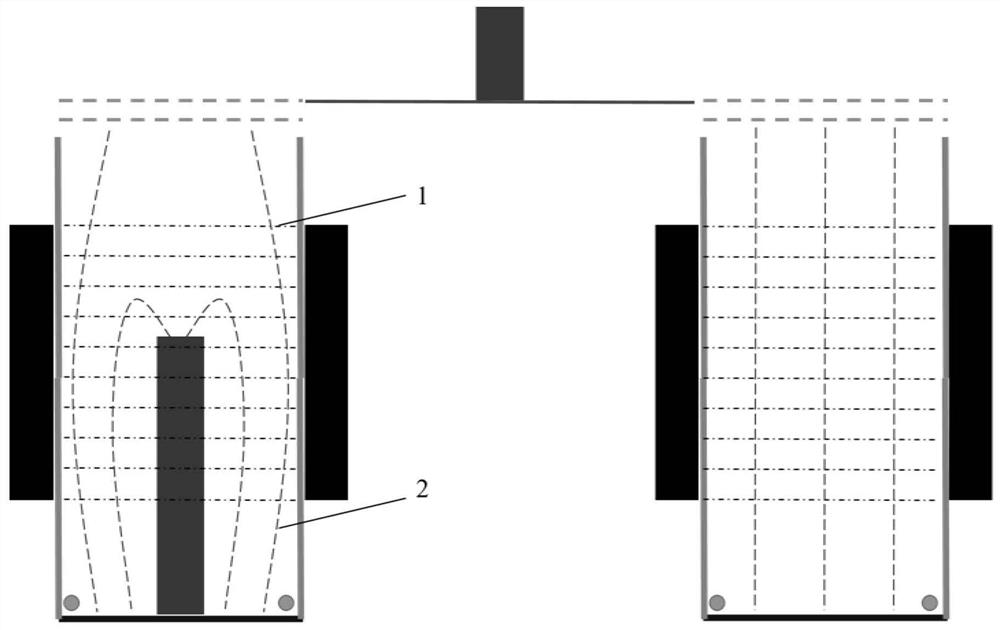

Self-reconstruction plasma antenna

InactiveCN1794516ASuppress interferenceEliminate radar scatter problemsAntenna supports/mountingsElectrical conductorPlasma antenna

This invention relates to a self-restructing plasma antenna including a column container, inert gases, a RF excitation antenna, a RF excitation source, a signal coupler, a feeding port and an earth plate characterizing that the column container is filled with inert gases, the source and the antenna are used in exciting and maintaining the plasma, in which, the excitation antenna is set in the inside or outside of the column container, its lead out wire is connected with the RF excitation source, the signal coupler is used to couple the signal to the plasma antenna set out of the container, the lead out wire is connected with the internal conductor of the feeding port and the outer conductor is connected with the earth plate.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing thorium dioxide pellets

The invention belongs to the technical field of manufacturing of nuclear fuel elements, and specifically relates to a method for preparing thorium dioxide pellets. The method comprises a powder granulating process: pressing thorium dioxide powder prepared by adopting an oxalate precipitation method and serving as an original raw material into sheets by adopting a compression molding method, crushing in a granulator, screening by a granulator screen, and shaking in a top-knocked sieve shaker to obtain granules for forming the thorium dioxide pellets; a powder molding process: performing die pressing on the granules to obtain a green blank of the pellets; and a pellet sintering process: putting the green blank of the thorium dioxide pellets into a vacuum atmosphere sintering furnace, vacuumizing, washing the furnace, then introducing argon and sintering. The cobalt pellets are prepared by adopting a powder metallurgy process, so that the difficulty of low density of the green blank of the thorium dioxide powder is overcome; and the pellets prepared by the granulating, molding and sintering processes have high density and grain size meeting the index requirements of preparation of fuel elements.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

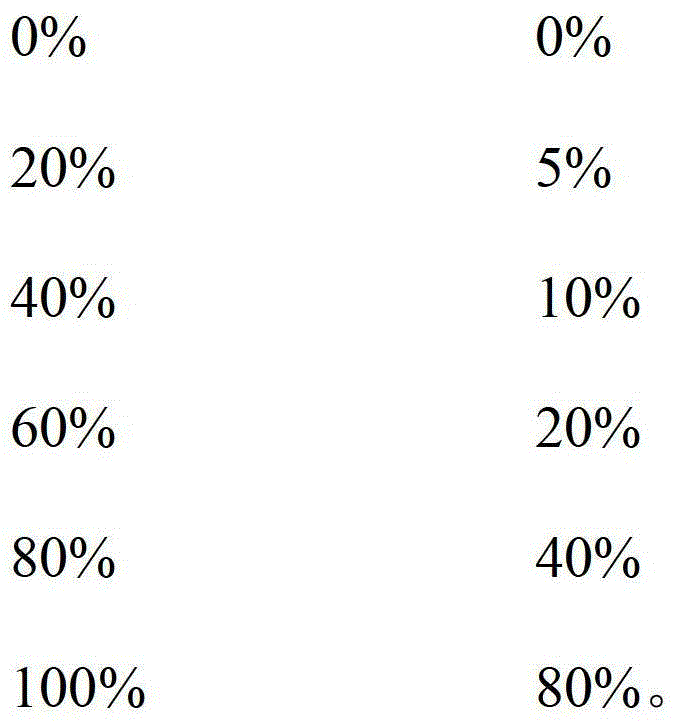

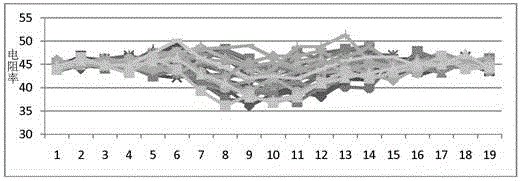

Method for producing straightly-pulled heavily-doped ultralow-resistivity silicon monocrystal

InactiveCN104831346ALow costReduce wastePolycrystalline material growthBy pulling from meltDopantSingle crystal

The invention provides a method for producing a straightly-pulled heavily-doped ultralow-resistivity silicon monocrystal. The method includes combining heavily-doped monocrystal head tailings (with certain resistivity) with protogenic polycrystal materials according to a certain ratio; performing doping according to normal doping quantity after mixing, switching blast furnace pressure parameters for baking during doping to enable dopants to be fused into melts quickly, starting crystal pulling after normal furnace pressure is stable, injecting argon mixed gas during crystal growth, and increasing partial pressure of the dopants in a furnace; when the monocrystal is kept and grows stably, increasing the furnace pressure gradually to further reduce volatilization of the dopants and resistivity. The method has the advantages that monocrystal cost is reduced through the heavily-doped monocrystal head tailings, head total resistivity can be reduced by 5-25% without addition of first doping amount, monocrystal silicon resistivity is reduced obviously without influence on monocrystal forming rate, resistivity reflex action is suppressed and axial uniformity of the resistivity is improved.

Owner:TIANJIN HUANOU SEMICON MATERIAL TECH CO LTD

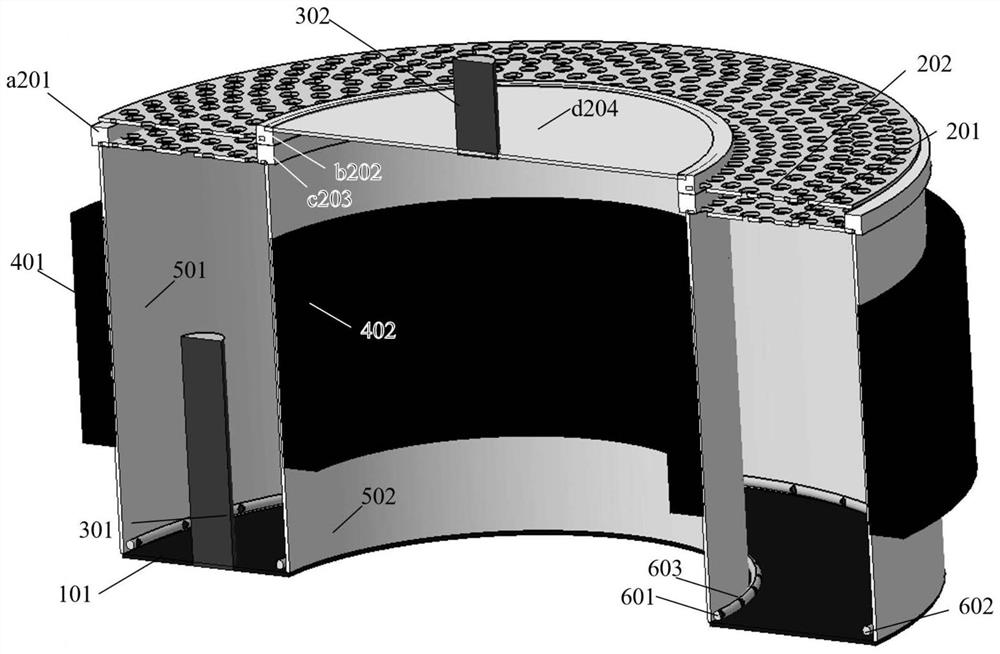

Hall effect ringlike ion thruster

ActiveCN111852802AReduce spanReduce manufacturing difficultyMachines/enginesUsing plasmaPlasmaElectric field

The invention discloses a Hall effect ringlike ion thruster and belongs to the technical field of ion thrusters. The ringlike ion thruster comprises a bottom positive pole, a ringlike grid electrode,ringlike permanent magnets, insulating sleeves, a working medium distributor set, a bias discharging negative pole and a neutralizer. Working medium gas enters a discharging chamber through bottom working medium distributors. Nozzles of the working medium distributors are oriented along the wall face so that the gas can be more uniform in a cavity. An axial electric field is formed among the positive pole, the negative pole and the grid electrode. A radial magnetic field is formed by the inner ringlike permanent magnet and the outer ringlike permanent magnet, and an E*B orthogonal field is formed by the radial magnetic field and the axial electric field. Electrons sprayed out of the negative pole are subjected to Hall drift under the effect of the orthogonal field, and the working medium gas is ionized to generate plasmas. Then, the plasmas are extracted and accelerated by the ringlike grid electrode and neutralized by electrons emitted by the neutralizer to generate thrust. The ionization rate and input power of the thrust generated by the Hall effect ringlike ion thruster are far higher than those of a traditional ion thruster, and performance of the ion thruster can be remarkably improved.

