Patents

Literature

34results about How to "Realize intermittent transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

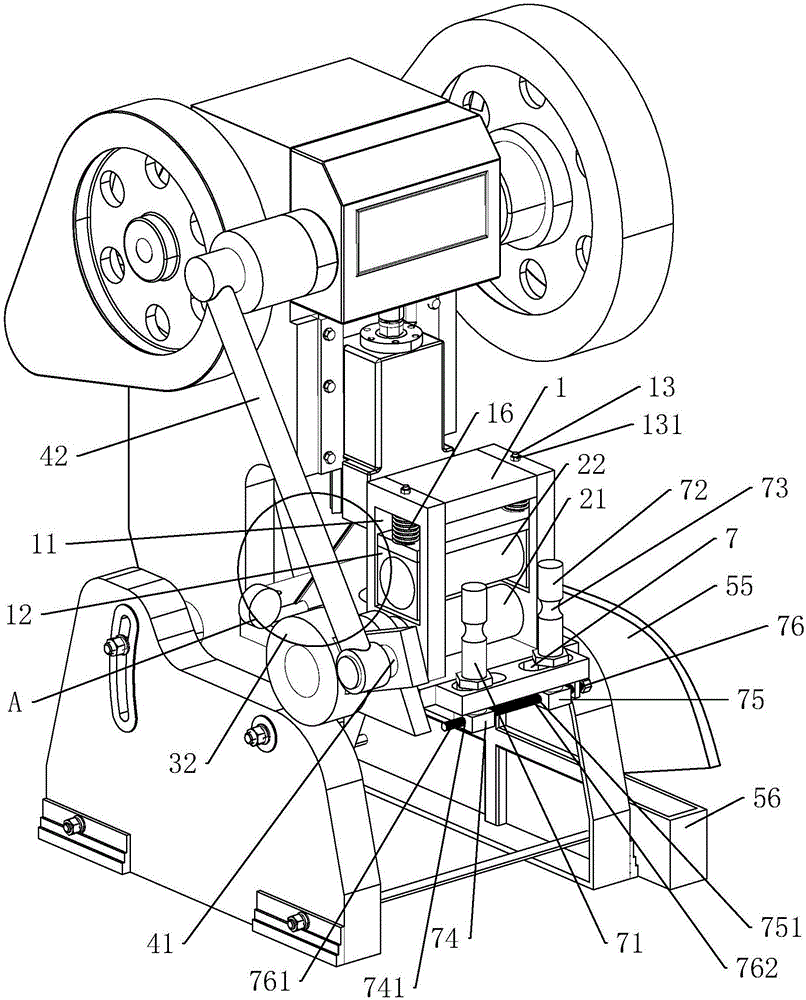

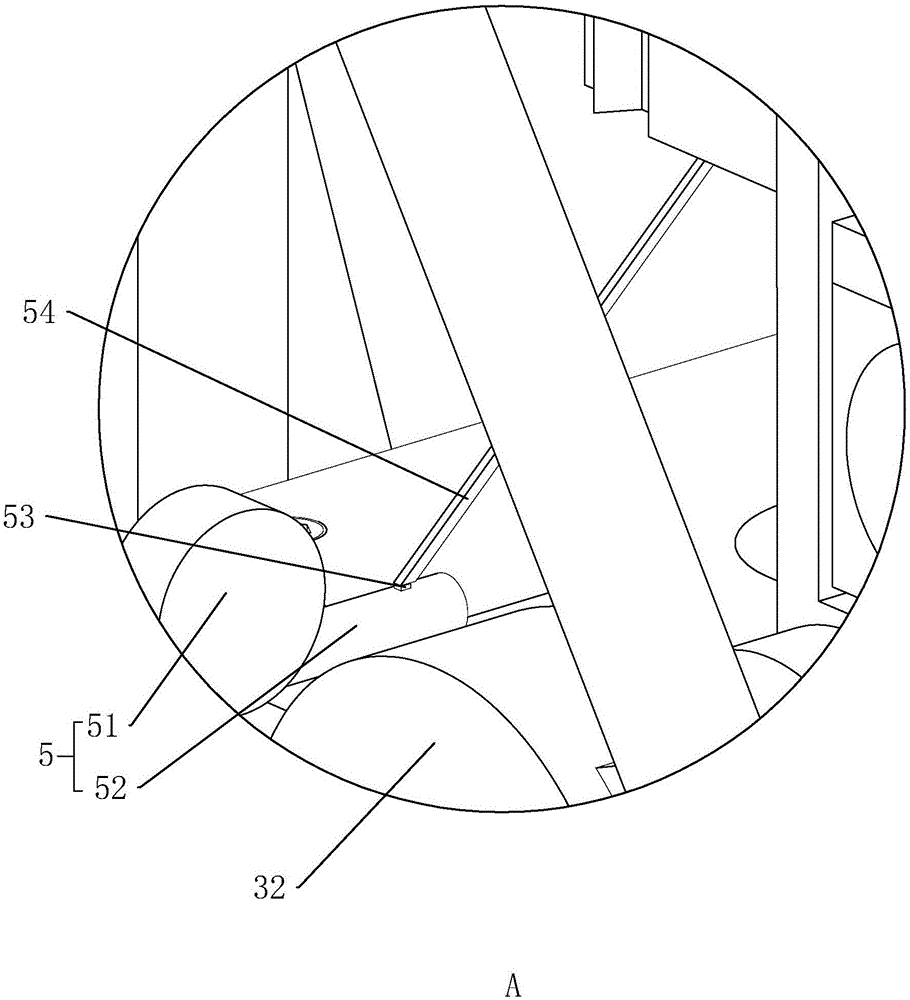

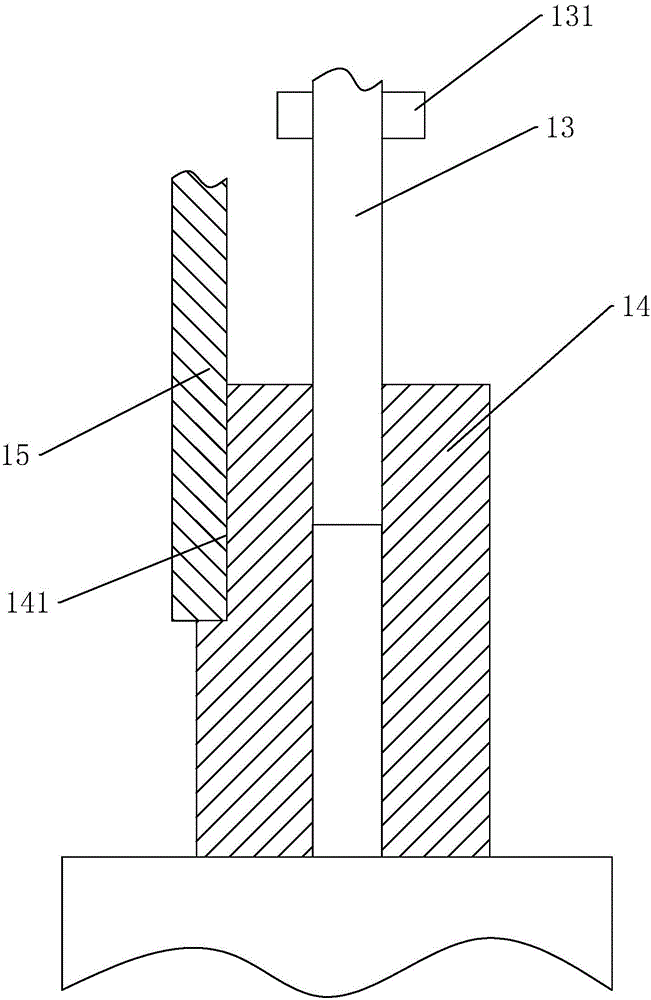

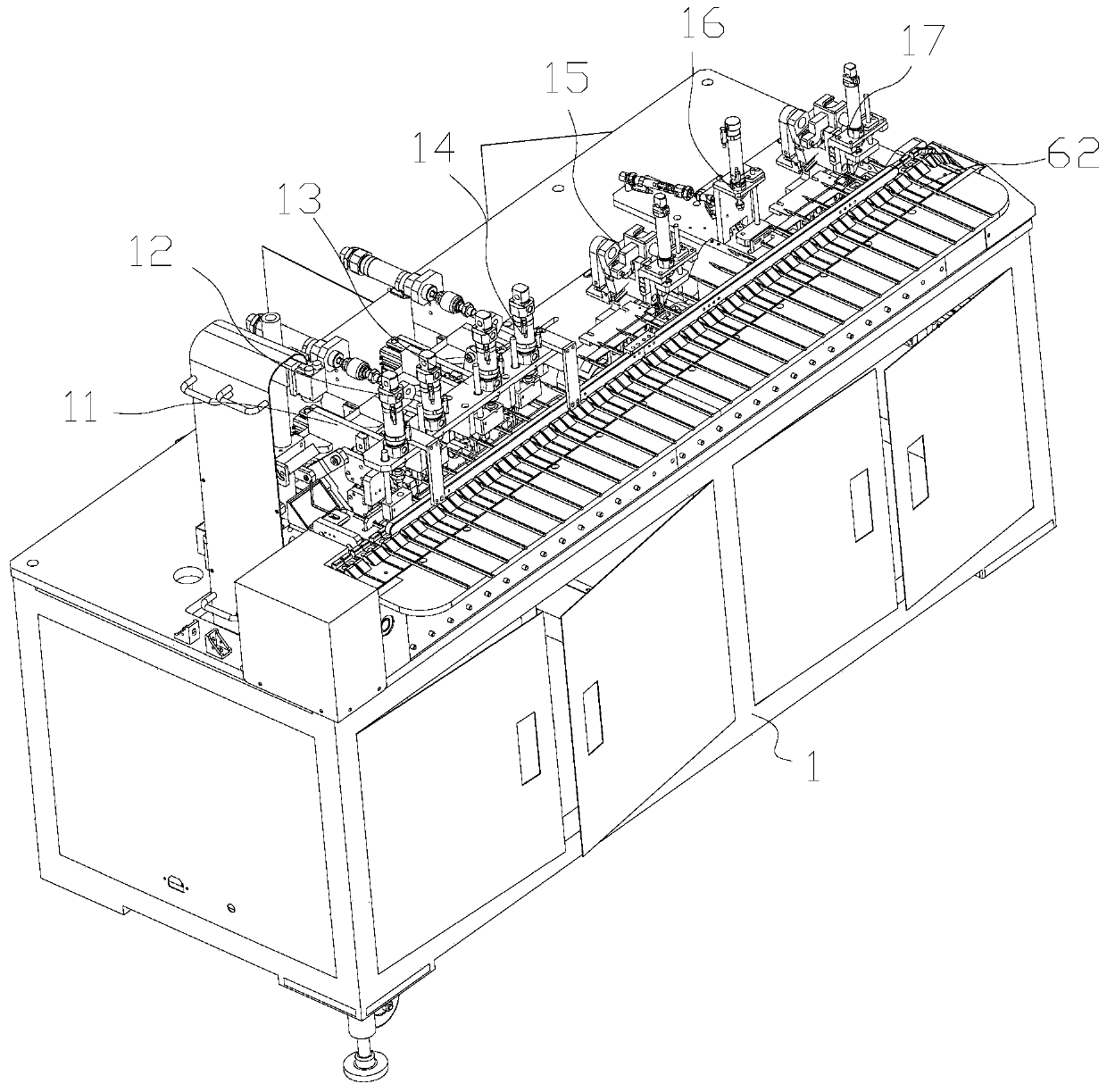

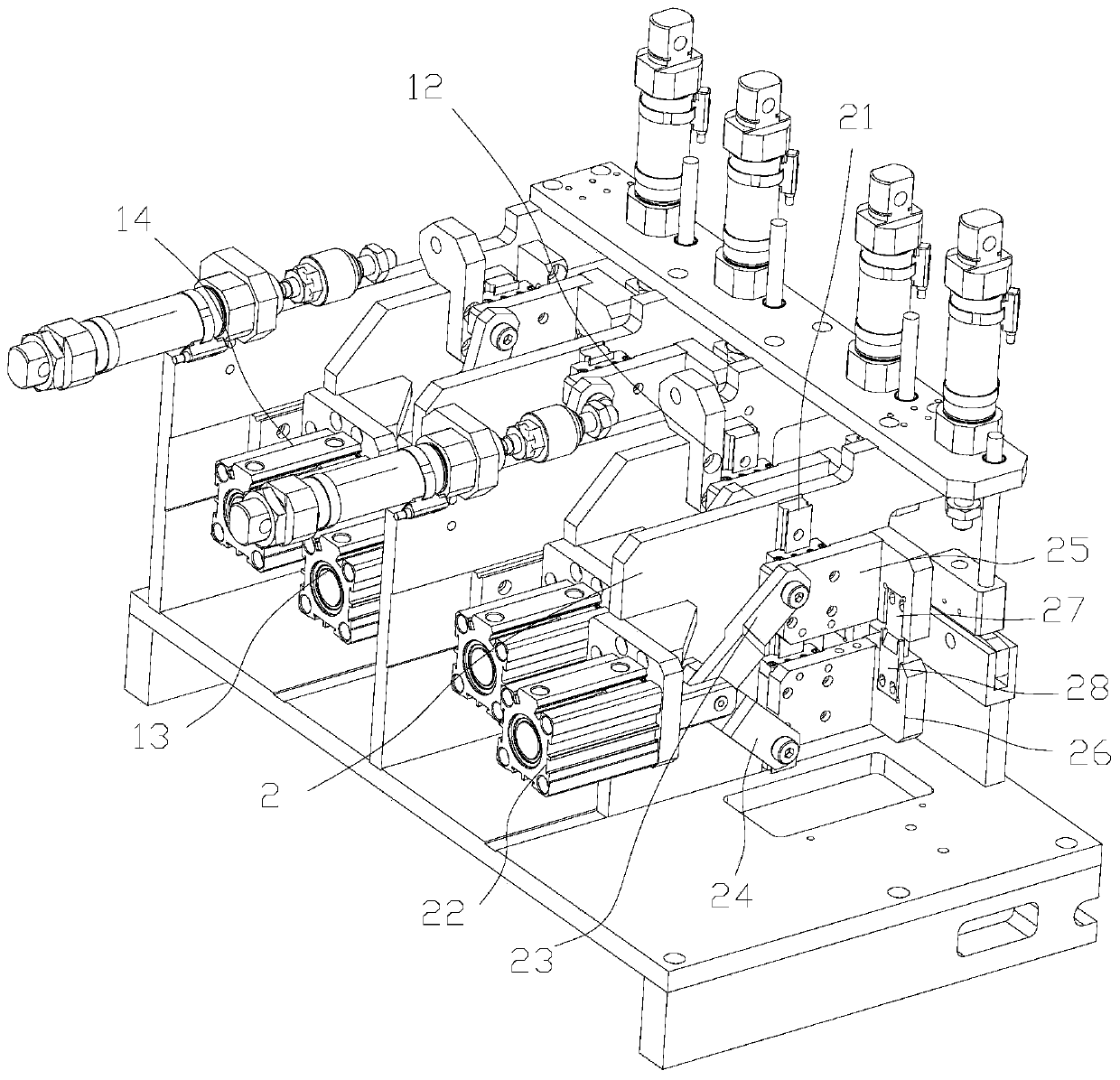

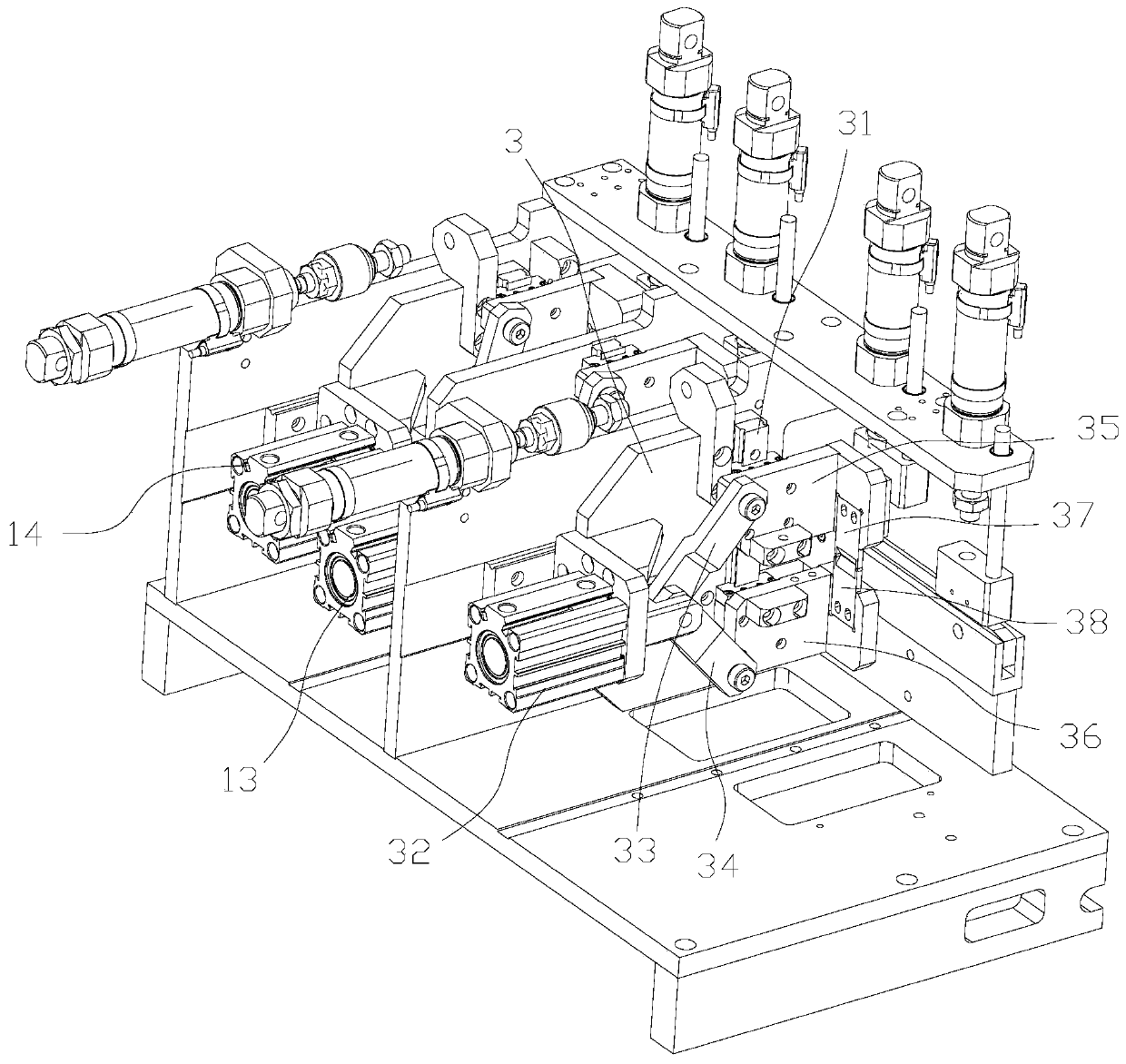

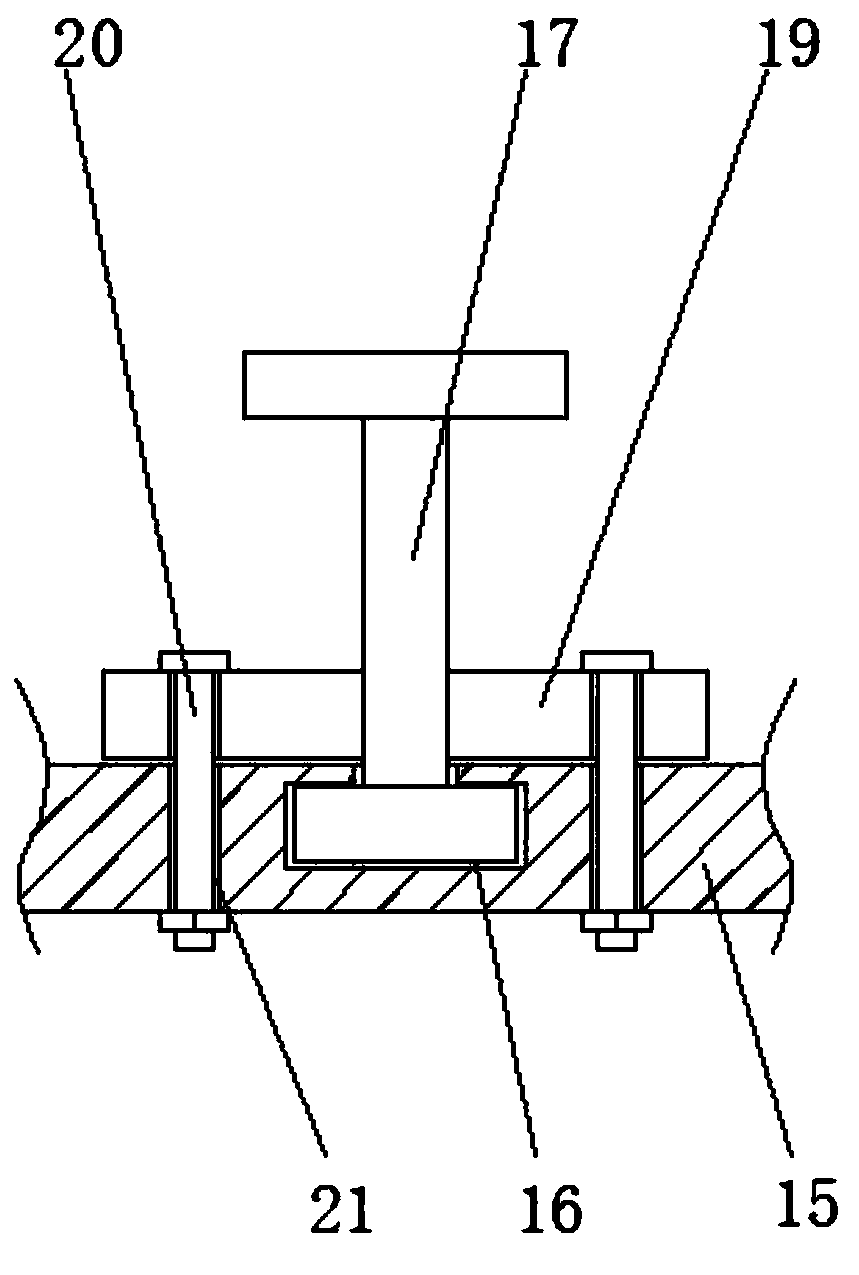

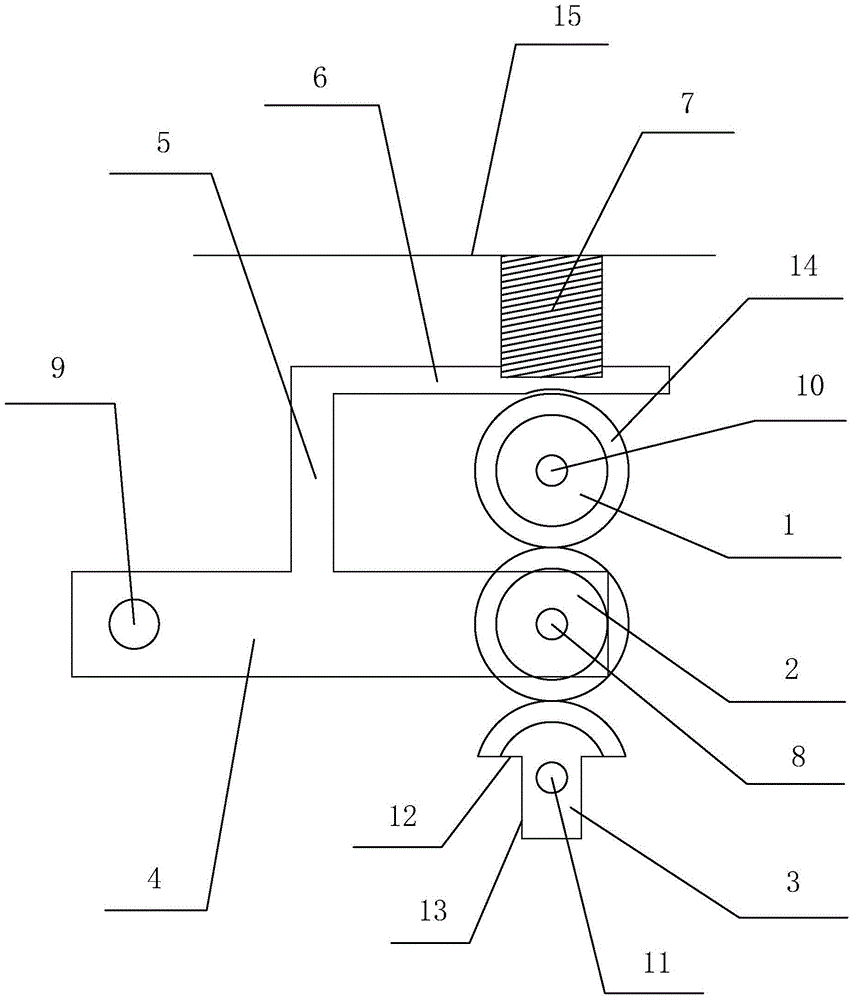

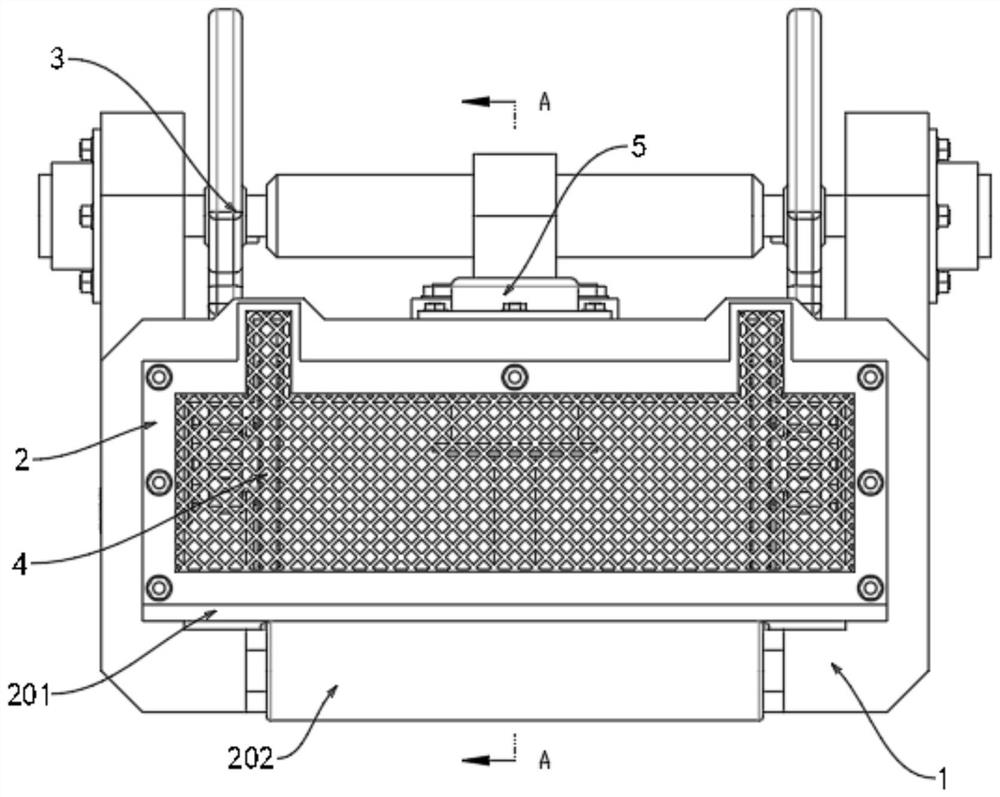

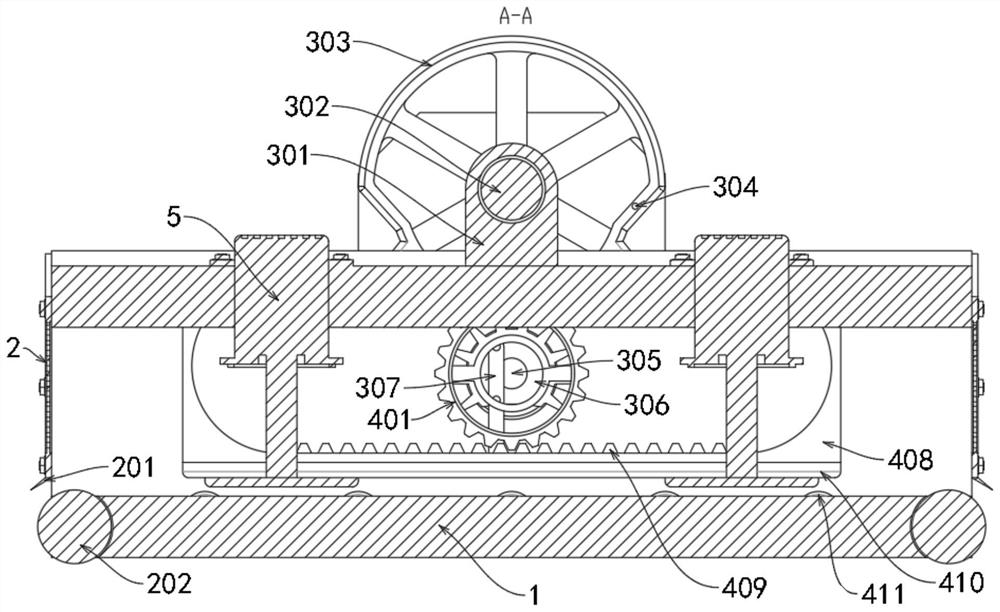

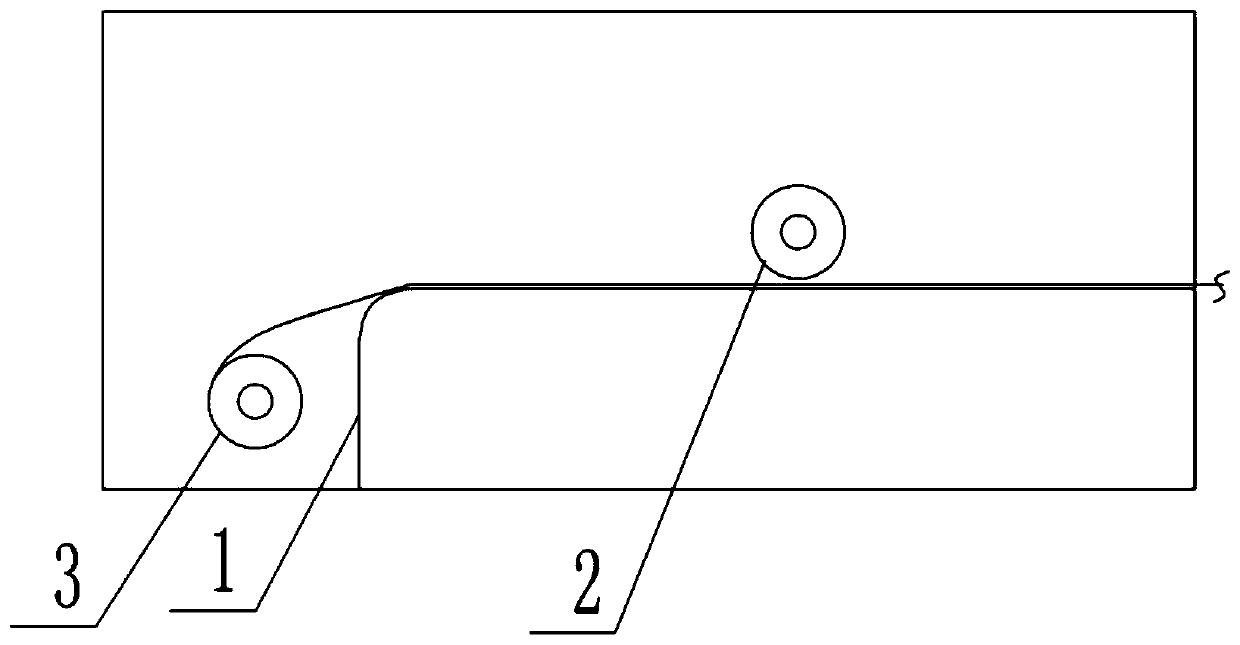

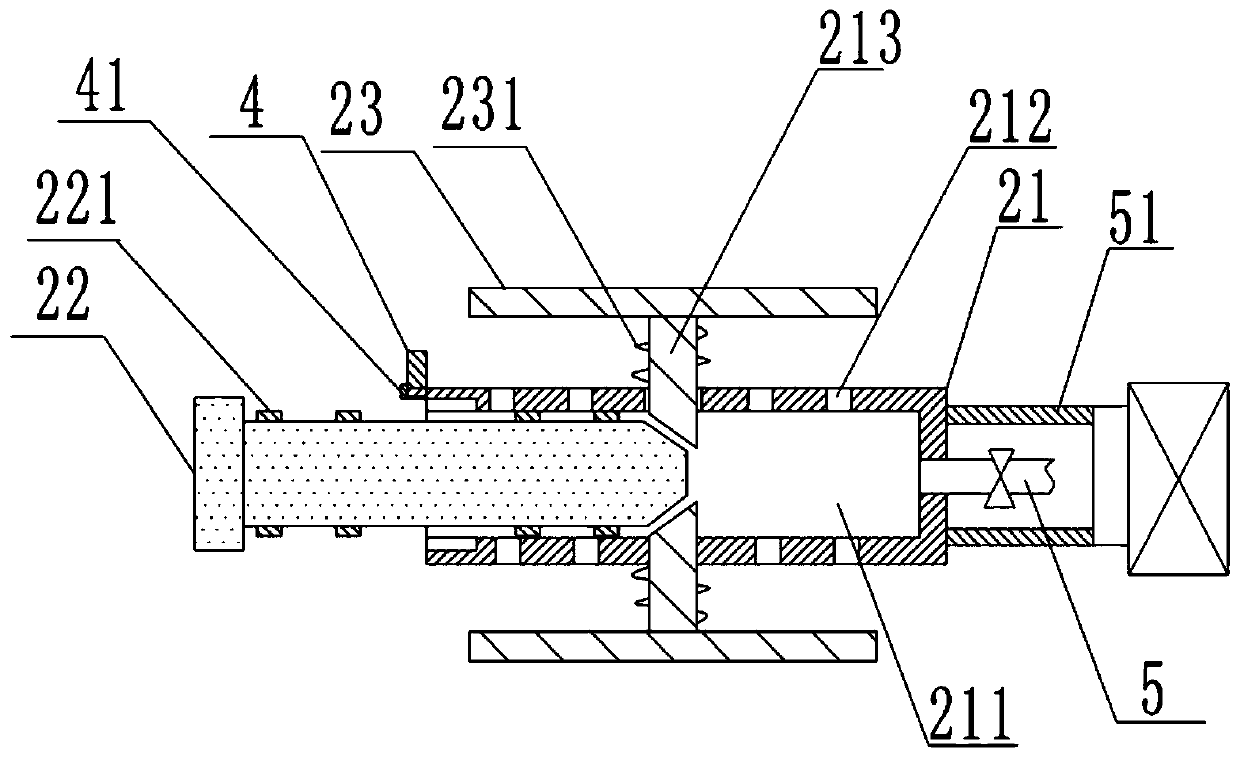

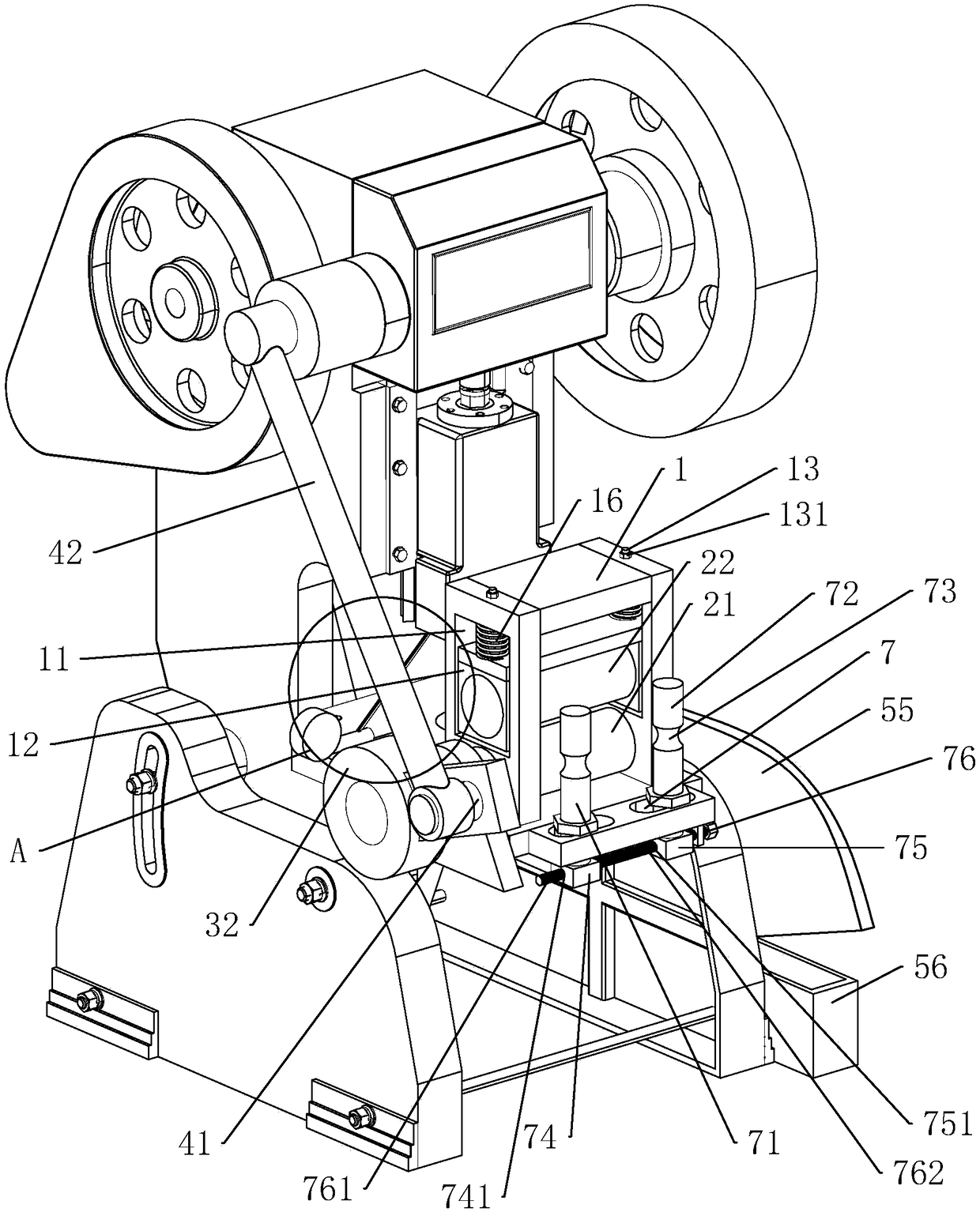

Feeding device for punch

ActiveCN106734691ARealize intermittent transmissionEasy to collectMetal-working feeding devicesStripping-off devicesEngineeringFlywheel

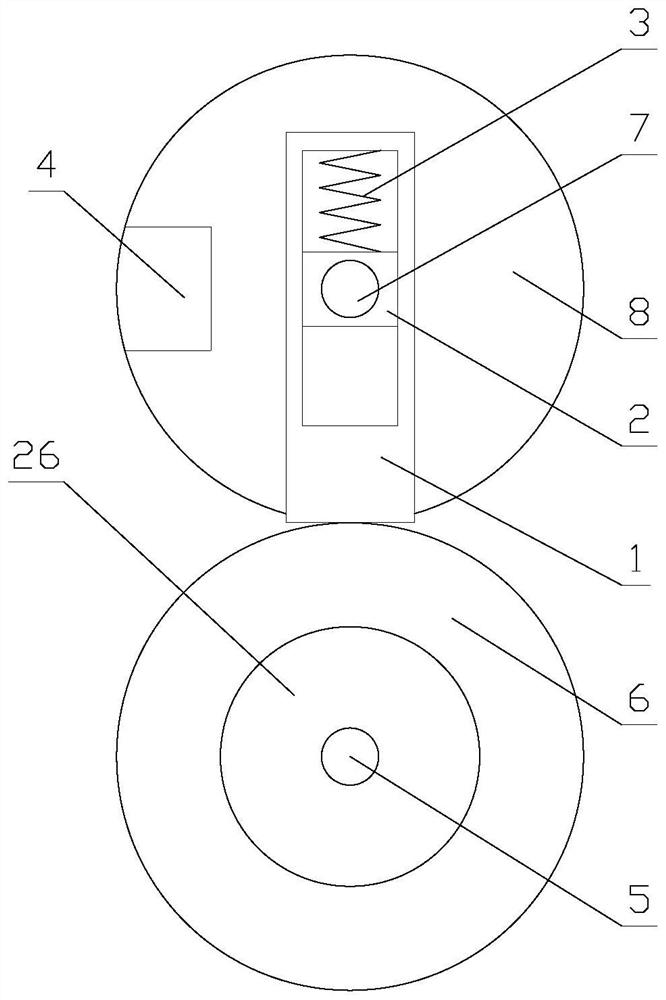

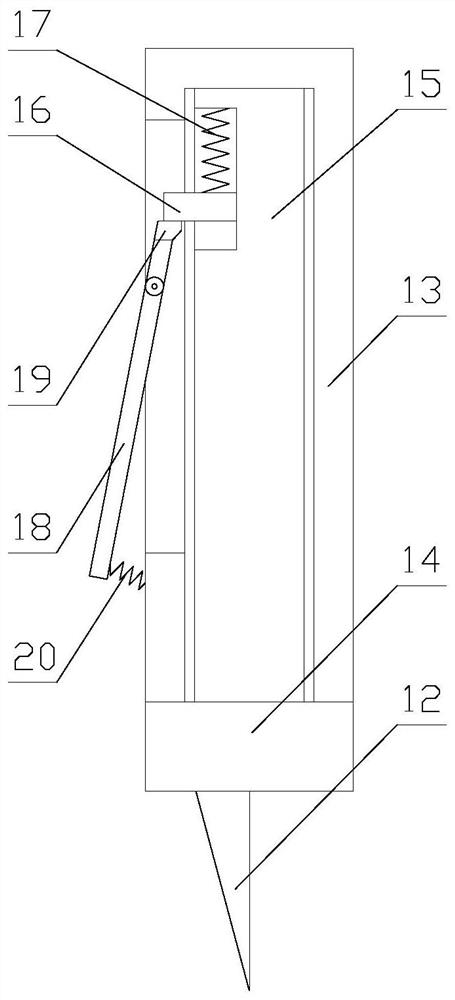

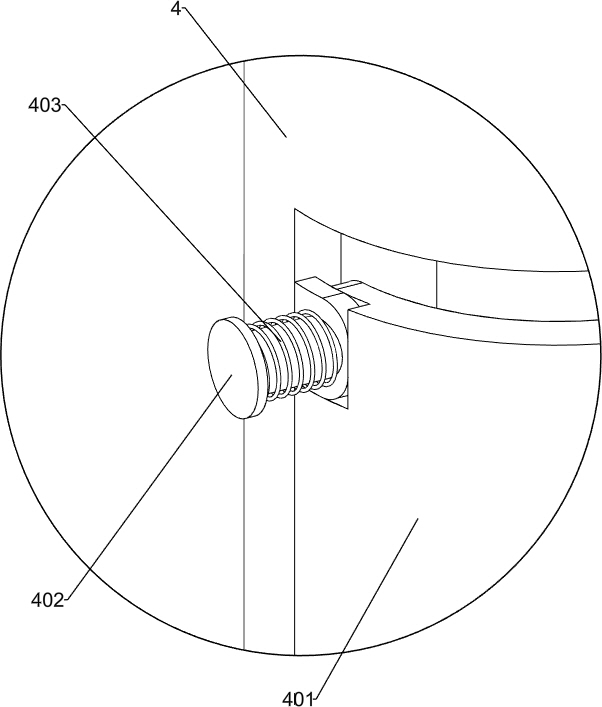

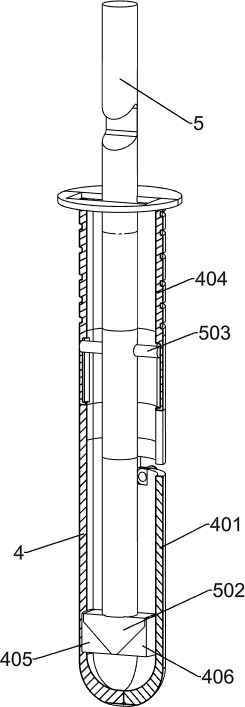

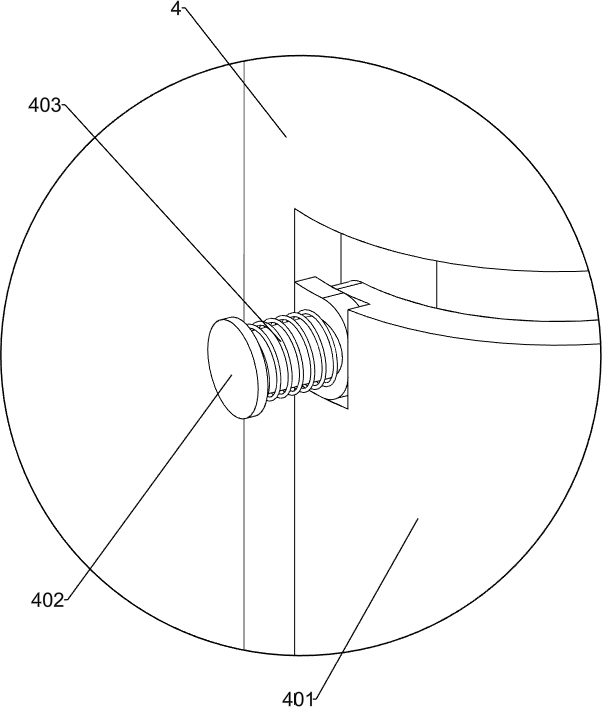

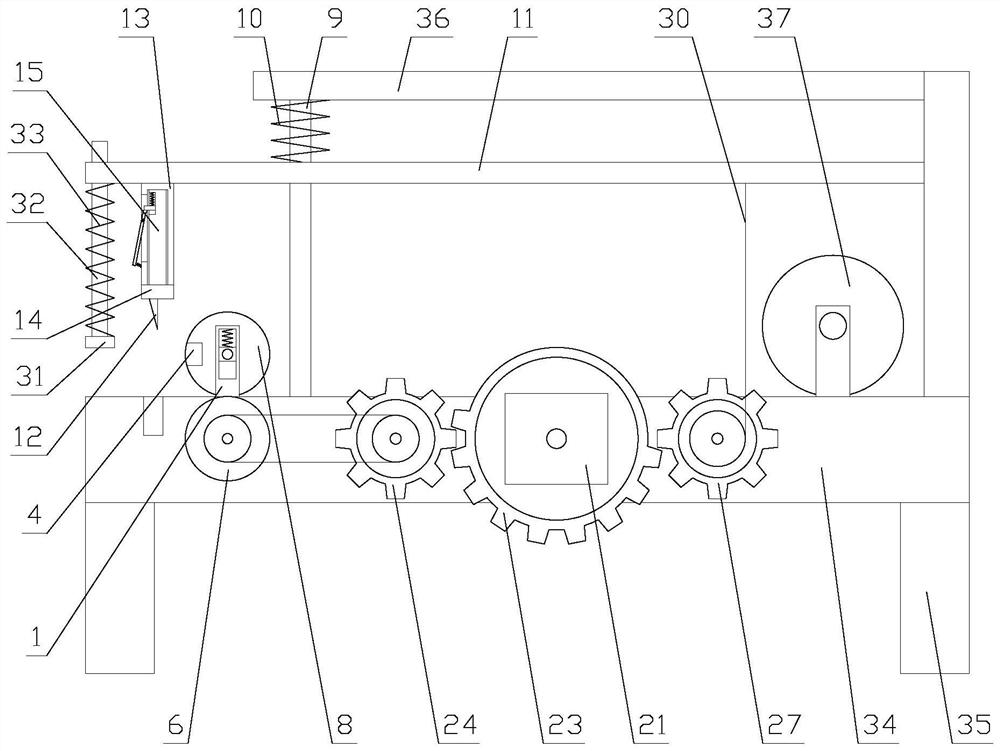

