A doping gas path for doping single crystal with zone melting gas

A doping gas and gas doping technology, which is applied in the field of doping gas circuit, can solve the influence of doping process that is not involved in the doping gas circuit, the uniformity and repeatability of the gas-doped single crystal are not ideal, and the gas-doped single crystal silicon axis is not involved. problems such as poor orientation uniformity, to achieve the effect of improving mixing effect, improving repeatability and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

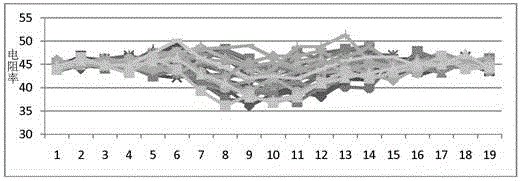

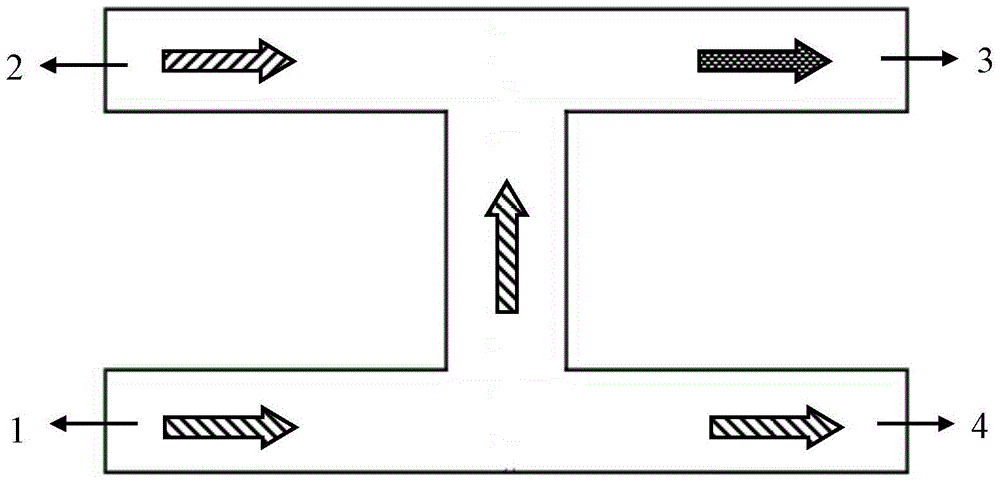

[0024] use as figure 2 The doping gas path shown in the drawing is to pull a 4-inch gas-doped single crystal to produce a gas-doped single crystal with a target resistivity of 30-45Ω·cm. During the normal production process, the flow rate of Ar gas is controlled at 2L / min; the flow rate of dopant gas (phosphine) is 260ml / min; The control pressure of the exhaust port is 3bar. By monitoring the pressure of the gas path, the pressure of the gas entering the furnace is guaranteed.

Embodiment 2

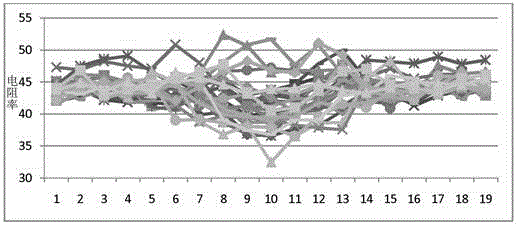

[0028] use as figure 2 The doping gas path shown in the drawing is to pull a 4-inch gas-doped single crystal to produce a gas-doped single crystal with a target resistivity of 2000±30% Ω·cm. During normal production, the flow rate of Ar gas is controlled at 2.5L / min; the flow rate of dopant gas (phosphine) is 20ml / min; the flow rate of mixed gas into the furnace is 100ml / min; excess gas is discharged from the gas path through the exhaust port , The exhaust port control pressure is 3bar. By monitoring the pressure of the gas path, the pressure of the gas entering the furnace is guaranteed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com