Owner:DALIAN UNIV OF TECH

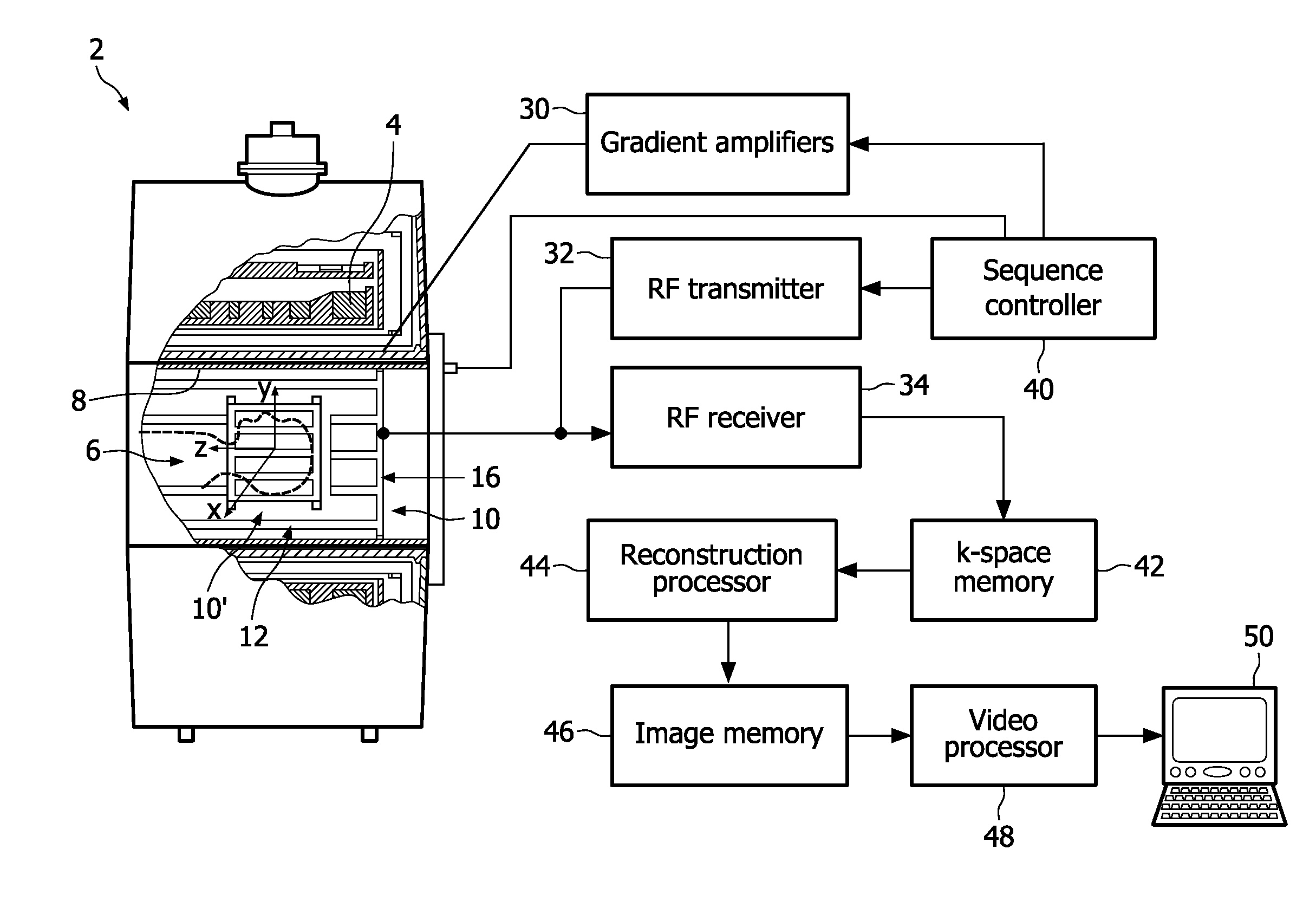

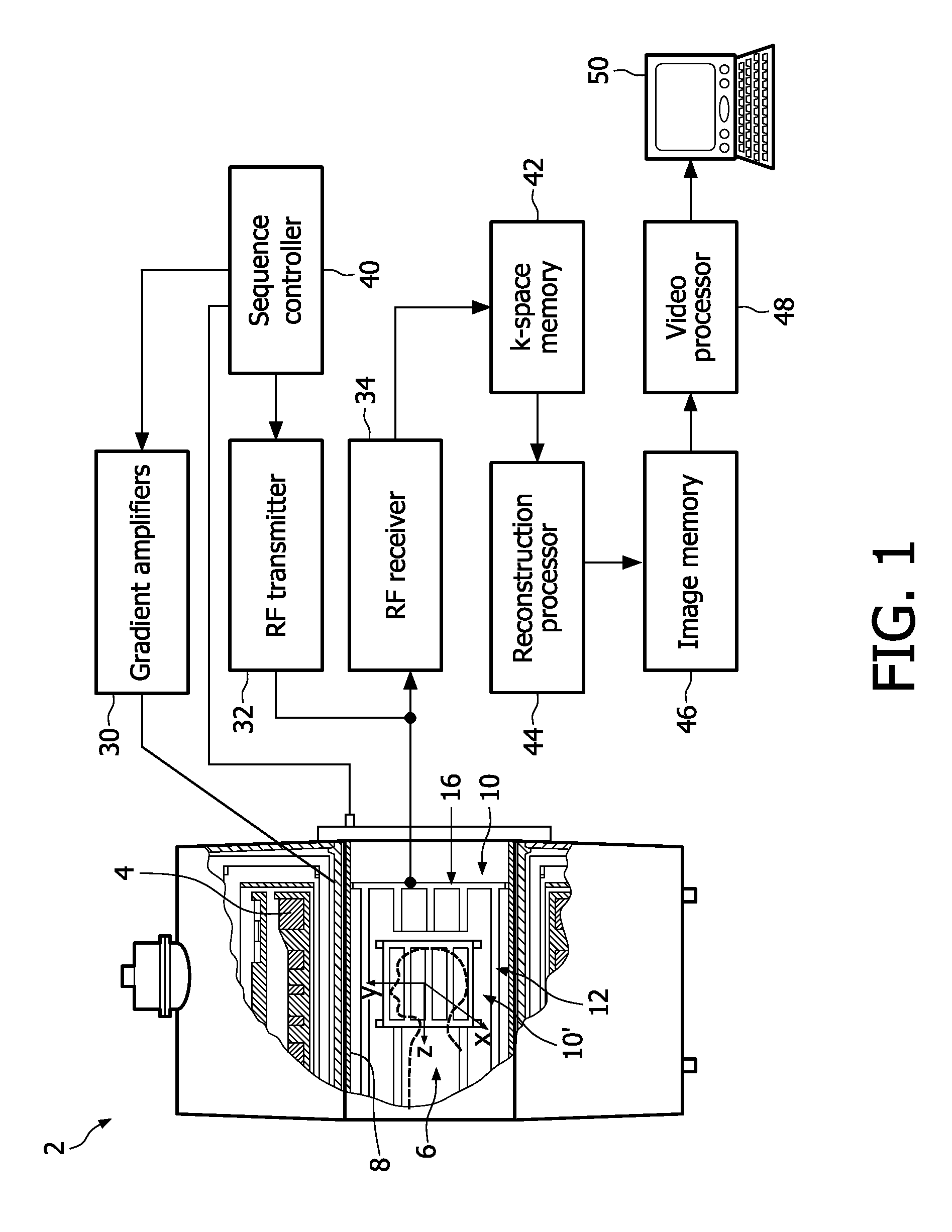

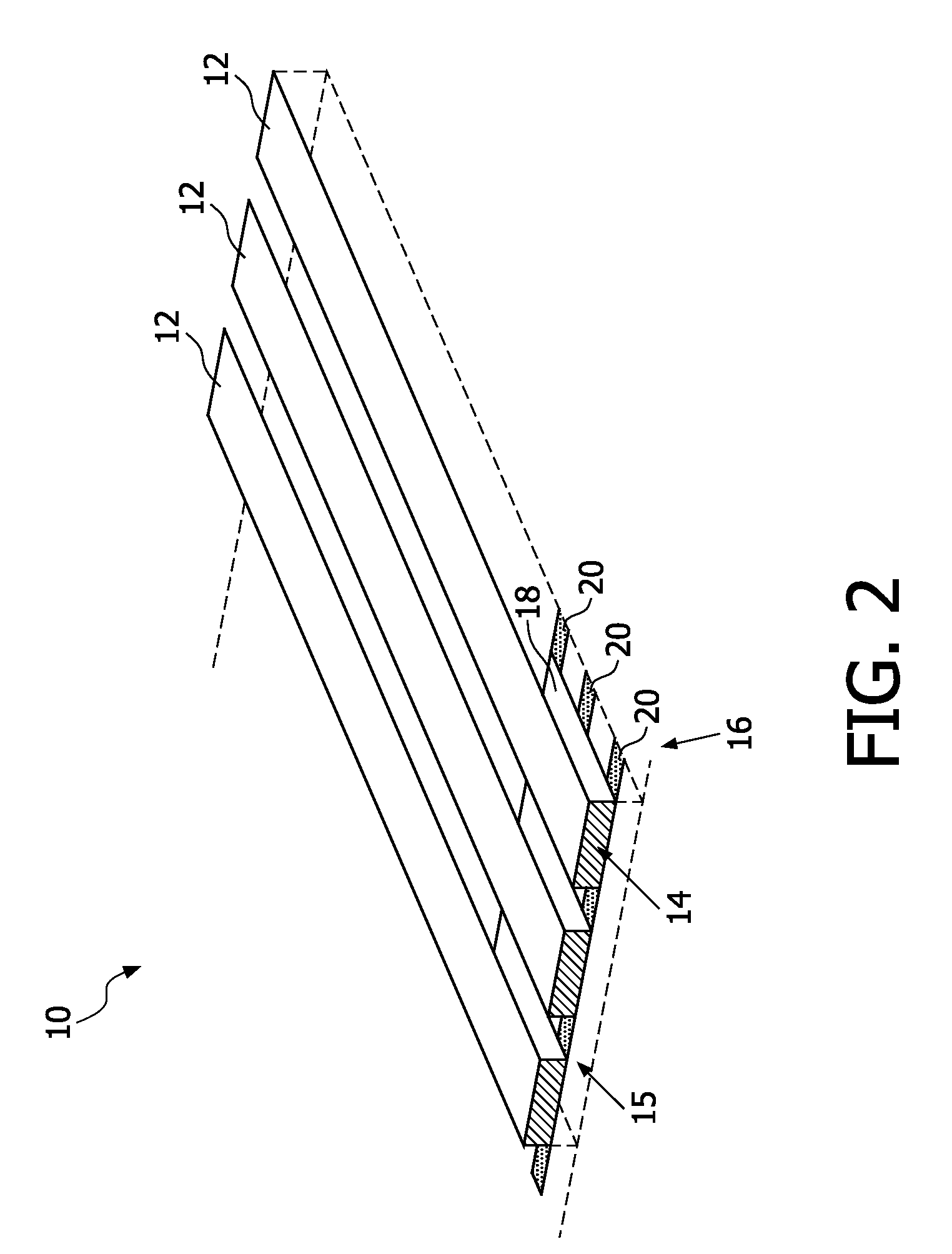

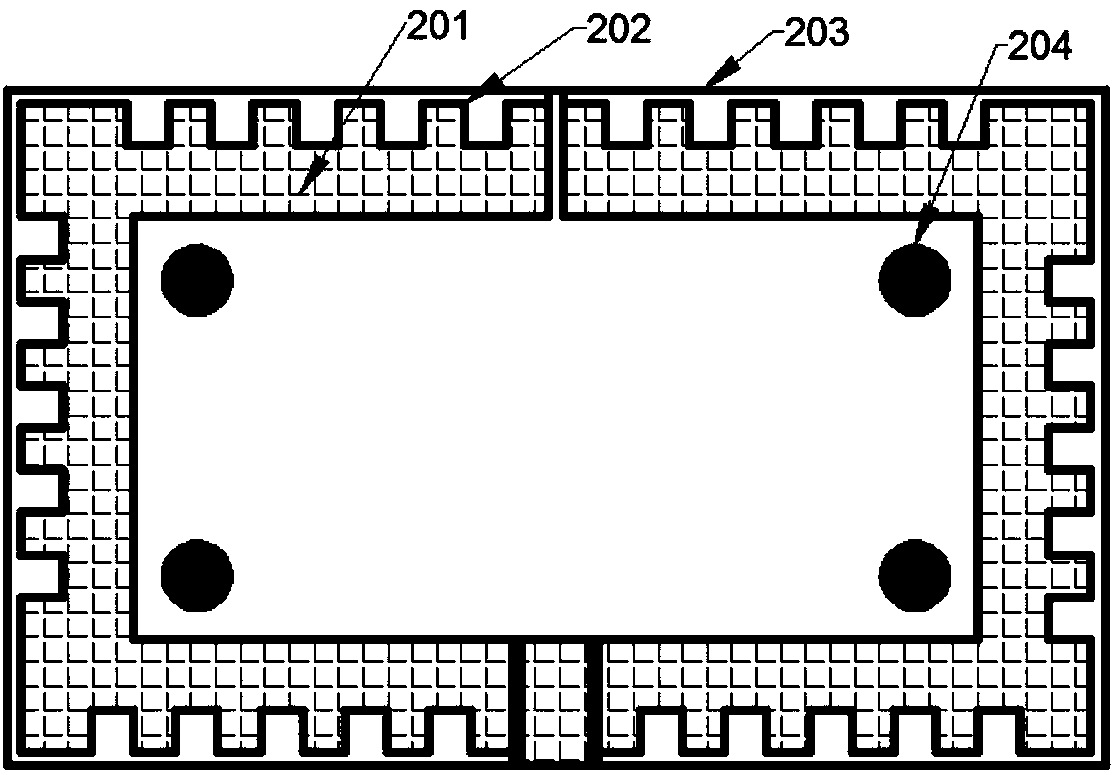

Birdcage coil with improved homogeneity and reduced SAR

InactiveUS20100219834A1Increase field strengthImprove axial uniformityElectric/magnetic detectionMeasurements using NMRCapacitorBiomedical engineering

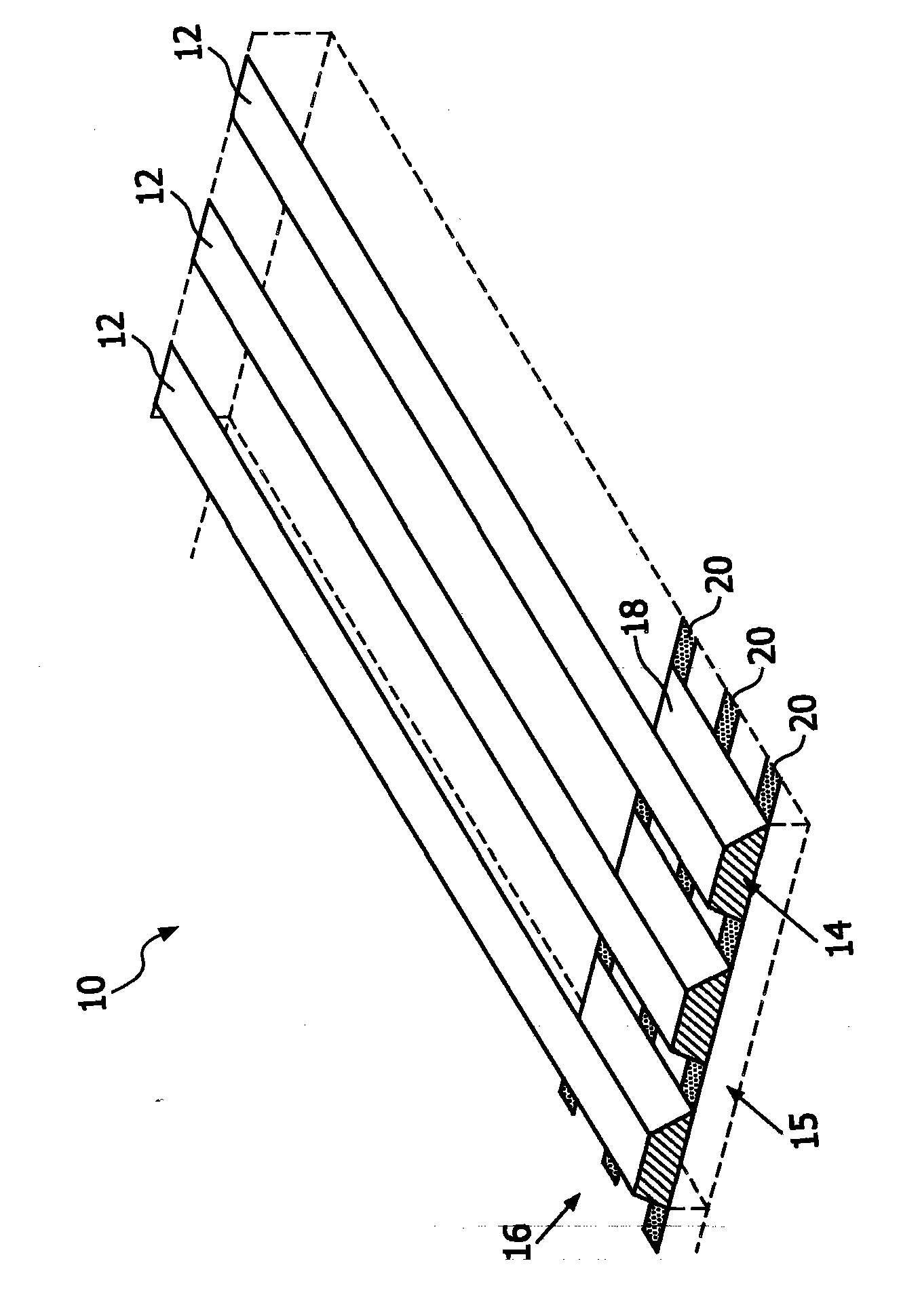

A birdcage coil (10) for a magnetic resonance imaging device includes a plurality of rungs (12) coupled to a distal edge (15) of each of two endrings (16). The endrings (16) comprise a plurality of ring segments (18) that are separated by sets of capacitors (20, 22, 24). The rungs (12) are coupled to the endrings (16) by connector portions (14), which create a gap between the endrings (16) and the rungs (12). Additionally, the rungs (12) can be positioned over the capacitors (20, 22, 24), and the connector portions (14) can be shaped to offset the position of the rungs (12) relative to the ring segments (16) to which they are coupled to achieve a desire rung position relative to the capacitors (20, 22, 24).

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

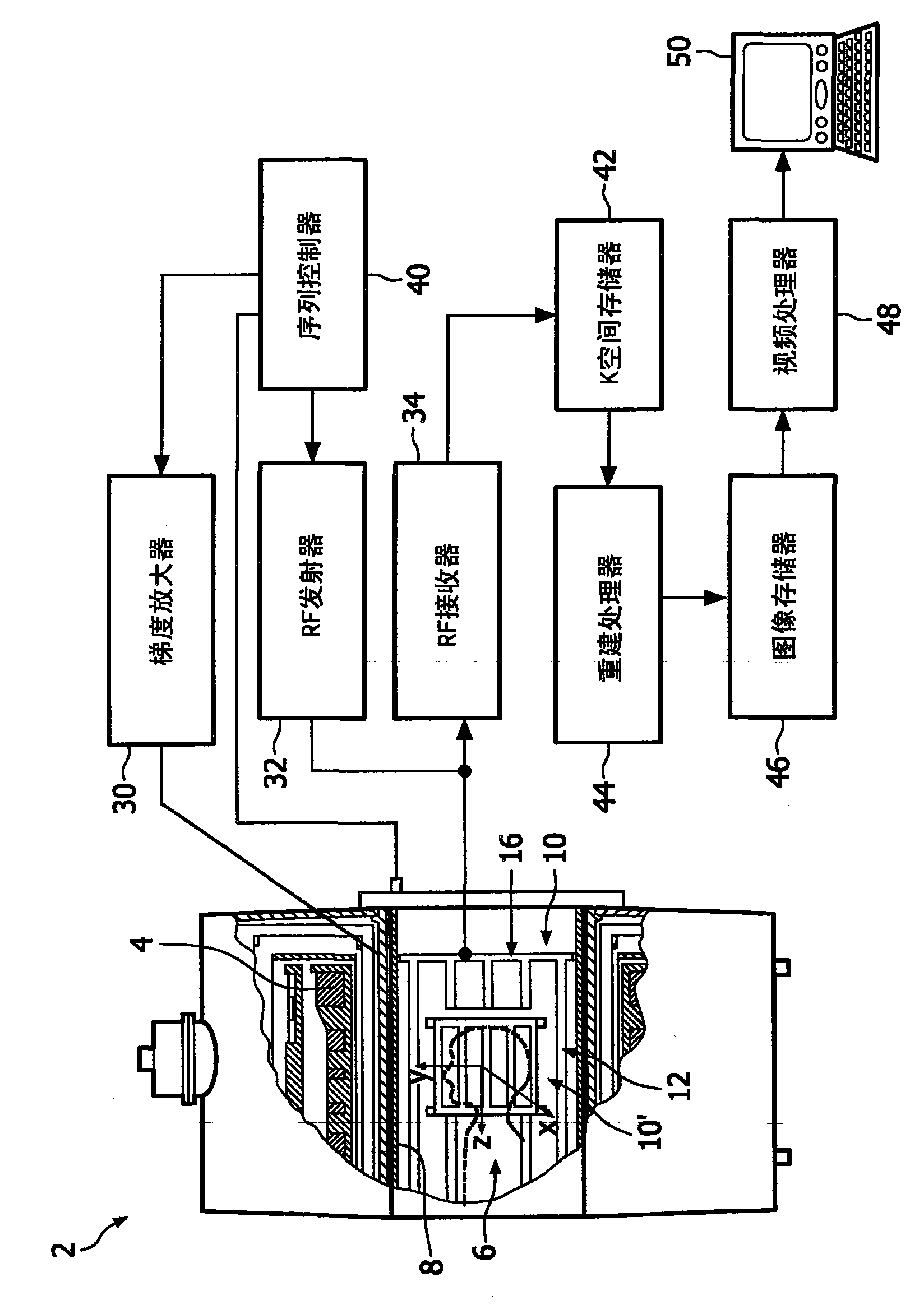

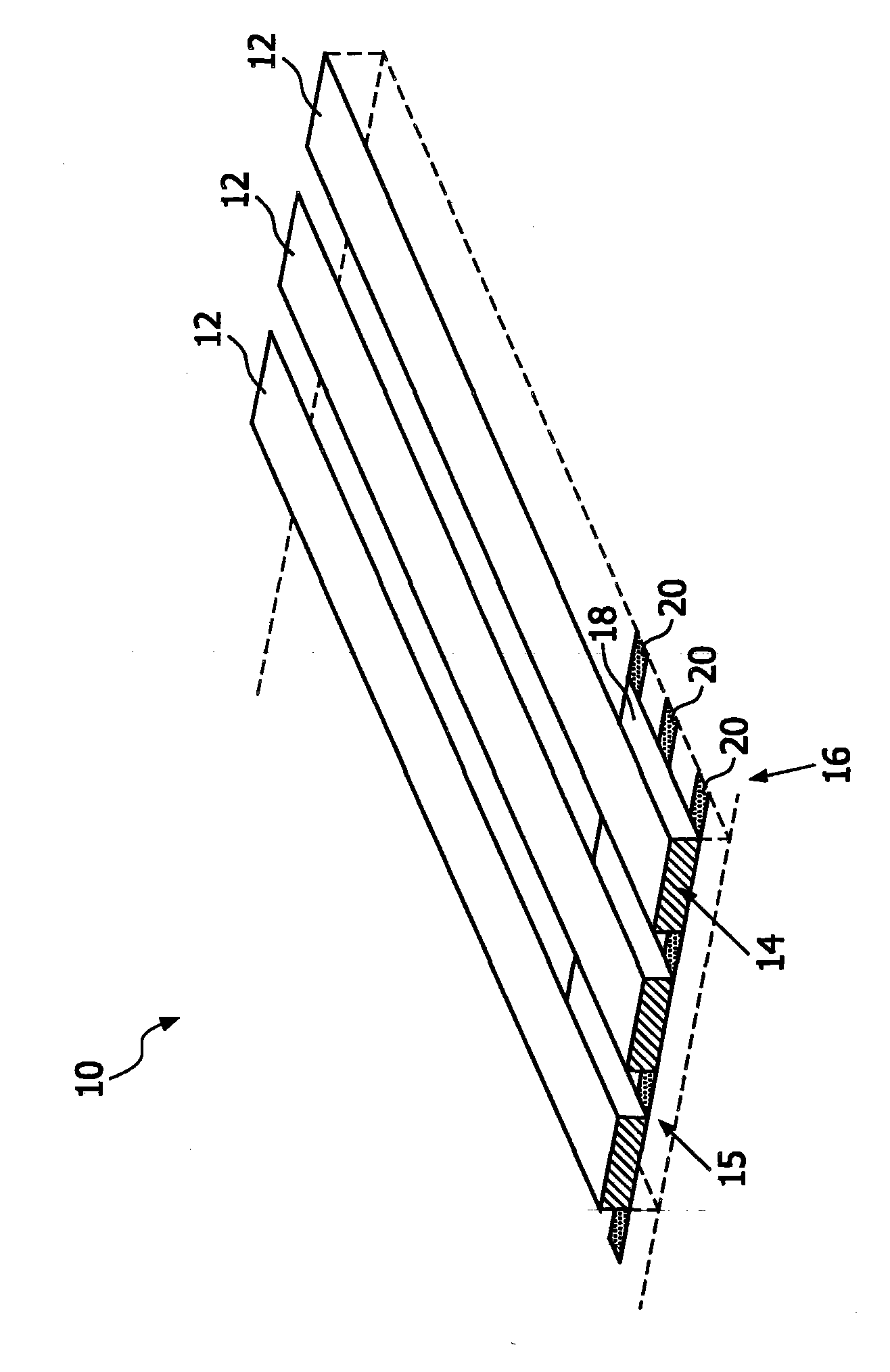

Birdcage coil with improved homogeneity and reduced SAR

InactiveCN101828125AImprove axial uniformityExpand the usable rangeMeasurements using magnetic resonanceCapacitorBiomedical engineering

A birdcage coil (10) for a magnetic resonance imaging device includes a plurality of rungs (12) coupled to a distal edge (15) of each of two endrings (16). The endrings (16) comprise a plurality of ring segments (18) that are separated by sets of capacitors (20, 22, 24). The rungs (12) are coupled to the endrings (16) by connector portions (14), which create a gap between the endrings (16) and the rungs (12). Additionally, the rungs (12) can be positioned over the capacitors (20, 22, 24), and the connector portions (14) can be shaped to offset the position of the rungs (12) relative to the ring segments (16) to which they are coupled to achieve a desire rung position relative to the capacitors (20, 22, 24).

