Patents

Literature

39results about How to "Remove creases" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

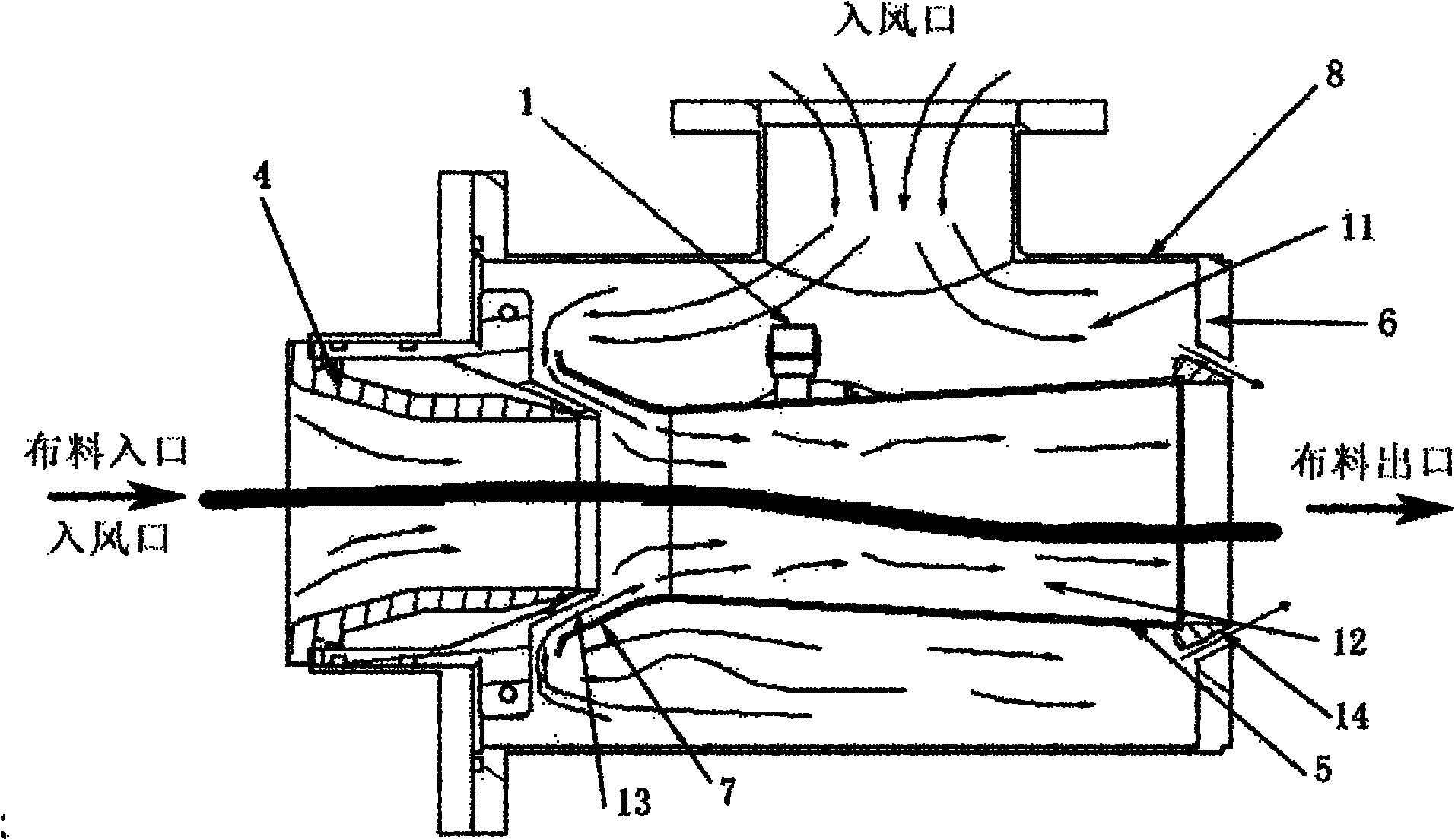

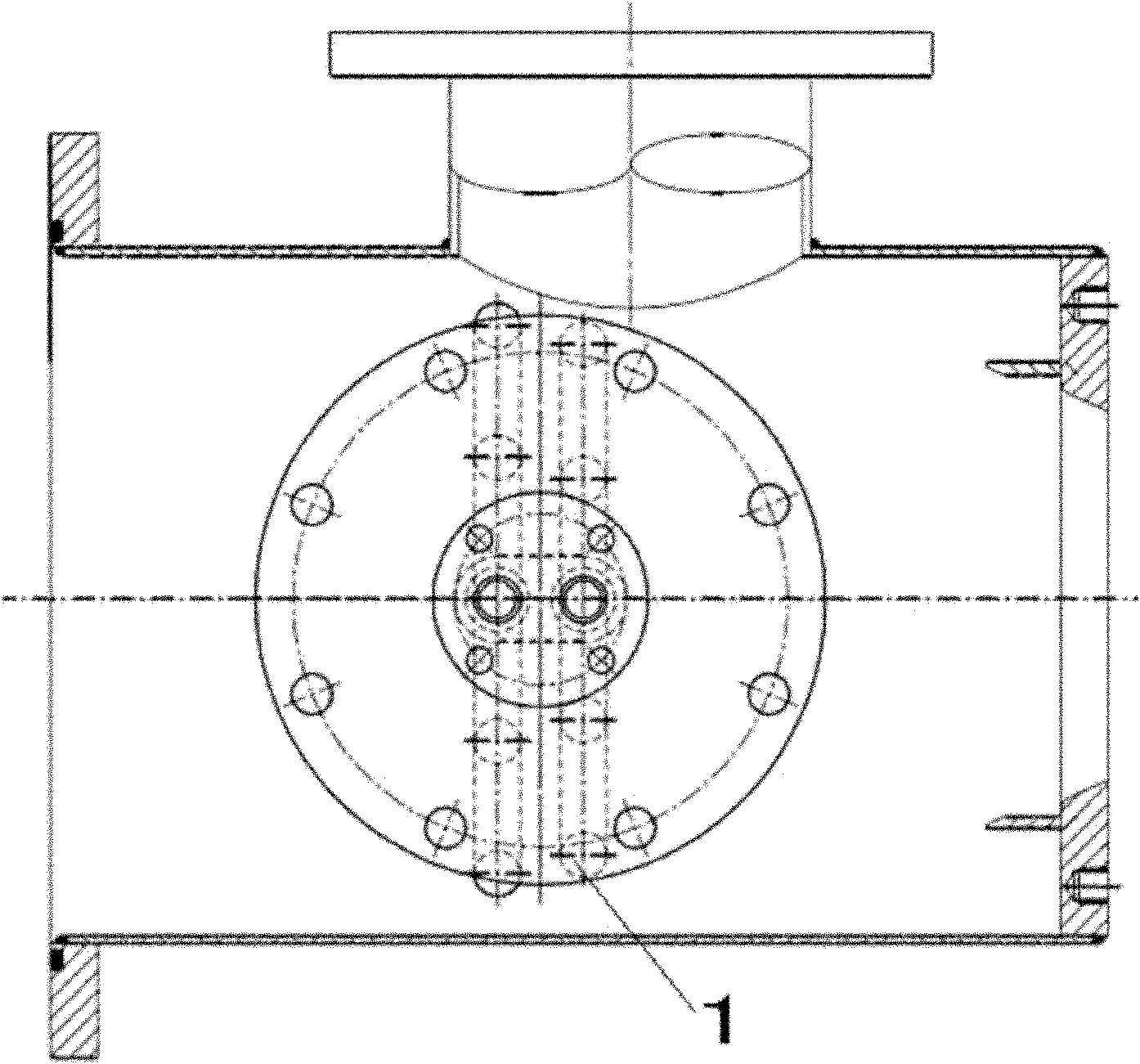

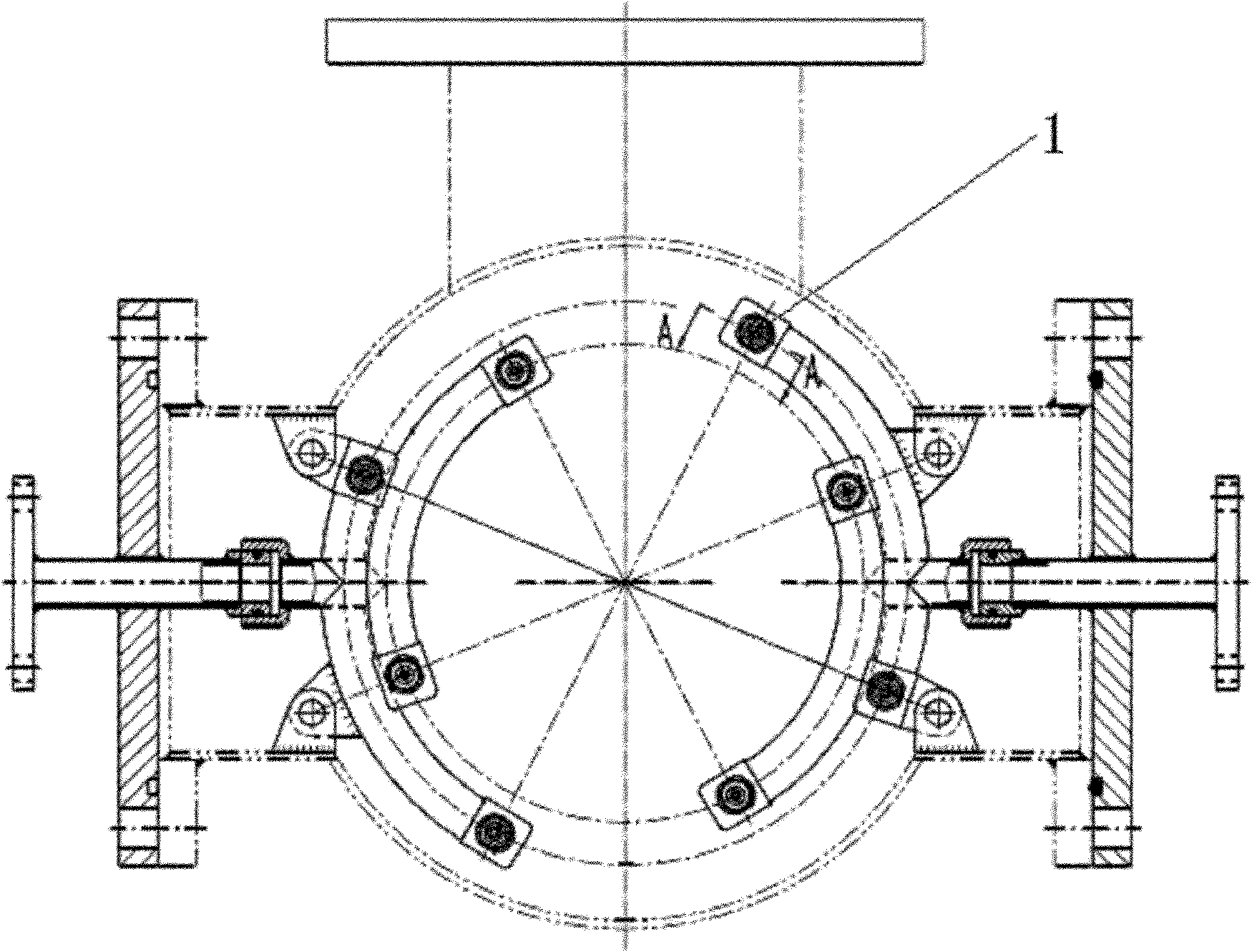

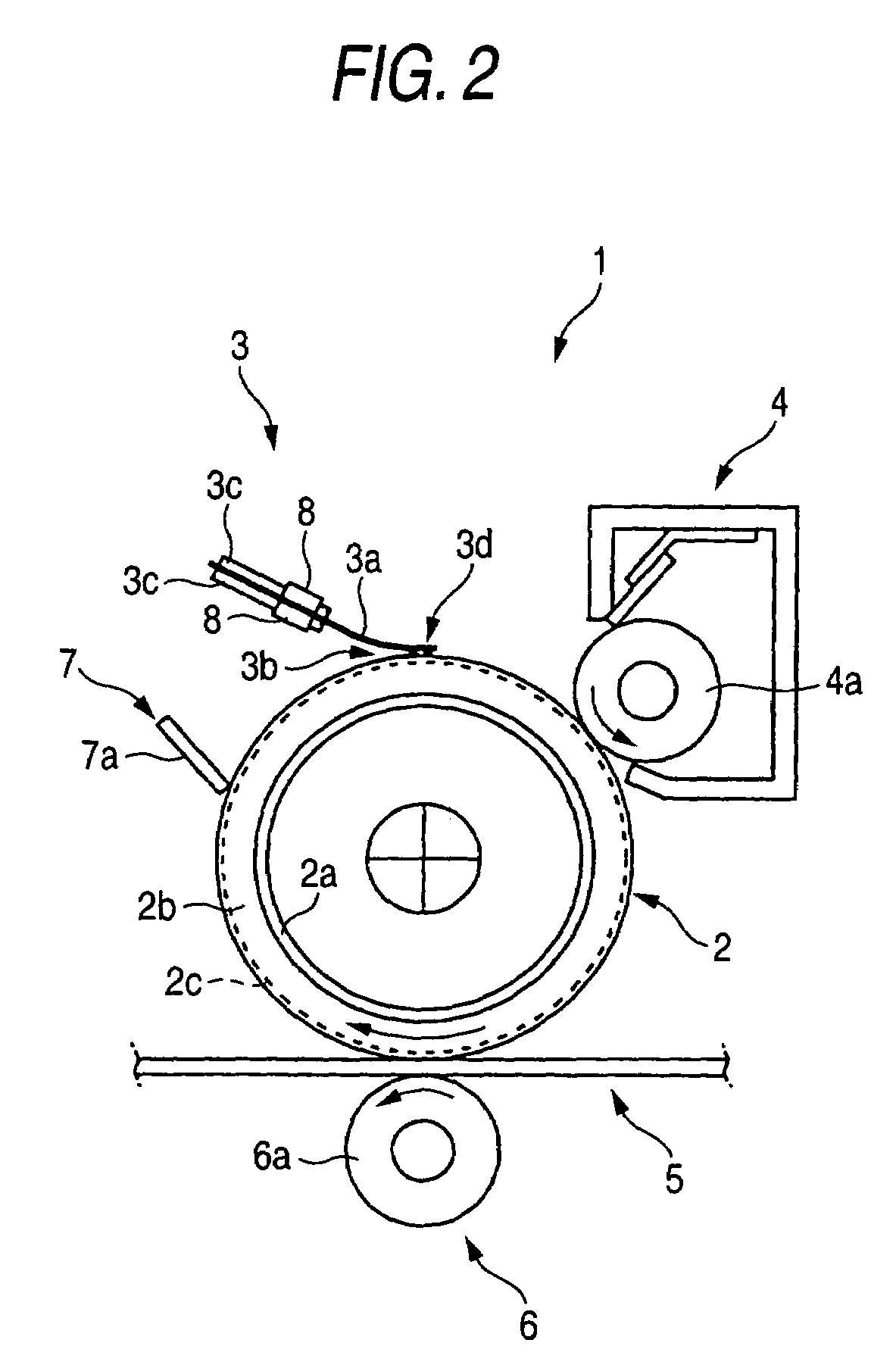

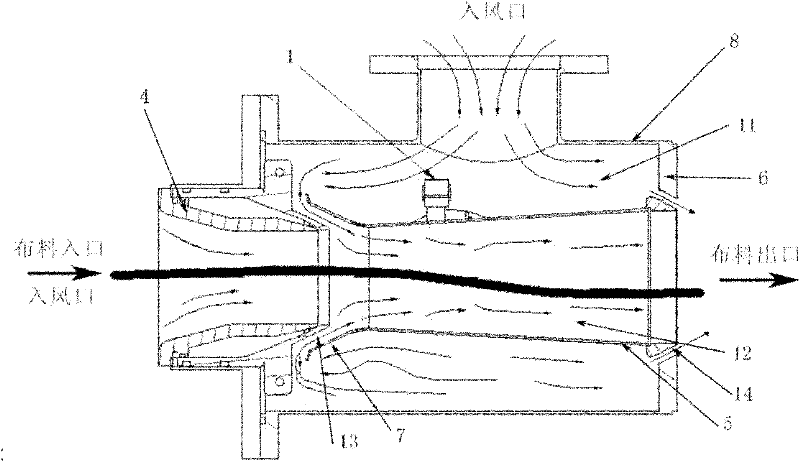