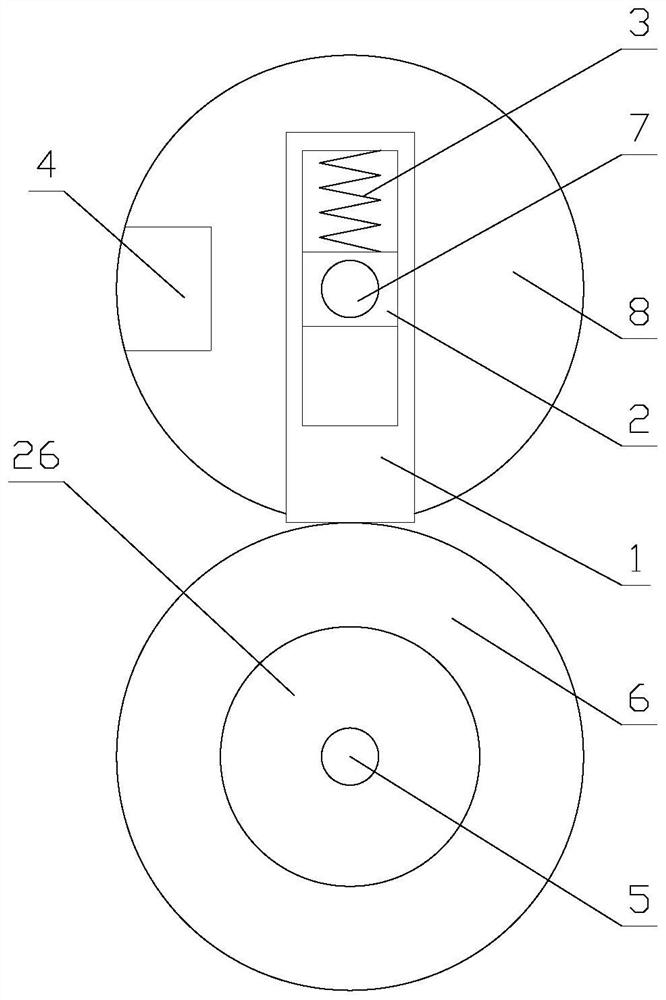

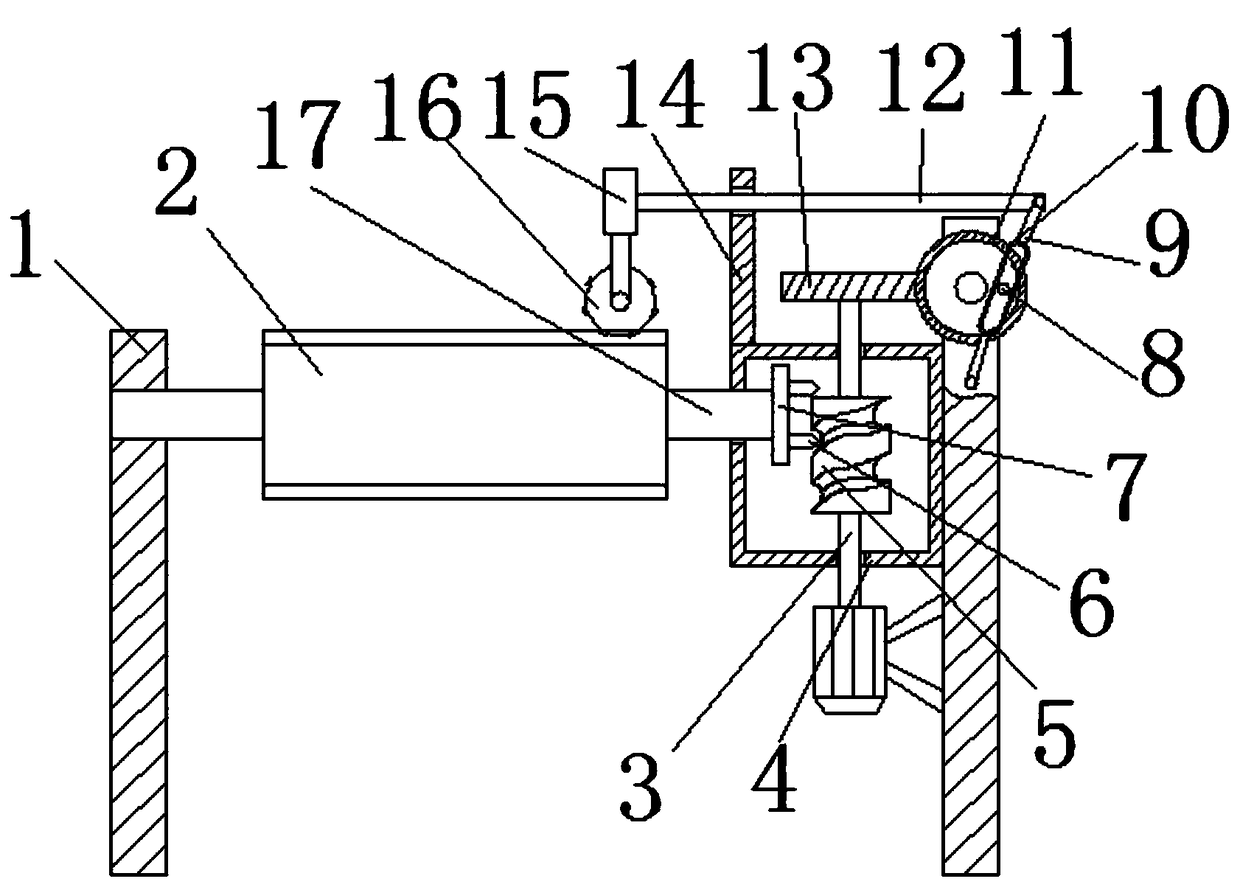

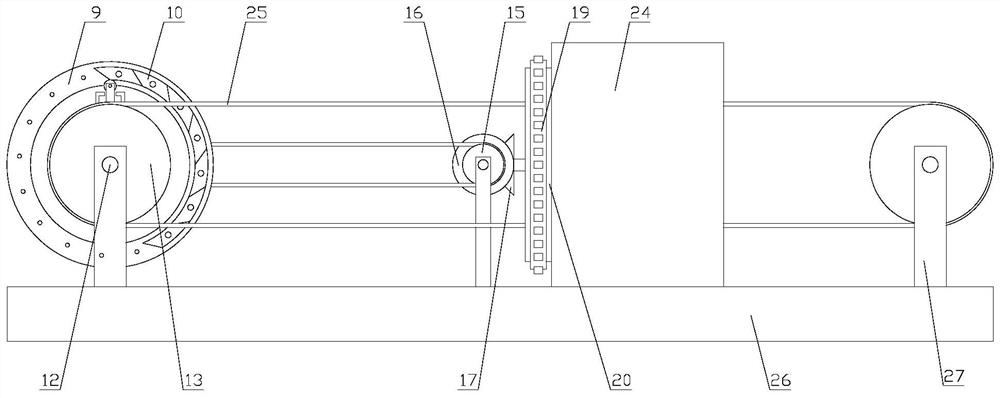

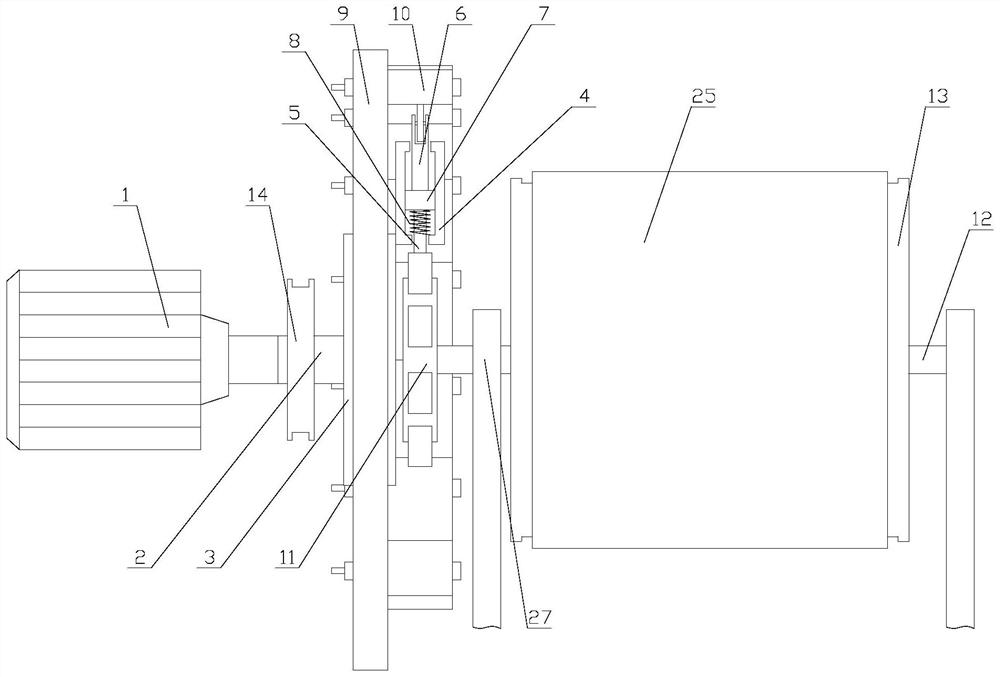

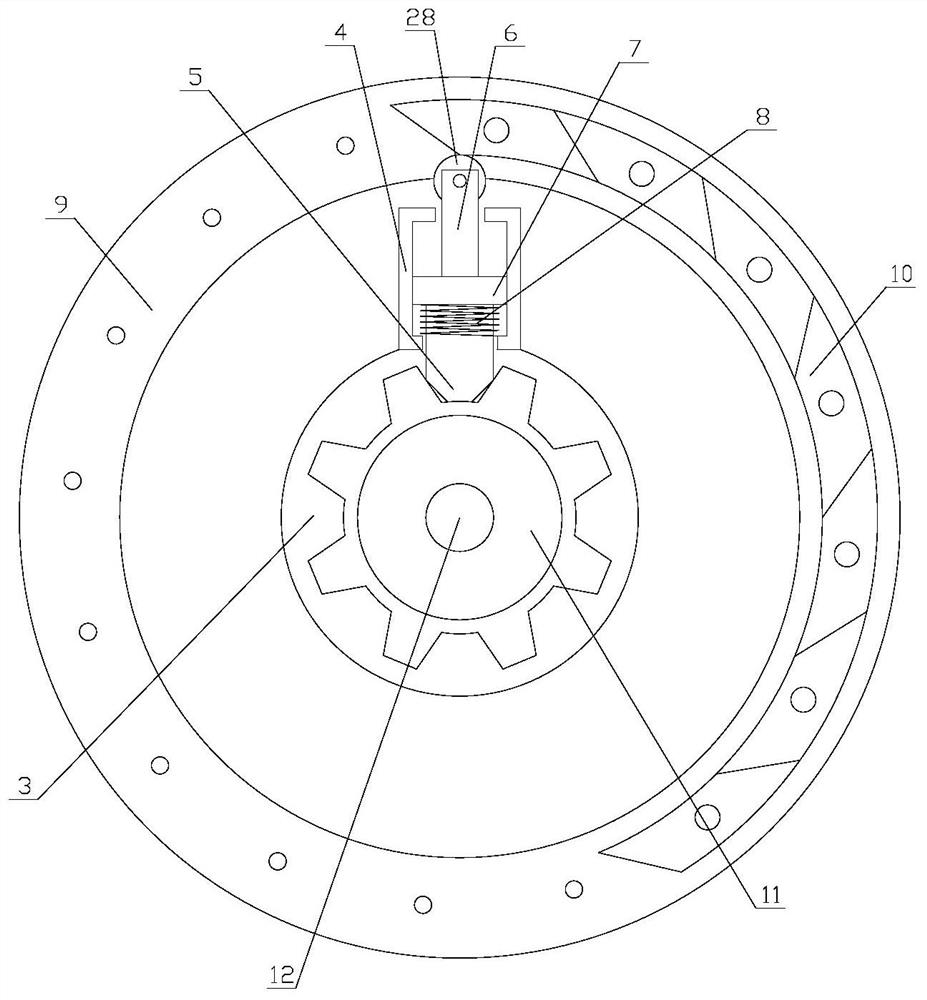

The invention discloses a feeding device for a punch. The feeding device comprises a frame fixed to a worktable. A first compression roller and a second compression roller, which abut against the upper and lower surfaces of a steel strip, respectively, are rotatably connected to the frame. A ratchet wheel is fixed to an end portion of the first compression roller. A drive sleeve is rotatably connected to the first compression roller. A ratchet is hinged to the inner wall of the drive sleeve, and the ratchet is connected to the drive sleeve by means of a first elastic part. A first connecting rod is fixed to an outer wall of the drive sleeve. A second connecting rod is hinged to the first connecting rod. One end, far away from the first connecting rod, of the second connecting rod is hinged to a flywheel. Thus, the purpose of improving the production efficiency is achieved.