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

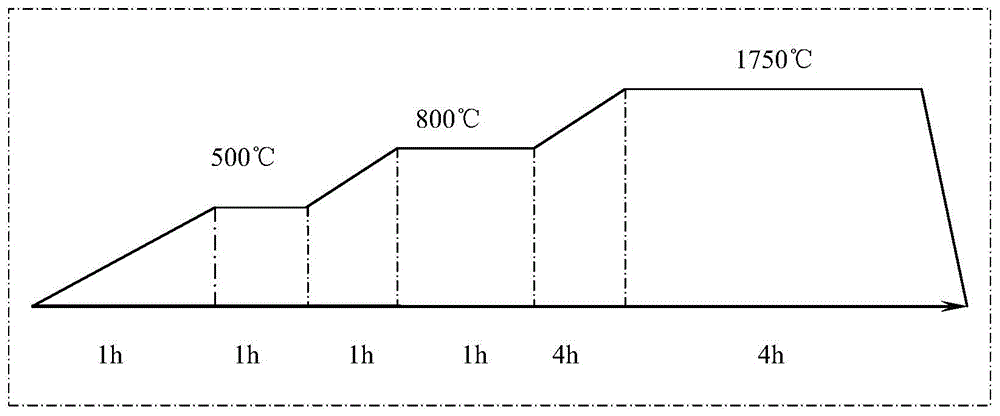

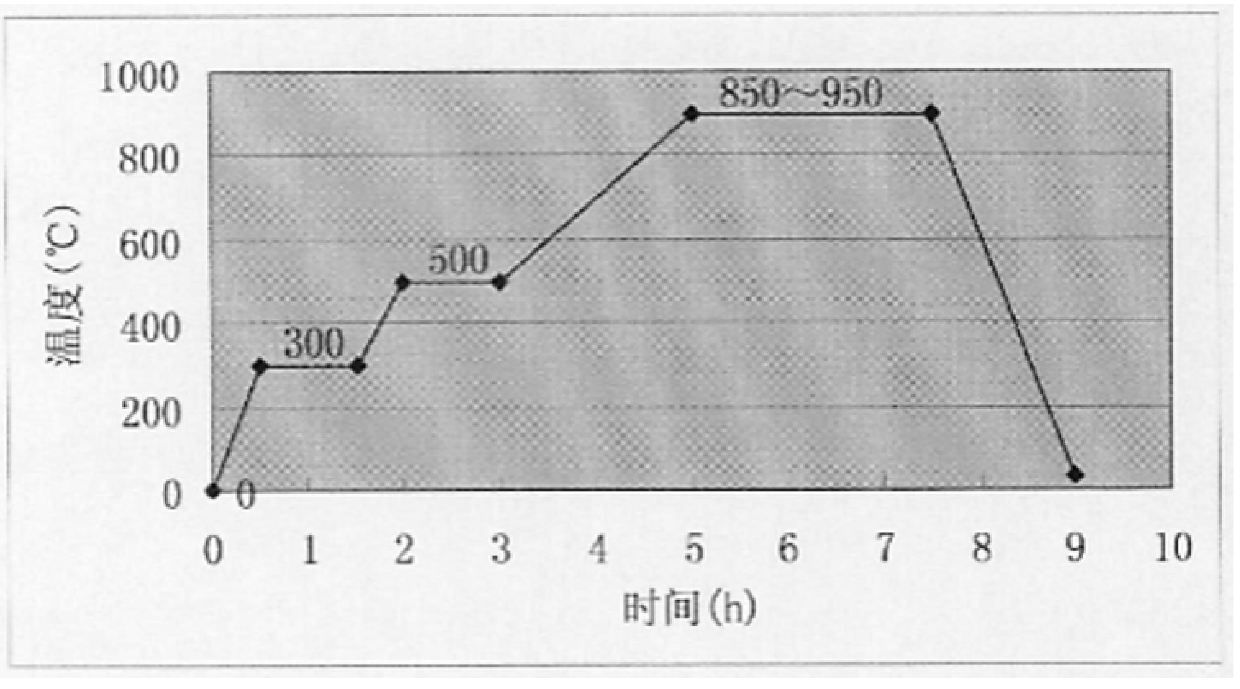

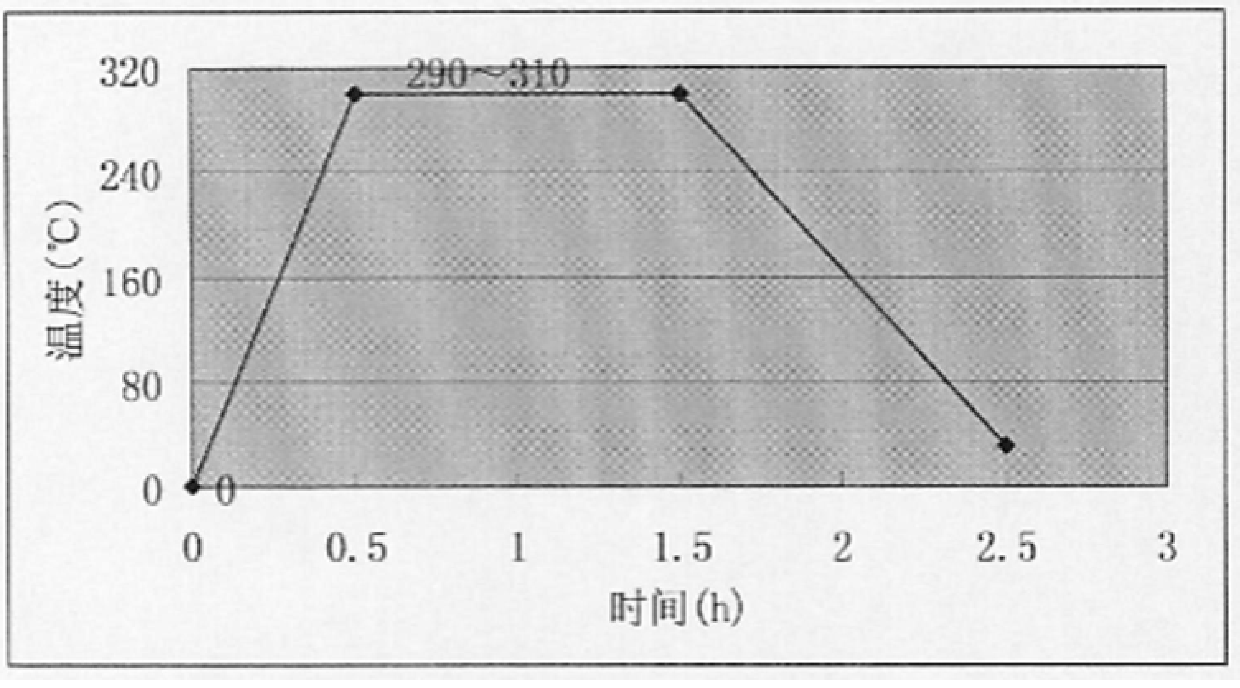

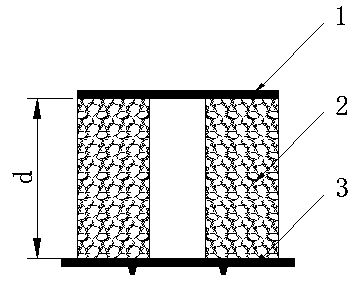

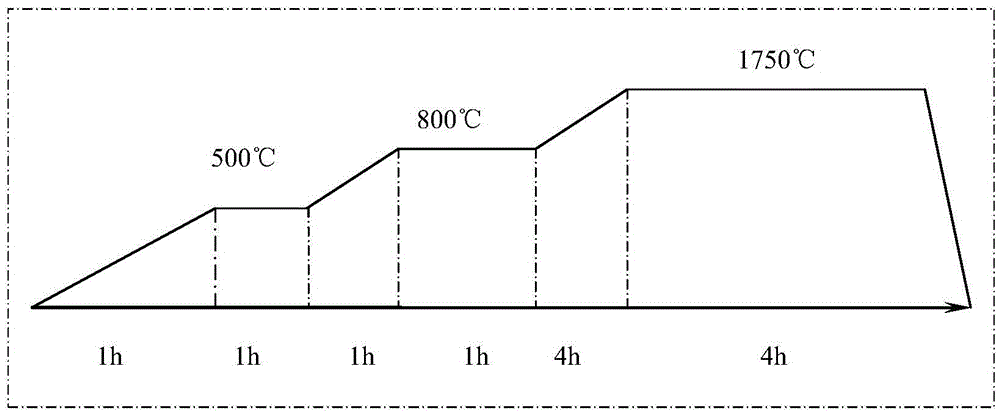

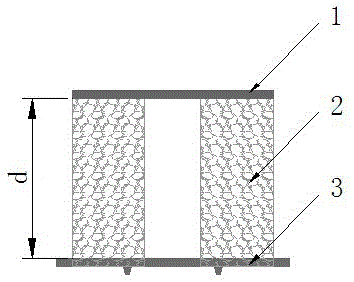

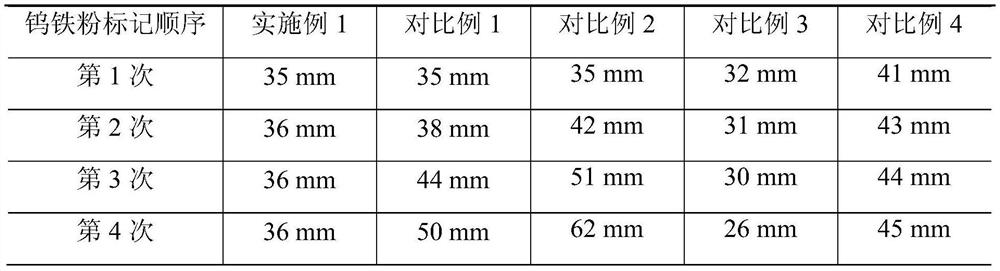

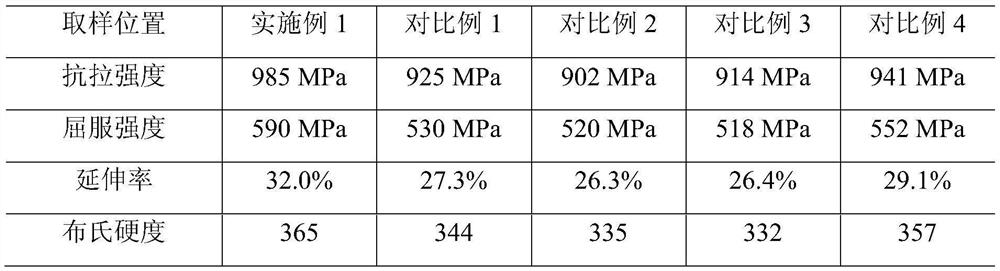

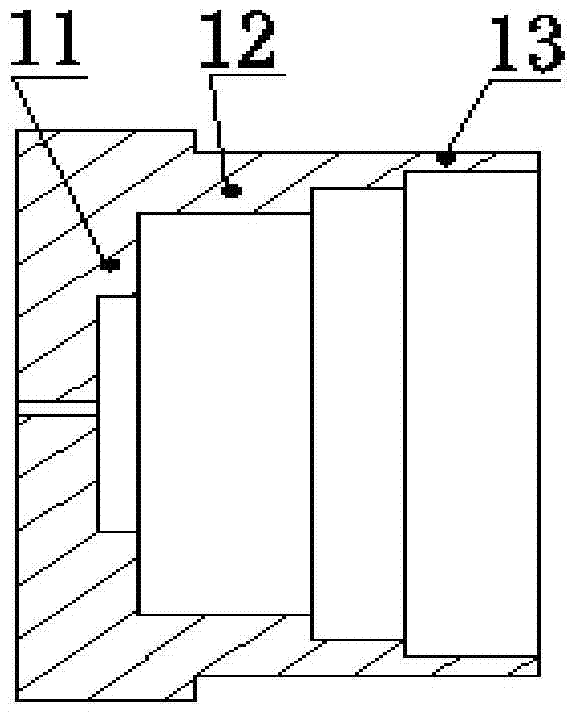

Preparation process of cobalt pellets in cobalt regulating rod assembly

ActiveCN106508058BImprove axial uniformityLower sintering temperatureFuel elementsNuclear energy generationHigh densityManufacturing technology

The invention relates to the manufacturing technology of nuclear fuel elements, in particular to a preparation process of pellets in cobalt regulating rod assemblies used in nuclear reactors. The process of the invention comprises the following steps: (1) powder granulation; (2) powder molding; (3) pellet sintering; (4) pellet degassing and sintering. The aspect ratio of the cobalt pellets produced by the process of the present invention is greater than 4, and the hydrogen impurity content is less than 1 μg / g, which meets the preparation requirements of high aspect ratio, high density, and defect-free cobalt pellets, and meets the requirements of the cobalt regulating rod assembly in the reactor. The technical requirements of the work are suitable for batch preparation.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

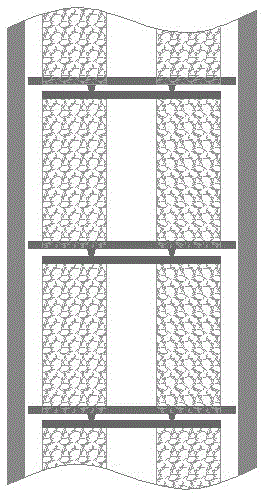

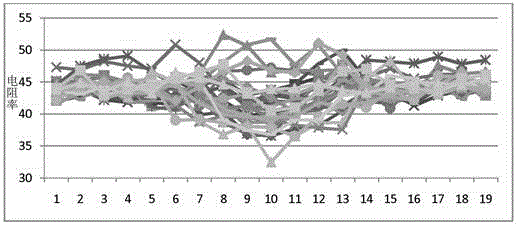

Device loaded with structured catalyst with radial wall flow

InactiveCN104289159ASimple structureReduce manufacturing difficultyChemical/physical processesEngineeringThermal expansion

The invention discloses a device loaded with a structured catalyst with radial wall flow. According to the invention, a plurality of structural units are loaded in a reaction tube. Each structural unit comprises a reactant stream wall flow guide panel, a structured carrier loaded with a catalyst, and an expansion ring with a thermal expansion and contraction effect. The reactant stream wall flow guide panel is arranged at the top end of the structured carrier loaded with the catalyst. The bottom end of the structured carrier loaded with the catalyst is embedded in the expansion ring with thermal expansion and contraction effect. The reactant stream wall flow guide panel is a solid cylindrical body coaxial with the structured carrier loaded with the catalyst. The expansion ring with thermal expansion and contraction effect is a hollow cylindrical body coaxial with the structured carrier loaded with the catalyst. The cross-sections of two hollow parts are overlapped. The device provided by the invention has the advantages of simple structure, low pressure drop, and uniform fluid distribution. With the device, advantages of the structured catalyst in the aspects of heat transfer and mass transfer can be fully performed. Material stream radial wall flow can be realized. The device can be used in industrialized production for producing propylene from methanol.

Owner:ZHEJIANG UNIV

Variable crucible ratio monocrystal silicon growth method

ActiveCN103305905AEasy to operateStrong production compatibilityPolycrystalline material growthBy pulling from meltCrucibleSingle crystal

The invention discloses a variable crucible ratio monocrystal silicon growth method which comprises the following steps of: growing monocrystal silicon in a crucible; and after the monocrystal silicon enters constant-diameter growth, regulating variable crucible ratio to continuously increase so as to carry out variable crucible ratio monocrystal silicon growth. According to the variable crucible ratio monocrystal silicon growth method disclosed by the invention, the liquid level of monocrystal interface growth can be slowly increased, the natural thermal convection of a molten mass can be effectively accelerated, the oxygen content concentration of the molten mass can be kept and the axial oxygen content consistency of monocrystal silicon can be effectively improved; and the variable crucible ratio monocrystal silicon growth method is convenient to operate and suitable for the industrialized production.