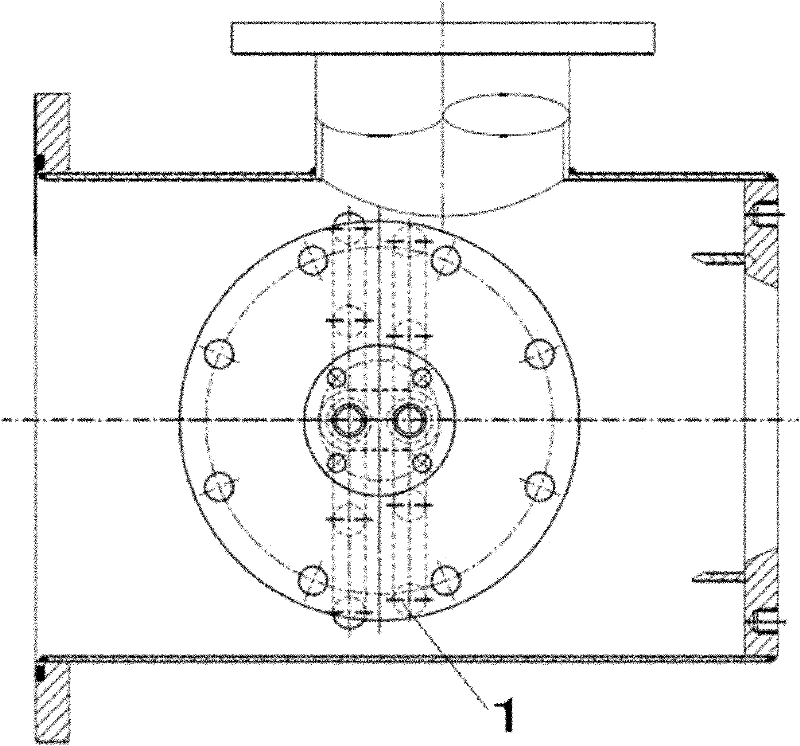

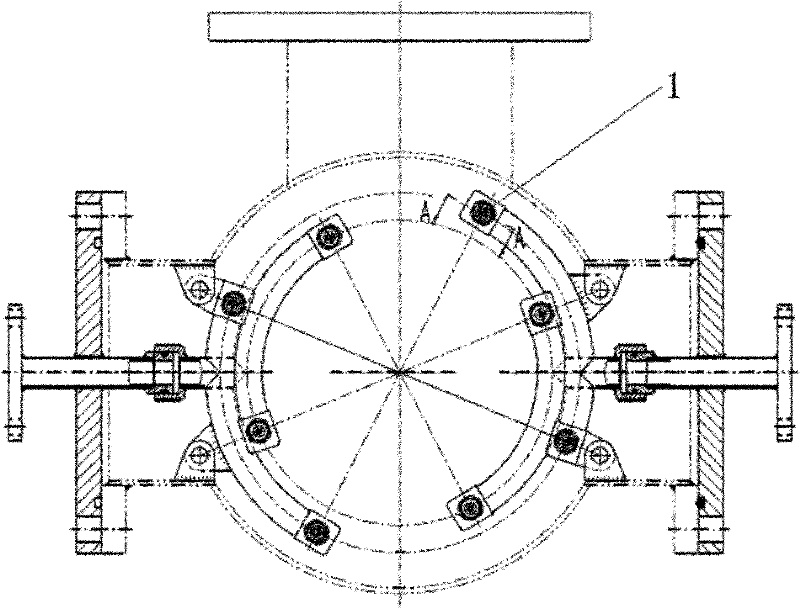

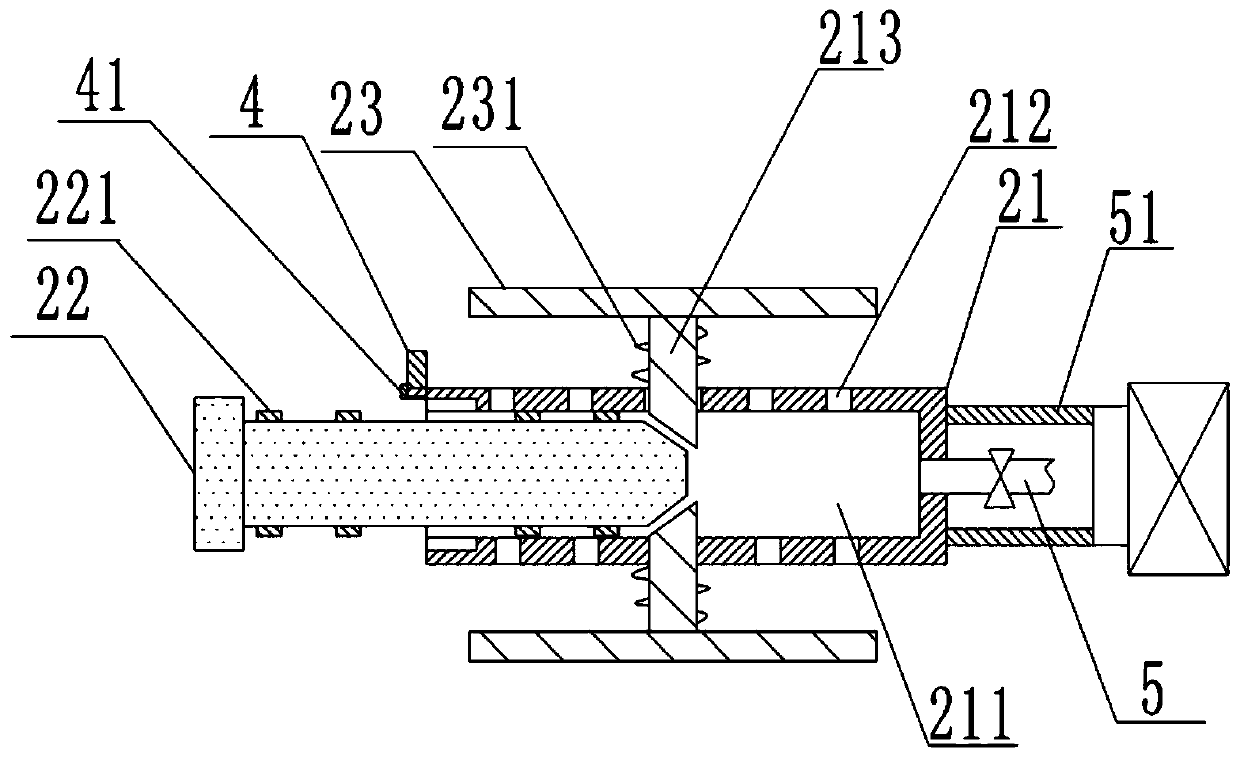

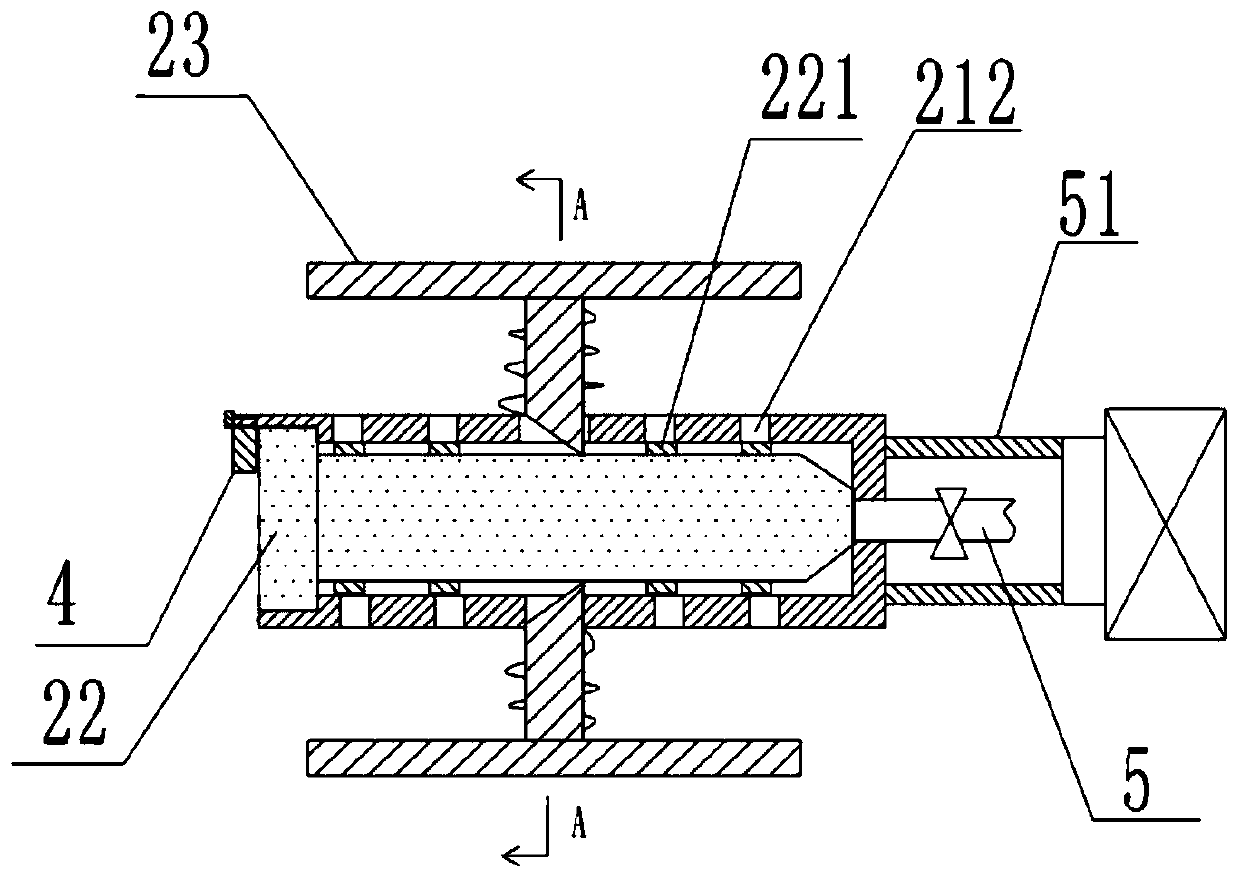

Atomizing nozzle structure of high-temperature high-voltage air flow dyeing machine and control method thereof