Owner:上海上垫垫圈有限公司

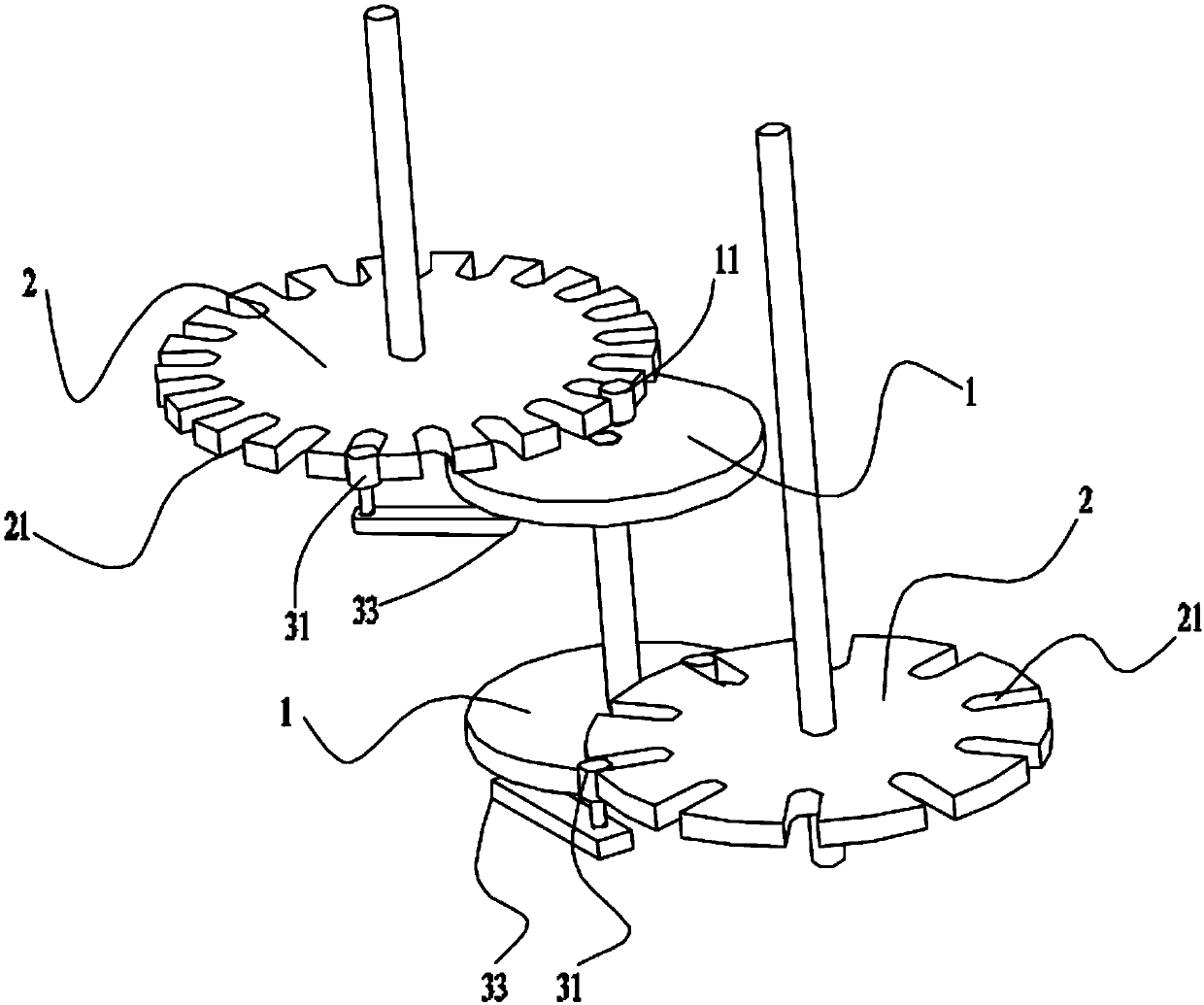

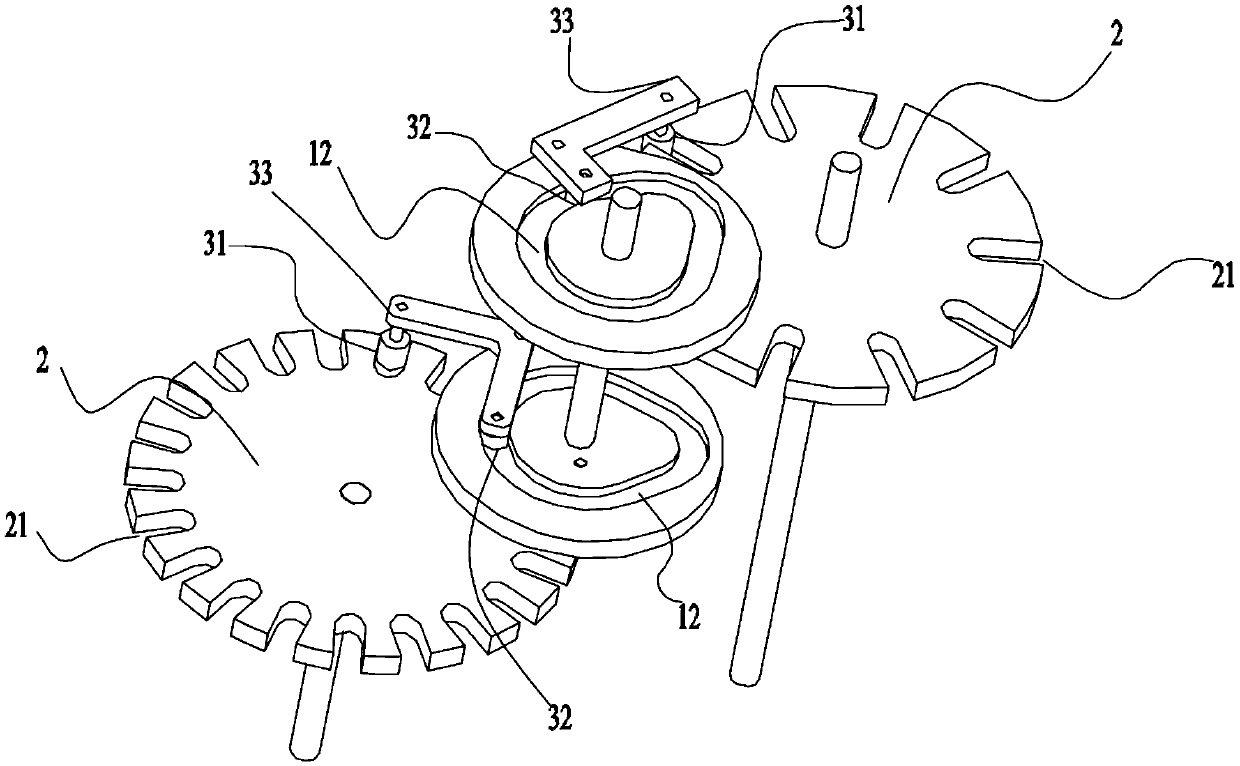

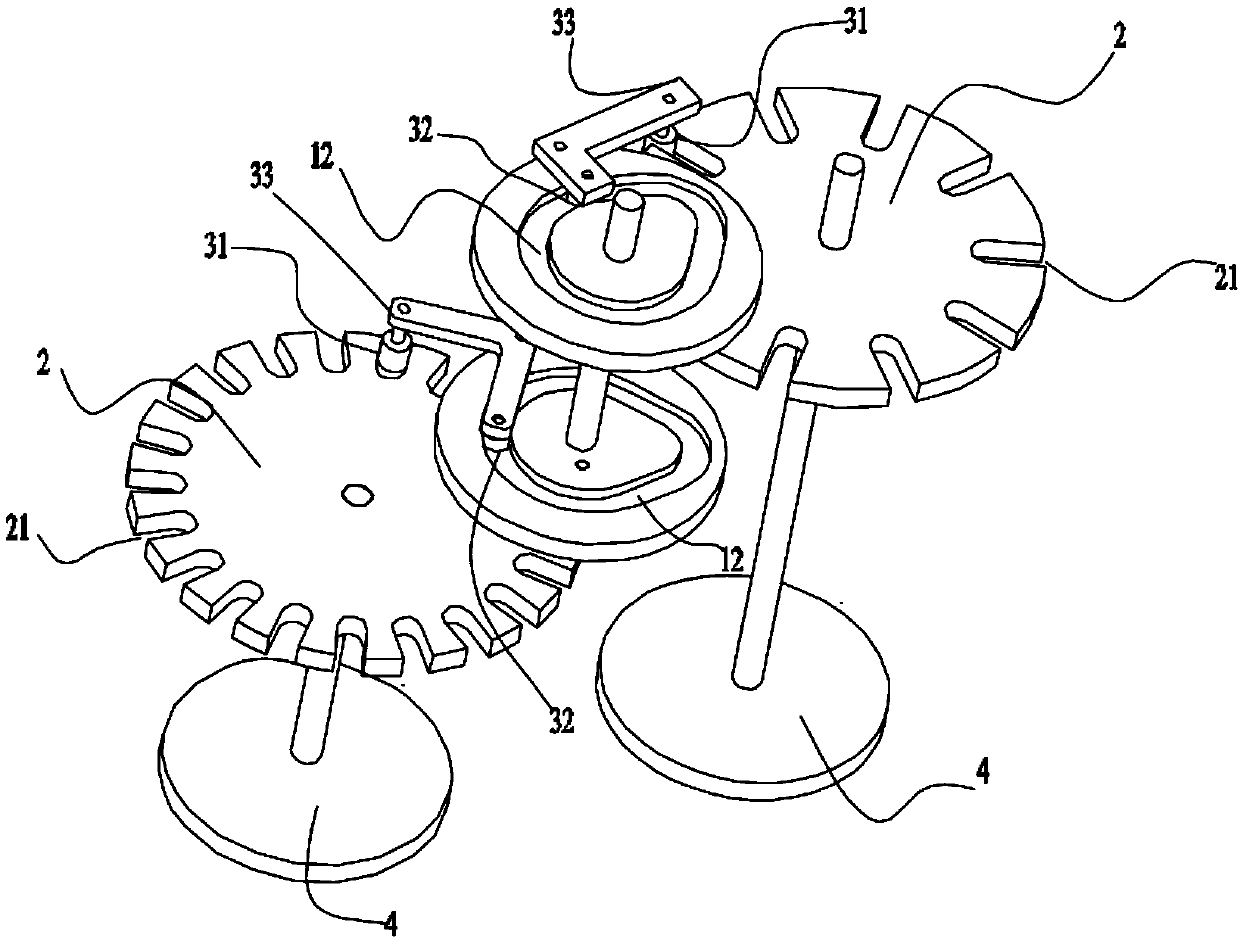

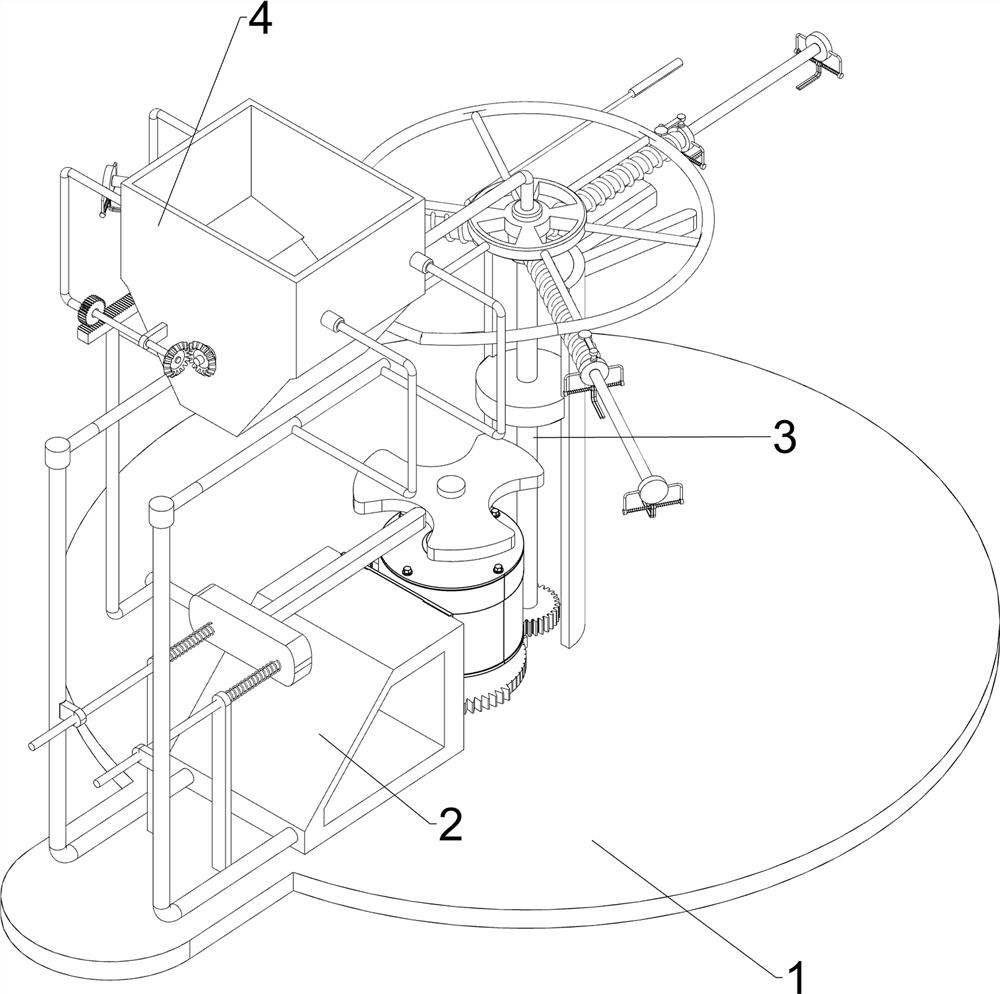

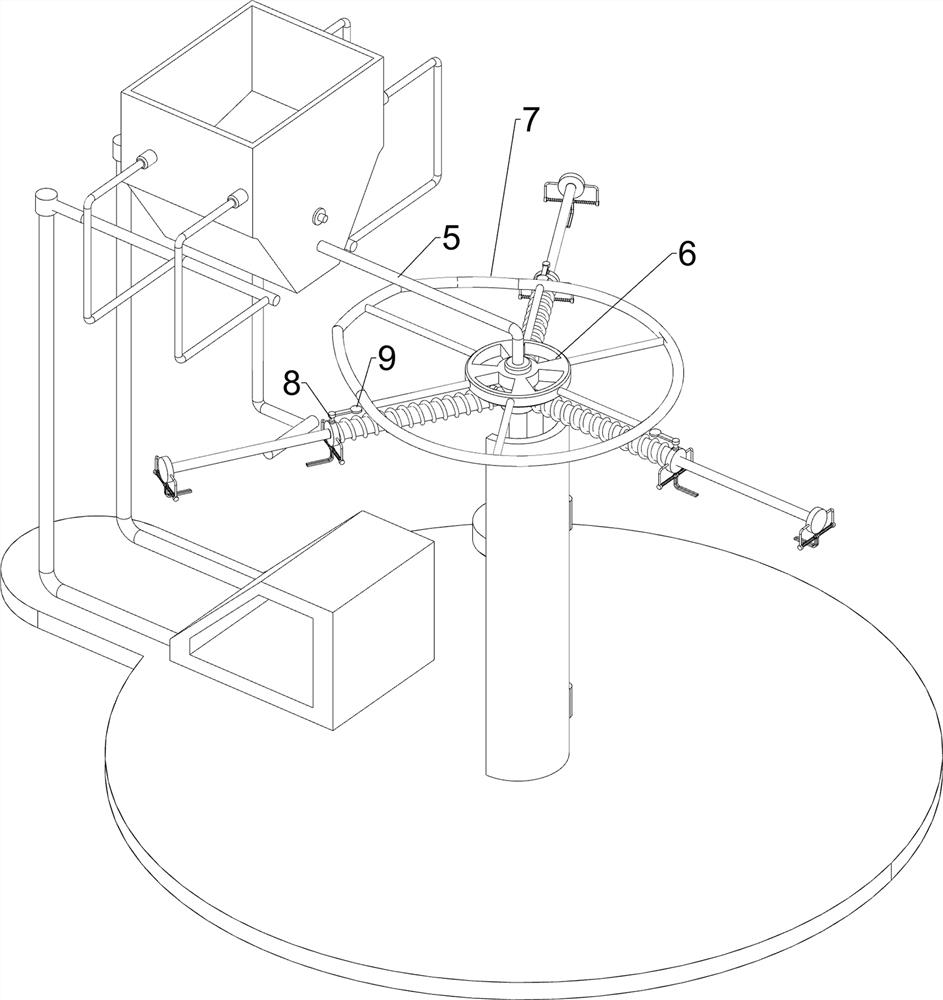

Intermittent transmission mechanism and stirring wheel bottle conveying device

PendingCN109625910AGuaranteed independenceRealize intermittent transmissionConveyorsConveyor partsDrive shaftEngineering

The invention relates to an intermittent transmission mechanism and a stirring wheel bottle conveying device. The intermittent transmission mechanism comprises at least one driving rotary disk, at least one driven rotary disk, at least one stop parts and connecting parts. Each driving rotary disk is connected with a driving device. A driving part is mounted on one surface of each driving rotary disk and located nearby a transmission shaft of the driving rotary disk. A driving mechanism is mounted on the other surface of each driving rotary disk. The outer edge of each driven rotary disk is provided with a plurality of grooves matched with the corresponding driving part. The connecting parts are used for connecting the stop parts with the corresponding driving mechanisms. Each stop part islocated at one end of the corresponding connecting part. The driving mechanisms drive the stop parts to stop the driven rotary disks from rotating through the connecting parts. The driving parts in the grooves drive the corresponding driven rotary disks to rotate until the driving parts rotate by the preset angle around the transmission shafts of the corresponding driving rotary disks and then leave the grooves, and the stops parts get into the grooves to stop the driven rotary disks from rotating. The intermittent transmission mechanism has the advantages of being low in cost and small in manufacturing difficulty.