Owner:ZHEJIANG COWIN ELECTRONICS

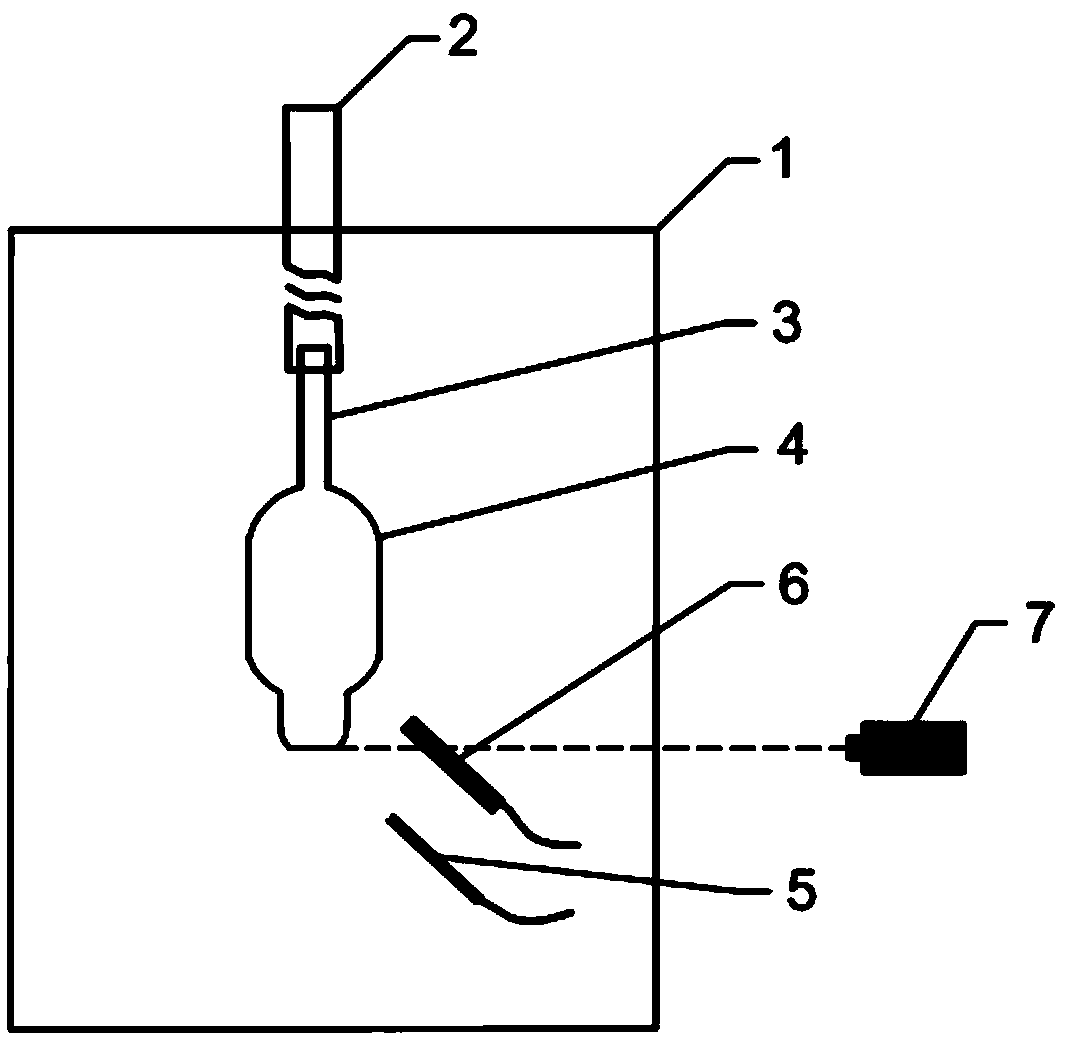

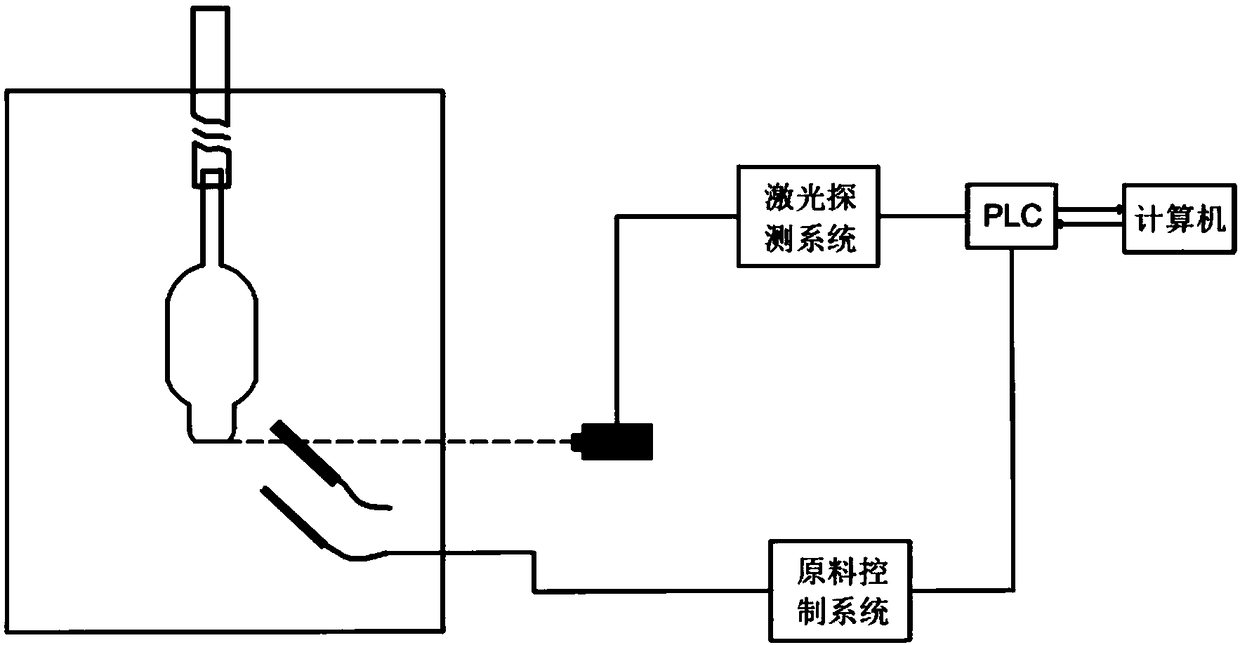

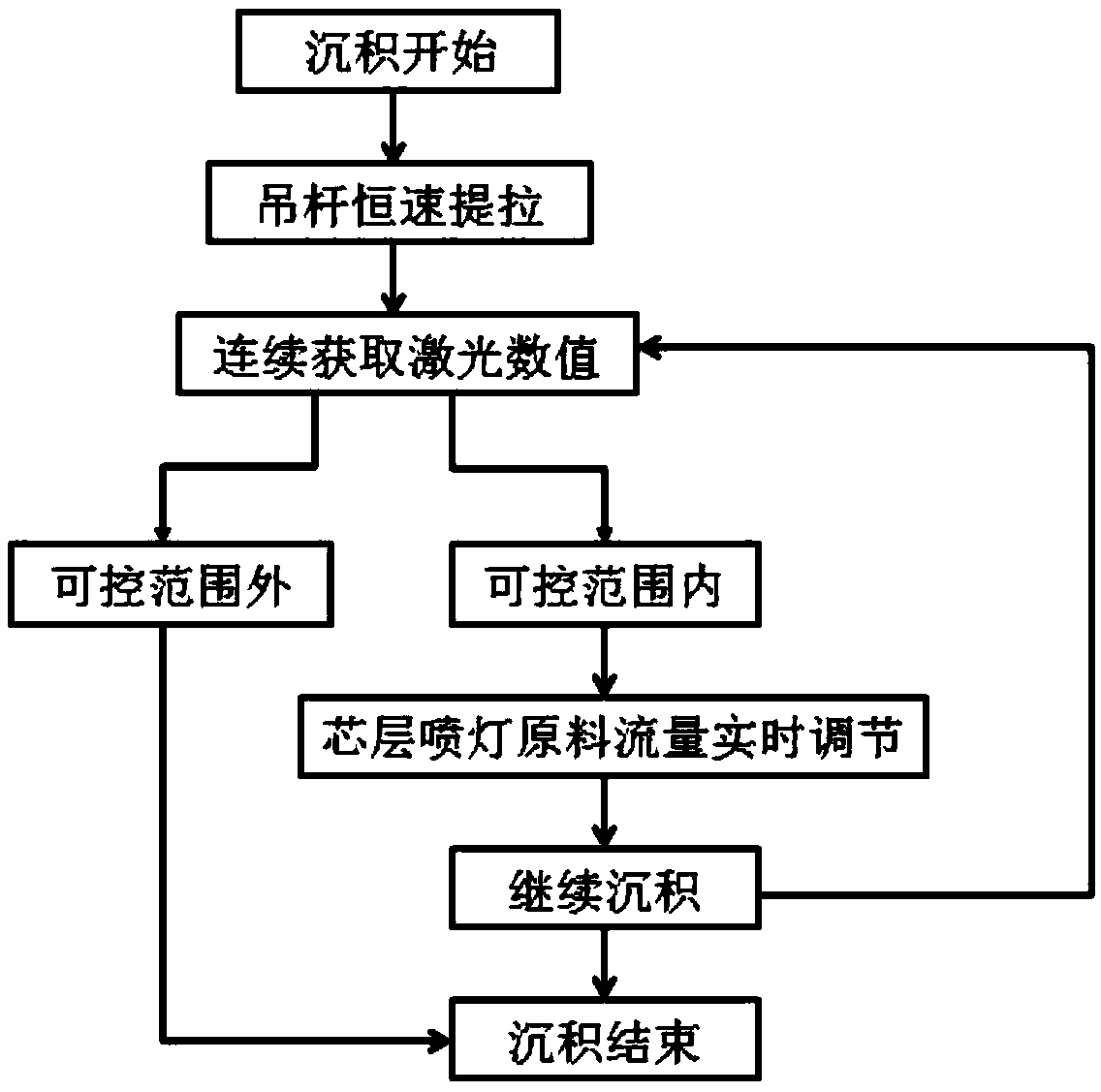

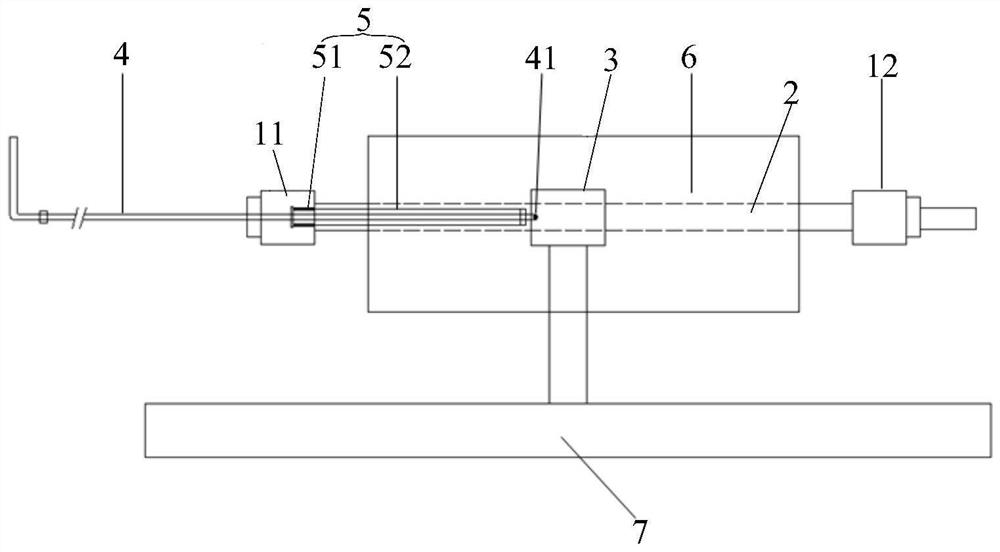

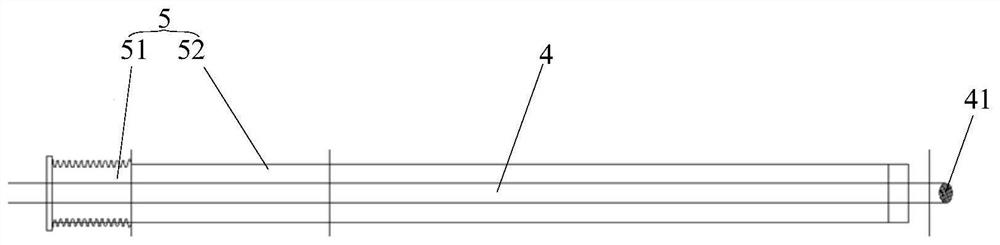

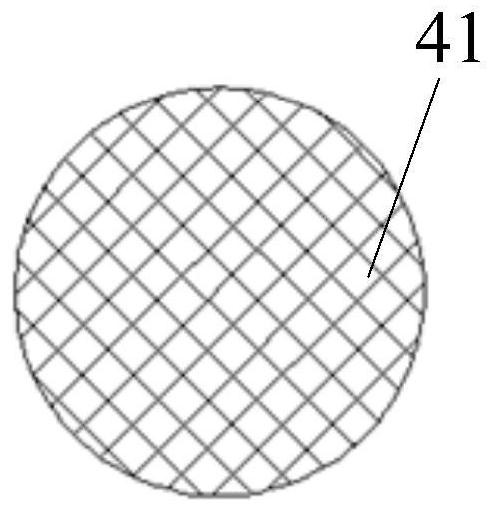

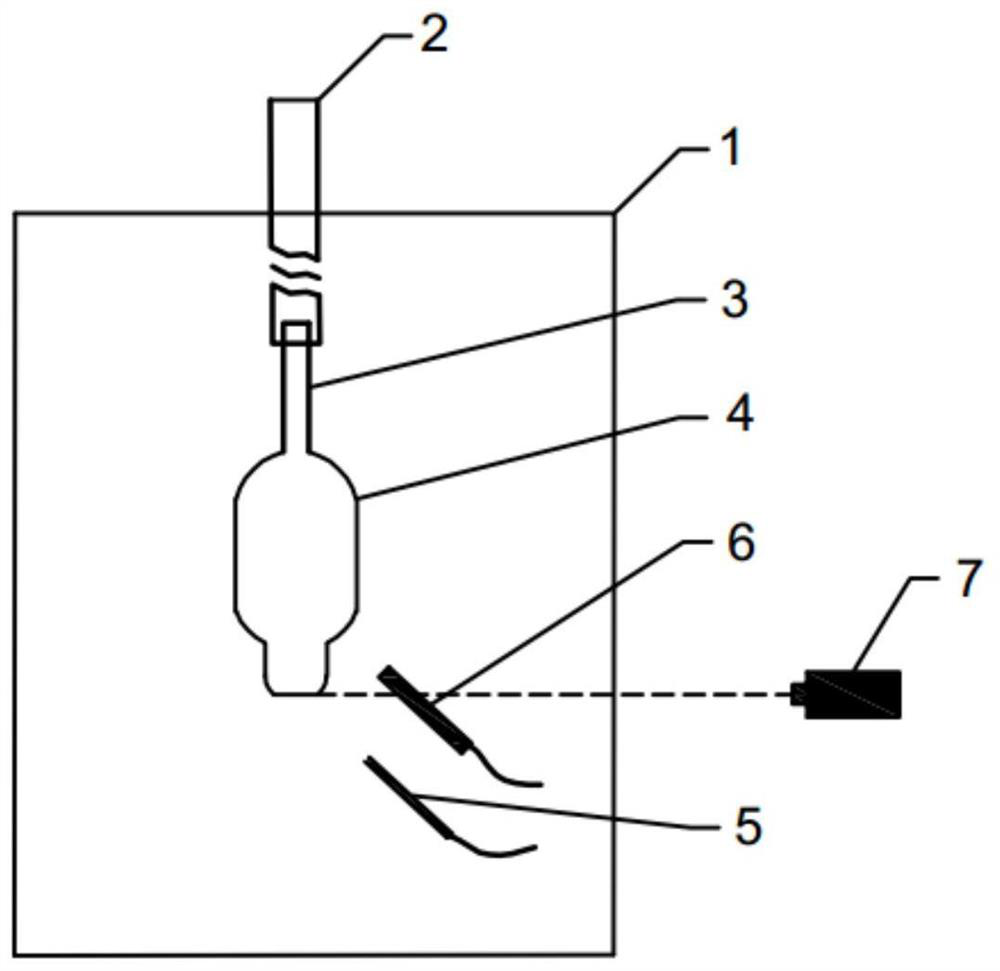

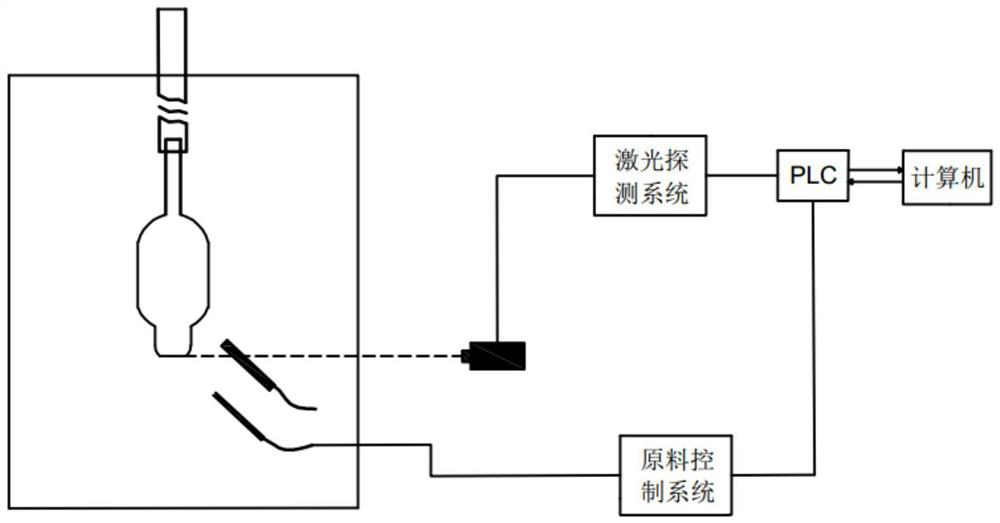

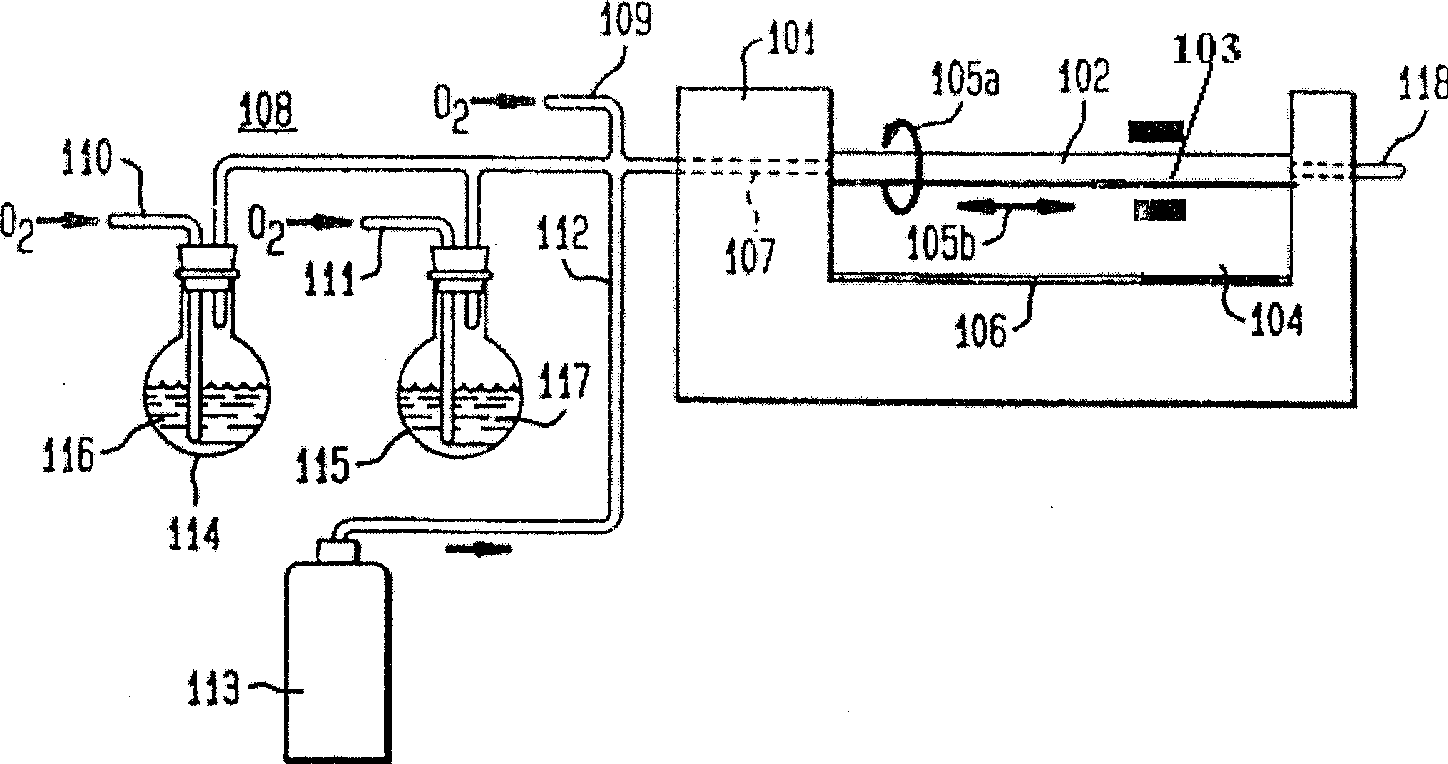

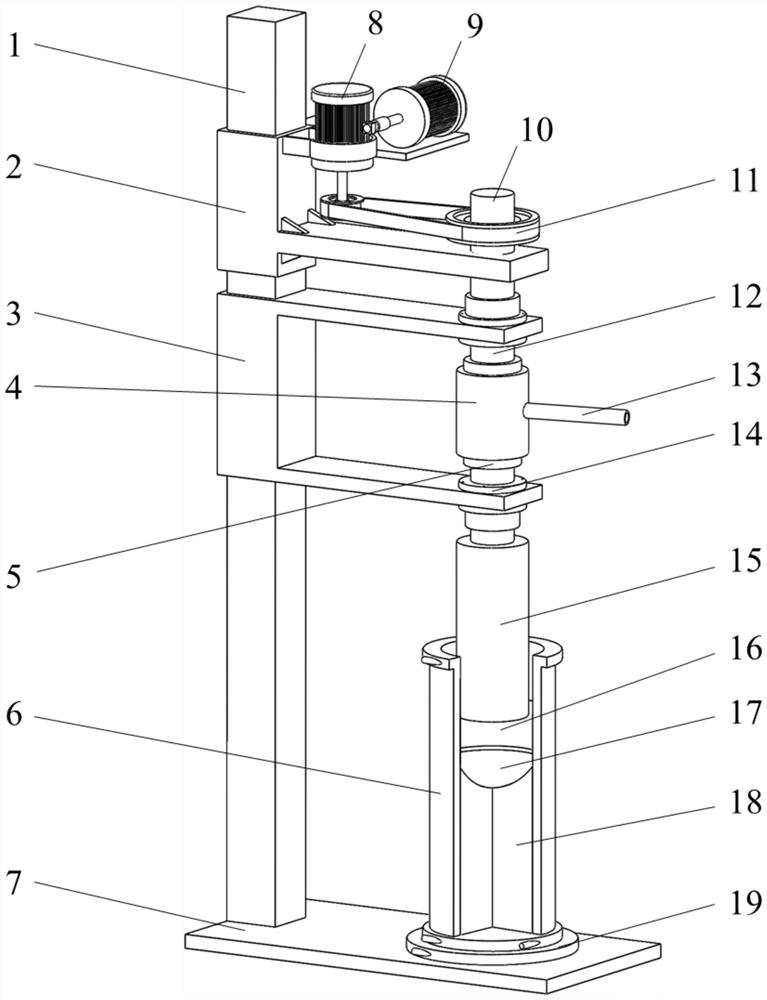

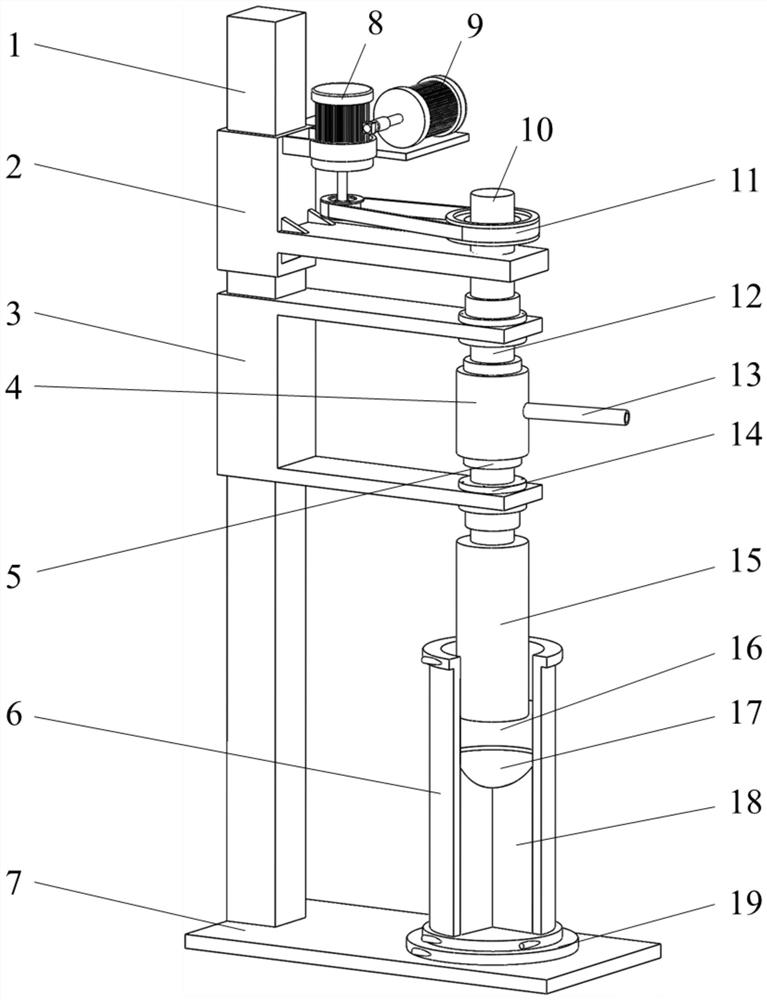

Device and method for preparing optical fiber prefabricated bar base material by VAD