InactiveCN102080318AGood level dyeingSuitable for processing environmentLiquid/gas/vapor treatment of propelled fabricsTextile treatment machine partsSpray nozzleHigh pressure

The invention discloses an atomizing nozzle structure of a high-temperature high-voltage air flow dyeing machine and control method thereof. The nozzle structure comprises a front nozzle cover, an inner main stream pipe, a rear nozzle head and a sleeve, wherein the sleeve is sleeved outside the inner main stream pipe, and two ends of the sleeve are respectively connected with the front nozzle cover and the rear nozzle head through a connecting piece; the sleeve is provided with an air inlet which is connected with a fan; and the sleeve and the inner main stream pipe form a circular outer chamber atomizing region; a nozzle head is arranged in the outer chamber atomizing region and is fixed on the outer wall of the inner main stream pipe, and the nozzle head is connected with a dye liquid pipeline; and the outer chamber atomizing region is provided with two outlets which are connected with a channel through which the cloth to be dyed passes in the inner main stream pipe. The invention also provides a control method based on the atomizing nozzle structure of the high-temperature high-voltage air flow dyeing machine. According to the types of the cloth to be dyed, the number of the nozzle heads started in the nozzle structure, the flow rate of the nozzle heads, the air flow of the fan and the temperature process curves adopted are defined. According to the invention, the levelling property is high, and the problem of cloth blocking can not happen.