Owner:TRUKING TECH LTD

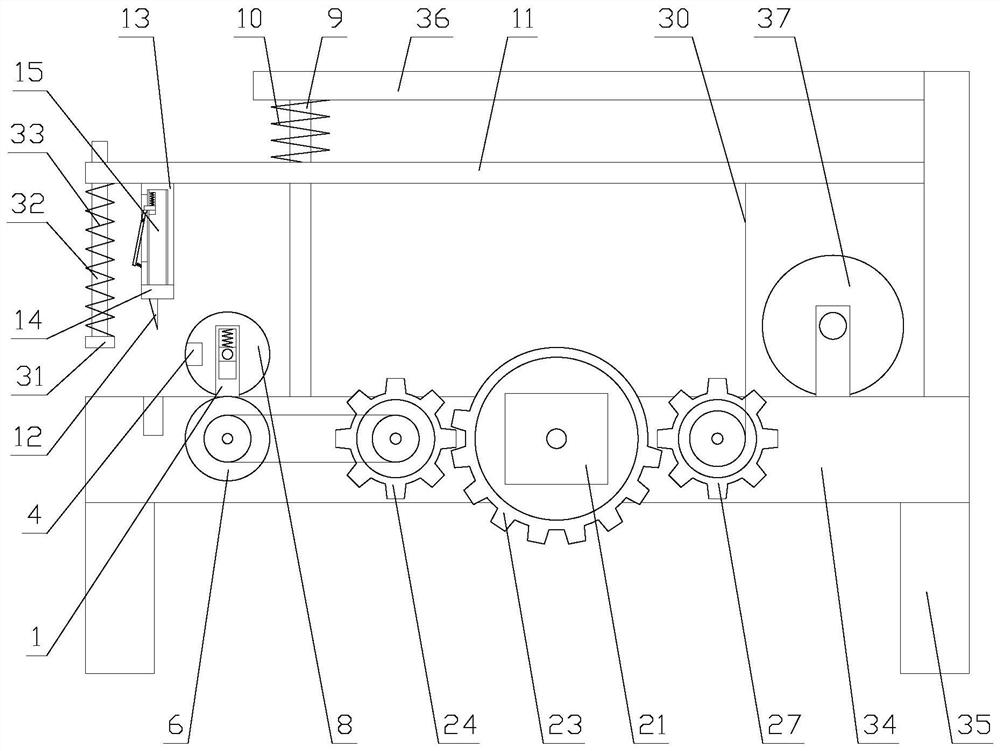

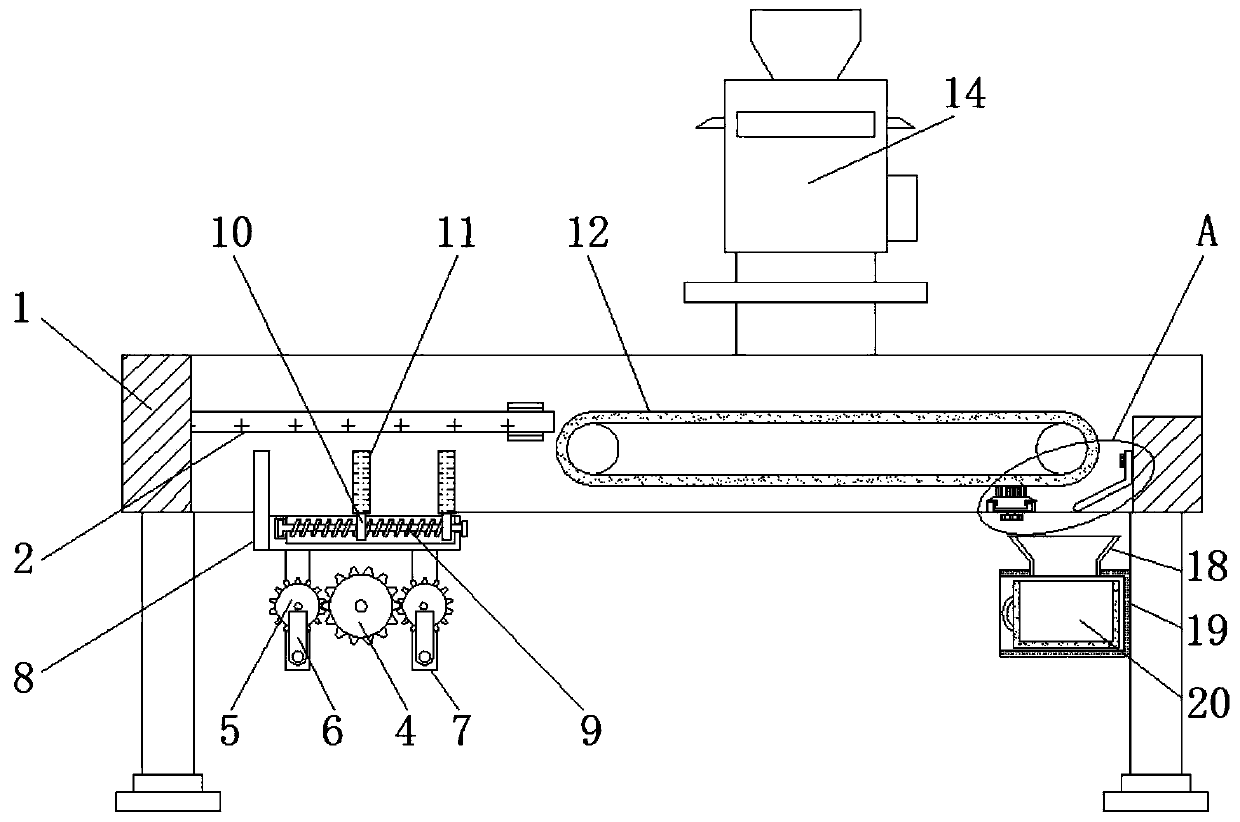

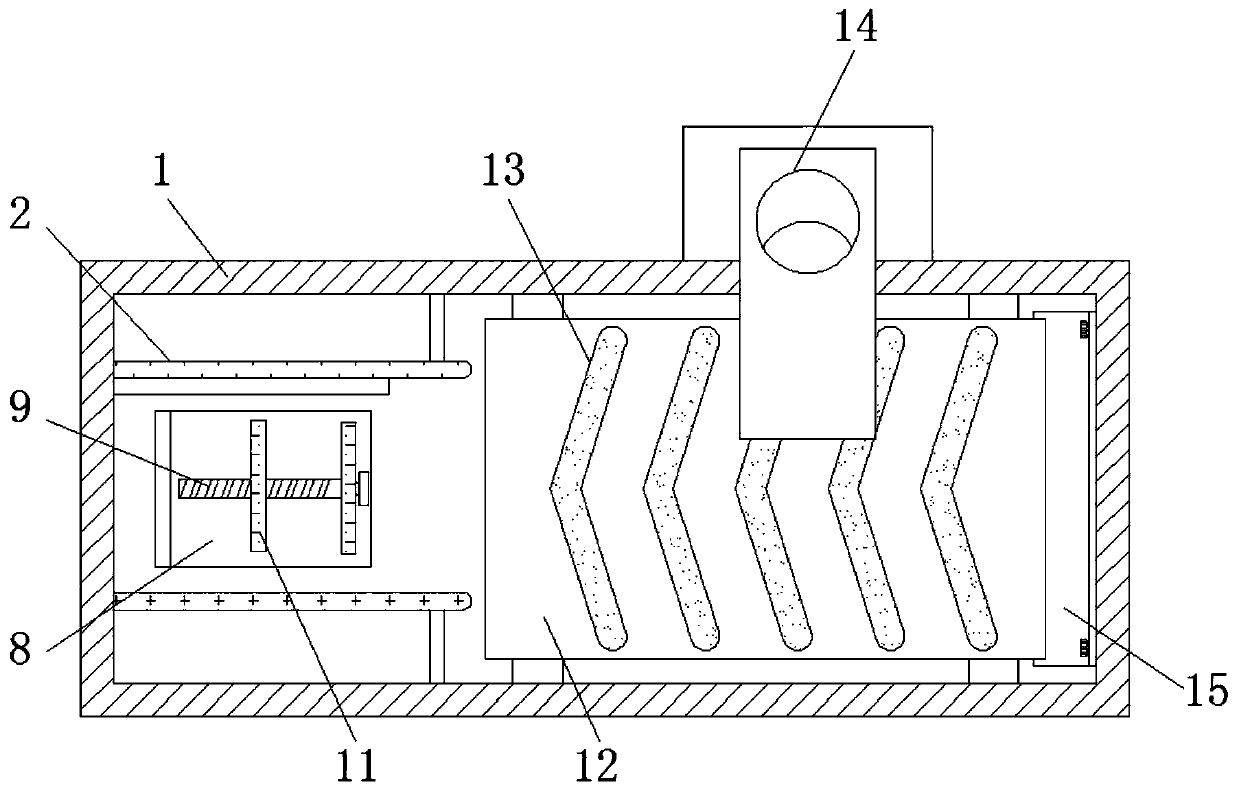

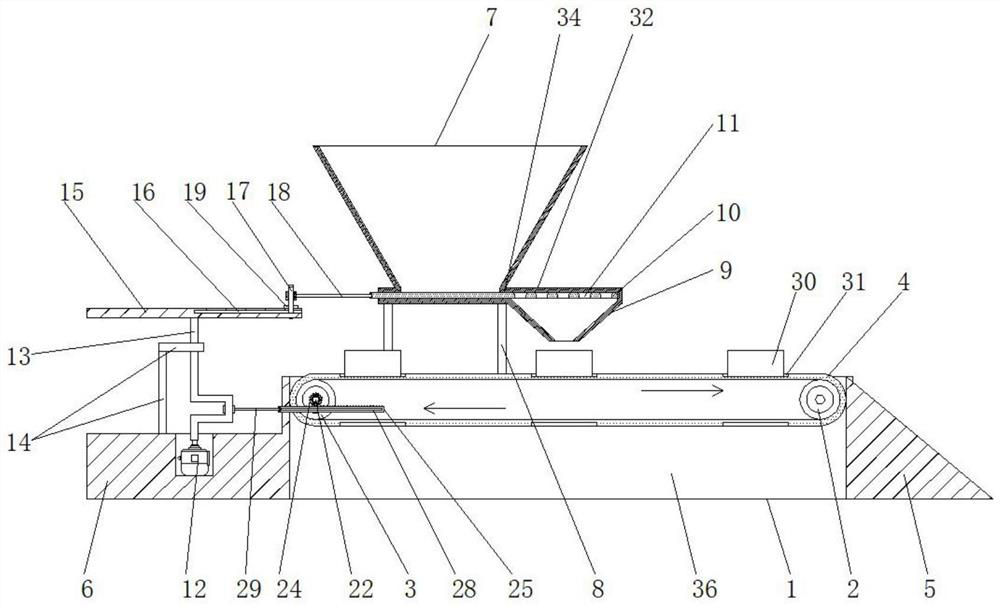

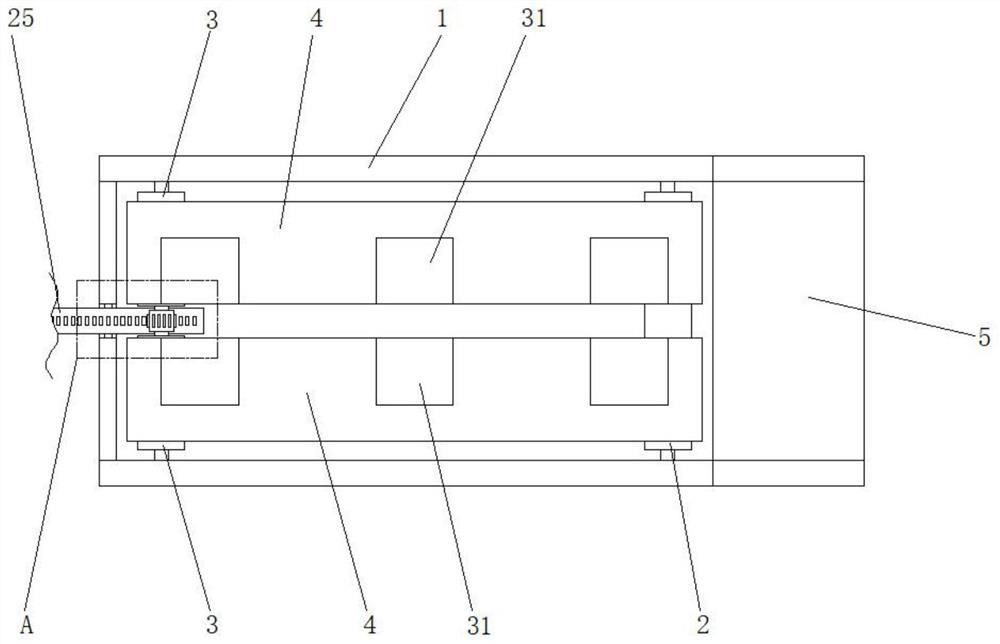

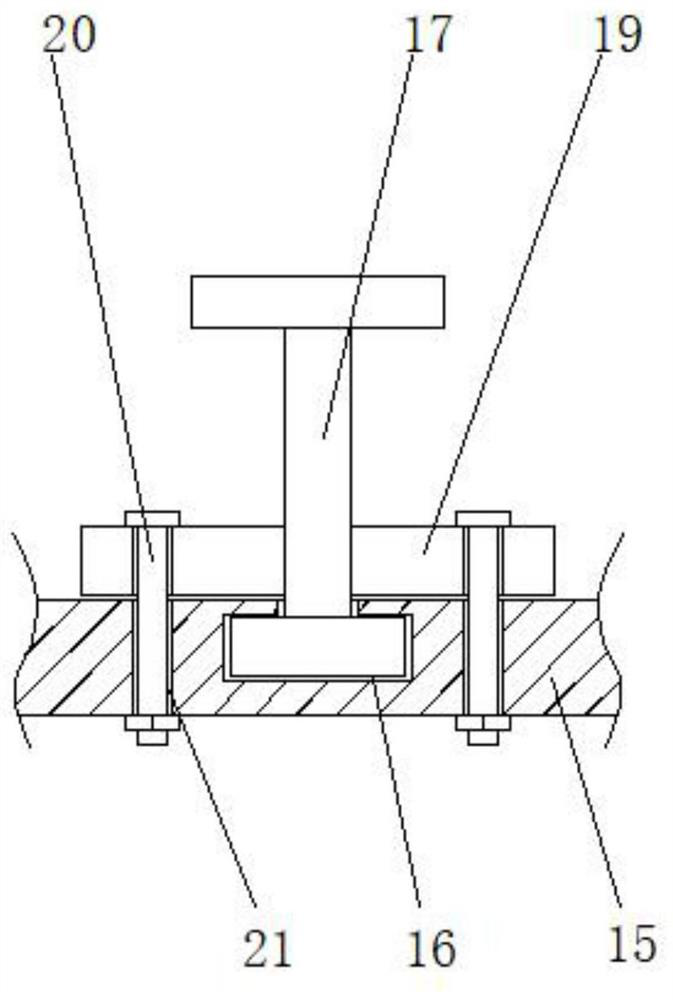

Bagged washing powder filling, sealing and packaging device

ActiveCN112078877ARealize intermittent transmissionRealize intermittent fillingPackage recyclingWrapper twisting/gatheringEngineeringMechanical engineering

The invention relates to a filling device, in particular to a bagged washing powder filling, sealing and packaging device. The bagged washing powder filling, sealing and packaging device is high in working efficiency, consistent in filling amount and capable of avoiding waste. The provided bagged washing powder filling, sealing and packaging device comprises a base plate, a conveying mechanism anda filling mechanism, wherein a fixing seat is arranged on one side of the top of the base plate, the conveying mechanism is arranged at the center of the top of the base plate, and the filling mechanism is arranged on the side, away from the conveying mechanism, of the fixing seat. An incomplete tooth gear and a first circular gear are meshed with each other to achieve intermittent conveyance ofwashing powder packaging bags. A fan-shaped material-discharging barrel rotates and cooperates with a funnel material-discharging opening to achieve intermittent filling of washing powder.

Owner:山东卓辰科技服务有限公司

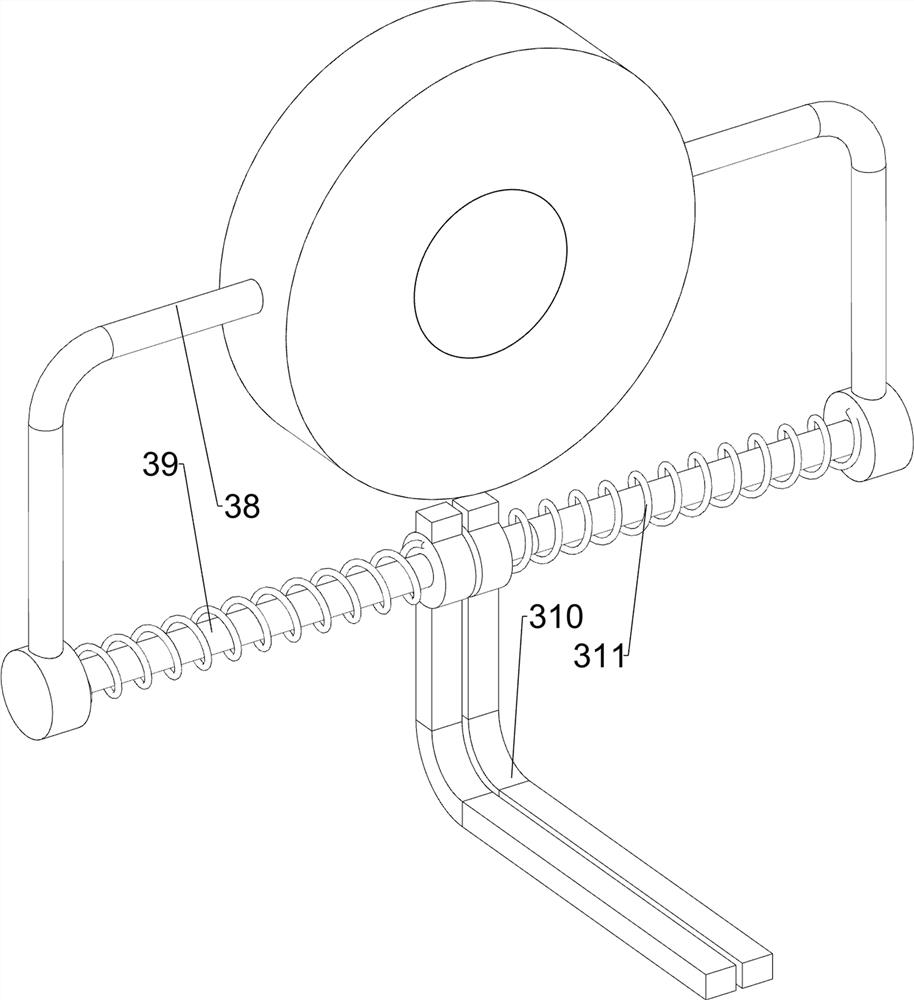

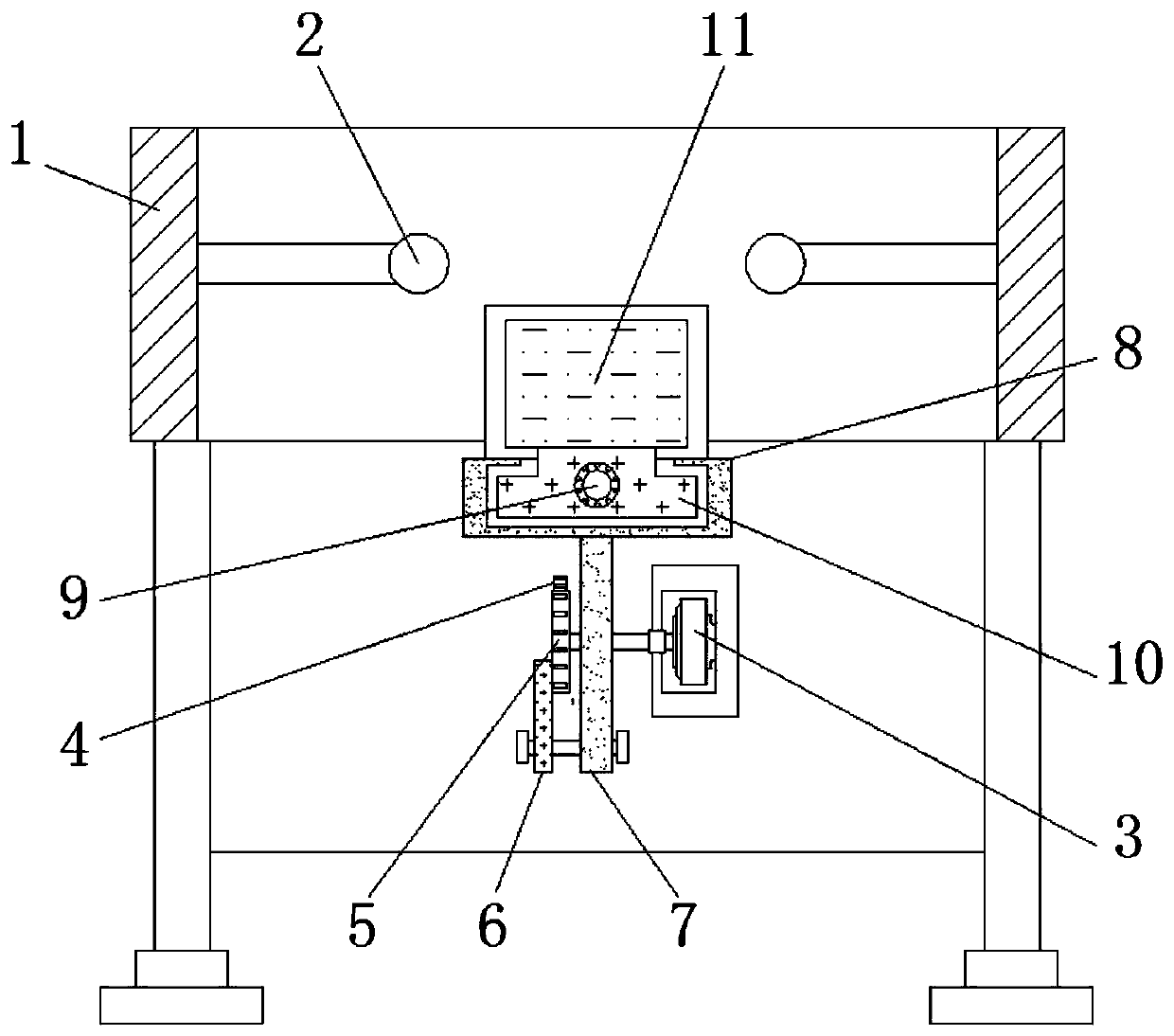

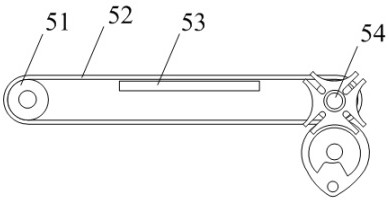

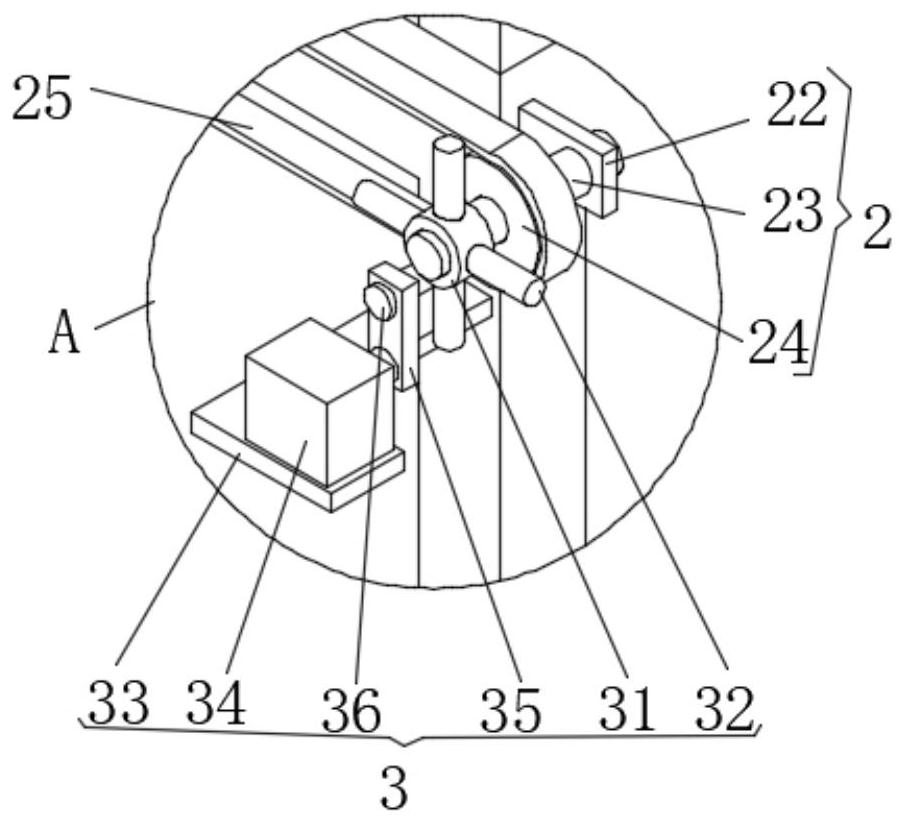

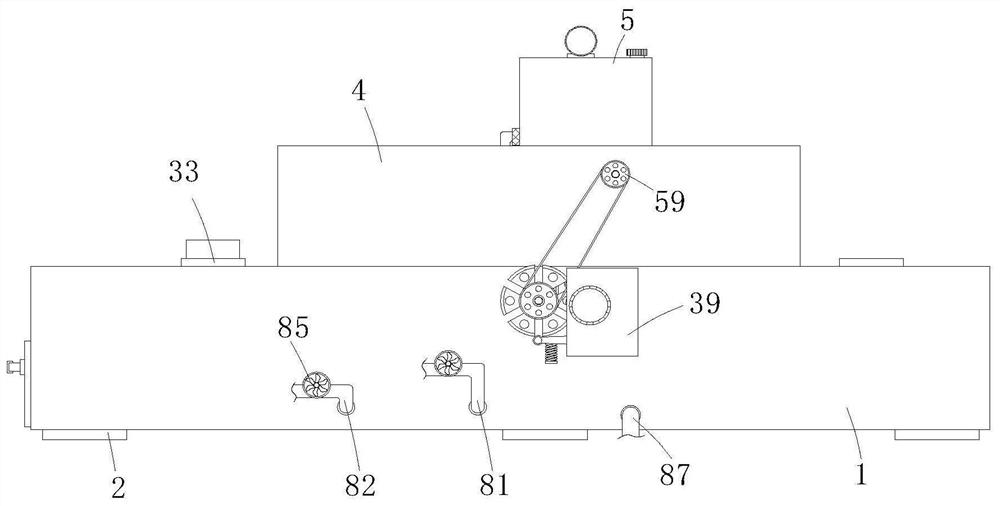

Automatic wire stripping and terminal crimping machine

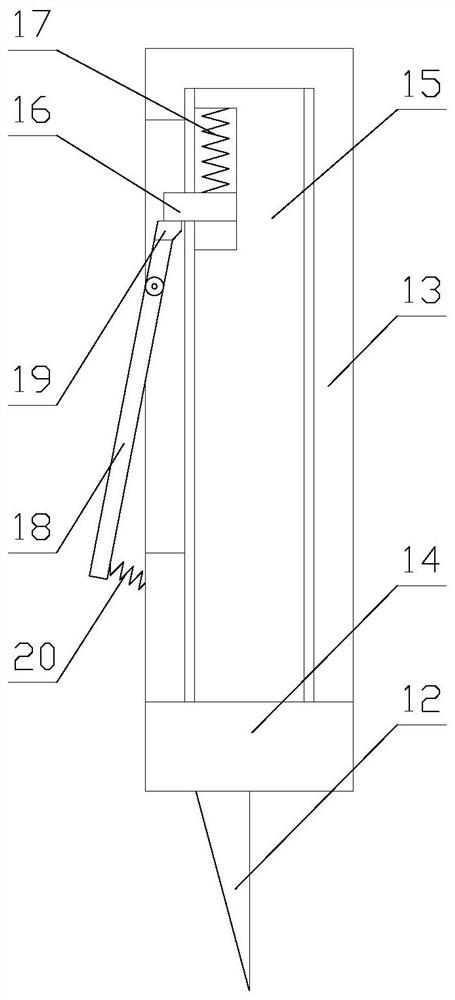

PendingCN110829139ARealize intermittent transmissionEasy to handleConnection formation by deformationRatchetWire rod

The invention relates to the technical field of automatic processing, in particular to an automatic wire stripping and terminal crimping machine. The machine comprises a machine table. A feeding mechanism is arranged on the machine table. The machine table is sequentially provided with a first cutting mechanism, a first stripping mechanism, a second cutting mechanism, a second stripping mechanism,a first terminal crimping mechanism, a branching mechanism and a second terminal crimping mechanism in the feeding direction of the feeding mechanism. The feeding mechanism comprises a driving assembly. The driving assembly comprises a connecting column, a feeding air cylinder, a hinge block, a ratchet wheel and a first pawl. The feeding air cylinder, the hinge block, the ratchet wheel and the first pawl are used as a driving assembly, so that intermittent transmission of a carrier is achieved, and wires can be conveniently controlled to be processed on the first cutting mechanism, the firststripping mechanism, the second cutting mechanism, the second stripping mechanism, the first terminal crimping mechanism, the branching mechanism and the second terminal crimping mechanism.

Owner:广东井岗智能精密有限公司

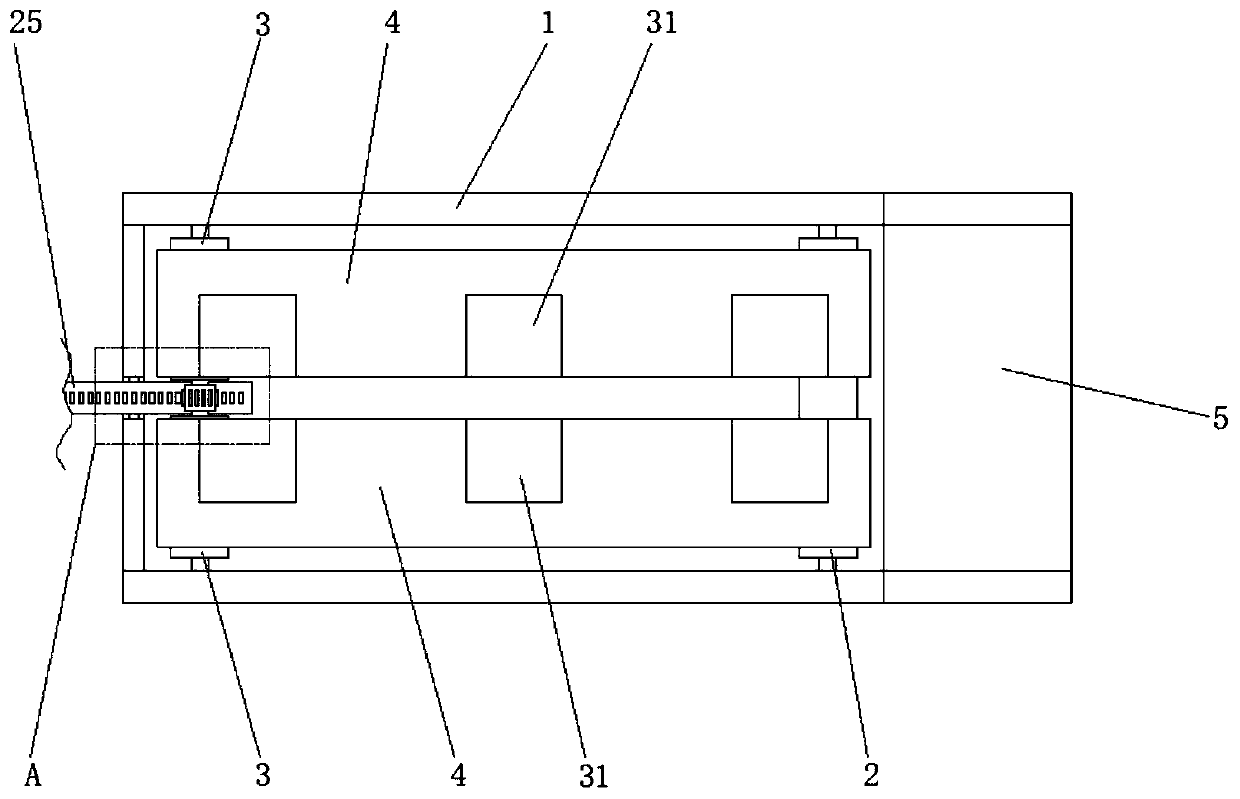

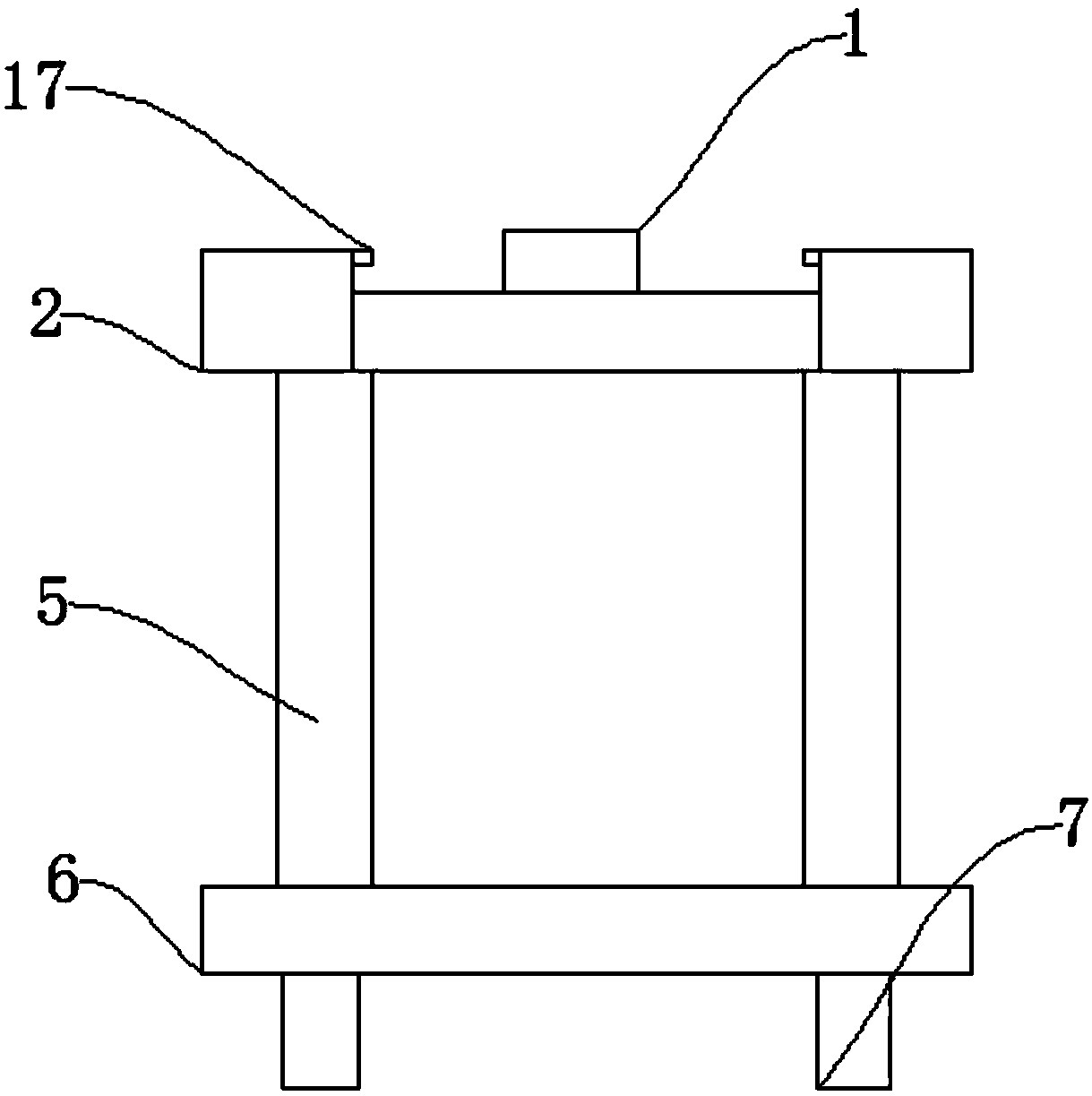

Automatic packaging delivery device for e-commerce

ActiveCN111114918AQuality impactRealize intermittent transmissionPackagingStructural engineeringMaterial storage

The invention discloses an automatic packaging delivery device for e-commerce, and belongs to the technical field of e-commerce packaging. The automatic packaging delivery device comprises a base, a material storage trough and supporting columns, the base is horizontally arranged, the supporting columns which are symmetrical with respect to a horizontal center line of the base are arranged at thebottom end of the material storage trough, and the material storage trough is erected over the base through the supporting columns; and a baffle extending rightwards horizontally is arranged at the bottom end of the material storage trough, and a regulating plate parallel to the baffle is arranged inside the baffle. Under slidable connection fit of a connecting block and a sliding groove, throughconnection between screw rods on fixing blocks and bolt holes in different positions, the number of discharging lines of material guiding openings in a material receiving area is regulated, in this way, the number of one-time boxing of the packaging device is regulated, thus the device can precisely regulate and control the material discharging amount according to the demand for the packaging number of boxes in each time, and the influence of the different numbers of spherical materials in the same-batch boxes on the boxing quality of the device is reduced.

Owner:江西环境工程职业学院

Bar code printer with online cutting function

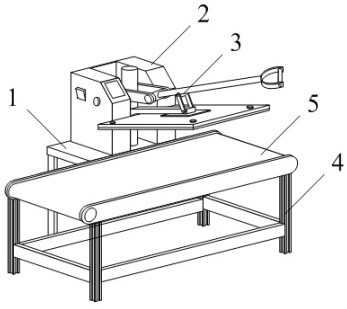

ActiveCN113334938AWith online cutting functionRealization of online cuttingOther printing apparatusComputer printingKnife blades

The invention relates to a bar code printer with the online cutting function, which comprises a support, a driving mechanism, a printing mechanism and a cutting mechanism. The driving mechanism, the printing mechanism and the cutting mechanism are all arranged on the support; the printing mechanism comprises a printing assembly and a limiting assembly; the cutting mechanism comprises a moving assembly and a cutting assembly; and the driving mechanism comprises a driving assembly and a linkage assembly. According to the bar code printer with the online cutting function, the printing mechanism and the cutting mechanism are driven by the driving mechanism to operate intermittently, so that intermittent conveying and cutting of paper sheets are implemented; printing is implemented through a main body; the device implements the operation of the printing mechanism and the cutting mechanism through one output end; energy is saved; meanwhile, linkage is adopted, so that online cutting of printing paper is implemented; and the linkage adopts a purely mechanical structure, so that stability of the device is improved and the service life of the device is prolonged. Compared with an existing cutting mechanism, the mechanism can implement assembling and disassembling of a blade by simple pressing, and is simple and convenient to operate.

