Device and method for preparing optical fiber prefabricated bar base material by VAD

A technology of optical fiber preform and base material, which is applied in the field of optical fiber manufacturing, can solve the problems of increasing product failure rate, product instability, temperature measurement and actual value deviation, etc., to improve production stability, product quality, and stable deposition performance Reliable, uniform core and outer diameter results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further specifically described below in conjunction with the embodiments and the accompanying drawings.

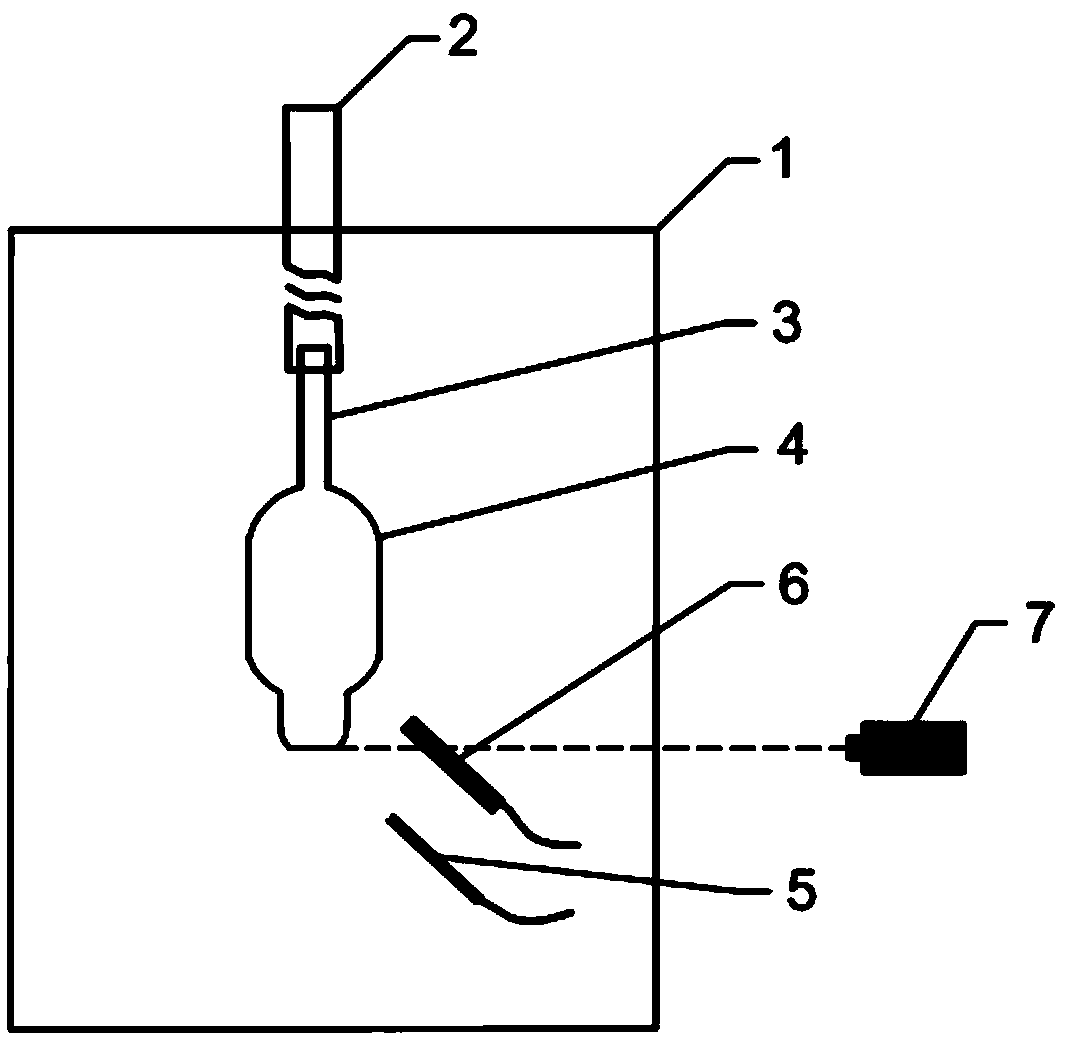

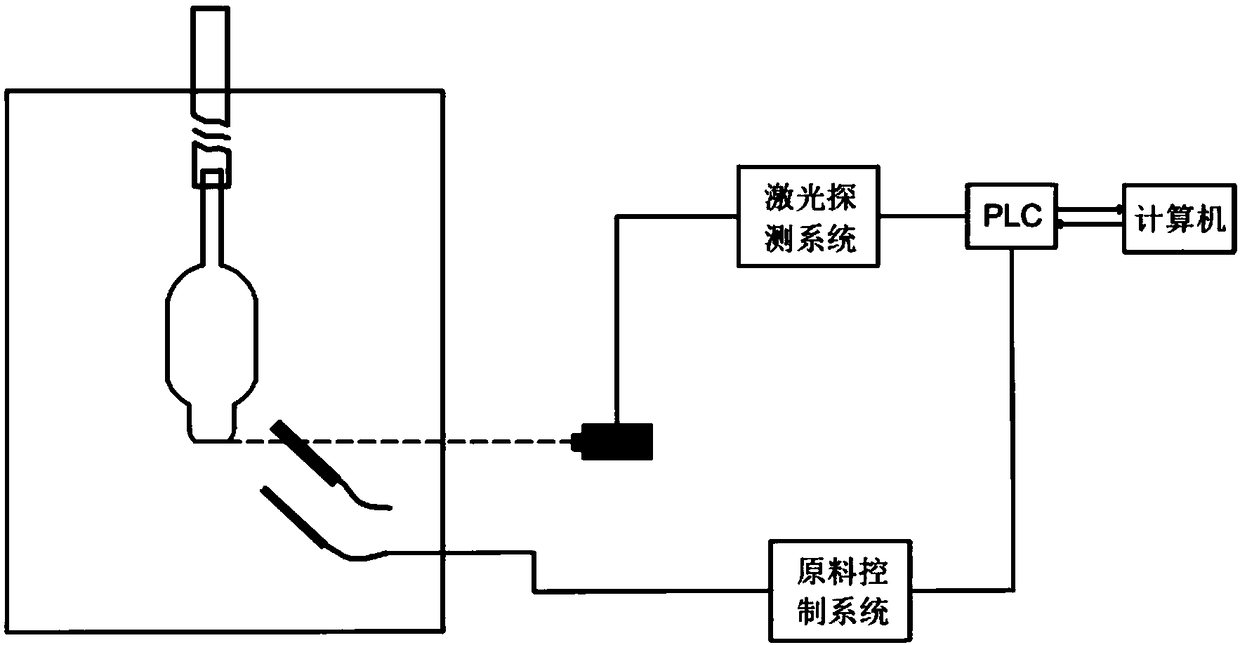

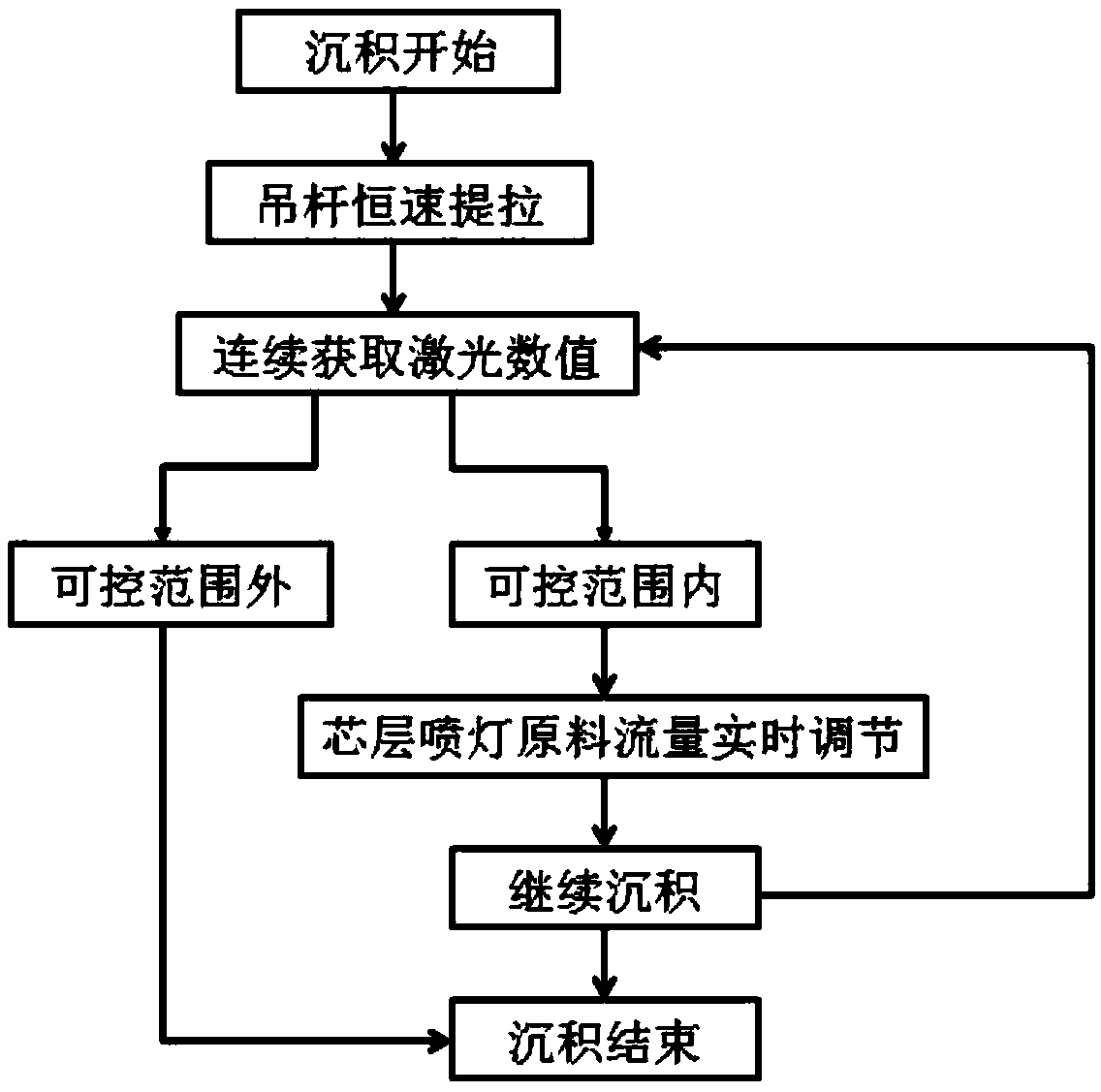

[0025] It includes a reaction chamber 1 for deposition and a rotating lifting boom 2 extending into the inner cavity of the reaction chamber. The upper end of the rotating lifting boom is connected with the vertical lifting mechanism and the rotating chuck, and the lower end of the rotating lifting boom is used to clamp the The glass target rod 3 of the deposition chamber, the core layer blowtorch and the cladding layer blowtorch are arranged at intervals under the corresponding glass target rod to be deposited under the inner cavity of the deposition chamber, the core layer blowtorch 5 and the cladding layer blowtorch 6 are respectively connected with the core layer raw material control system and the cladding layer raw material control system The system is connected, and under the target rod is a powder rod 4 formed by spraying and gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com