Device and method for preparing composite roller through electroslag remelting method of crystallizer additional magnetic field

A technology of electroslag remelting and composite rolls, which is applied in the field of metallurgical equipment, can solve problems such as excessive melting of the mandrel surface, reduction of roll quality and service life, dilution of cladding layer components, etc., to improve circumferential uniformity and shaft Good uniformity and surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

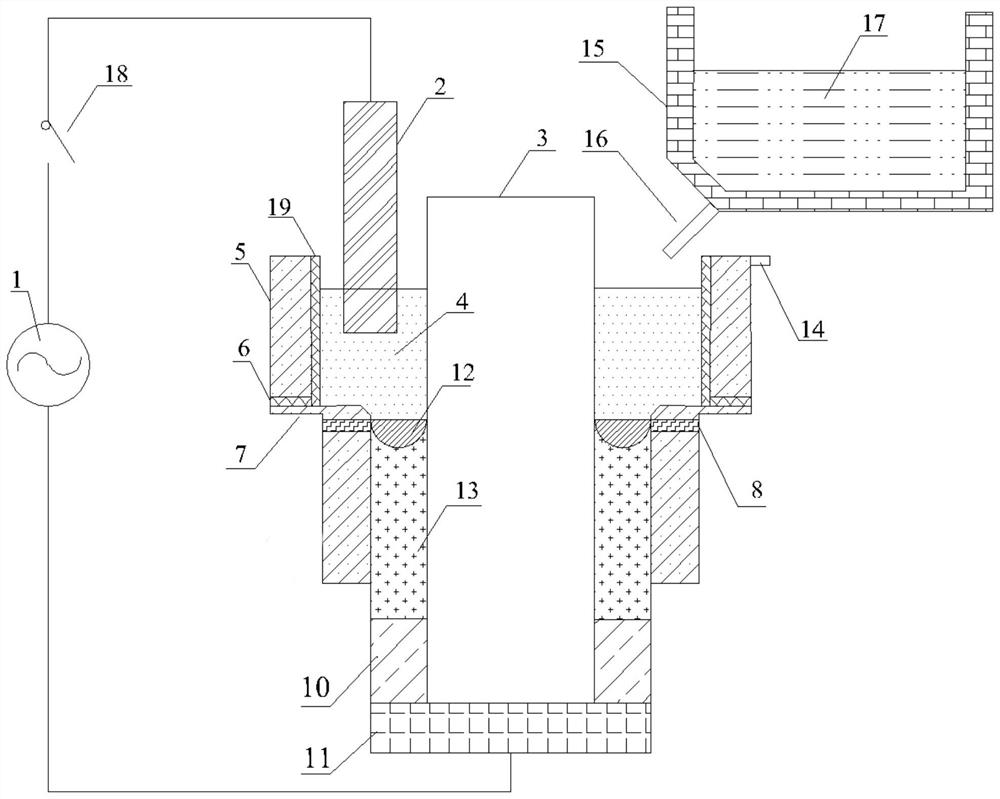

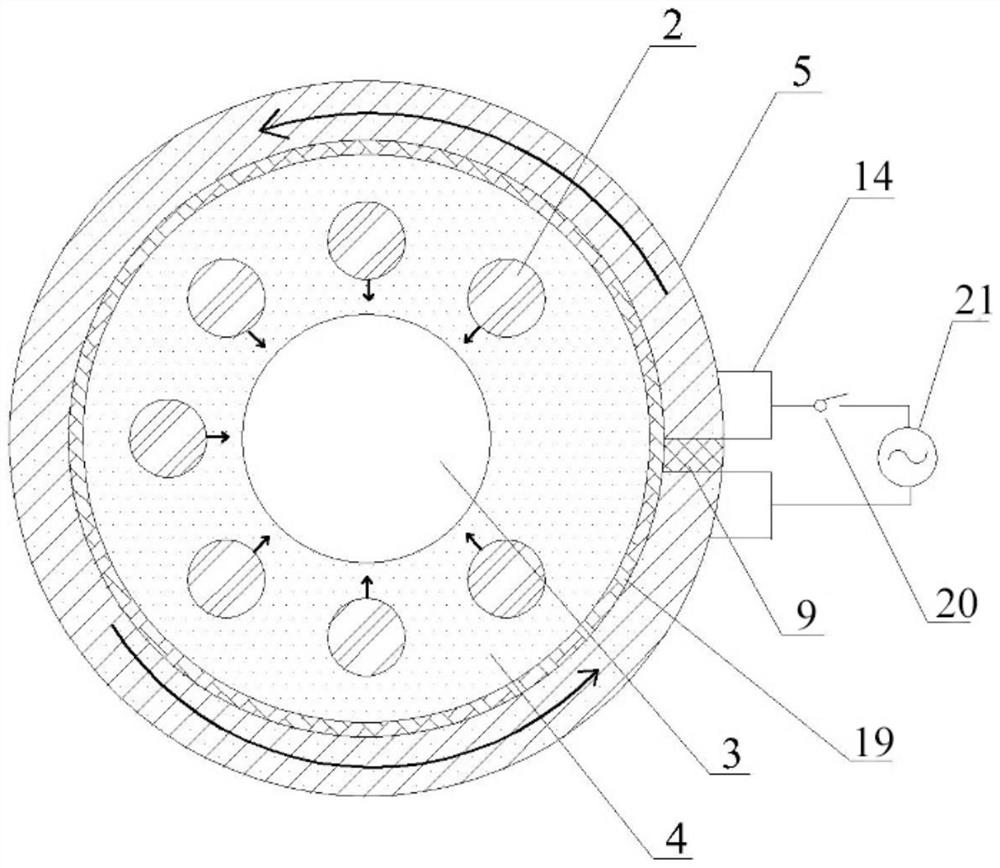

[0042] The structure of the device for preparing the composite roll by the electroslag remelting method with the additional magnetic field of the crystallizer is as follows figure 1 , the top view is as figure 2 As shown, it includes remelting power supply 1, mold power supply 21, dummy plate 11, upper mold 5 and lower mold 7; lower mold 7 is T-shaped, and upper mold 5 and lower mold 7 constitute electroslag Furnace crystallizer; The upper crystallizer 5 and the lower crystallizer 7 are separated by a ring-shaped insulating gasket 6;

[0043] The inner wall of the upper crystallizer 5 is covered with an insulating ring 19; the upper crystallizer 5 is provided with a gap, the gap runs through the top surface and the bottom surface of the upper crystallizer 5, and connects the inside and outside of the upper crystallizer 5, and the gap is filled with insulating blocks. 9;

[0044] One pole of the remelting power supply 1 is connected to the dummy plate 11, and the other pole ...

Embodiment 2

[0057] The structure of the device is the same as that of Embodiment 1, and the difference lies in:

[0058] The projection of the axes of the two liquid level detection probes 8 on the horizontal plane forms an included angle θ; the included angle θ is 90°;

[0059] The method is the same as in Example 1, except that:

[0060] When the mold power is turned on, the current in the mold loop is 1000A; the temperature of the slag pool is still unevenly distributed along the circumferential direction during the thermal process. In the process of cladding and compounding, the surface of the mandrel melts unevenly, the temperature near the graphite electrode is high, the surface of the mandrel melts faster and the depth is deeper; the temperature away from the electrode and the casting point is low, and the surface of the mandrel melts slowly. , the depth is shallow, and the overall composite effect of the roll circumferential direction is still poor.

Embodiment 3

[0062] The structure of the device is the same as that of Embodiment 1, and the difference lies in:

[0063] The projection of the axes of the two liquid level detection probes 8 on the horizontal plane forms an included angle θ; the included angle θ is 180゜;

[0064] The method is the same as in Example 1, except that:

[0065] When the power of the mold is turned on, the current in the mold loop is 5000A; the slag pool rotates counterclockwise during the preheating process and the cladding composite process, which greatly improves the distribution of the temperature field. In the process of cladding and recombination, the circumferential flow promotes the heat transfer of the circumferential flow, and promotes the uniform melting of the mandrel surface and the metallurgical bonding process of the composite interface. The process was successfully completed and the interface bonding quality was good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com