Owner:WUHAN JINGCHEN INTELLIGENT IDENTIFICATION TECH CO LTD

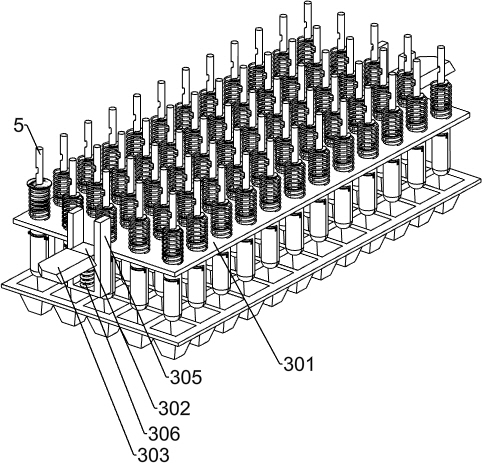

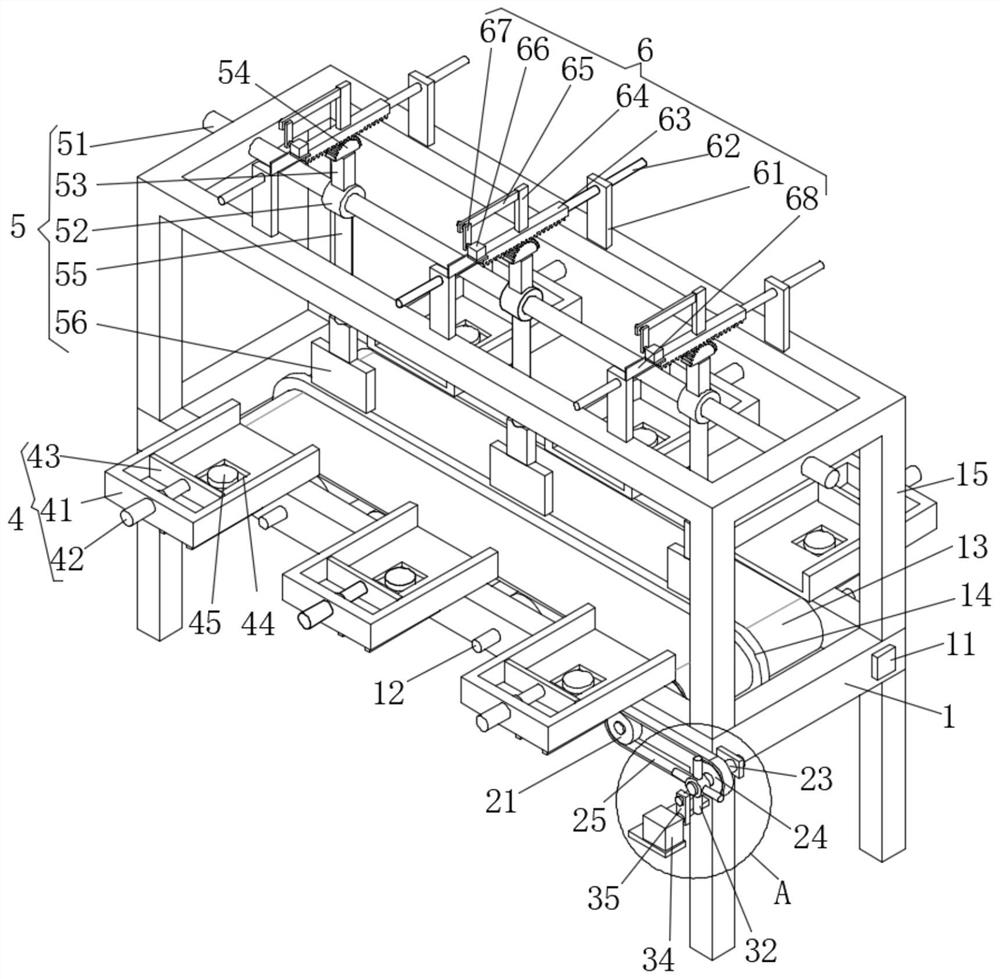

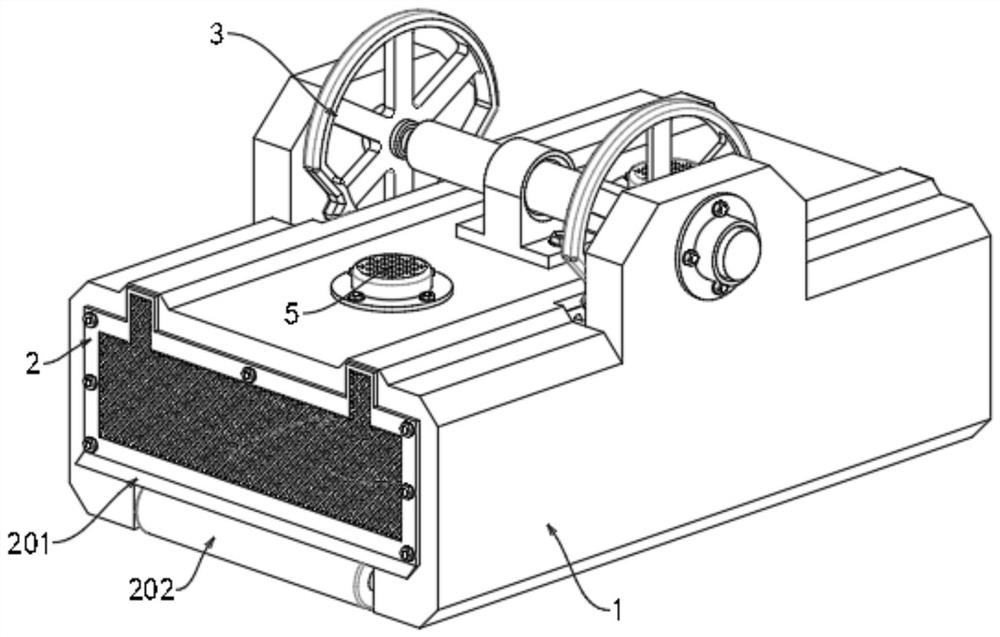

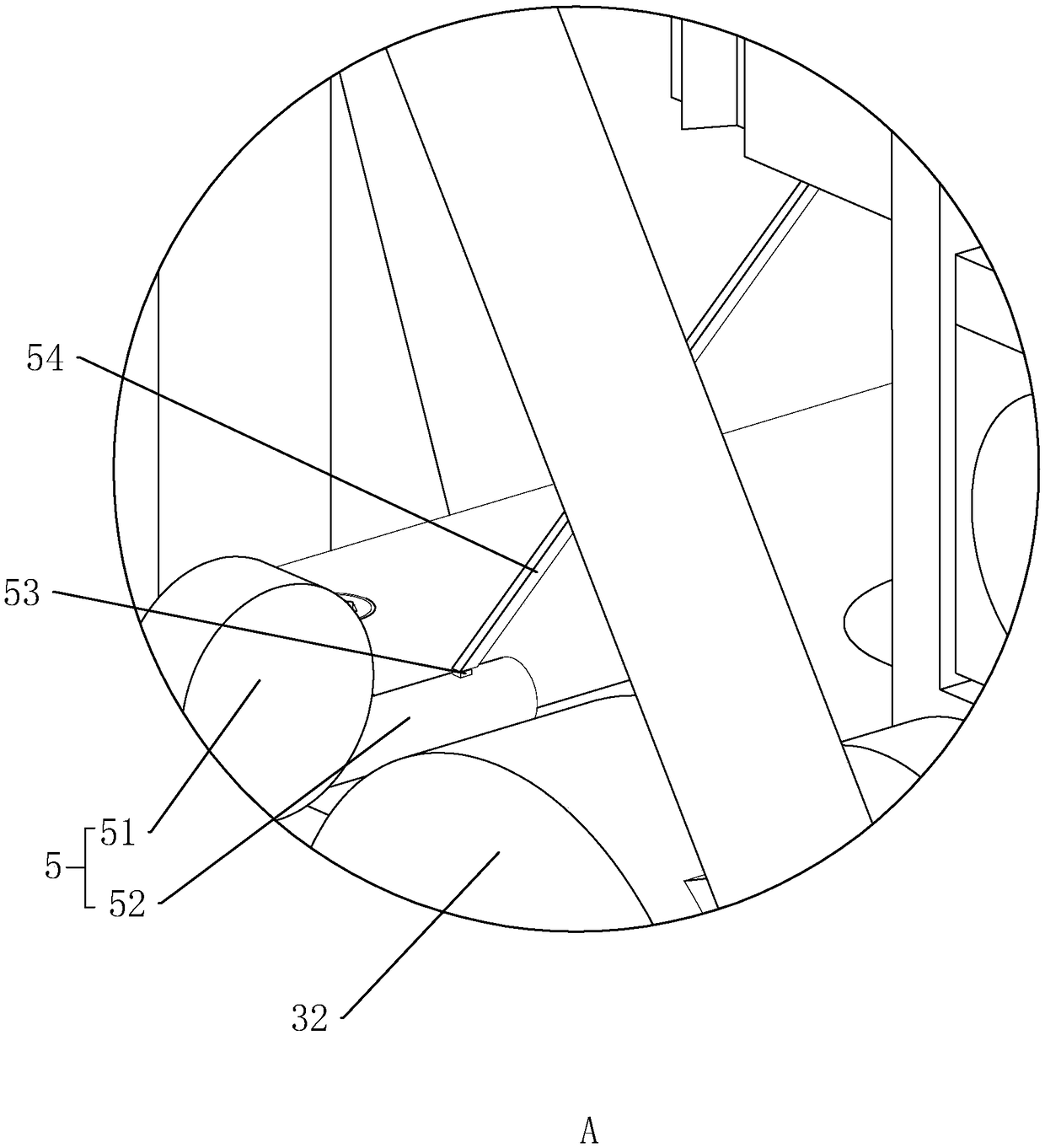

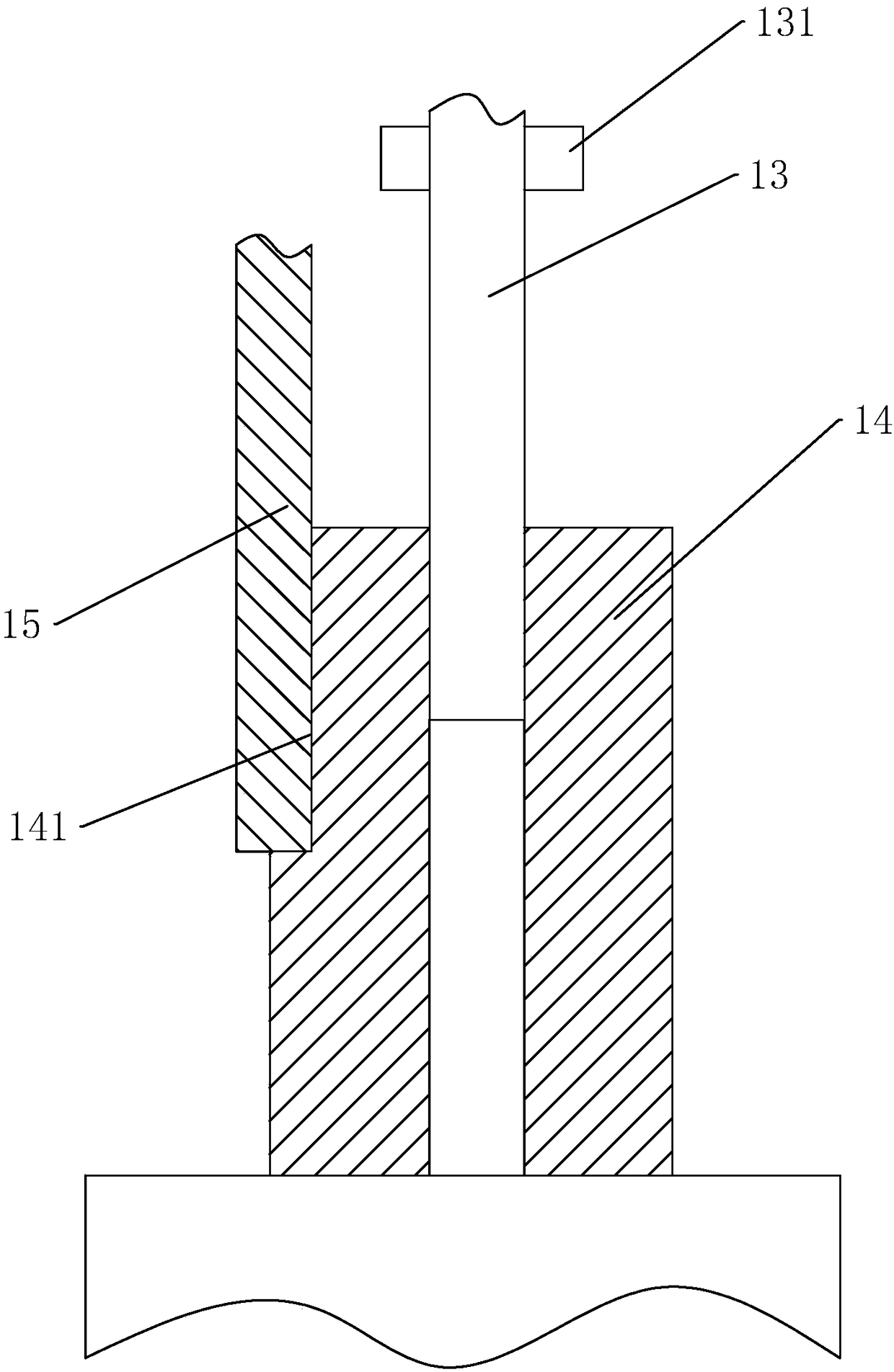

Vegetable seedling raising device capable of automatically, accurately and quantitatively seeding

ActiveCN113079760AGuaranteed germination ratePrevent feePlantingDibble seedersAgricultural engineeringEnvironmental geology

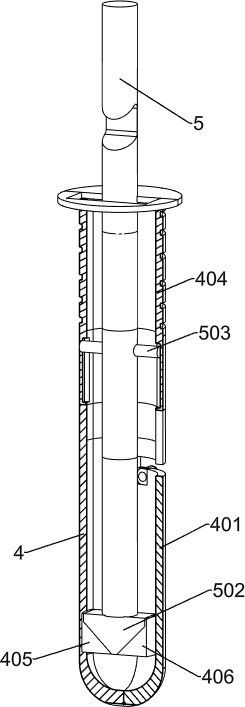

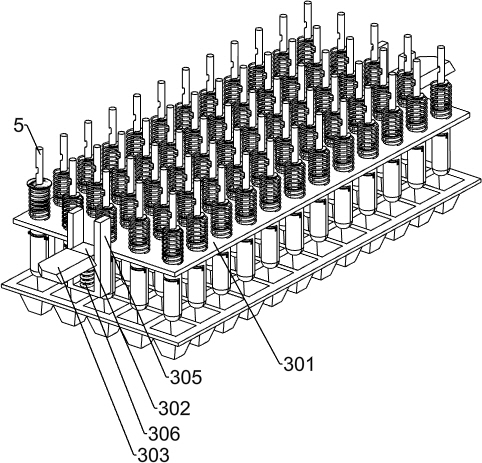

The invention relates to a vegetable seedling raising device, in particular to a vegetable seedling raising device capable of automatically, accurately and quantitatively seeding. In order to solve the technical problem, the vegetable seedling raising device which is high in working efficiency and capable of automatically and accurately controlling the accurate depth of nutrition pit pressing and accurately and quantitatively seeding is provided. According to the technical scheme, the vegetable seedling raising device capable of automatically, accurately and quantitatively seeding comprises a supporting frame and the like; wherein the supporting frame comprises a front support, a rear support, two first supports, two second supports, two third supports and two transverse connecting plates, the front support and the rear support are symmetrically arranged front and back, the lower ends of the two first supports are fixedly connected to the outer sides of the upper portions of the front support and the rear support respectively, and the lower ends of the two second supports are fixedly connected to the outer sides of the upper portions of the front support and the rear support respectively. The device achieves the effect that vegetable seeds are accurately and quantitatively scattered and sown in seedling raising trays through a downward pressing mechanism, a hole pressing mechanism and a seeding mechanism.

Owner:湖南康之源农业发展有限公司

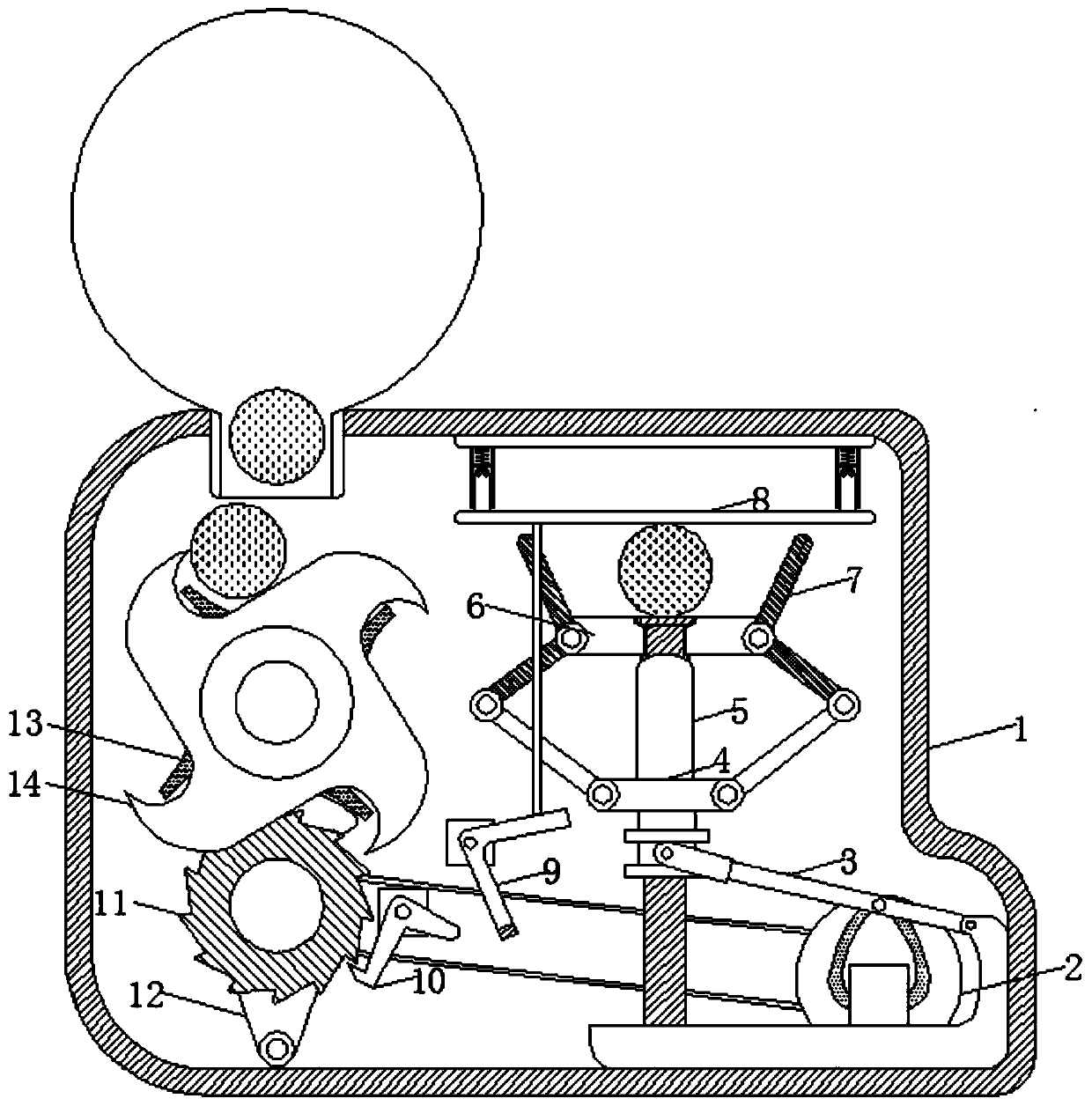

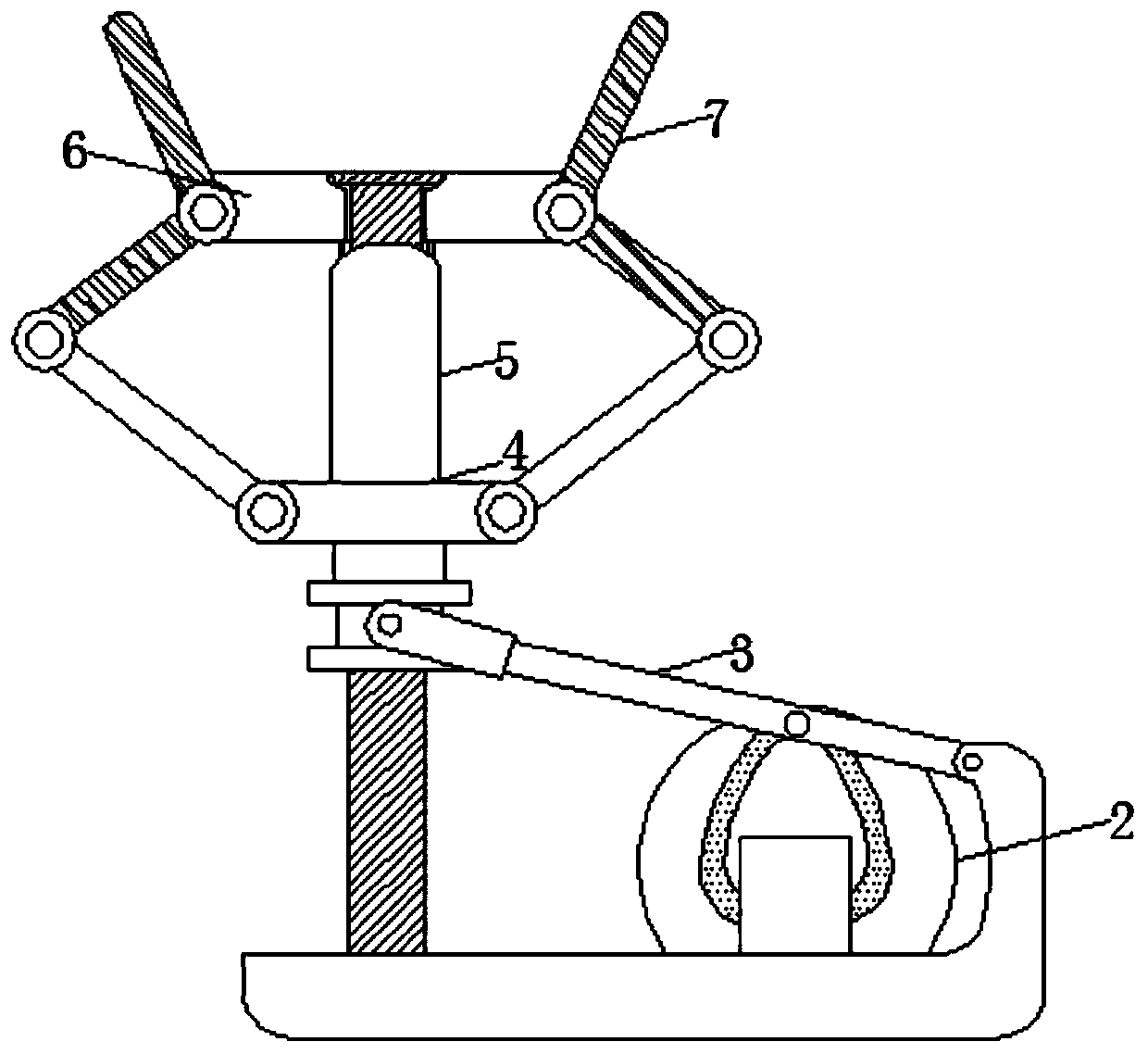

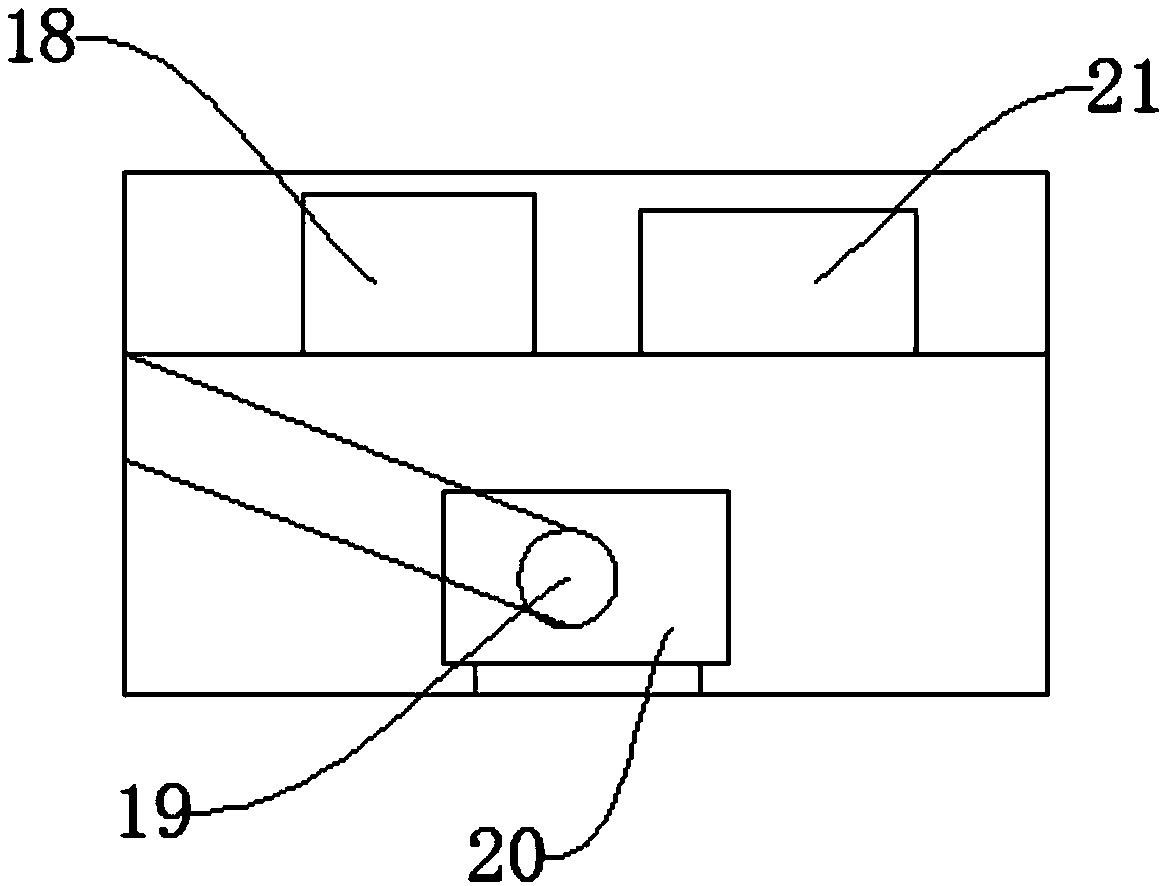

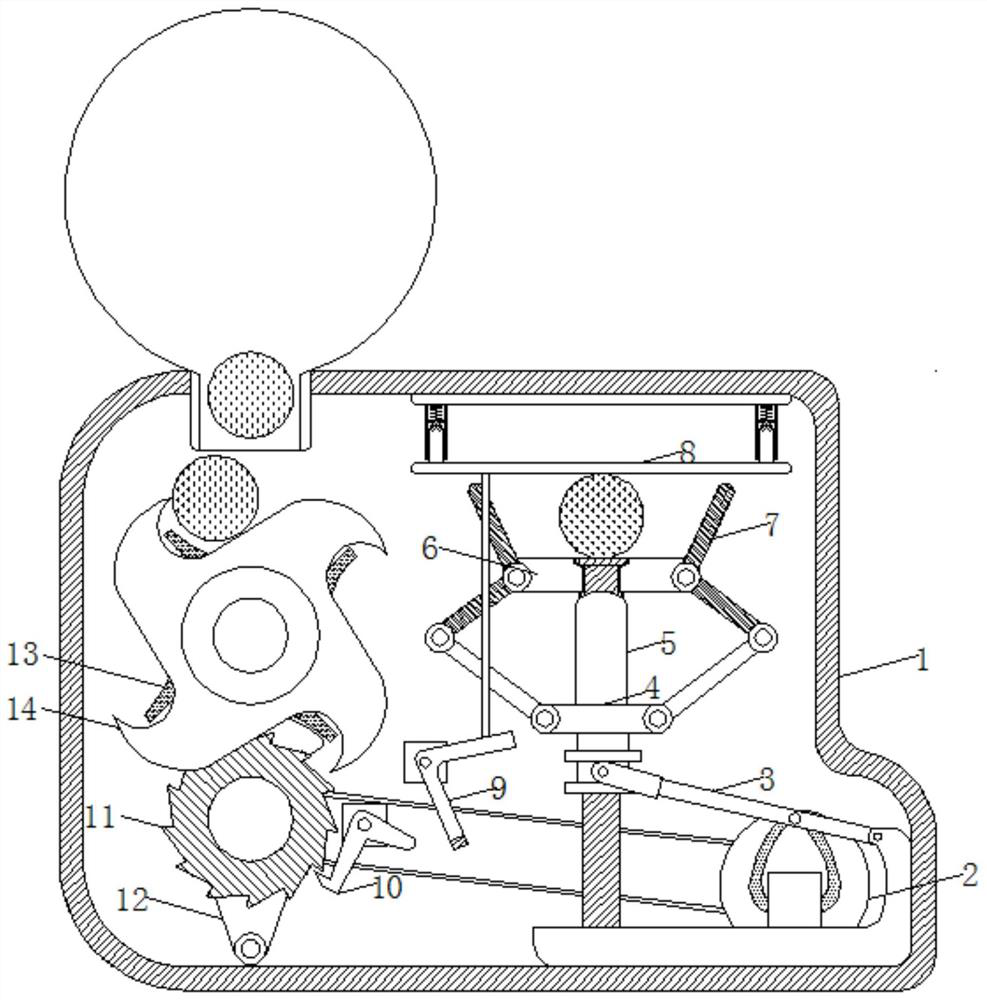

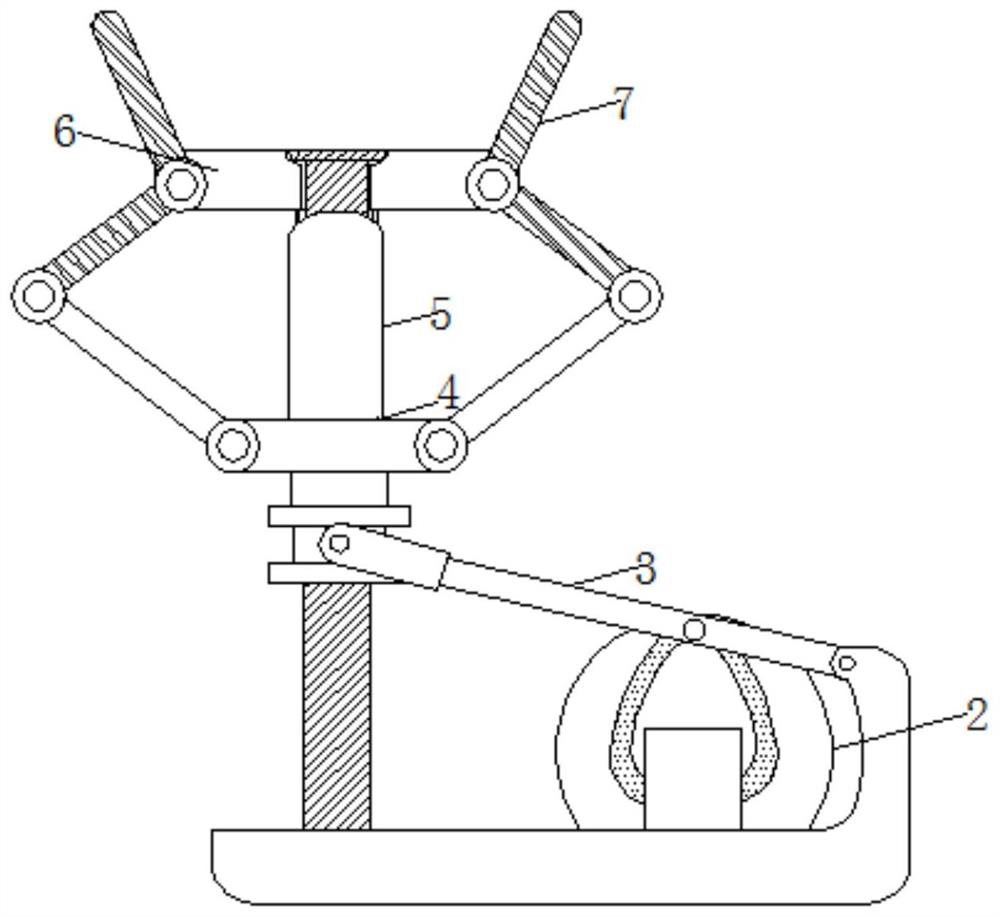

Spherical daily use article vending machine capable of automatically replenishing articles according to article storage condition

The invention relates to the technical field of daily used articles and discloses a spherical daily use article vending machine capable of automatically replenishing articles according to the articlestorage condition. The spherical daily use article vending machine comprises an outer shell. A first rotary disk is movably connected to the interior of the outer shell. A pressing plate moves downwards to drive a clamping bar to get away from a ratchet wheel. After articles are taken down, the machine is automatically started to drive a rotary plate to rotate to enable a transfer plate to do 90-degree intermittent rotation. The transfer plate automatically falls under the action of gravity of the articles to convey the articles. The spherical daily use article vending machine realizes intermittent conveying of the articles and automatically replenishes the articles. The first rotary disk rotates to drive a sleeve block to move up and down to cause first rotary rods to get close to each other to limit the articles and enable a carrying platform to move up to the highest position. The position of the articles is adjusted automatically. The situation that the arrangement tidiness of thearticles is reduced due to position deviation is avoided. Moreover, the spherical daily use article vending machine can automatically fix the articles to prevent the articles from moving, enables thearticles to be located at a delivery port to facilitate taking. The situation that excessive articles are arranged simultaneously and get disordered is avoided.