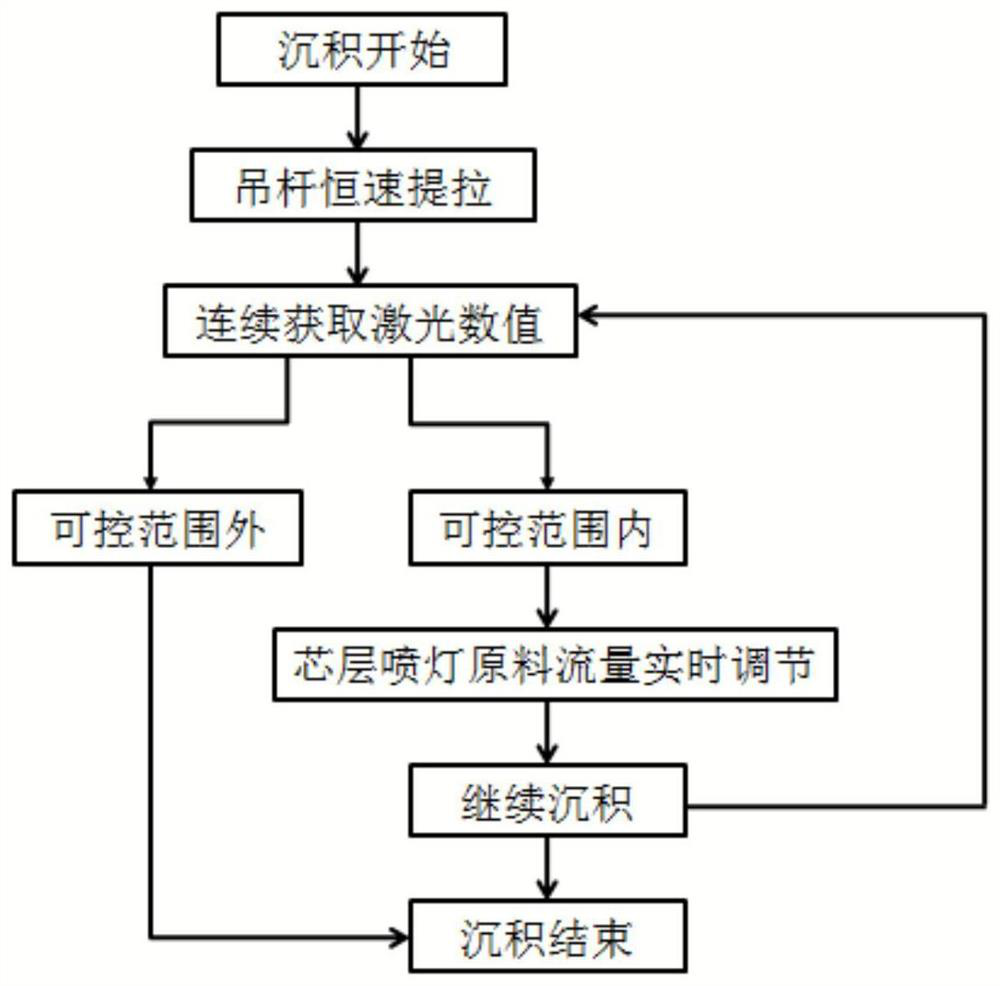

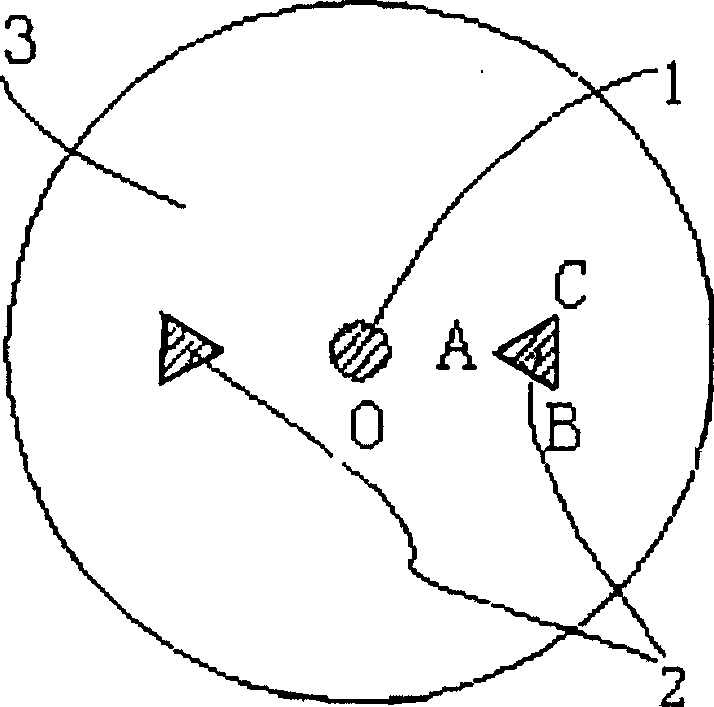

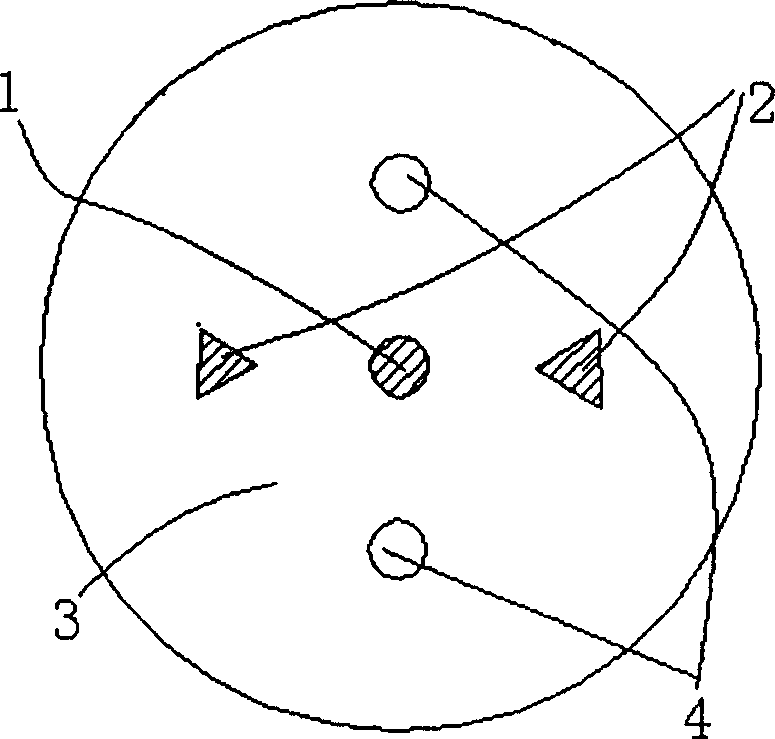

ActiveCN108929031AAcceleration profileSpeed-up core diameterGlass making apparatusControl systemClosed loop

The invention relates to a device and method for preparing an optical fiber prefabricated bar base material by VAD, wherein the device includes a reaction chamber for deposition and a rotating liftingsuspending rod extending into an inner cavity of the reaction chamber. A part, corresponding to the lower side of a to-be-deposited glass target bar, below the inner cavity of the deposition chamberis provided with a core layer spray lamp and a cladding layer spray lamp at intervals; the core layer spray lamp and the cladding layer spray lamp are connected with a core layer raw material controlsystem and a cladding layer raw material control system respectively; parts, corresponding to the deposition lower end face of the core layer, of two opposite sides of the exterior of the deposition cavity are provided with a laser emitting end and a laser receiving end respectively, and a core layer laser detection system is constructed. The device is characterized in that the core layer raw material control system and the core layer laser detection system are connected with a PLC, a PID closed-loop adjusting system between the flow rate of a core layer spray lamp raw material and the laser detection received value is formed, and a real-time feedback control is formed. The device has the advantages of simple structure, clear control logic, direct and rapid feedback, stable and reliable deposition performance, stable powder bar cross sections, and uniform core diameter and outer diameter, thereby improving production stability and product quality.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

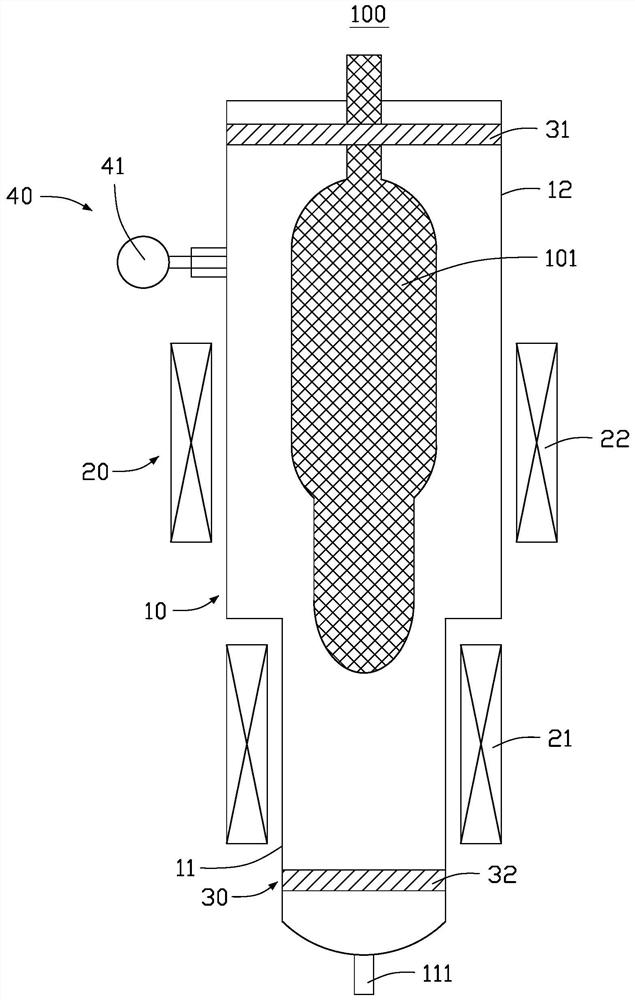

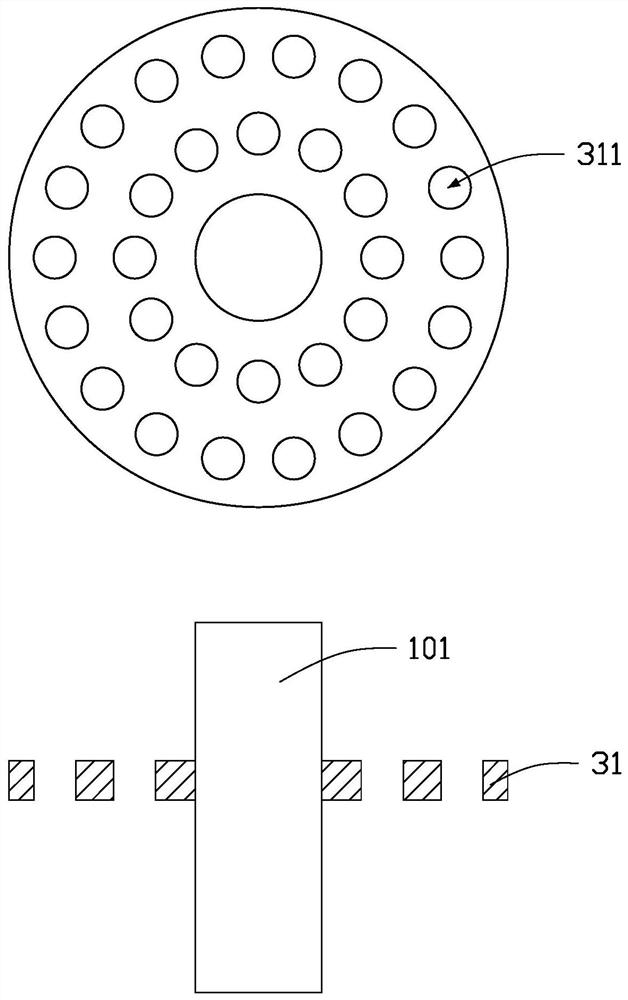

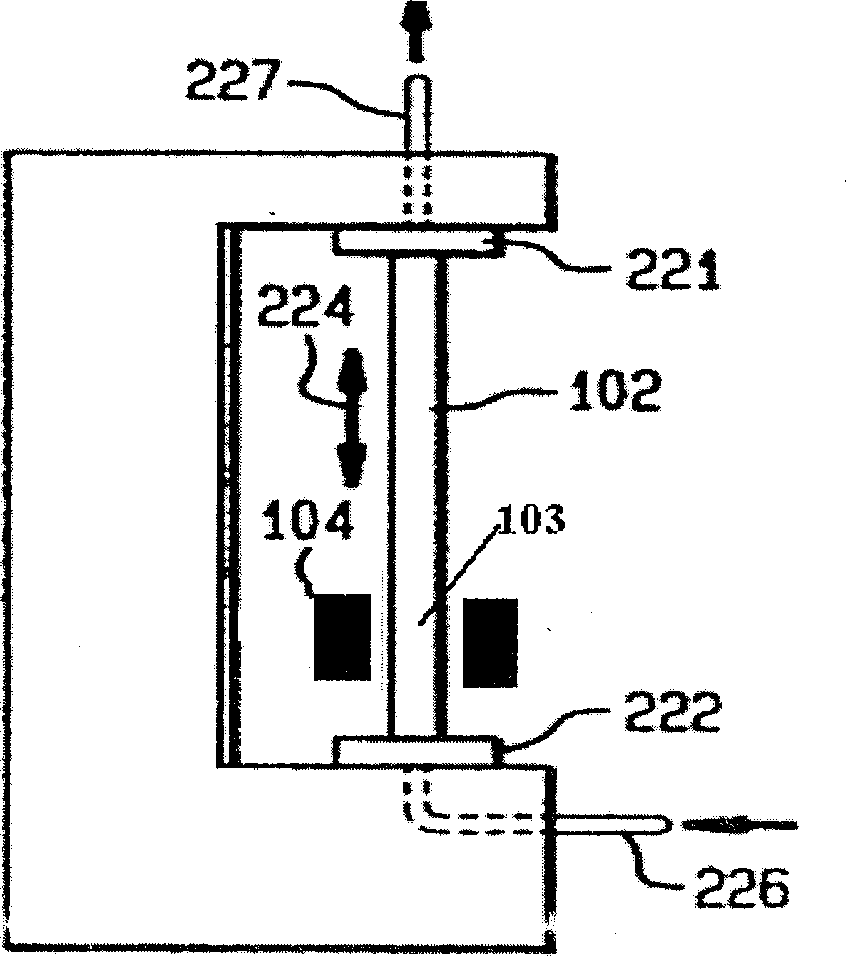

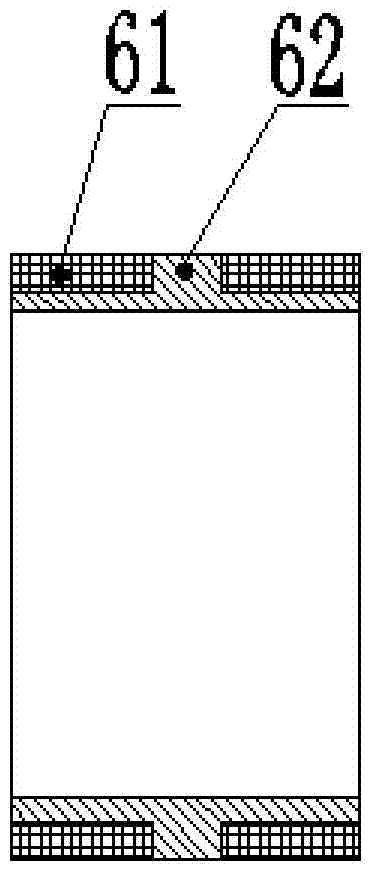

Optical fiber preform manufacturing equipment

ActiveCN112408775AEnsure consistencyImprove axial uniformityGlass making apparatusPhysicsReaction tube

The invention relates to the technical field of optical fiber preform production, in particular to optical fiber preform manufacturing equipment which comprises a sealing mechanism, a microwave resonant cavity and an air inlet pipe, wherein the sealing mechanism comprises an air inlet end sealing piece and an air outlet end sealing piece arranged at an interval for sealing the two ends of a reaction pipe; the microwave resonant cavity is used for being arranged on the outer side of the reaction tube in a sleeving manner and can do reciprocating motion in the axial direction of the reaction pipe; and the air inlet pipe comprises an air outlet end used for extending into the reaction pipe, the air inlet pipe penetrates through the air inlet end sealing piece, and the air outlet end is configured to synchronously reciprocate with the resonant cavity in the reaction pipe. The problem that in the prior art, due to the fact that the reaction concentrations of reactants in a reaction pipe atall deposition points are inconsistent, an optical wand is not uniform in the axial direction can be solved.

Owner:FENGHUO COMM SCI & TECH CO LTD +1

A VAD device and method for preparing optical fiber preform base material

ActiveCN108929031BAcceleration profileImprove axial uniformityGlass making apparatusControl systemLaser detection

The invention relates to a device and method for preparing an optical fiber preform base material by VAD, comprising a reaction chamber for deposition and a rotating lifting boom extending into the inner chamber of the reaction chamber, and the lower part of the inner chamber of the deposition chamber corresponds to the glass target rod to be deposited The core layer blowtorch and the cladding layer blowtorch are arranged at intervals below, and the core layer blowtorch and the cladding layer blowtorch are respectively connected with the core layer raw material control system and the cladding layer raw material control system. The transmitting end and the laser receiving end form a core layer laser detection system, which is characterized in that the core layer material control system is connected with the core layer laser detection system and PLC to form a PID between the core layer blowtorch material flow rate and the laser detection receiving value Closed-loop regulation system forms real-time feedback regulation. The invention has the advantages of simple structure, clear control logic, direct and rapid feedback, stable and reliable deposition performance, stable powder stick profile, uniform core diameter and outer diameter, thereby improving production stability and product quality.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

Polarization maintaining optical fibre with high birefringence and its manufacturing method

InactiveCN1204421CIncrease stressHigh birefringenceFibre mechanical structuresElectromagnetic transmissionPolarization-maintaining optical fiberOptoelectronics

A polarization maintaining fibre with high birefringence is composed of fibre core and cladding layer in which there are the triangular stress element arranged symmetrically at both sides of fibre core and the optional stress holes. Its preparing process includes combining core rod with stress rods by OVD technology, spraying the cladding layer, and drawing. Its advantages are simple preparing process, and high axial uniforming, strength and performance.

