Polymer, chip and preparation method and application thereof

A polymer, selected technology, applied in the direction of biochemical equipment and methods, chemical instruments and methods, laboratory containers, etc., can solve the problems of chip manufacturing process and application limitations, low probe density, etc., to overcome Air sensitivity and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0113] Embodiments of the present invention also provide a method for preparing the polymer as described above, comprising the steps of:

[0114] The polymer is prepared by copolymerizing monomer A and monomer B; the monomer A forms the repeating unit A, and the monomer B forms the repeating unit B.

[0115] In one specific embodiment, the molar ratio of the monomer A and the monomer B is 1:(1-30). Specifically, the molar ratio of the monomer A and the monomer B is 1:1, 1:3, 1:5, 1:8, 1:10, 1:12, 1:15, 1:20, 1:1 25, 1:30.

[0116] In one specific embodiment, the copolymerization reaction refers to the polymerization reaction of the monomer A and the monomer B under the initiation of an initiator at 30-60° C. (reaction temperature). Specifically, the reaction temperature can adopt the following specific temperature values: 30°C, 35°C, 36°C, 37°C, 38°C, 40°C, 41°C, 42°C, 43°C, 45°C, 50°C, 52°C , 54℃, 55℃, 56℃, 58℃, 60℃.

[0117] In one specific embodiment, the initiator is s...

Embodiment 1

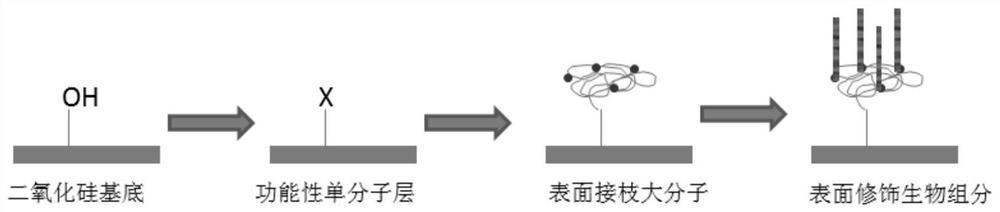

[0137] This embodiment provides a chip, the preparation method of which is as follows (for the process flow diagram, see figure 1 ):