Owner:上海世柯仓储设备工程有限公司

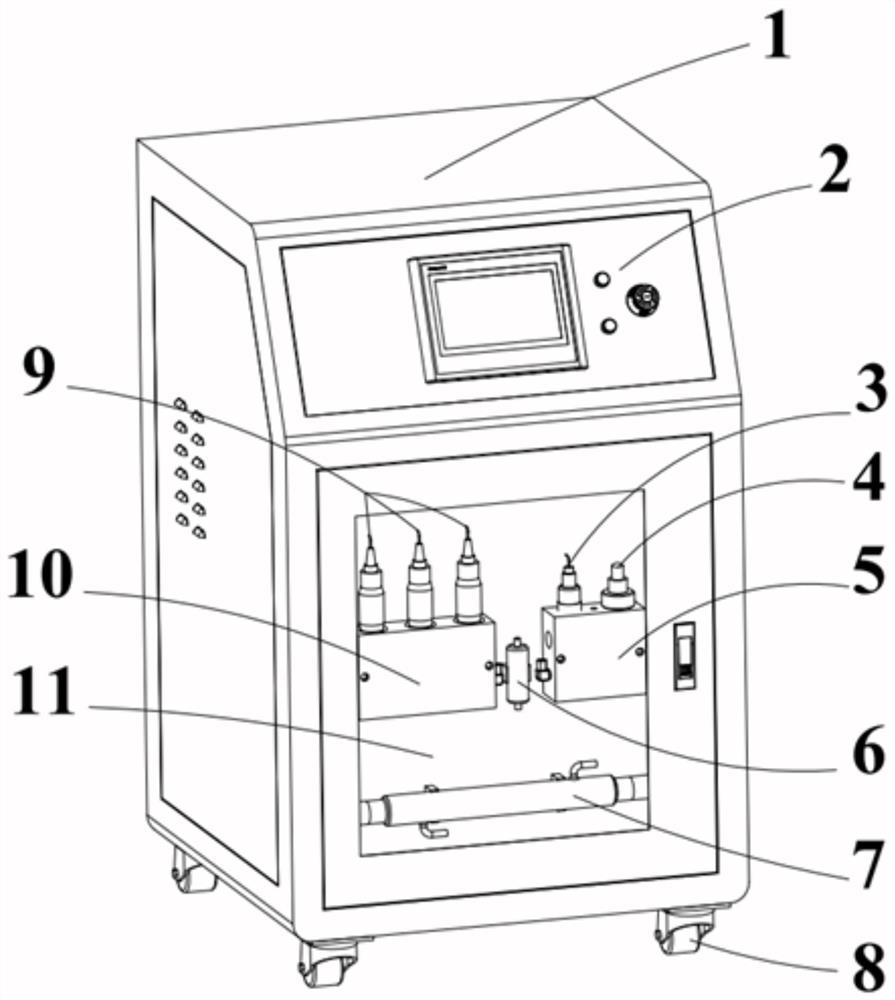

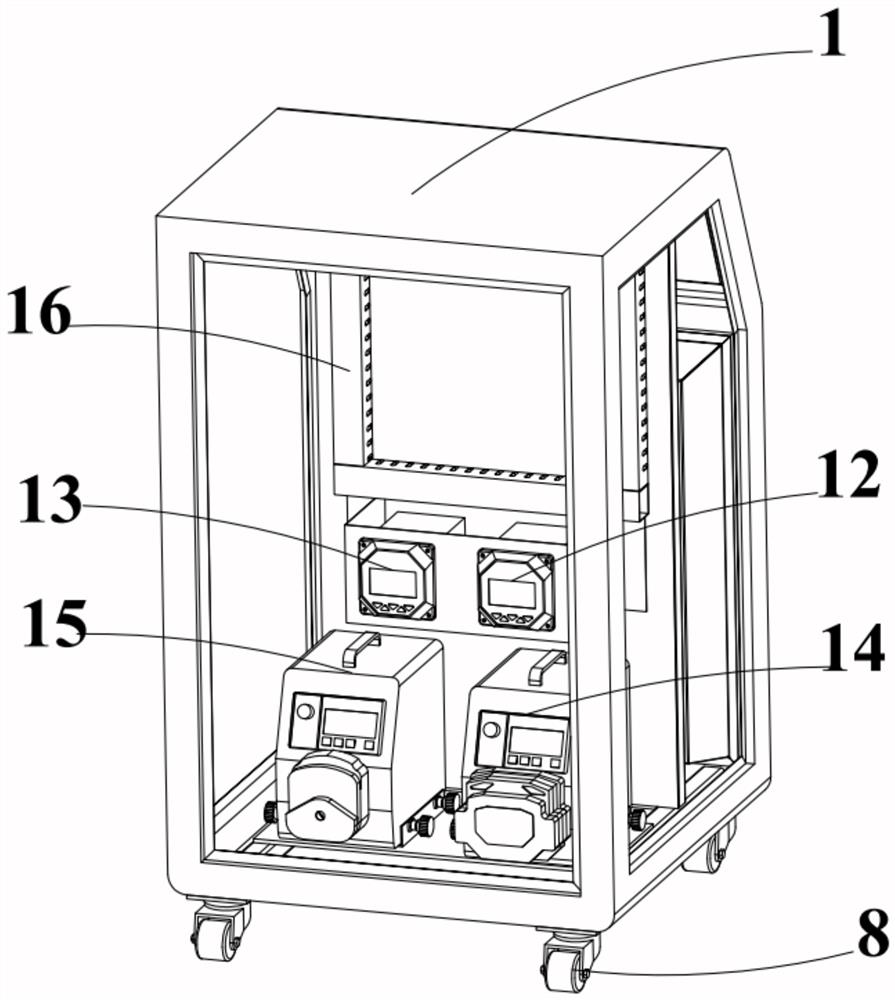

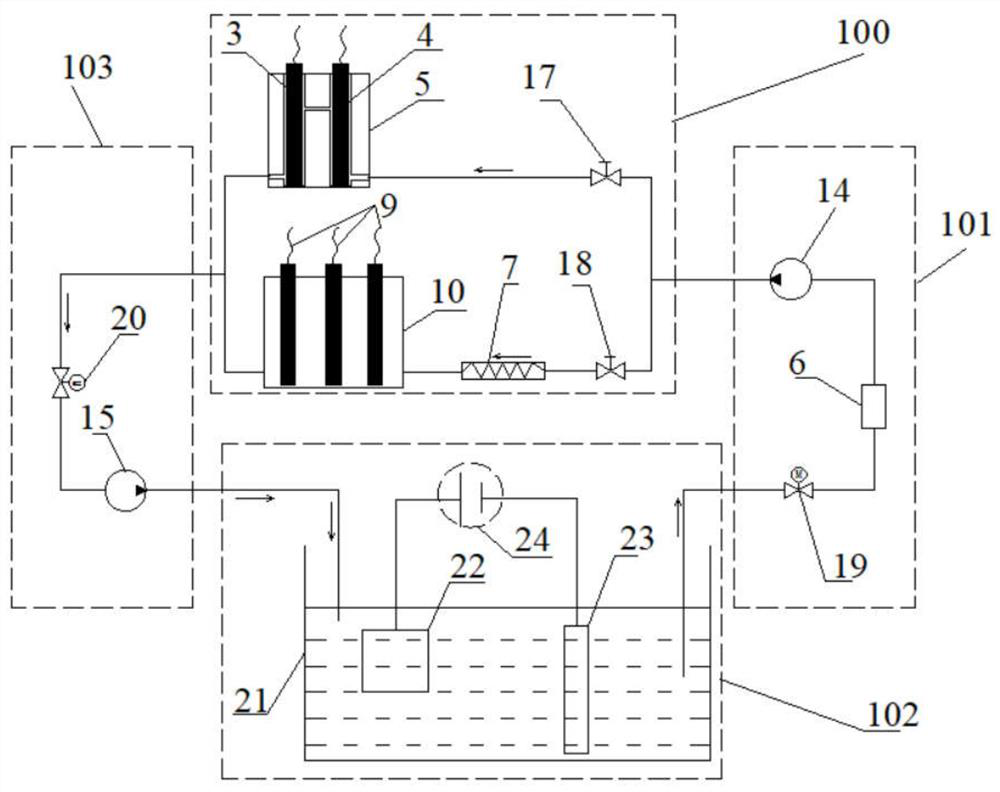

Real-time solution detection equipment and method

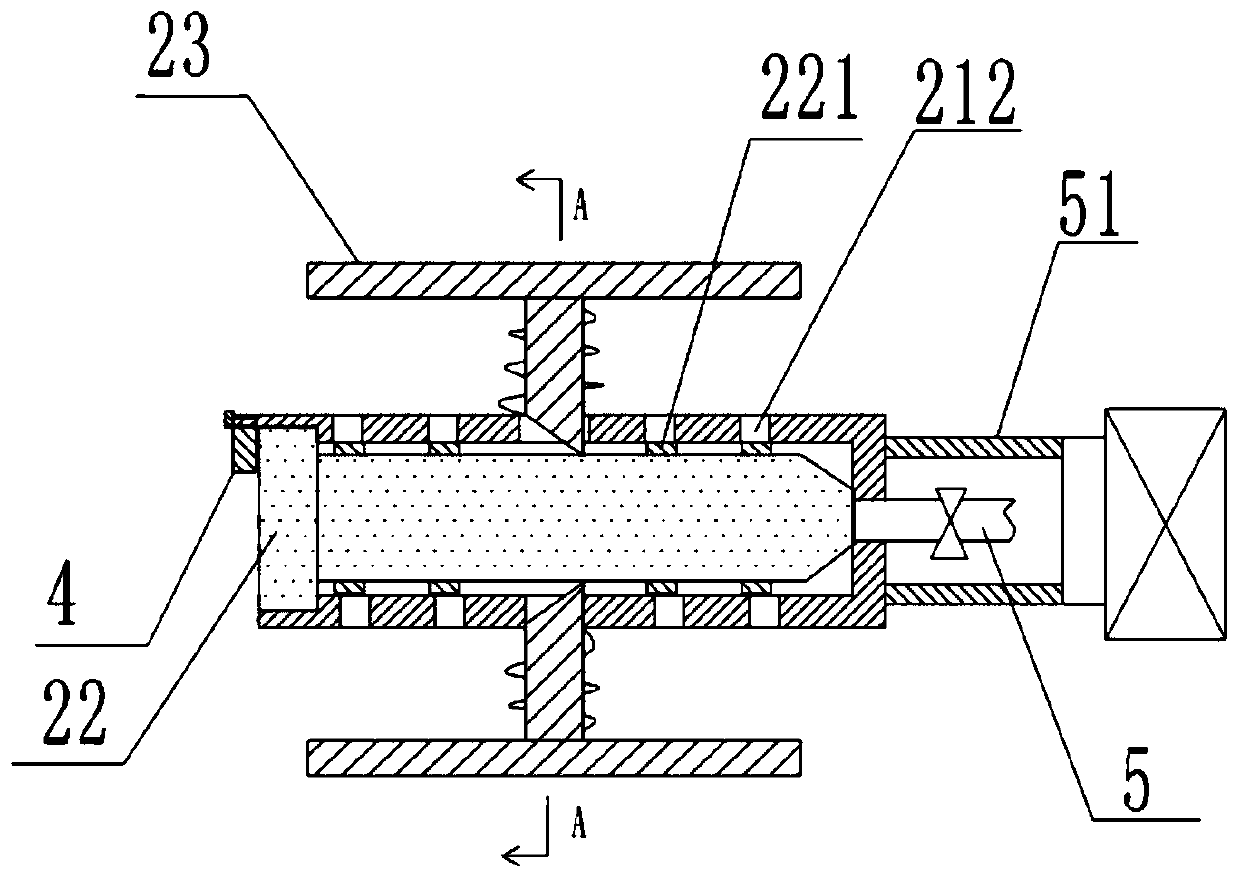

PendingCN112630277ARealize intermittent transmissionNo currentMaterial resistanceMaterial electrochemical variablesPeristaltic pumpProcess engineering

The invention provides real-time solution detection equipment and a real-time solution detection method, the real-time solution detection equipment is externally connected with an electromachining system or a waste liquid treatment system, the real-time solution detection equipment comprises an equipment shell, a controller, a solution detection system, a liquid conveying system and a liquid return system, the liquid return system and the liquid conveying system are both provided with distribution filling type peristaltic pumps, and the solution detection system is provided with a heat exchange cooling pipe. The phenomenon that a detection sensor is damaged due to direct measurement in the electromachining solution containing current is avoided, parameters of the electromachining solution can be continuously, accurately and effectively detected on line in real time so that the parameters can be adjusted in time when deviating, it is guaranteed that the production process is stable and controllable, and the precision of the electromachining solution is improved; the equipment and method can be applied to industrial production, improve the production quality, can also be applied to scientific research experiments, and provide an experiment detection platform for research of a processing mechanism; and waste liquid generated after processing can be discharged after treated effluent waste liquid reaches the standard, and environmental pollution caused by poor treatment is avoided.

Owner:GUANGDONG UNIV OF TECH

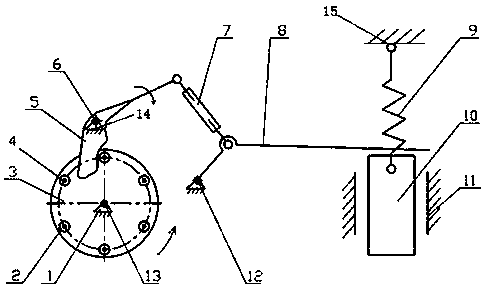

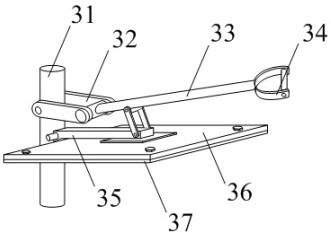

Intermittent linear power mechanism with cam pushed by rollers to move

ActiveCN108071763ARealize long-distance linear transmissionRealize intermittent transmissionGearingDrive shaftLap joint

The invention relates to the field of intermittent power mechanisms, and discloses an intermittent linear power mechanism with a cam pushed by rollers to move. The intermittent linear power mechanismcomprises a driving shaft, a rotary disc, the rollers and the cam. The rotary disc is mounted on the driving shaft. The rollers are evenly distributed on the rotary disc in the circumferential direction. A driven shaft is arranged above the rotary disc. The cam is mounted on the driven shaft. In the movement process of the rotary disc, the roller intermittently makes contact with the cam; the freeend of the cam is connected with the upper end of a turnbuckle, and the lower end of the turnbuckle is connected with the front section of a rocker; the front end of the rocker is mounted on a supporting shaft, and the rear end of the rocker is in lap joint with a sliding block; and the sliding block is connected with the lower end of a spring, and the upper end of the spring is fixed to a thirdrack. By adoption of the intermittent linear power mechanism with the cam pushed by the rollers to move, the problem that in the prior art, a cam type intermittent mechanism cannot directly provide linear power for an actuator under a long-distance condition is solved.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

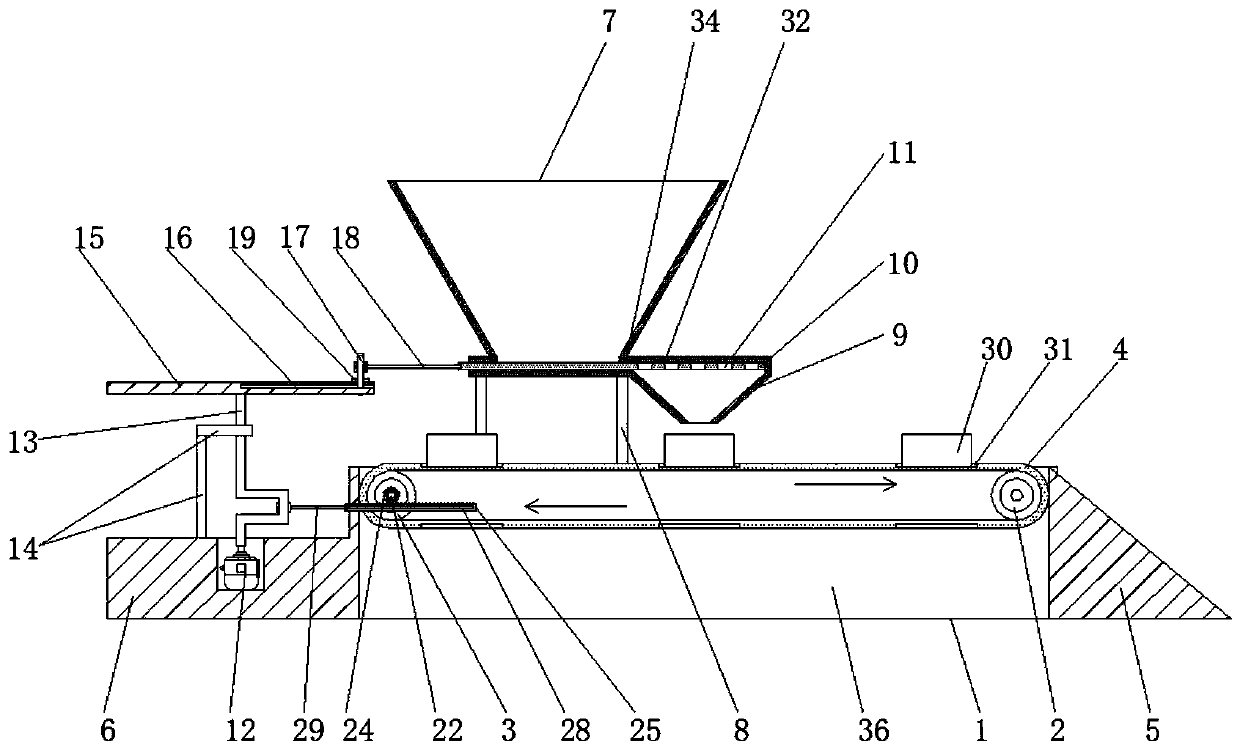

Automatic weighing and packaging machine

InactiveCN111409883ARealize intermittent transmissionHigh precisionCleaningSolid materialStructural engineeringDrive motor

The invention discloses an automatic weighing and packaging machine which comprises a machine body, a driving motor, a conveying belt and an automatic weighing and feeding device. A placement frame isfixed to the left side of the machine body, the driving motor is installed below the placement frame, the output end of the driving motor is connected with a first connecting block, and second connecting blocks are arranged on the outer side of the first connecting block; and an adjusting rod is connected to the lower portion of each second connecting block, a fixing plate is fixed to the top ends of supporting rods, connecting pieces are arranged on the outer side of a threaded rod, the conveying belt is installed on the right side of the machine body, the automatic weighing and feeding device is installed behind the conveying belt, a fixing rod is installed on the left side of a flow guide plate, and a collecting cylinder is arranged below the flow guide plate. According to the automatic weighing and packaging machine, intermittent conveying of packaging boxes can be achieved, the feeding and packaging precision is high, packaging boxes of different sizes are fixedly clamped, the conveying stability is high, and scattered materials can be conveniently recycled.