Owner:FENGHUO COMM SCI & TECH CO LTD

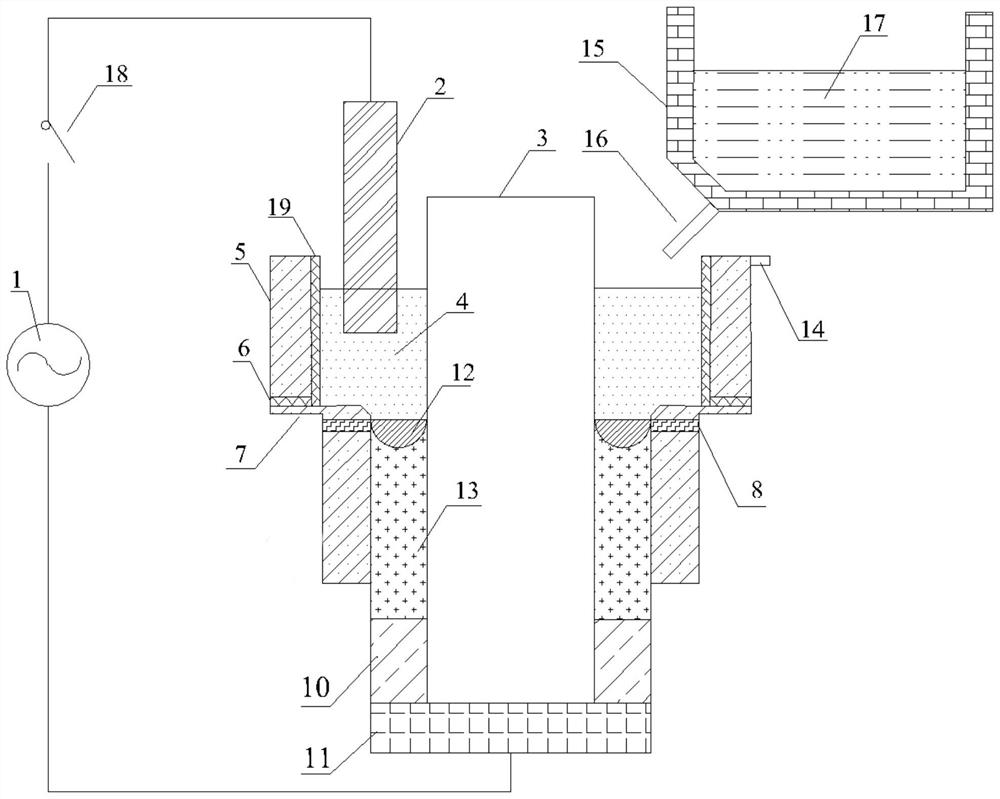

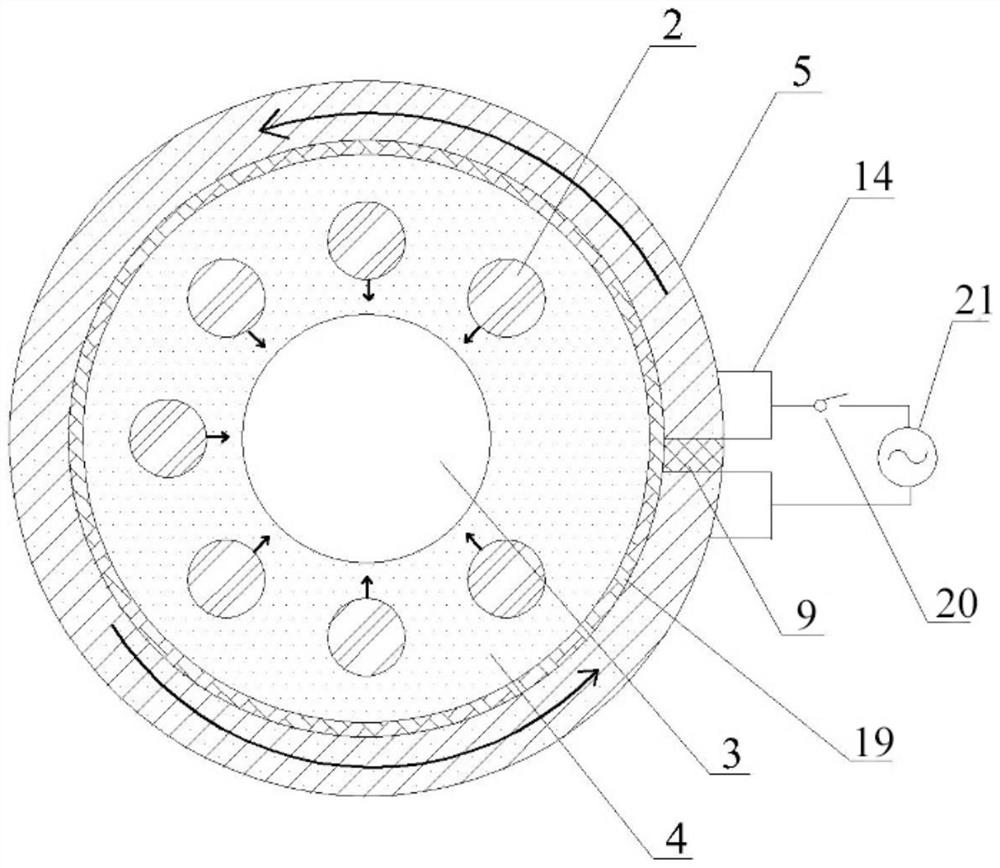

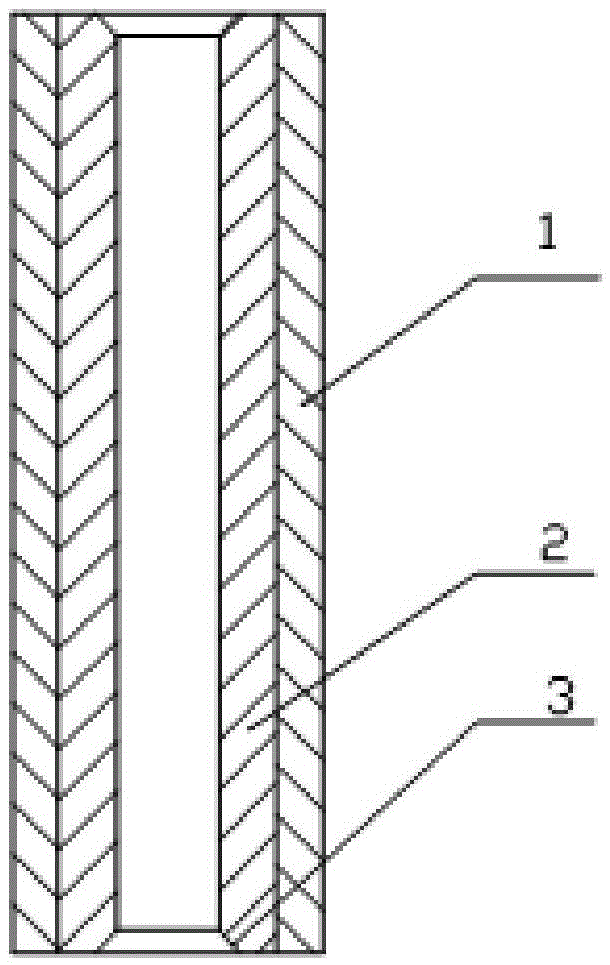

Device and method for preparing composite roller through electroslag remelting method of crystallizer additional magnetic field

PendingCN114653926AImprove axial uniformityImprove circumferential uniformityElectrically conductiveEngineering

The invention discloses a device and a method for preparing a composite roller by an electroslag remelting method of a crystallizer additional magnetic field. The device comprises a remelting power supply, a crystallizer power supply, a dummy ingot plate, an upper crystallizer and a lower crystallizer, a notch is formed in the upper crystallizer and is filled with an insulating block; two conductive interfaces are assembled on the upper portion of the outer wall of the upper crystallizer, located on the two sides of the insulating block and connected with the two electrodes of a crystallizer power source respectively. The method comprises the following steps: (1) placing the mandrel in an electroslag furnace crystallizer; (2) arranging a coating layer; (3) putting the ladle molten pool into an electroslag furnace crystallizer to form a liquid slag pool; (4) descending the consumable electrode to a liquid slag pool; the remelting switch is switched on; (5) connecting two conductive interfaces with two electrodes of a crystallizer power supply; and (6) starting an ingot pulling system. A conductive loop in the crystallizer is additionally arranged in the composite system, and the temperature field of a slag bath, especially the temperature field near a slag-metal interface, is reasonably optimized by adding an axial extra magnetic field in a remelting composite area.

Owner:NORTHEASTERN UNIV

A kind of preparation method of thorium dioxide pellet

ActiveCN104446478BHigh densityOvercome the difficulty of low green densityManufacturing technologyThorium oxide

The invention belongs to the technical field of manufacturing of nuclear fuel elements, and specifically relates to a method for preparing thorium dioxide pellets. The method comprises a powder granulating process: pressing thorium dioxide powder prepared by adopting an oxalate precipitation method and serving as an original raw material into sheets by adopting a compression molding method, crushing in a granulator, screening by a granulator screen, and shaking in a top-knocked sieve shaker to obtain granules for forming the thorium dioxide pellets; a powder molding process: performing die pressing on the granules to obtain a green blank of the pellets; and a pellet sintering process: putting the green blank of the thorium dioxide pellets into a vacuum atmosphere sintering furnace, vacuumizing, washing the furnace, then introducing argon and sintering. The cobalt pellets are prepared by adopting a powder metallurgy process, so that the difficulty of low density of the green blank of the thorium dioxide powder is overcome; and the pellets prepared by the granulating, molding and sintering processes have high density and grain size meeting the index requirements of preparation of fuel elements.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

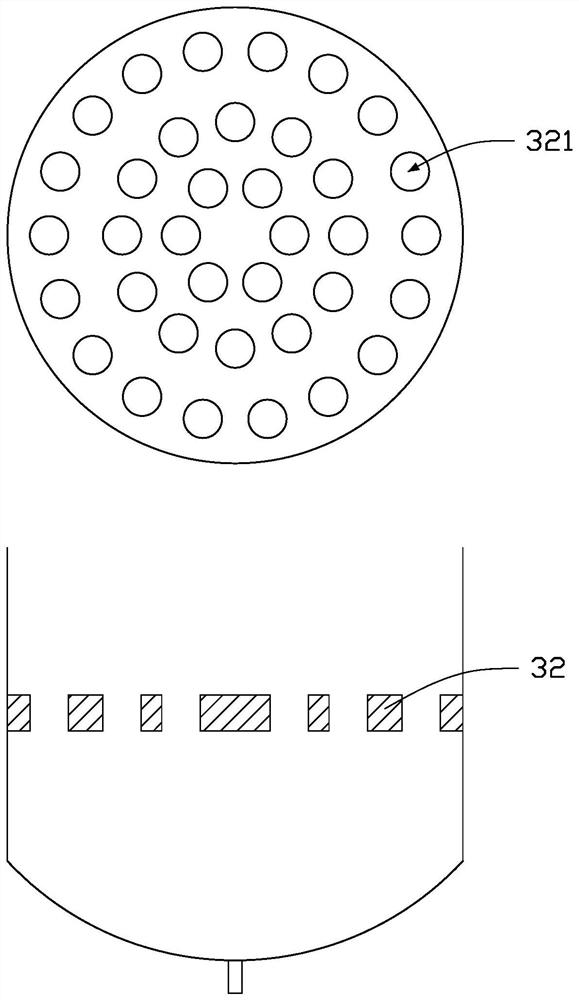

Sintering equipment and sintering method

PendingCN113716858AImprove axial uniformitySintering method is simpleGlass making apparatusHeating systemRaw material

The invention provides sintering equipment and a sintering method, and is used for sintering a preform rod by heating raw material gas, the sintering equipment comprises a furnace tube and a heating system, the heating system is arranged on the periphery of the furnace tube and used for heating the raw material gas and sintering the preform rod, and the sintering equipment further comprises an adjusting mechanism, the adjusting mechanism comprises a heat insulation buffer plate and a rectifying plate, the rectifying plate is arranged at one end of the furnace tube and used for buffering and dispersing raw material gas entering the furnace tube, and the heat insulation buffer plate is arranged at the other end of the furnace tube and used for reducing the speed of discharging the raw material gas out of the furnace tube so as to control the pressure in the furnace tube. According to the sintering equipment, by arranging the heat insulation buffer plate and the rectifying plate, the gas temperature and the convection state in the furnace tube are adjusted, stable control over pressure fluctuation in the furnace tube is fundamentally achieved, and the rod radial and axial uniformity of the preform rod is effectively improved.