[0138] (1) Polymer preparation

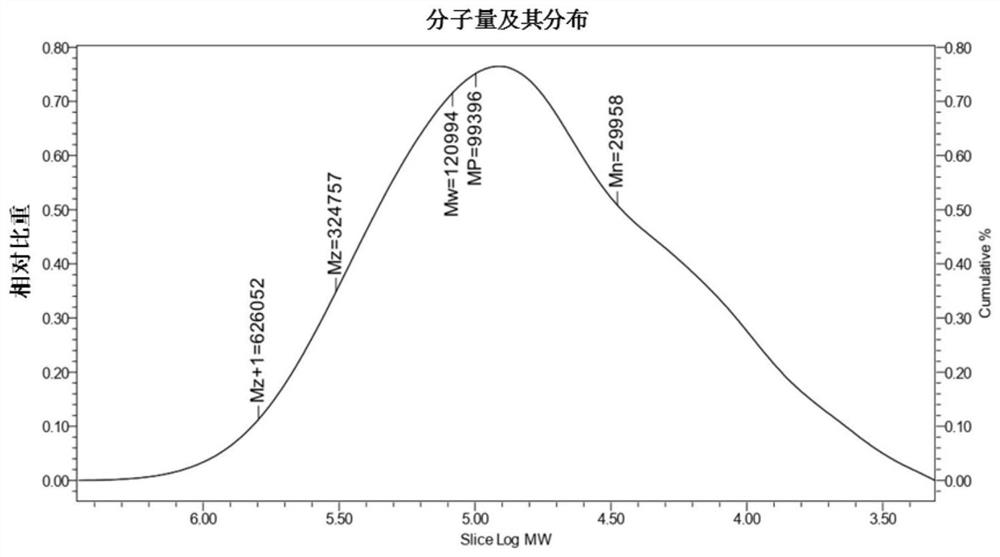

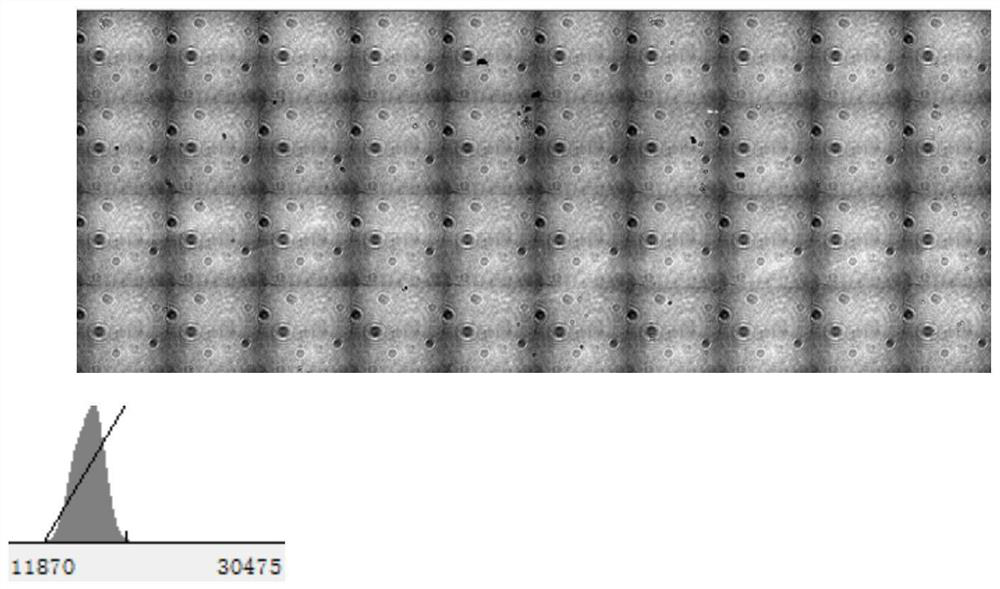

[0139] Using toluene as a solvent, according to the volume ratio, 5wt% of GMA (glycidyl methacrylate) and 0.1wt% of PEGDA (polyethylene glycol (glycol) diacrylate) with a molecular weight of 1000 g / mol were added to the system, 0.1 wt% AIBN (azodiisobutyronitrile; azobisisobutyronitrile, Chinese name is azobisisobutyronitrile) initiator, after nitrogen and oxygen removal, the polymerization reaction occurs at 55°C. After the reaction was carried out for 3 hours, oxygen was injected to terminate the reaction. After methanol was used to extract the polymer, the epoxy-based macromolecules of the body shape were obtained by vacuum drying, and GPC detection (gel permeation chromatography) was used. The detection results are as follows figure 2 As shown, an epoxy-based macromolecule with a peak molecular weight of ...

Embodiment 2

[0151] The present embodiment provides a chip, and its preparation method is as follows:

[0152] (1) Polymer preparation

[0153] Use water and DMF (dimethylformamide) as solvents, wherein the volume ratio of water and DMF is not 4:1. According to the mass ratio, 2% of acrylamide AM, 0.2% of GMA monomer, 0.1% of KPS (potassium persulfate) initiator and 0.01% of TEMED (tetramethylethylenediamine) gel accelerator were added to the system, After nitrogen and oxygen removal, the polymerization reaction occurred at 42°C. After the reaction was carried out for 3 hours, oxygen was injected to terminate the reaction, and methanol was used to extract the polymer, followed by vacuum drying to obtain linear epoxy-based macromolecules, which were detected by GPC (gel permeation chromatography), and the detection results were as follows: Figure 5 As shown, an epoxy-based macromolecule with a peak molecular weight of 191,619 was obtained.

[0154]

[0155] (2) Substrate surface modi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com