Owner:中山市星科自动化设备有限公司

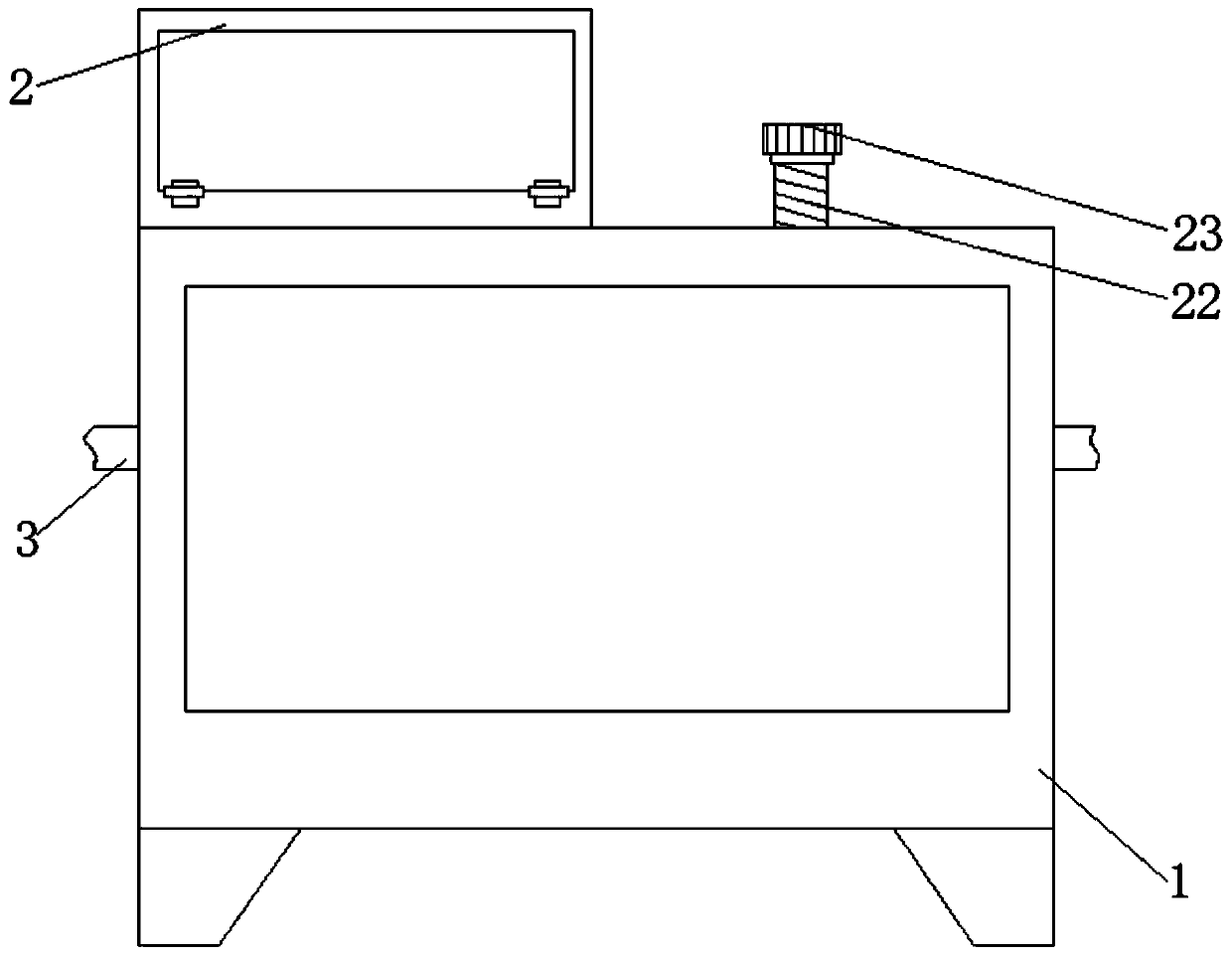

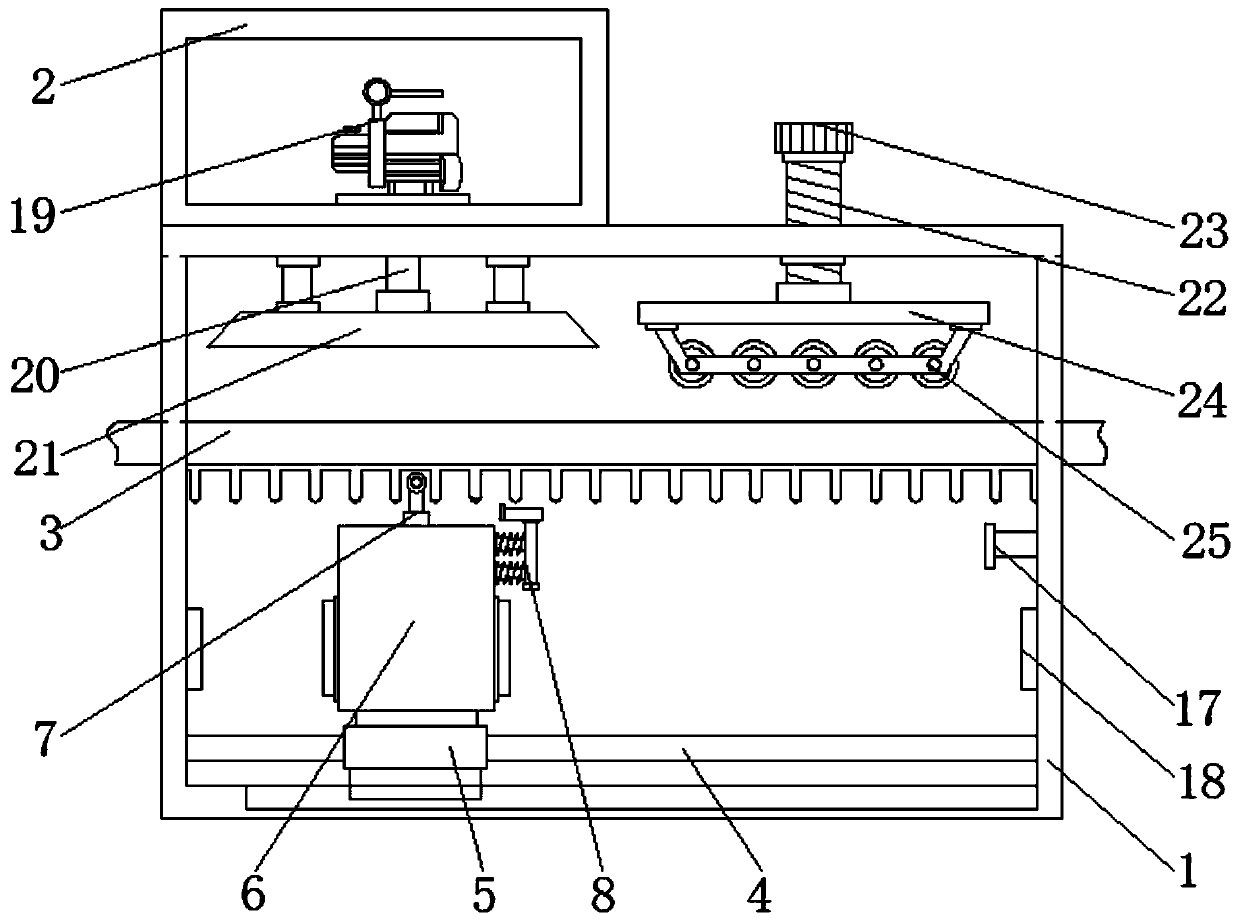

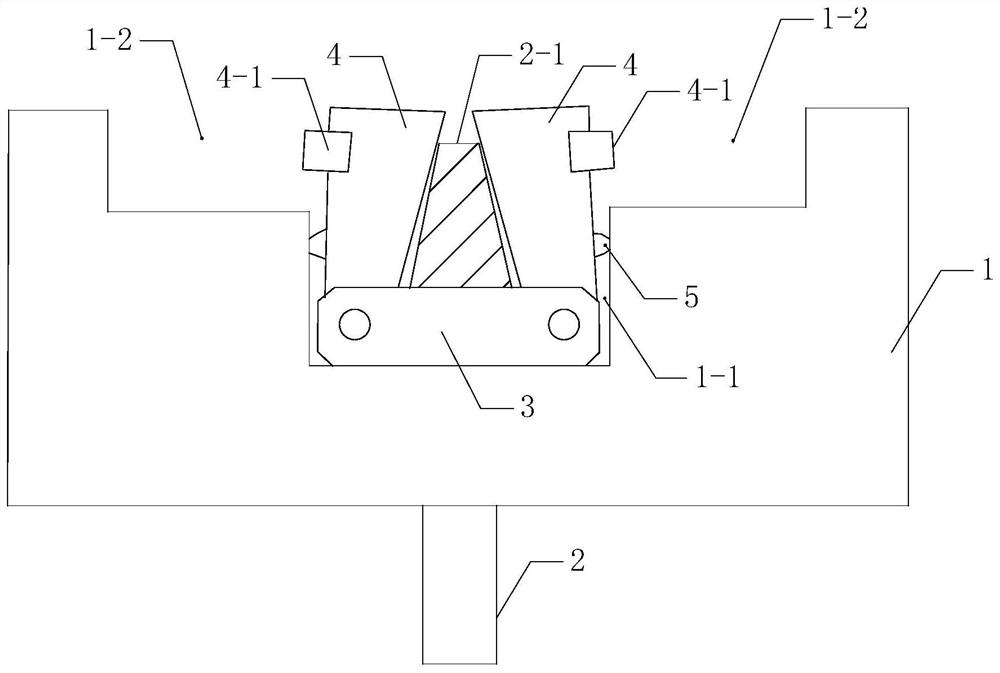

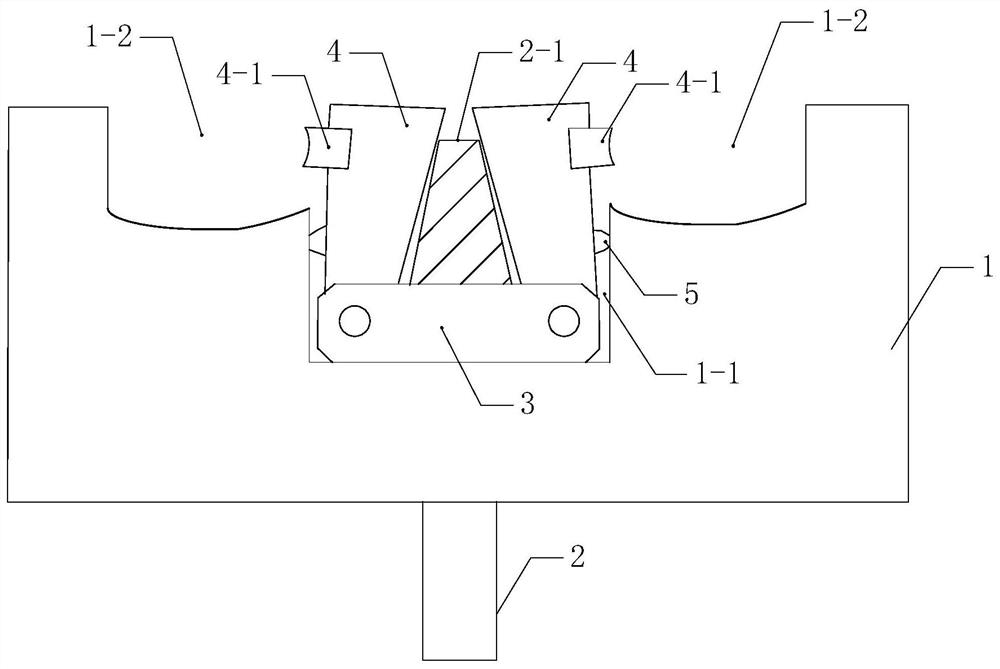

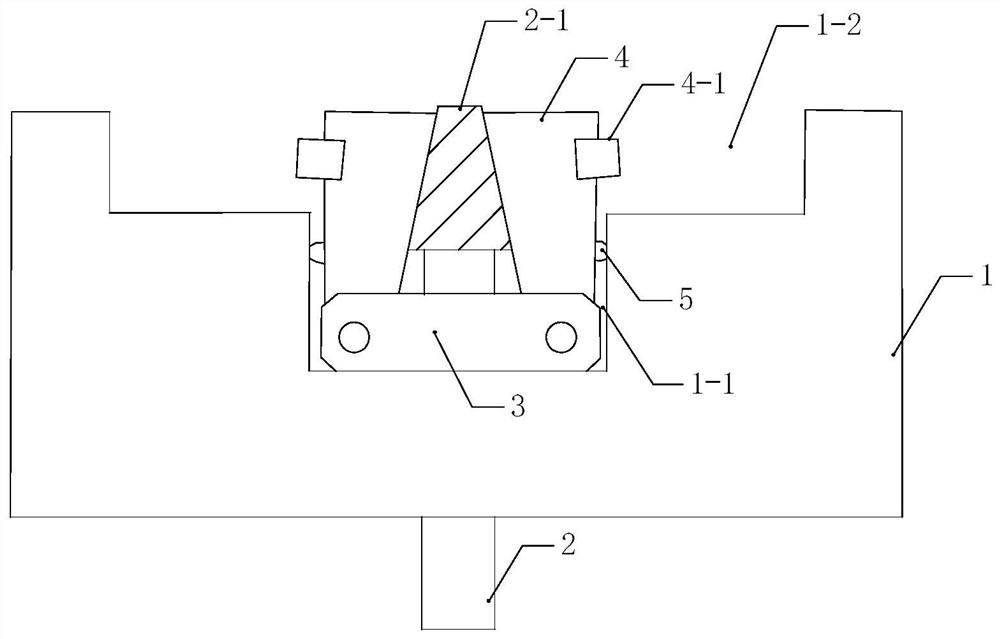

Discontinuous transmission device provided with brake mechanism and used for mask production line

ActiveCN104960899ARealize intermittent transmissionImprove braking effectConveyor partsProduction lineDrive wheel

The invention discloses a discontinuous transmission device provided with a brake mechanism and used for a mask production line. The discontinuous transmission device is characterized in that the discontinuous transmission device comprises the brake mechanism, a driving wheel, a transmission wheel and a cam, the left end of the brake mechanism rotates around a second shaft pin to be connected, a pressure spring is arranged at the upper end of the brake mechanism, a pressure spring mounting plate is arranged at the upper end of the pressure spring and connected with the brake mechanism through the pressure spring, the transmission wheel is arranged at the right end of the brake mechanism, the driving wheel is arranged above the transmission wheel, the cam is arranged below the transmission wheel, and the driving wheel and the cam rotate around a first rotary shaft and a second rotary shaft respectively to be connected. According to the discontinuous transmission device provided with the brake mechanism and used for the mask production line, full-automatic production is achieved, production efficiency is high, labor is liberated greatly, production cost is lowered, and market competitiveness is improved.

Owner:ZHEJIANG JIANDE CHAOMEI DAILY CHEM

A vegetable seedling raising device that can automatically and accurately and quantitatively plant

ActiveCN113079760BAffect germination rateGuaranteed germination ratePlantingDibble seedersAgricultural engineeringPlanting seed

The invention relates to a vegetable seedling raising device, in particular to a vegetable seedling raising device that can automatically and accurately and quantitatively plant. Technical problem: to provide a vegetable seedling raising device with high work efficiency, which can automatically and accurately control the accurate depth of the nutrient pressure pit and accurately and quantitatively plant. The technical solution is as follows: a vegetable seedling raising device that can automatically and accurately and quantitatively plant seeds, including a support frame and the like; the support frame includes a front support, a rear support, a first support, a second support, a third support and a horizontal connecting plate. The brackets and the rear brackets are symmetrically arranged in the front and rear, the first bracket, the second bracket, the third bracket and the horizontal connecting plate are all arranged in two, the lower ends of the two first brackets are respectively fixedly connected to the upper outer sides of the front bracket and the rear bracket, and the two The lower ends of the second brackets are respectively fixed and connected to the upper outer sides of the front bracket and the rear bracket. The present invention achieves the effect that the present invention realizes accurate and quantitative sprinkling of vegetable seeds in the seedling tray through the pressing mechanism, the pressing hole mechanism and the seeding mechanism.

Owner:湖南康之源农业发展有限公司

A bar code printer with online cutting function

ActiveCN113334938BWith online cutting functionRealization of online cuttingOther printing apparatusComputer printingBarcode

The invention relates to a barcode printer with an online cutting function, comprising a bracket, a driving mechanism, a printing mechanism and a cutting mechanism, the driving mechanism, the printing mechanism and the cutting mechanism are all arranged on the bracket, the printing mechanism includes a printing component and a limit component, the cutting The mechanism includes a moving component and a cutting component, and the driving mechanism includes a driving component and a linkage component. The barcode printer with online cutting function drives the printing mechanism and the cutting mechanism to run intermittently through the driving mechanism, so as to realize the intermittent transmission and cutting of paper sheets. Through the main body To achieve printing, the device realizes the operation of the printing mechanism and the cutting mechanism through one output end, which saves energy. At the same time, it adopts linkage to realize online cutting of printing paper, and the linkage adopts a purely mechanical structure, which improves the stability and stability of the device. Compared with the existing cutting mechanism, the mechanism can realize the disassembly and assembly of the blade by simple pressing, and the operation is simple and convenient.

Owner:WUHAN JINGCHEN INTELLIGENT IDENTIFICATION TECH CO LTD

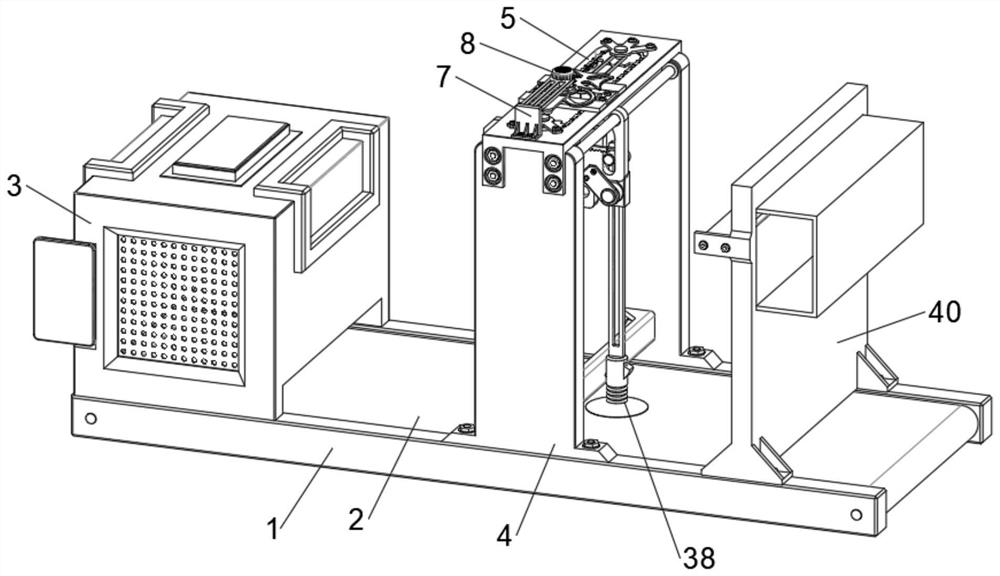

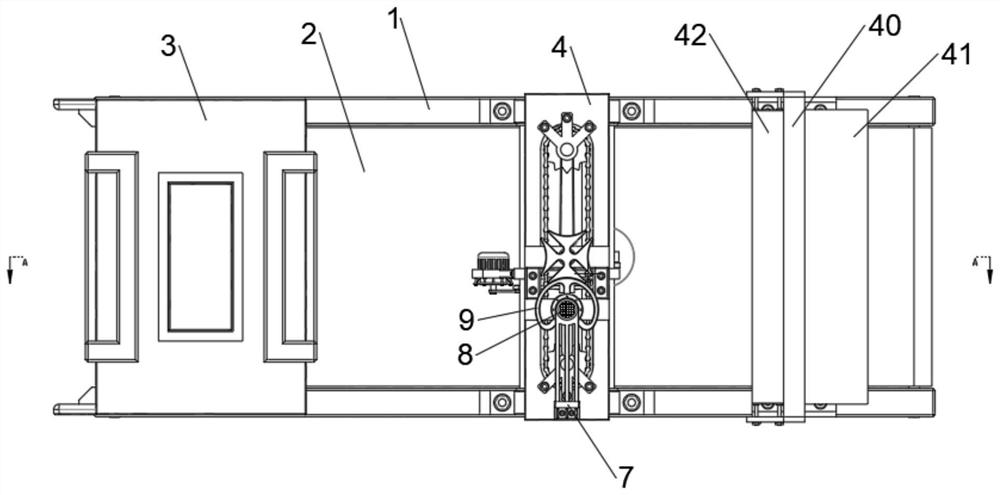

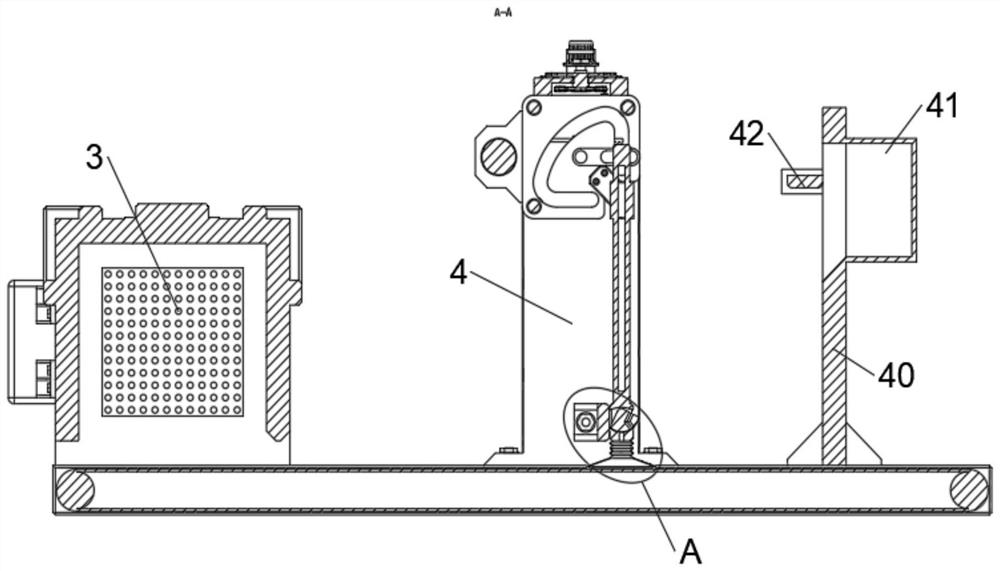

Press-fitting equipment for evaporator

InactiveCN111750571AEven by forceImprove bonding efficiencyEvaporators/condensersDomestic refrigeratorsRubber matMechanical engineering

The invention provides press-fitting equipment for an evaporator. The press-fitting equipment comprises a rack body, a case, a press-fitting mechanism, a conveying support and an intermittent conveying device. According to the equipment, through arrangement of the press-fitting mechanism, a downward-pressing rod is driven by a handle to perform downward pressing, a fixing plate provided with a press-fitting plate is driven by a moving assembly to move downwards, the evaporator is press-fitted on an inner container, press-fitting is performed through the structure, the evaporator can be ensuredto be uniformly stressed, the bottom of the evaporator can be firmly stuck to the inner container, the sticking efficiency is high, and the evaporator is not prone to falling; through arrangement ofthe press-fitting plate, a rubber pad is stuck to one side, far away from the fixing plate, of the press-fitting plate, so that the evaporator can be prevented from being damaged during press-fitting;through arrangement of the intermittent conveying device, streamline operation of the evaporator and the inner container can be realized, the production efficiency can be improved, and the labor intensity can be reduced; and through arrangement of a bearing plate, the bearing plate provides the supporting force during press-fitting of the inner container and the evaporator, and the press-fittingeffect is guaranteed.

Owner:滁州众德自动化装备有限公司

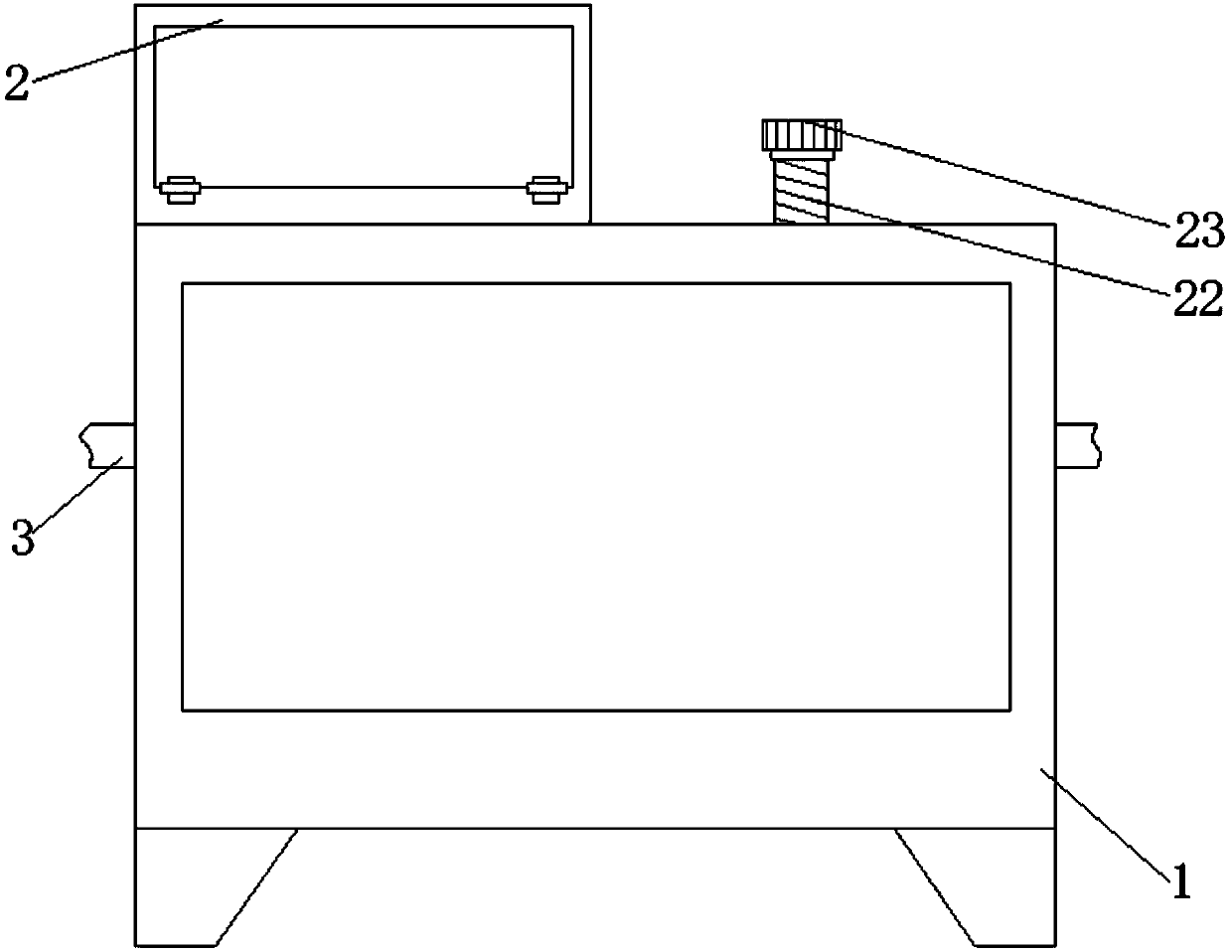

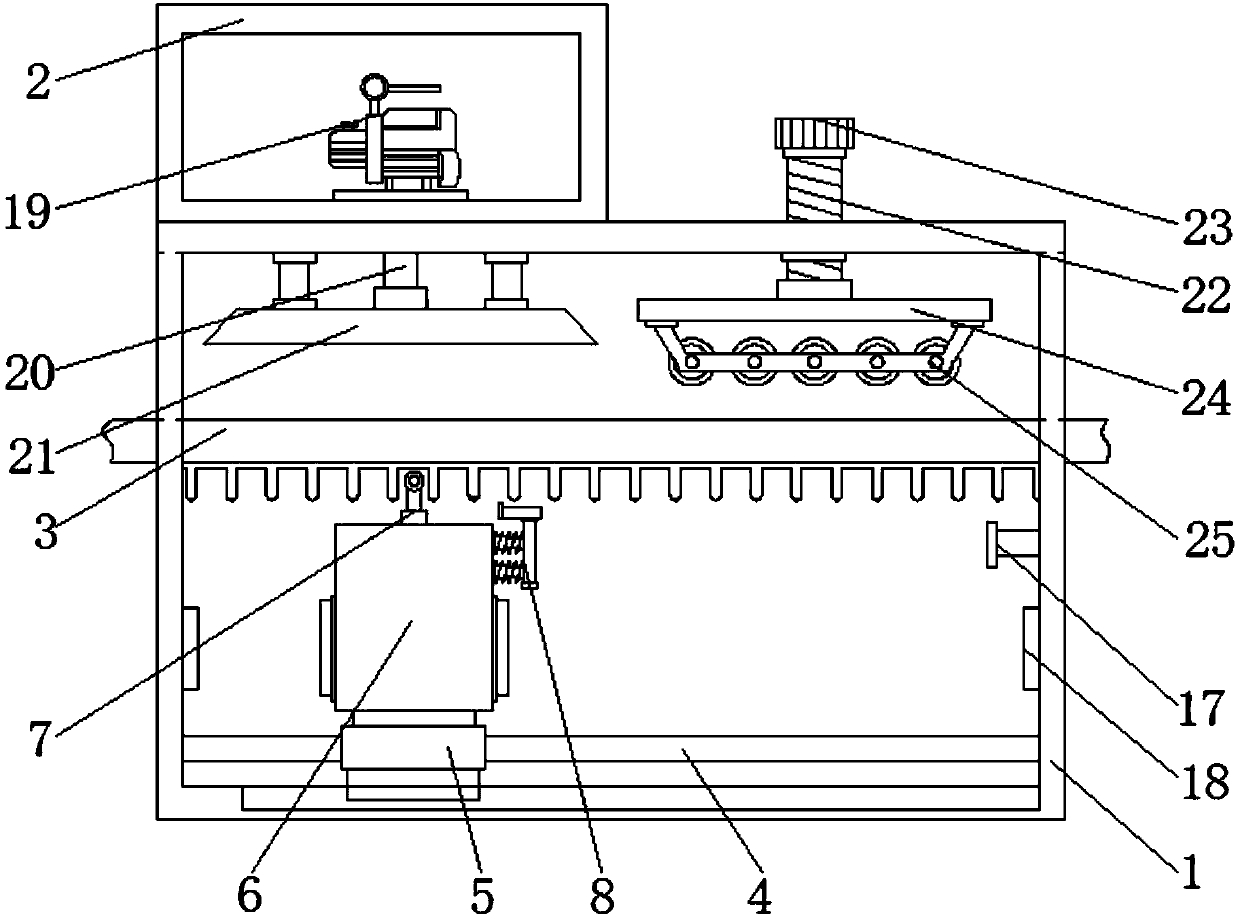

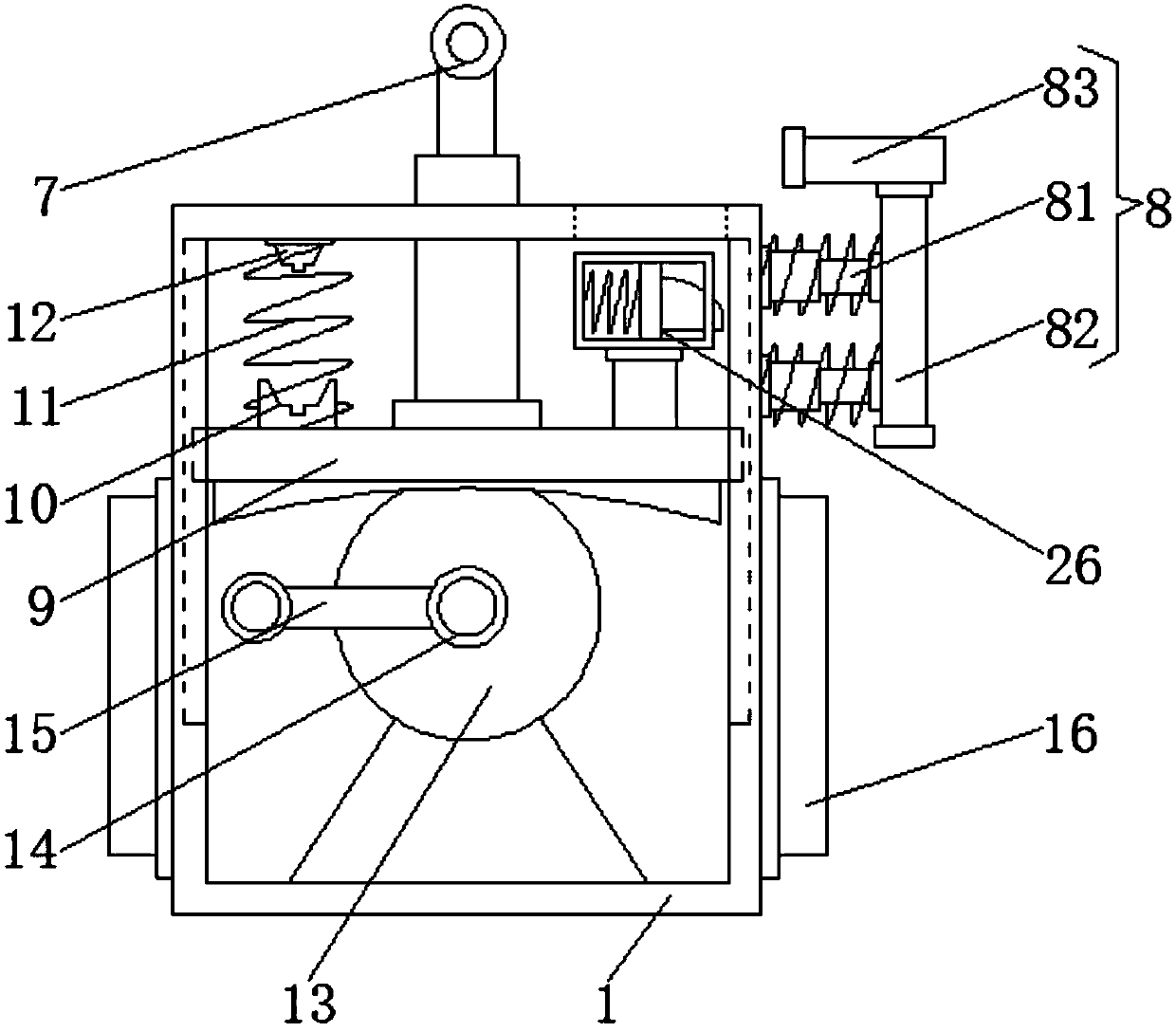

A convenient transmission device

ActiveCN107763182BEasy to useFacilitate transmissionGearboxesGearing detailsSlide plateTransmission equipment

The invention discloses transmission equipment convenient to use and relates to the technical field of transmission equipment. The transmission equipment comprises a box body; a top box is fixedly connected to the top of the box body; a transmission plate penetrates through the box body; a slide plate is fixedly connected between the two sides of the inner wall of the box body, and a moving blockis slidably connected to the surface of the slide plate; the bottom of the moving block is slidably connected with the bottom of the inner wall of the box body, and the top of the moving block is fixedly connected with a bottom box; a thrust device penetrates through the top of the bottom box, and a squeezing device is fixedly connected to the right side of the bottom box; and a top plate is fixedly connected to the position, located in the bottom box, of the bottom of the thrust device, and the two sides of the top plate are both slidably connected with the inner wall of the bottom box. The transmission equipment convenient to use can effectively conduct transmission and achieve intermittent transmission, using is very convenient, time is saved, the transmission efficiency is greatly improved, and the thickness of discharged materials can be adjusted as required.

Owner:安徽悠咔食品有限公司

Transmission equipment convenient to use

The invention discloses transmission equipment convenient to use and relates to the technical field of transmission equipment. The transmission equipment comprises a box body; a top box is fixedly connected to the top of the box body; a transmission plate penetrates through the box body; a slide plate is fixedly connected between the two sides of the inner wall of the box body, and a moving blockis slidably connected to the surface of the slide plate; the bottom of the moving block is slidably connected with the bottom of the inner wall of the box body, and the top of the moving block is fixedly connected with a bottom box; a thrust device penetrates through the top of the bottom box, and a squeezing device is fixedly connected to the right side of the bottom box; and a top plate is fixedly connected to the position, located in the bottom box, of the bottom of the thrust device, and the two sides of the top plate are both slidably connected with the inner wall of the bottom box. The transmission equipment convenient to use can effectively conduct transmission and achieve intermittent transmission, using is very convenient, time is saved, the transmission efficiency is greatly improved, and the thickness of discharged materials can be adjusted as required.