Owner:ZHONGTIAN TECH ADVANCED MATERIALS CO LTD

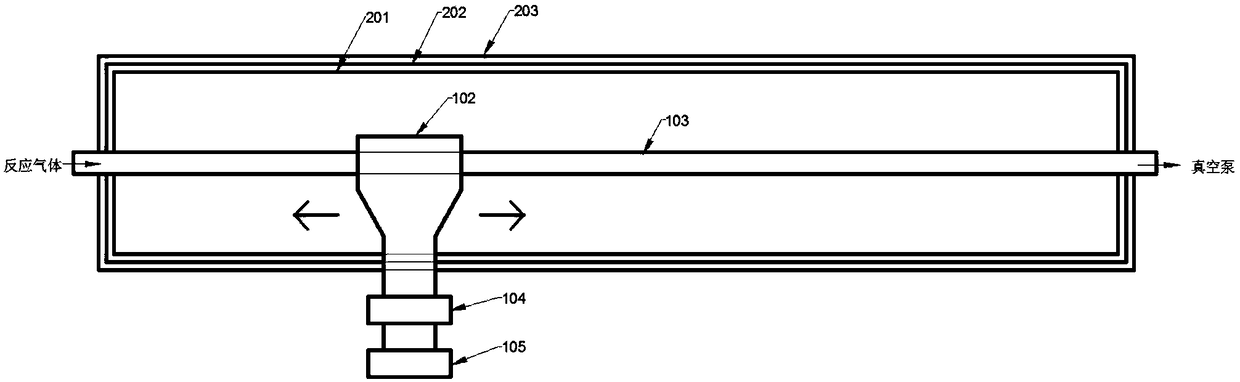

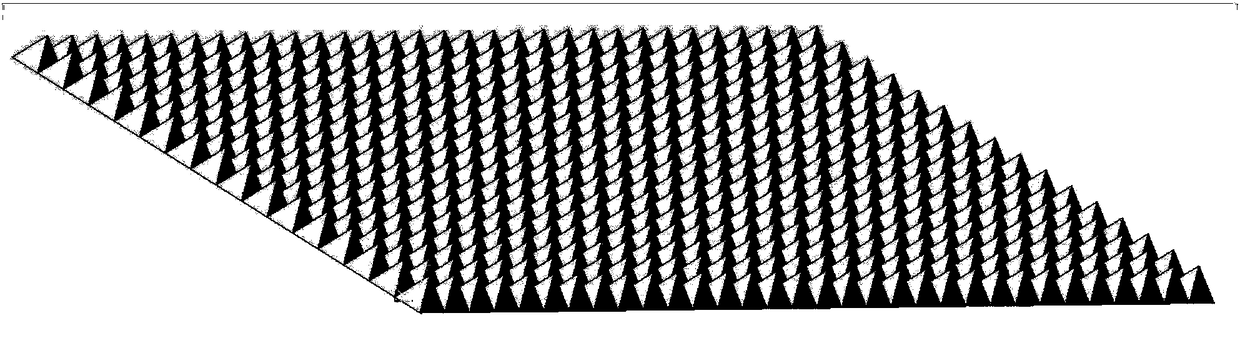

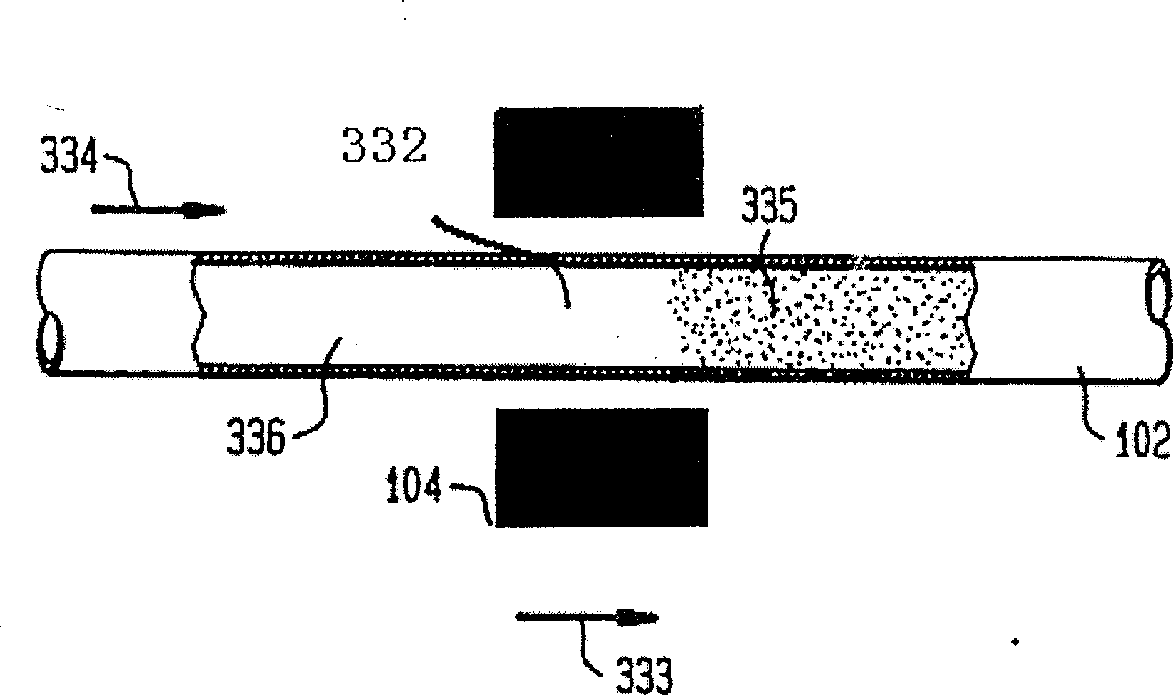

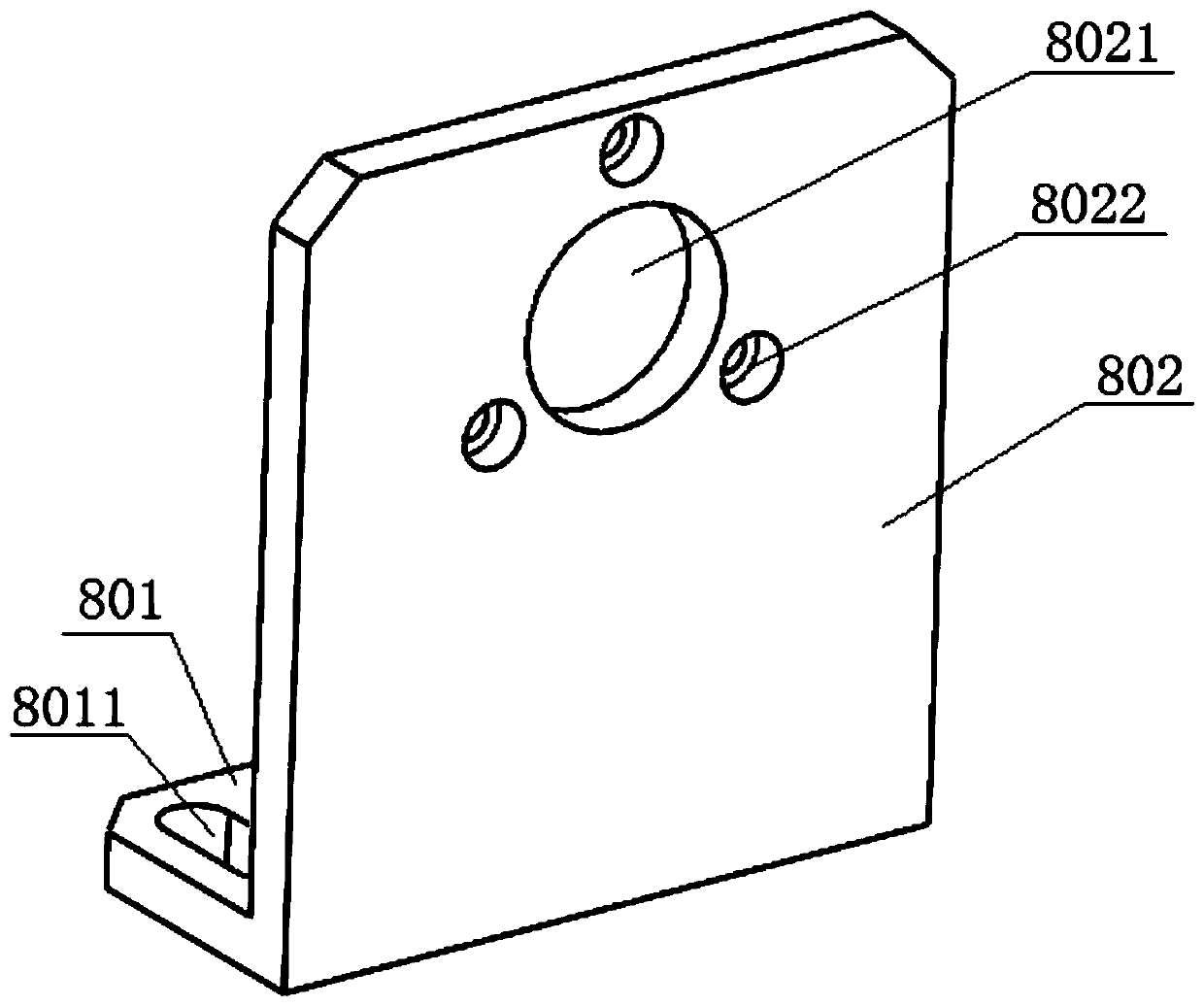

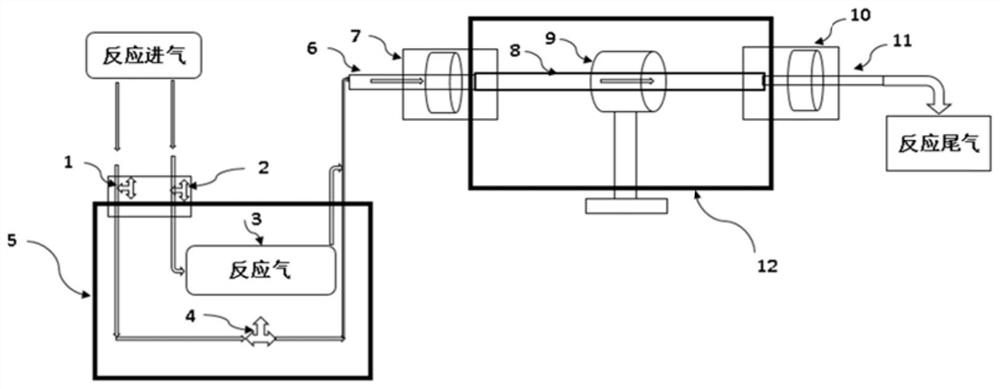

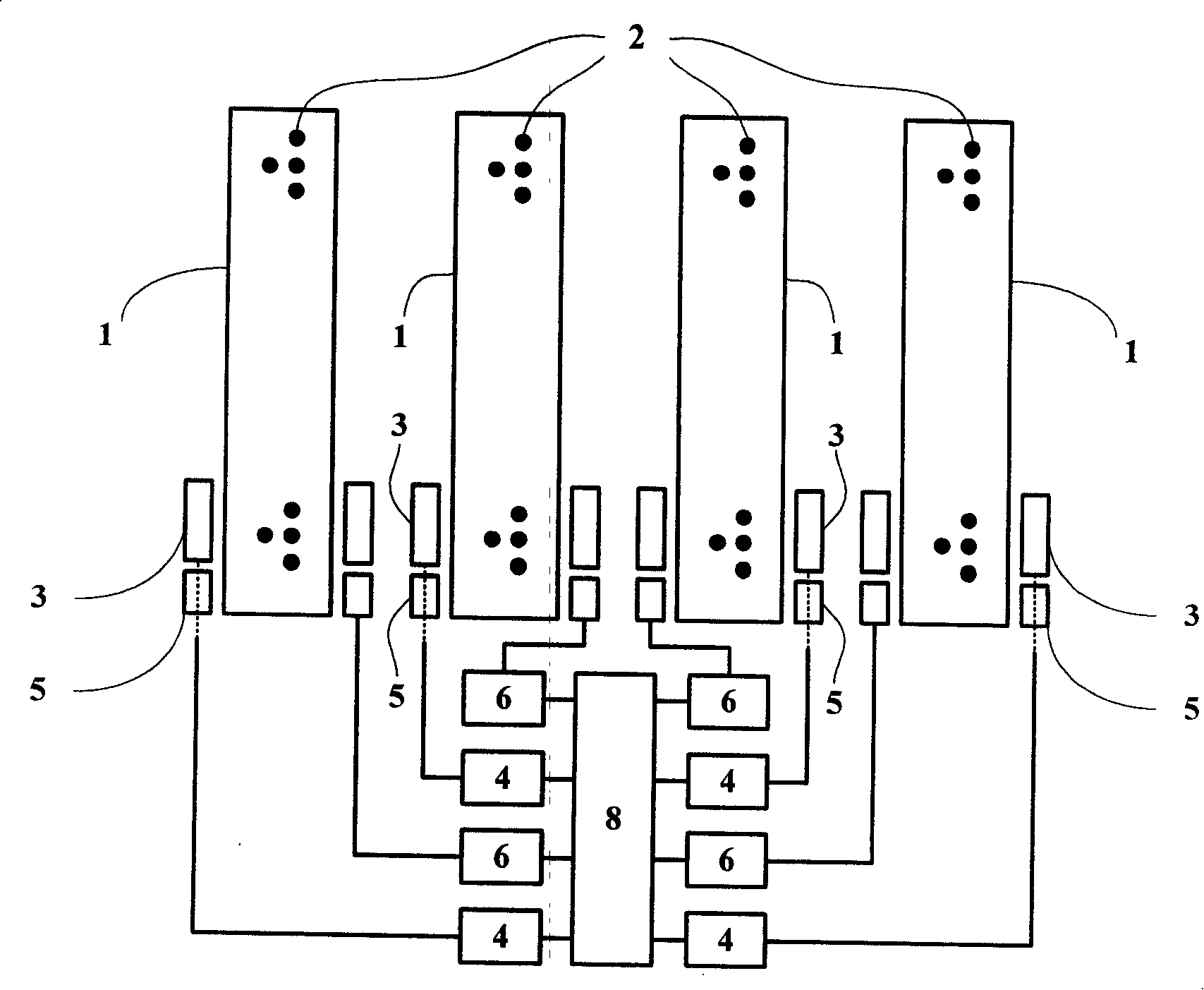

PCVD (plasma chemical vapor deposition) device

InactiveCN108298810AReduce standing wave intensityImprove axial uniformityGlass making apparatusStanding waveResonant cavity

The invention relates to a PCVD (plasma chemical vapor deposition) device, which comprises a long tubular heating furnace and a resonant cavity arranged in a furnace cavity of the heating furnace, wherein the resonant cavity extends out of the heating furnace through wave guide and is connected with an axial reciprocating device and a microwave source; the long tubular heating furnace comprises acasing; a heat insulation layer is arranged on the inner wall of the casing; a heating element is arranged in a furnace cavity of the heating furnace in the circumferential direction. The PCVD deviceis characterized in that a wave absorption layer is laid between the heating furnace casing and the heat insulation layer; the wave absorption layer is formed by convex blocks with the same shape through uniform arrangement. The microwaves leaked into the furnace cavity of the heating furnace can be absorbed after the multi-time reflection and refraction; the goals of reducing the intensity of standing waves in the heating furnace is achieved, so that the axial uniformity of the deposition is improved; the parameter of a core rod of an optical fiber prefabricated rod is improved. The influenceof the standing waves in the furnace on the optical fiber parameter is reduced, so that the microwave intensity leaked into a workshop can be correspondingly reduced; the harm to the bodies of operation personnel in the workshop is reduced. The axial uniformity of the core rod is improved, so that the length of the qualified core rod is increased; the optical fiber manufacturing cost is reduced.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

Improved chemical vapor-phase deposition method by uisng graphite heating furnace as hot source

InactiveCN1354277AEliminate huge security risksEliminate potential safety hazardsChemical vapor deposition coatingFiberHydrogen

The present invention is characterized by that it uses graphitc heating furnace us heaitng source and adopts improved chemical vapor deposition process to prepare optical fiber preform. Said invented produce incldues the following steps: A. using raw materials to produce deposition reaction to obtain deposit lining tube; and B. melt-condensing the deposit lining tube into solid core rod. Said invention can improve performance of otpical fiber preform, and improve performance of optical fiber, and can raise deposition rate and can save cost of equipment and operation. The invention avoids hidden safe trouble since hydrogen used in traditional technique.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

A method for growing single crystal silicon with variable pot ratio

ActiveCN103305905BEasy to operateStrong production compatibilityPolycrystalline material growthBy pulling from meltCrucibleSingle crystal

Owner:ZHEJIANG COWIN ELECTRONICS

A device packed with radial wall flow structured catalyst

InactiveCN104289159BSimple structureReduce manufacturing difficultyChemical/physical processesEngineeringThermal expansion

The invention discloses a device loaded with a structured catalyst with radial wall flow. According to the invention, a plurality of structural units are loaded in a reaction tube. Each structural unit comprises a reactant stream wall flow guide panel, a structured carrier loaded with a catalyst, and an expansion ring with a thermal expansion and contraction effect. The reactant stream wall flow guide panel is arranged at the top end of the structured carrier loaded with the catalyst. The bottom end of the structured carrier loaded with the catalyst is embedded in the expansion ring with thermal expansion and contraction effect. The reactant stream wall flow guide panel is a solid cylindrical body coaxial with the structured carrier loaded with the catalyst. The expansion ring with thermal expansion and contraction effect is a hollow cylindrical body coaxial with the structured carrier loaded with the catalyst. The cross-sections of two hollow parts are overlapped. The device provided by the invention has the advantages of simple structure, low pressure drop, and uniform fluid distribution. With the device, advantages of the structured catalyst in the aspects of heat transfer and mass transfer can be fully performed. Material stream radial wall flow can be realized. The device can be used in industrialized production for producing propylene from methanol.

Owner:ZHEJIANG UNIV

Electrode rotating speed control-based constant-smelting pool shaped electroslag remelting method

ActiveCN113249585AImprove melting efficiencyEnhanced convective heat transferSlagElectro-slag remelting

According to an electrode rotating speed control-based constant-smelting pool shaped electroslag remelting method, a consumable electrode is rotated in an electroslag remelting process, a rotating speed of the consumable electrode is dynamically adjusted, and under the action of a centrifugal force applied by rotation of the electrode, molten metal is not gathered centripetally any more but is separated from an outer side of an end part of the electrode earlier, convective heat exchange between a slag bath and a solid electrode is enhanced through electrode stirring and molten drop dispersion and dripping, the electrode melting efficiency is remarkably improved, and compared with a method adopting a fixed electrode, the melting speed or the production efficiency of the method can be improved by 25% at most. By the rotating effect of the electrode, the slag bath and the metal smelting pool can get a more uniform temperature; meanwhile, convective heat exchange from the slag bath to a crystallizer is enhanced, so that the temperature of the slag bath is lowered, a metal smelting pool which is more shallow and flatter is easily formed, macroscopic defects such as segregation and looseness in a electroslag steel ingot are restrained, and the solidification quality of the electroslag steel ingot is improved.

Owner:NORTHEASTERN UNIV

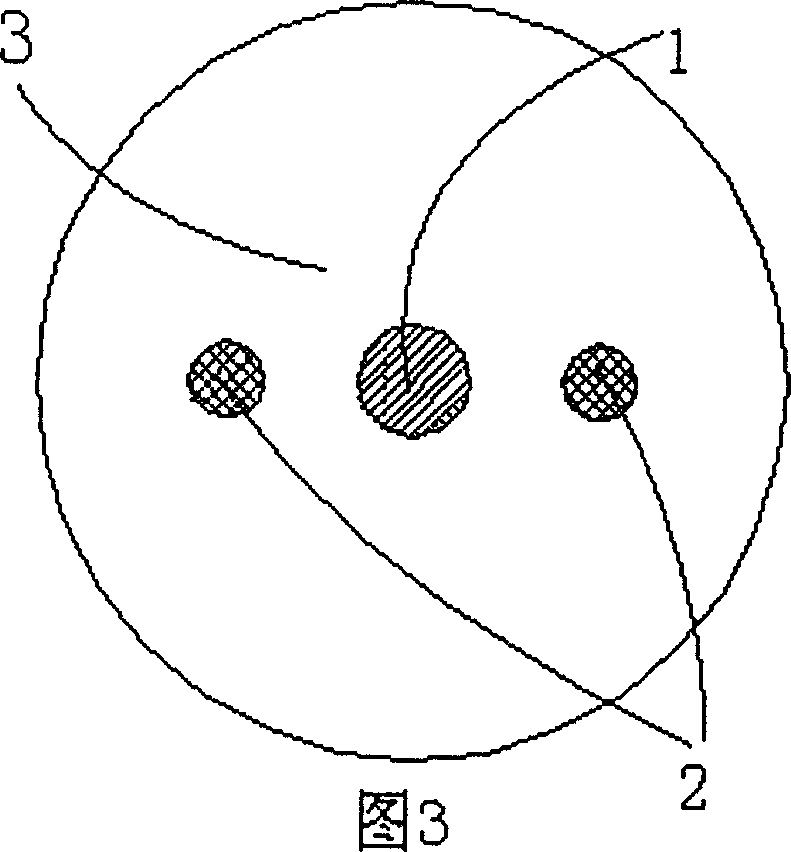

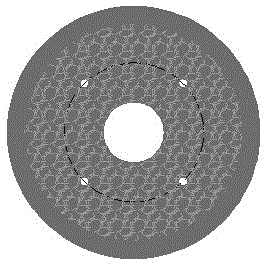

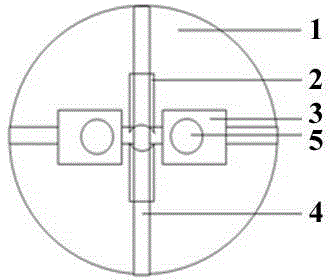

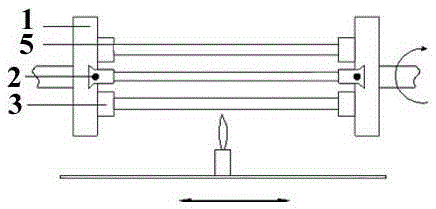

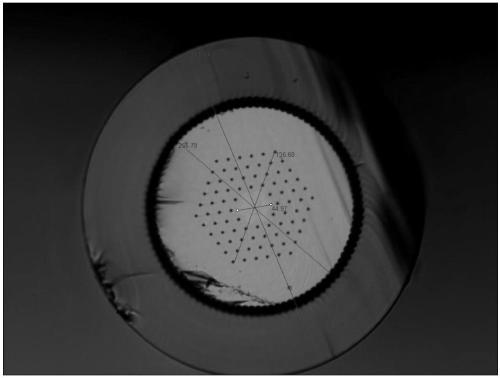

A kind of manufacturing device and manufacturing method of polarization maintaining optical fiber preform rod

ActiveCN103708721BMeet preparationIncrease productivityGlass making apparatusPolarization-maintaining optical fiberEngineering

The invention relates to a manufacturing device and a manufacturing method for a polarization maintaining optical fiber preform. The device comprises a disk with scaled calibration, four claws forming a cross shape and screws in one-to-one correspondence and meshing connection with the claws; and the rotating screw can control relative movement of the four claws. Two claws in the horizontal direction are respectively provided with a groove with adjustable diameter.

Owner:JIANGSU HENGTONG PHOTOELECTRIC +1

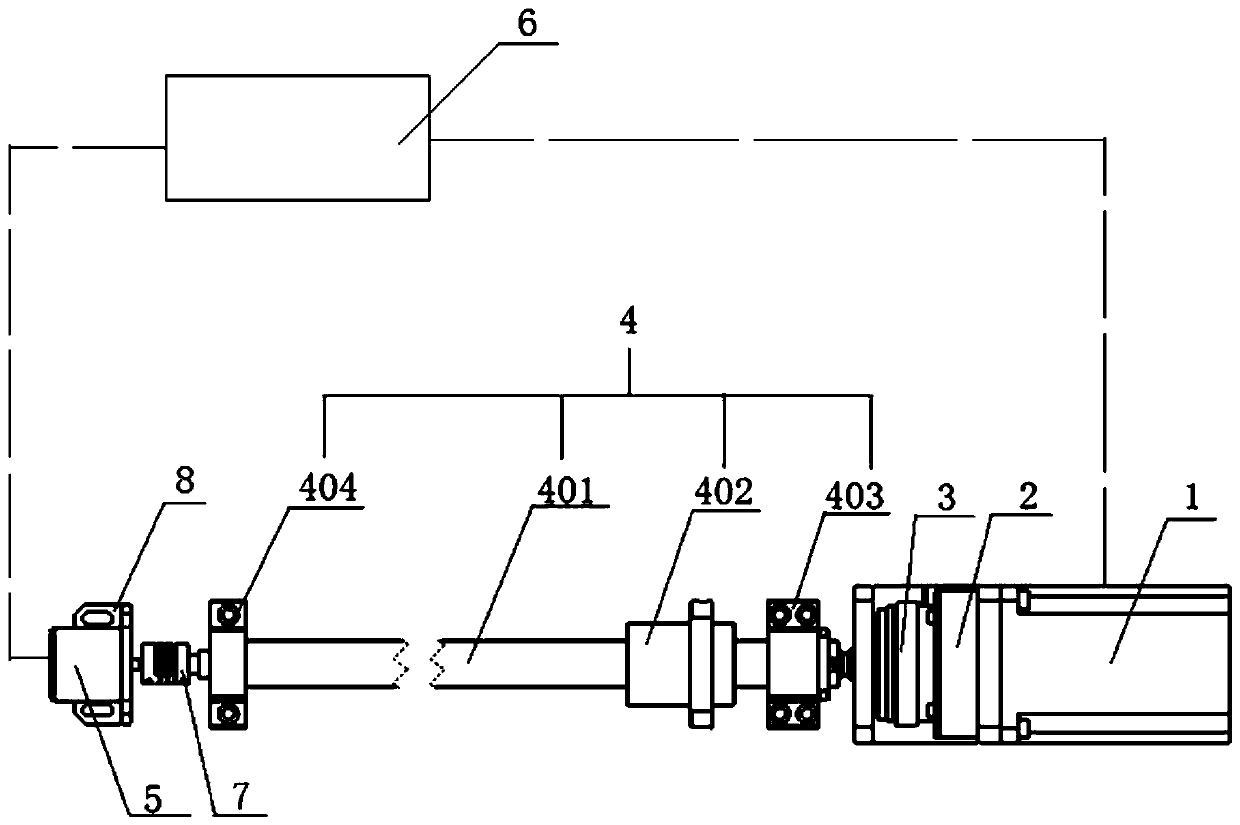

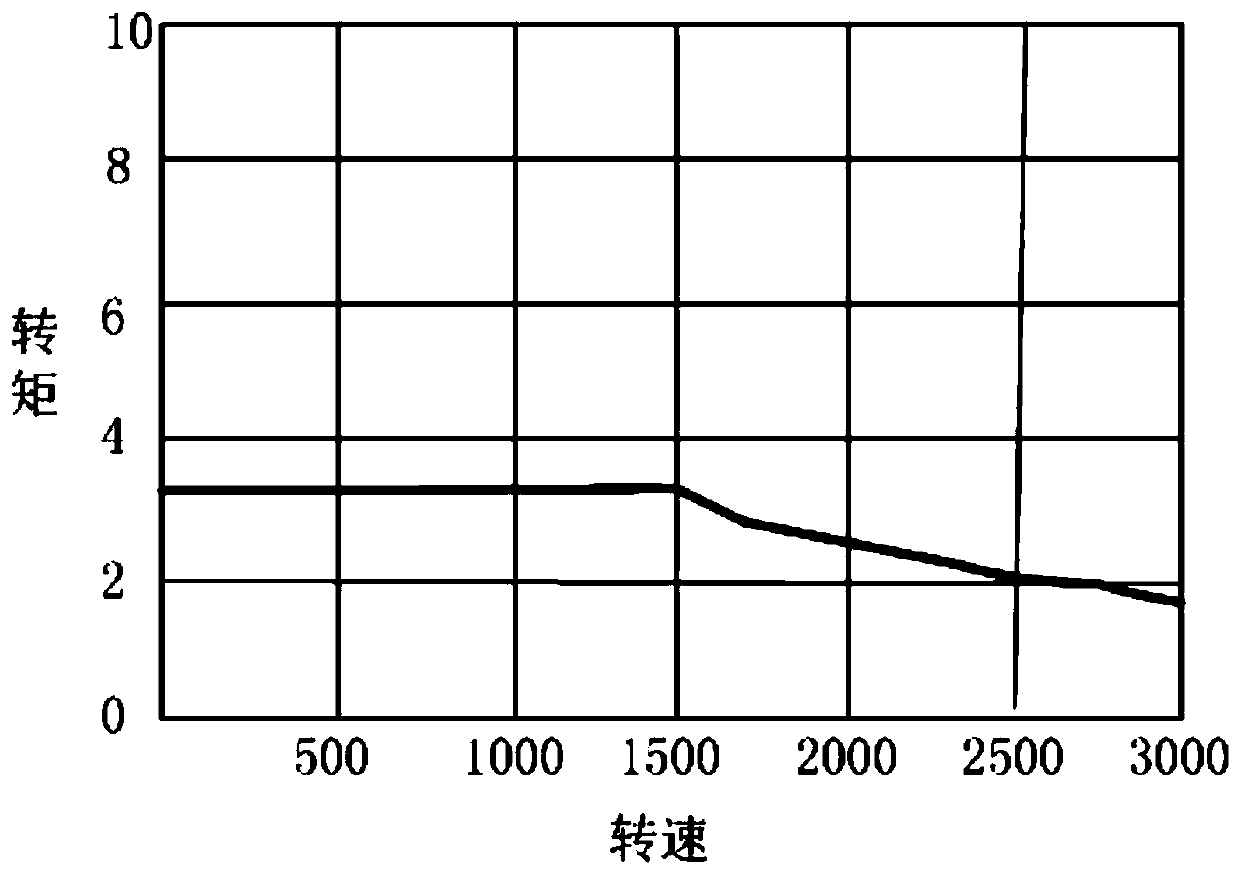

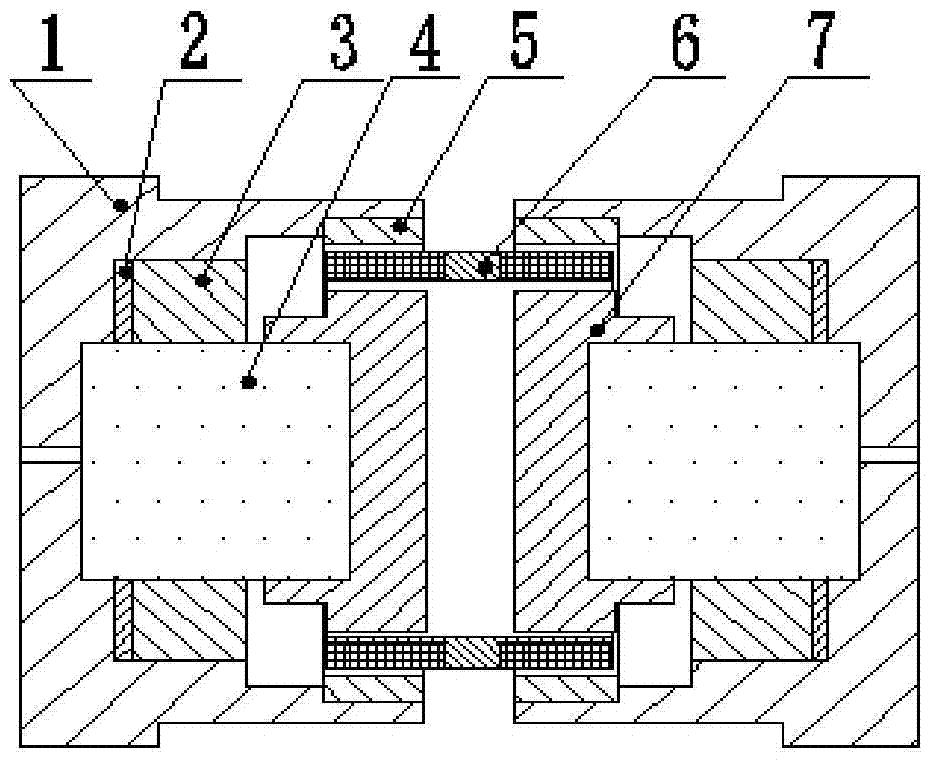

A linear drive

ActiveCN107769452BLow costAvoid damage to healthGearingStructural associationLinear motionBall screw

The invention discloses a linear transmission device, and belongs to the field of medical imaging. The device comprises a motor, a speed reduction device, a clutch and a transmission assembly which are coaxially connected, wherein the transmission assembly comprises a ball screw connected with the clutch and a ball nut, the ball nut is adaptive to the ball screw, the ratio between the lead of theball screw and the diameter of the ball screw is 1.0-2.0, the ball nut can be driven to do linear motion by the ball screw, and when the clutch is powered off, the ball nut can be manually pulled anda scanning bed arranged on the ball nut and loaded with a patient can be driven. With the linear transmission device provided by the invention, low-speed linear motion can be achieved, an end effect of a linear motor having the same function can be effectively prevented on the premise that the scanning bed loaded with the patient can be pulled out of a scanning region, the scanning bed can be enabled to be in a uniform low-speed motion state within the whole scanning range, and the axial uniformity of a scanning image is improved.

Owner:JIANGSU SINOGRAM MEDICAL TECH CO LTD

A high-stability force generator with compensation

Owner:BEIJING PULIMEN ELECTRO MECHANICAL HIGH TECHN CO

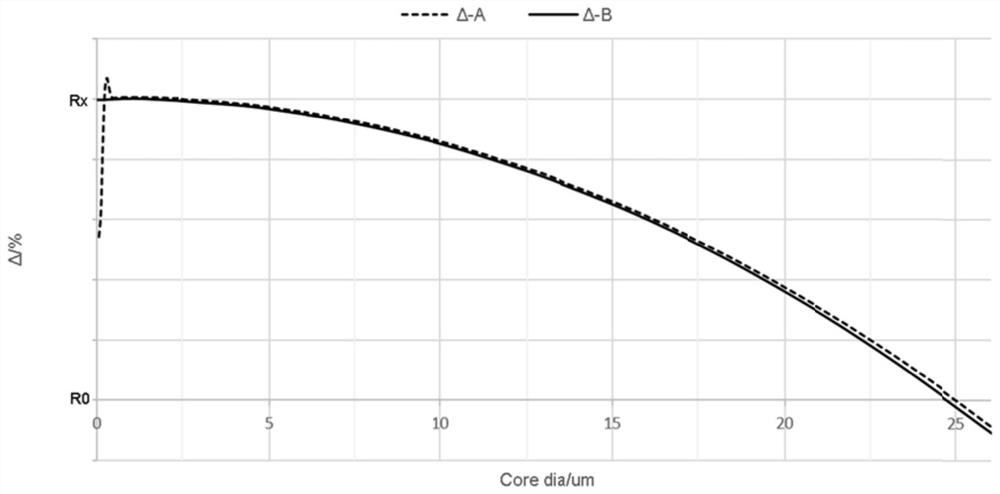

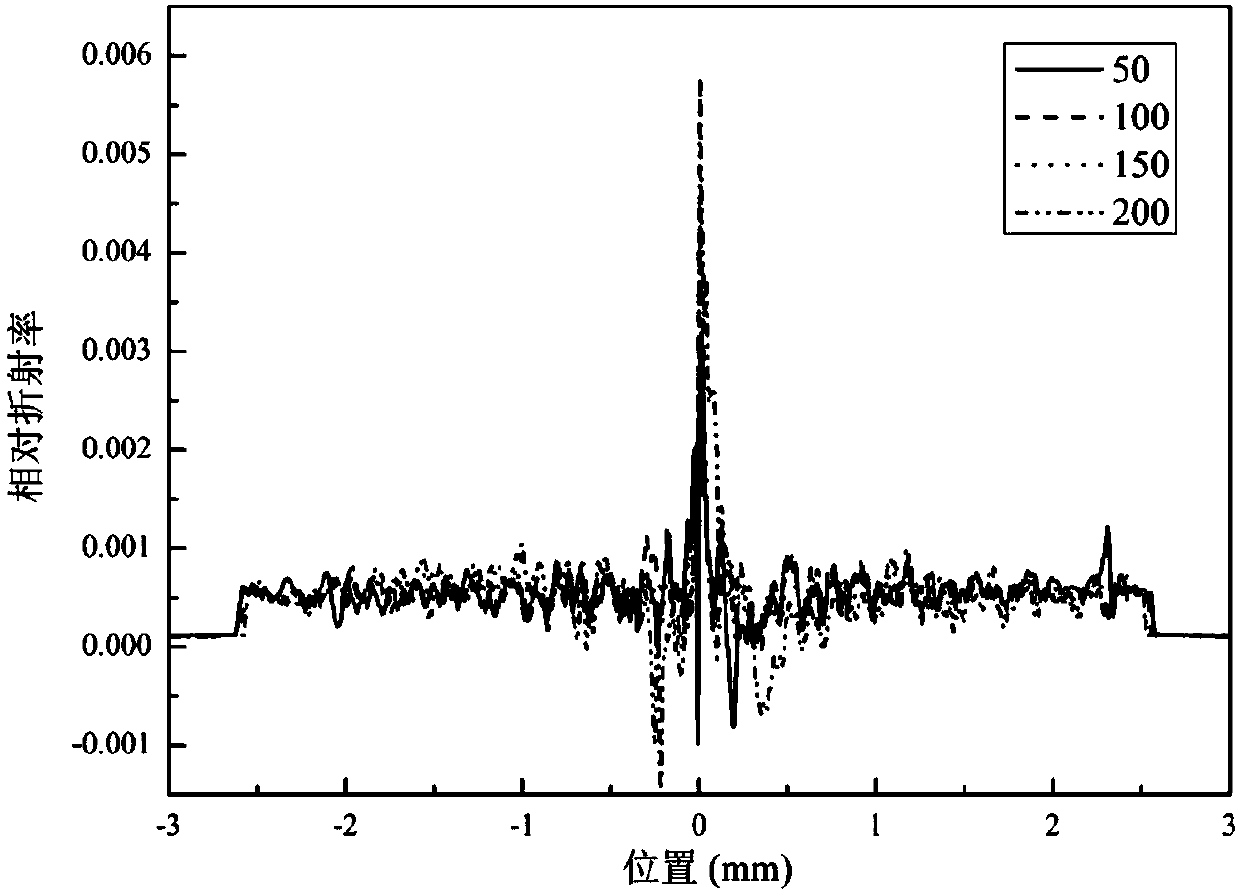

A kind of optical fiber preform, multimode optical fiber and preparation method thereof

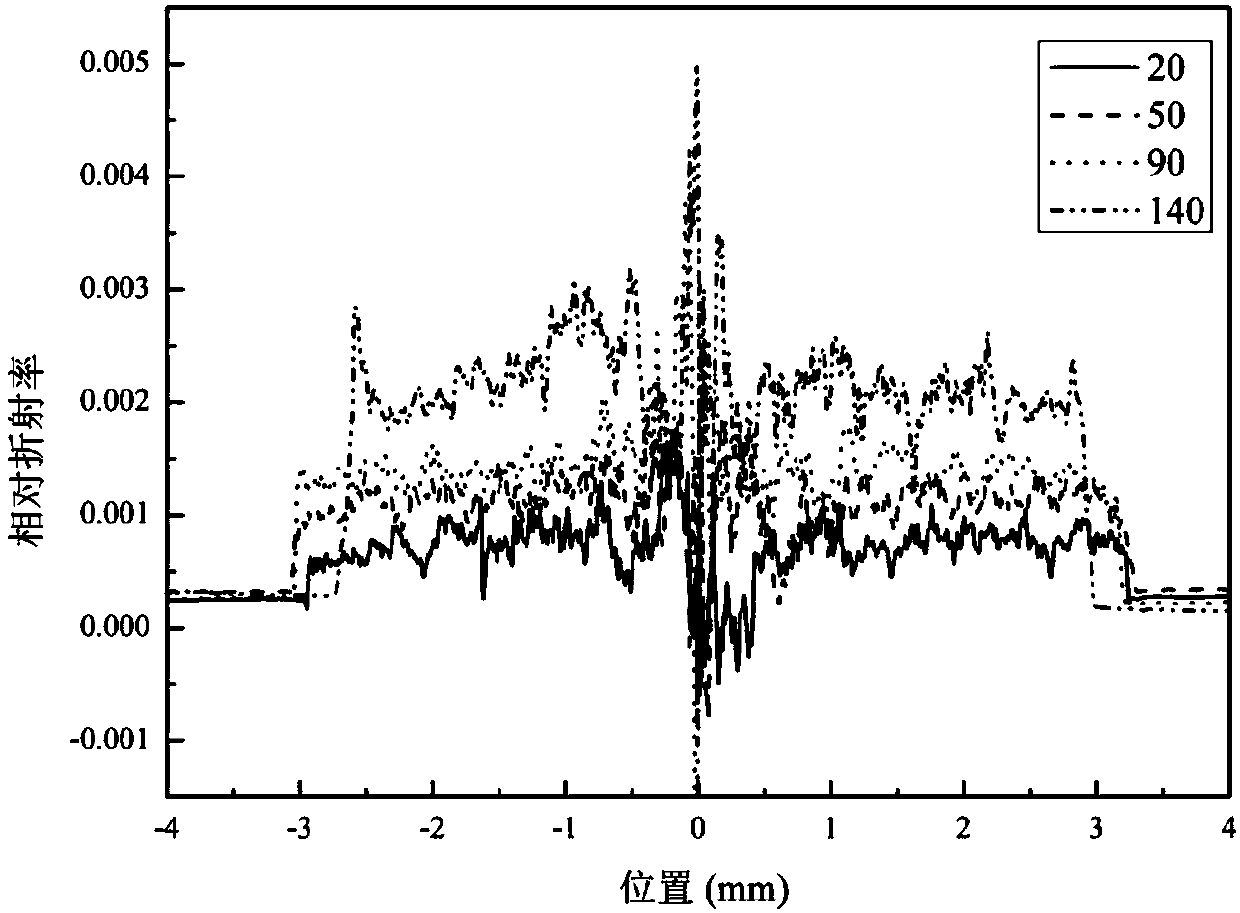

ActiveCN111676468BImprove stabilityImprove axial uniformityGlass making apparatusChemical vapor deposition coatingFiberRefractive index

The invention discloses an optical fiber prefabricated part, a multimode optical fiber and a preparation method thereof, which belong to the technical field of optical fiber manufacturing. The openings of the flow controllers of each channel are such that the reactant flows through the segmental control of the flow controllers of each channel and then enters the subsequent deposition process to participate in the deposition reaction to obtain an optical fiber preform. By adding the reactant gas path to control the segmental control of the multi-flow controller with different openings of reactants in the initial stage and the middle stage of deposition to the core layer, it ensures that the core rod is deposited to the edge of the core layer in the initial stage of doping. The stability of the agent flow control improves the control accuracy of the refractive index at the initial stage of the core layer. Due to the increased control stability of the low opening flow rate, it is beneficial to the stability of the reactant during deposition to the core layer, avoiding the disturbance of the unstable reactant gas flow to the core layer deposition stage, and improving the axial uniformity of the mandrel.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

Method for improving the uniformity of rare earth doped quartz glass rod

PendingCN109956664AImprove axial uniformityImprove laser efficiency and beam qualityGlass making apparatusGlass fibre productsLaser fiberWavelength

The invention relates to a method for improving the uniformity of a rare earth doped quartz glass rod. A large-size rare earth doped glass rod is prepared by a powder sintering technology, wherein theglass rod is stretched into a fine rod with a diameter of 0.5-2mm by a high-temperature drawing furnace, the fine rods are stacked together and stretched to a rod with a diameter of 0.5-2mm again, the process is repeated for 2-5 times, and the core rod required for optical fiber preform is finally drawn. The principle of this method is by stretching-stacking-stretching way, the non-uniformity inthe axial direction of the large-size glass rod is transformed into the non-uniformity in the radial direction. By repeated stretching, the non-uniformity in the radial direction is reduced below thewavelength scale, and the generation and transmission of the fiber laser are not affected. By improving the uniformity of the core rod, the efficiency and beam quality of the fiber laser can be improved effectively.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

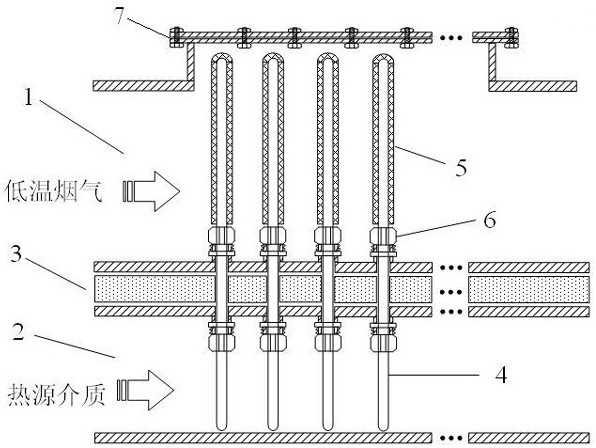

Heat pipe type SCR denitration reactor and low-temperature sulfur-containing flue gas denitration method thereof

PendingCN114082299AImprove axial uniformityDelayed low temperature inactivationGas treatmentDispersed particle separationThermodynamicsPtru catalyst

The invention relates to a heat pipe type SCR denitration reactor and a low-temperature sulfur-containing flue gas denitration method thereof. A flue and a heat source medium channel which are horizontally arranged up and down are arranged in a reactor body, a heat insulation layer is arranged between the flue and the heat source medium channel, a heat pipe array is vertically arranged in the reactor body, the middle portions of heat pipes penetrate through the heat insulation layer, a condensation section and an evaporation section of the heat pipe are located in the flue and the heat source medium channel respectively, and a denitration catalyst layer of a porous structure is arranged outside the condensation section of the heat pipe. During operation, the temperature of a heat source medium needs to be higher than the temperature of flue gas, the requirement for the working temperature of the catalyst is met, the catalyst in the flue is maintained in a high-activity and high-sulfur-resistance temperature window by means of the characteristics of fast heat transfer and good axial temperature uniformity of the heat pipe, stable low-temperature flue gas denitration can be achieved even if a traditional medium-temperature SCR catalyst is adopted, high energy consumption of a conventional process for overall reheating of low-temperature flue gas is avoided, and in-situ continuous regeneration of the catalyst can be achieved by increasing the operation temperature of a heat source medium channel after the catalyst is inactivated at low temperature.

Owner:NANJING UNIV OF TECH

A constant molten pool shape electroslag remelting method based on electrode speed control

In the electroslag remelting method based on the electrode rotation speed control, the electroslag remelting method with constant molten pool shape rotates the consumable electrode during the electroslag remelting process, and dynamically adjusts its rotation speed. The molten metal no longer converges centripetally but detaches from the outside of the electrode end earlier. The stirring of the electrode and the dispersion and dripping of molten droplets strengthen the convective heat transfer between the slag pool and the solid electrode, which significantly improves the melting efficiency of the electrode. Fixed electrode method, which can increase melting rate or production efficiency by up to 25%. The rotation of the electrode makes the temperature of the slag pool and the metal molten pool more uniform, and at the same time strengthens the convective heat transfer from the slag pool to the crystallizer, reduces the temperature of the slag pool, and is easy to form a shallower metal molten pool, which is beneficial to suppress electroslag Macroscopic defects such as segregation and porosity in steel ingots can improve the solidification quality of electroslag steel ingots.

Owner:NORTHEASTERN UNIV LIAONING

Self-reconstruction plasma antenna

InactiveCN100388559CSuppress interferenceEliminate radar scatter problemsAntenna supports/mountingsElectrical conductorPlasma antenna

Owner:SHANGHAI JIAOTONG UNIV

A doping gas path for doping single crystal with zone melting gas

ActiveCN104328484BImprove the mixing effectImprove axial uniformityPolycrystalline material growthBy zone-melting liquidsZone meltingSingle crystal

The invention provides a novel doping gas path for a zone-melting gas-doped single crystal. The pipeline structure of the doping gas path is shaped like a Greek letter Pi, the middle part of the Pi-shaped doping gas path is an L-shaped section pipeline with an enough length, one end of the L-shaped section pipeline is communicated with a protective gas inlet and a doping gas inlet, the other end of the L-shaped section pipeline is communicated with a gas outlet and a gas exhaust outlet, the gas outlet enters a hearth, a flow meter is arranged at each of the protective gas inlet, the doping gas inlet and the gas outlet, and a pressure valve is arranged at the gas exhaust outlet. By the novel doping gas path provided by the invention, the doping gas can be fully and uniformly mixed with the protective gas in a limited space inside a zone-melting furnace before entering the furnace and thus the uniformity of the gas-doped single crystal is improved and the doping efficiency is increased.

Owner:ZHONGHUAN ADVANCED SEMICON MATERIALS CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com