Owner:安徽悠咔食品有限公司

Multifunctional mechanical-electrical integration conveying device

InactiveCN113320927AAchieve swingRealize intermittent rotationConveyorsControl devices for conveyorsTransmission beltEngineering

The invention discloses a multifunctional mechanical-electrical integration conveying device which comprises a frame table and a distribution assembly. Conveying rollers are uniformly connected into the frame table in a rotating manner. The conveying rollers located on the two sides are in transmission connection through a conveying belt. A partition strip is arranged on the middle portion of the surface of the conveying belt. An installing frame is arranged on the surface of the frame table. A swinging assembly is arranged on the installing frame. Feeding assemblies are symmetrically arranged on the two sides of the frame table. The distribution assembly comprises an installing shaft, lantern rings, an installing rod, an arc-shaped gear block, a swing rod and a poking plate. The two ends of the installing shaft penetrate through the two sides of the top of the installing frame correspondingly. The lantern rings uniformly sleeve the installing shaft in a moving manner. The multifunctional mechanical-electrical integration conveying device has more functions, materials on the conveying belt can be distributed automatically, meanwhile, the materials can be placed automatically, frequent taking and placing of personnel are avoided, the working efficiency is improved, the labor intensity is reduced, and practicability is high.

Owner:JINING POLYTECHNIC

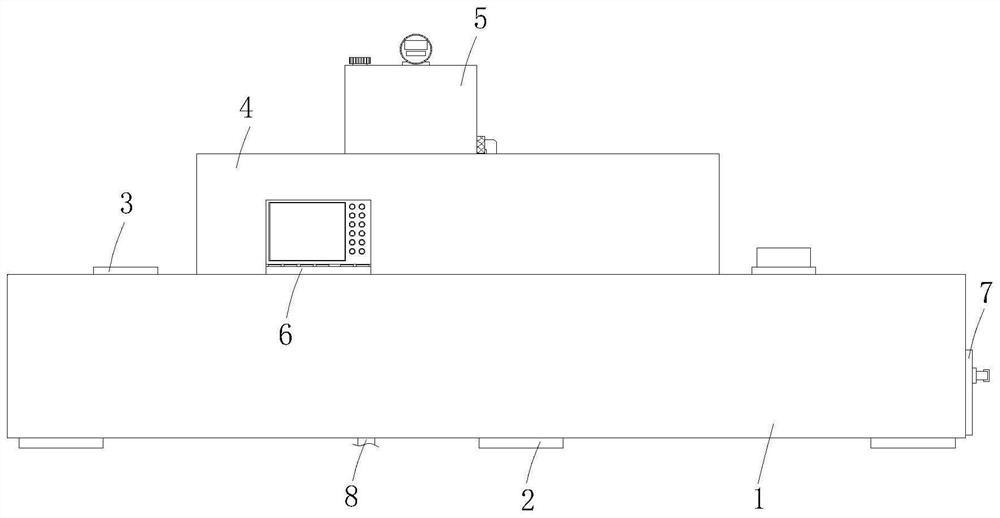

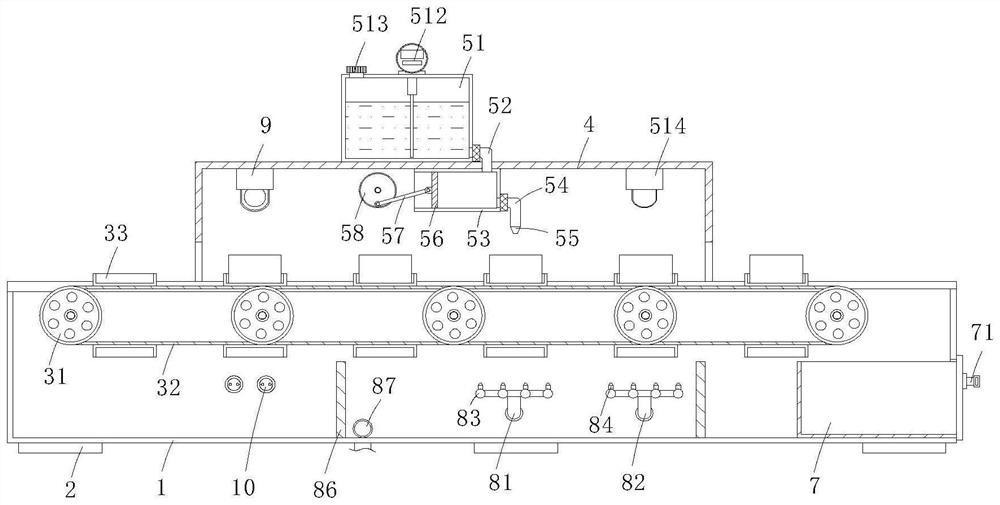

A safety detection equipment for functional food processing and its operation method

ActiveCN112394043BFully automatedEasy to detectMaterial analysis by observing effect on chemical indicatorHollow article cleaningFood safetyAgricultural engineering

The invention relates to the technical field of functional food detection, and provides a safety detection device for functional food processing and an operation method thereof, aiming at solving the problems of unreasonable structural design, long detection time and slow speed in the use process of the existing food safety detection device. , lack of accuracy and other drawbacks, all make the safety detection of functional foods defective, including the bar-shaped case with the upper end not closed and a plurality of feet installed at the lower end of the bar-shaped case, the upper part of the inner cavity of the bar-shaped case is installed horizontally There is a transmission mechanism, and the upper end of the bar-shaped case is provided with a detection box shell, an infrared spectrometer is installed on the inner top wall of the detection box shell on the side near the input end of the transmission mechanism, and a detection mechanism is arranged in the detection box shell; the transmission mechanism It includes a transmission chain plate belt horizontally arranged on the upper part of the inner cavity of the bar-shaped chassis. The invention is especially suitable for automatic and intelligent detection of functional food, has high detection accuracy, and has high social use value and application prospect.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Automatically cutting device for medical packaging bag production

PendingCN109049853ASimple structureSmooth intermittent motionBag making operationsPaper-makingCamEngineering

The invention discloses an automatic cutting device for medical packaging bag production, comprising supports and a conveyor belt fixedly connected between two of the supports. A side wall of one endof the support is fixedly connected with a side wall of one end of a protective shell and a case of a motor. The motor is connected with an external power supply through a wire, and an output end of the motor is connected with a lower end of a rotating shaft. The automatic cutting device for medical packaging bag production is simple in structure. The automatic cutting device for medical packagingbag production, by adding a combined structure of a cam divider and a helical gear, not only achieves intermittent transmission of the conveyor belt, but also achieves that another set makes a cutterto move to cut back and forth through swings of the helical gear by using a reversing drive of the helical gear in case that there is only one set of motors. Therefore, the conveying belt can be stopped for a certain time to allow the cutter to cut the packaging bag while conveying, two sets of intermittent motion are relatively stable, the production quality is stable, the cost is low, and the practicability is great.

Owner:ANQING TIANRUN PAPER PACKAGING

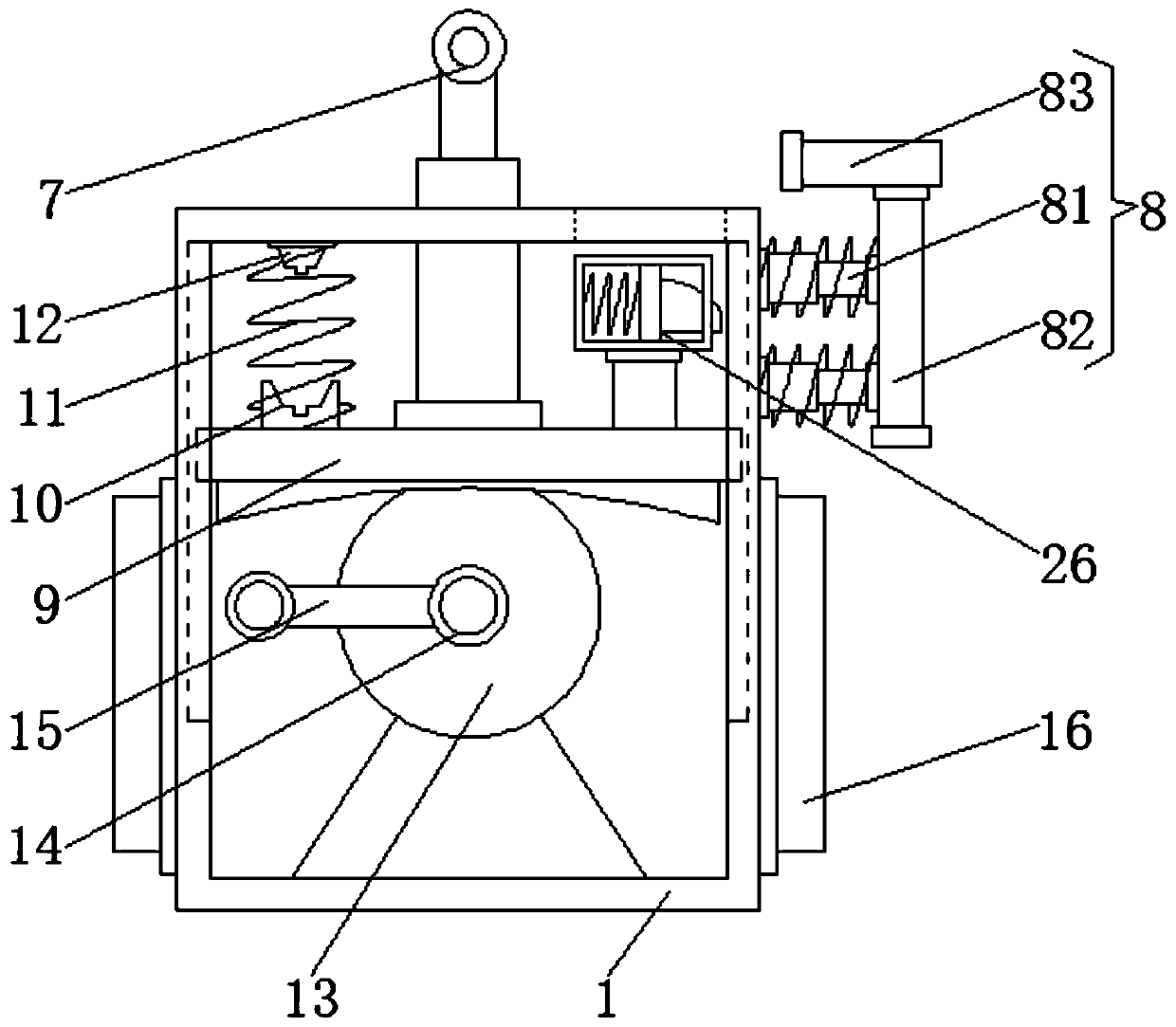

Batch sterilization and disinfection device for medical products

InactiveCN114010815ARealize intermittent transmissionExtended service lifeLavatory sanitoryRadiationGear wheelDrive shaft

The invention relates to a medical product batch sterilization and disinfection device which comprises a support, a driving mechanism, a driven mechanism, a limiting mechanism and a disinfection mechanism, the driving mechanism comprises a motor, a rotating shaft, a rotating disc and a driving unit, the limiting mechanism comprises a limiting ring and a plurality of limiting blocks, and the driven mechanism comprises a first gear, a driven shaft and a roller. The driving mechanism drives the driven mechanism to operate, intermittent conveying is achieved, the conveying distance is adjusted through the limiting mechanism, all medical products of different sizes can be moved to the ultraviolet lamp to be sterilized and disinfected, the sterilization effect is improved, intermittent conveying is achieved without the need for controlling starting and stopping of a motor through a PLC. The service life of the motor is prolonged, electronic elements are prevented from being used, a pure mechanical mechanism is adopted, the stability and the service life of the device are improved. Meanwhile, the driving mechanism drives the disinfection mechanism to rotate on line, all the ultraviolet lamps rotate around medical products, and the better sterilization effect is achieved.

Owner:平晨

Touch screen production equipment and processing method thereof

ActiveCN114803508AReduce manual retrieving operation stepsPrevent Skew ProblemsCharge manipulationConveyor partsClosed spaceTouchscreen

The invention discloses touch screen production equipment and a processing method thereof.The touch screen production equipment comprises a working frame, a transmission device used for transmitting screen glass is arranged on the inner side of the working frame, a cutting device used for cutting the screen glass is fixedly installed on the working frame, and a supporting frame is fixedly connected to the working frame through bolts; a transmission groove used for intermittent transmission is formed in the supporting frame, a transmission assembly used for intermittent transmission is arranged in the transmission groove, a material taking suction cup is pushed by a first fixed push plate to rotate in a rotating groove, then a piston block is made to block a vacuum hole, and after the material taking suction cup makes contact with screen glass, extrusion is conducted; and a closed space is formed in the material taking suction cup, then vacuum adsorption material taking of the screen glass is achieved, manual material taking operation steps are reduced, the problem that an equipment material taking tool inclines in the manual material taking process is solved, and then the material taking efficiency of the screen glass is improved.

Owner:ZHE JIANG CHANGXING HELI OPTOELECTRONIC TECH CO LTD

Plate forming device for fire exit door

InactiveCN114603423AQuality improvementReduce scratchesEdge grinding machinesGrinding carriagesStructural engineeringWorkbench

The plate forming device of the fire exit door comprises a workbench, the outer wall of the workbench is fixedly connected with a blocking net through bolts, the bottom of the blocking net is fixedly connected with a scraping strip, the portion, close to the bottom of the scraping strip, of the outer side of the workbench is rotationally connected with rolling wheels, and a transmission mechanism is arranged on the inner wall of the workbench; a traction mechanism is arranged in the workbench, the outer wall of the transmission mechanism is fixedly connected with the outer wall of the traction mechanism, and a grinding device is fixedly connected to the top of the workbench. When the fire exit door plate is conveyed, some holes and burrs machined on the surface of the plate can be polished, so that scratches of production workers caused by the burrs are reduced, meanwhile, the quality of the fire exit door plate is improved, scratches of customers caused by the burrs can be reduced when the fire exit door plate is used by users, and the safety of the equipment in the using process is improved.

Owner:江苏久泰消防设备有限公司

Weaving equipment

ActiveCN107956028BRemove creasesRealize intermittent transmissionLoomsAuxillary apparatusEngineeringMechanical engineering

The invention relates to the technical field of weaving, and especially relates to a device used for weaving. The device comprises a transmission table, a transmission roller used to transmit a clothon the transmission table, and a wind-up roller used to wind up the cloth. The wind-up roller is on a discharge end of the transmission table. The transmission roller comprises a roller body, a pressing column, and a smoothing platform. The roller body is internally provided with a steam channel. The roller body is provided with an air outlet hole and a sliding hole. The sliding hole is internallyslidably connected with a sliding rod. The sliding rod is fixedly connected with the smoothing platform. A spring is arranged between the smoothing platform and the roller body. The pressing column is used to insert into the steam channel and control sliding of the sliding rod. The pressing column is provided with a blocking column used to block the air outlet hole. An end of the transmission roller is rotatably connected with a steam pipe. One end of the pressing column, close to the steam pipe, can contact with an orifice of the steam pipe. The transmission roller is also provided with a positioning portion used to fix the pressing column in the steam channel. The pressing column, the sliding rod, and the smoothing platform are made of a heat conduction material. The scheme can eliminate folds on a surface of the cloth.

Owner:NINGBO HIGH TECH ZONE SHENGWENTU TEXTILE CO LTD

Clamping mechanism suitable for cable conveying and cable conveyor

ActiveCN112520490ARealize simultaneous grippingImprove transmission efficiencyFilament handlingEngineeringStructural engineering

The invention discloses a clamping mechanism suitable for cable conveying and a cable conveyor, and relates to the field of cable conveying. The problems that an existing cable conveyor can only convey one cable each time; the conveying efficiency is low; pushing belts on the left side and the right side of the cable generate friction heat for a long time in a conveying process; and the skin and the service life of the cable are affected are solved. The clamping mechanism suitable for cable conveying comprises a base, a feeding rod, a base plate, two clamping plates and two elastic pieces; a cable storage groove is formed between each clamping plate and a corresponding upper reverse edge of the base, and the cable storage grooves are used for storing cables; and by controlling the feedingdepth of the feeding rod, the two clamping plates are controlled to be in a clamping or opening state. The clamping mechanism is mainly applied to cable conveying.

Owner:STATE GRID HEILONGJIANG ELECTRIC POWER COMPANY +1

An automatic packaging and shipping device for e-commerce

ActiveCN111114918BQuality impactRealize intermittent transmissionPackagingStructural engineeringE-commerce

The invention discloses an automatic packaging and shipping device for e-commerce, belonging to the technical field of e-commerce packaging, comprising a base, a material storage tank and a support column, the base is arranged horizontally, and the bottom end of the material storage tank is provided with a The support column is symmetrical to the horizontal center line, and the storage tank is erected directly above the base through the support column. The bottom end of the storage tank is provided with a baffle extending horizontally to the right, and the inside of the baffle is provided with a adjustment board. In the present invention, under the cooperation of the sliding connection between the connecting block and the chute, through the connection between the screw rod on the fixed block and the bolt holes at different positions, the number of columns of the material guide outlet on the receiving area is adjusted, so that the packaging device The number of boxes packed at one time is adjusted, so that the device can accurately control the output of materials according to the needs of the number of boxes packed each time, thereby reducing the number of spherical materials in the same batch of boxes. And the impact on the quality of the device packing.

Owner:江西环境工程职业学院

A feeding device for a punching machine

ActiveCN106734691BRealize intermittent transmissionEasy to collectMetal-working feeding devicesStripping-off devicesEngineeringFlywheel

The invention discloses a feeding device for a punch. The feeding device comprises a frame fixed to a worktable. A first compression roller and a second compression roller, which abut against the upper and lower surfaces of a steel strip, respectively, are rotatably connected to the frame. A ratchet wheel is fixed to an end portion of the first compression roller. A drive sleeve is rotatably connected to the first compression roller. A ratchet is hinged to the inner wall of the drive sleeve, and the ratchet is connected to the drive sleeve by means of a first elastic part. A first connecting rod is fixed to an outer wall of the drive sleeve. A second connecting rod is hinged to the first connecting rod. One end, far away from the first connecting rod, of the second connecting rod is hinged to a flywheel. Thus, the purpose of improving the production efficiency is achieved.

Owner:上海上垫垫圈有限公司

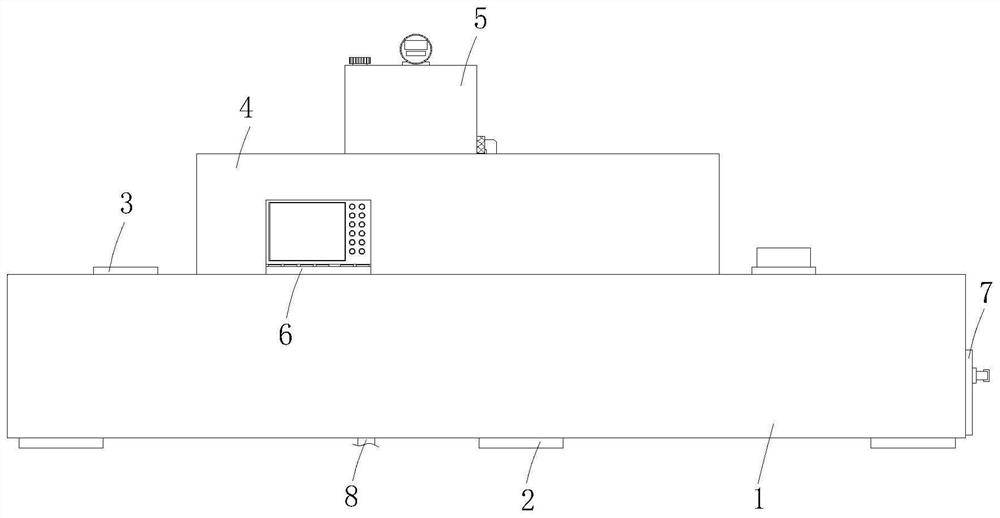

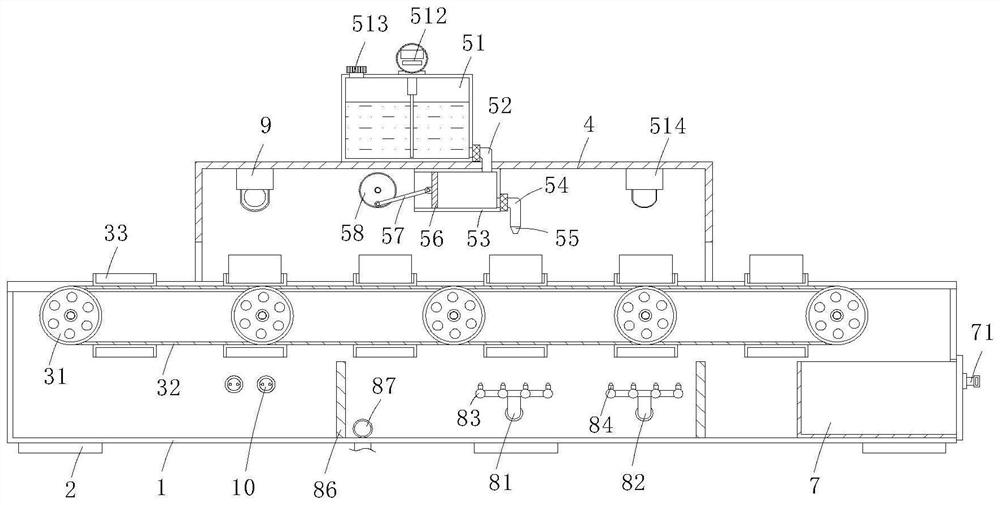

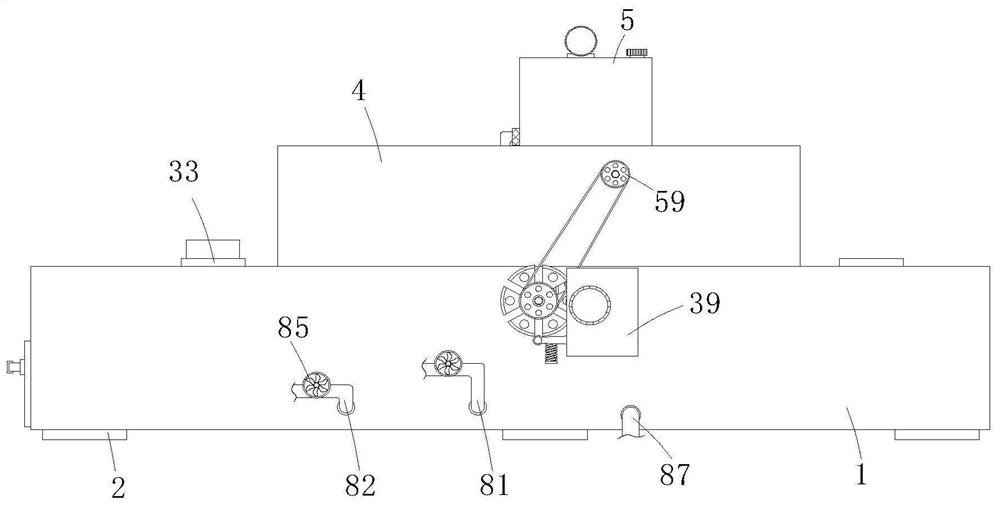

Safety detection equipment for functional food processing and operation method of safety detection equipment

ActiveCN112394043AFully automatedEasy to detectMaterial analysis by observing effect on chemical indicatorHollow article cleaningFood safetyAgricultural engineering

The invention relates to the technical field of functional food detection, provides safety detection equipment for functional food processing and an operation method of the safety detection equipment,and aims at overcoming the defects that existing food safety detection equipment is unreasonable in structural design, long in detection time, low in speed, insufficient in accuracy and the like in the using process so that defects exist in the safety detection of functional food. The safety detection equipment comprises a strip-shaped machine box with the upper end not closed and a plurality offoot pads installed at the lower end of the strip-shaped machine box, a conveying mechanism is horizontally installed on the upper portion of an inner cavity of the strip-shaped machine box, and a detection box shell is erected at the upper end of the strip-shaped machine box; an infrared spectrometer is installed on the inner top wall of the side, close to the input end of the conveying mechanism, of the detection box shell, and a detection mechanism is arranged in the detection box shell. The conveying mechanism comprises a conveying chain plate belt horizontally arranged on the upper portion of an inner cavity of the strip-shaped machine box. The equipment is especially suitable for automatic and intelligent detection of functional food, is high in detection precision, and has high social use value and application prospect.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

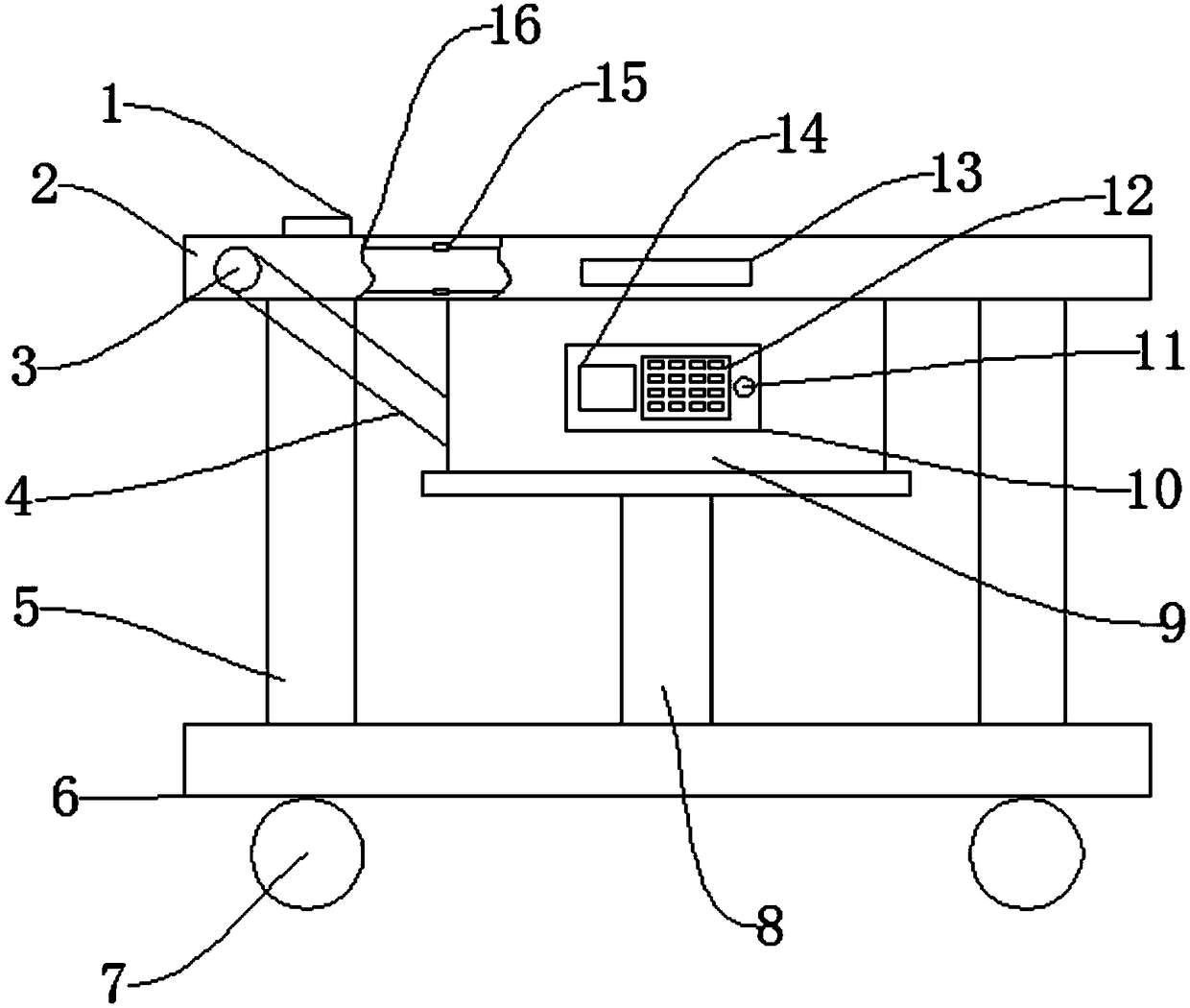

Device conveying device for endocrinology department

InactiveCN108657769AReasonable structureEasy to operateConveyorsControl devices for conveyorsEndocrinology departmentMedical treatment

The invention discloses a device conveying device for an endocrinology department. The device comprises a base plate, a chassis and a conveying table; wheels are arranged at four corners of the lowerend of the base plate; a bracket is arranged at the middle part of the upper end of the base plate; the chassis is arranged at the top end of the bracket; an operation plate is arranged at the middlepart of one side wall of the chassis; support legs are arranged at four corners of the upper end of the base plate; the conveying table is arranged at the top ends of the support legs; a conveying belt is arranged at the middle part of the upper end of the conveying table, and is provided with medical devices, connecting blocks and driving wheels; induction heads are arranged at the upper end, near two sides of the conveying belt, of the conveying table; and pull grooves are formed in the middle parts of two side walls of the conveying table. The device has the beneficial effects of reasonablestructure and convenience to operate; through arrangement of the pull grooves, convenient movement of the conveying table can be realized; and through arrangement of the operation plate and the induction heads, intermittent conveying of the medical devices can be realized, and the conveying reliability is improved.

Owner:王志鸿

A spherical daily-use department store vending equipment that automatically replenishes goods according to the placement of goods

The invention relates to the technical field of daily necessities, and discloses a spherical general merchandise vending device that automatically replenishes goods according to the placement of goods, including a shell, the inside of which is movably connected with a first turntable; The clamping rod is far away from the ratchet, so that after the goods are removed, the operation of the automatic start-up equipment turns and the turn plate rotates to make the transfer plate rotate 90 degrees intermittently. With the help of the gravity of the goods, it automatically falls and the goods are transported to realize the intermittent transmission of the goods. Automatically To replenish the goods, the rotation of the first turntable makes the block move up and down, causing the first rotating rod to approach each other to limit the position of the goods and move the placement table to the highest position, automatically adjust the position of the goods, avoid the position too far, and reduce the goods The display is beautiful, and the goods are automatically fixed to prevent the goods from moving, so that they are located at the pick-up port for easy access, and avoid placing too many goods at the same time and causing confusion.

Owner:上海世柯仓储设备工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com