Owner:高勋绿色智能装备(广州)有限公司

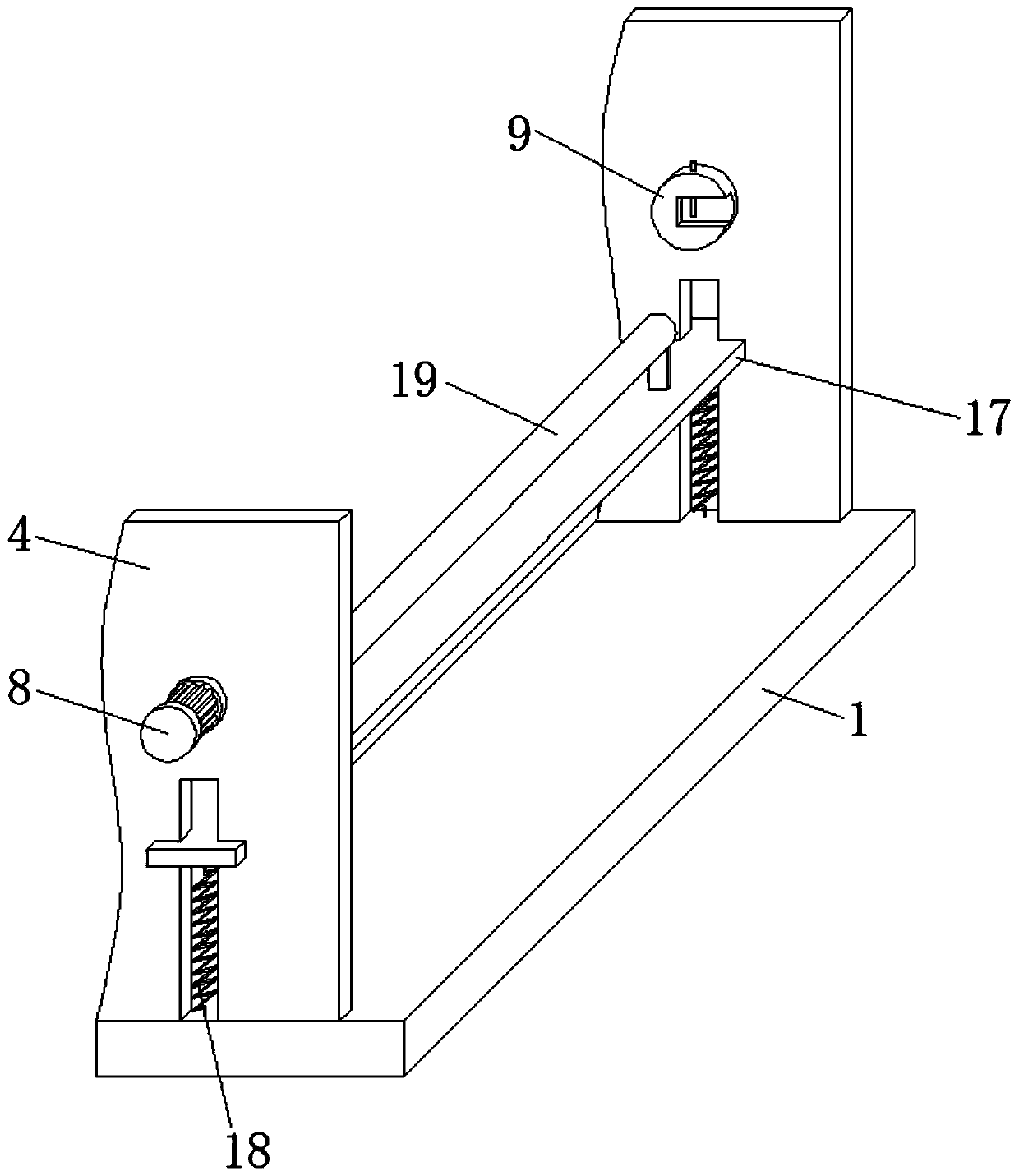

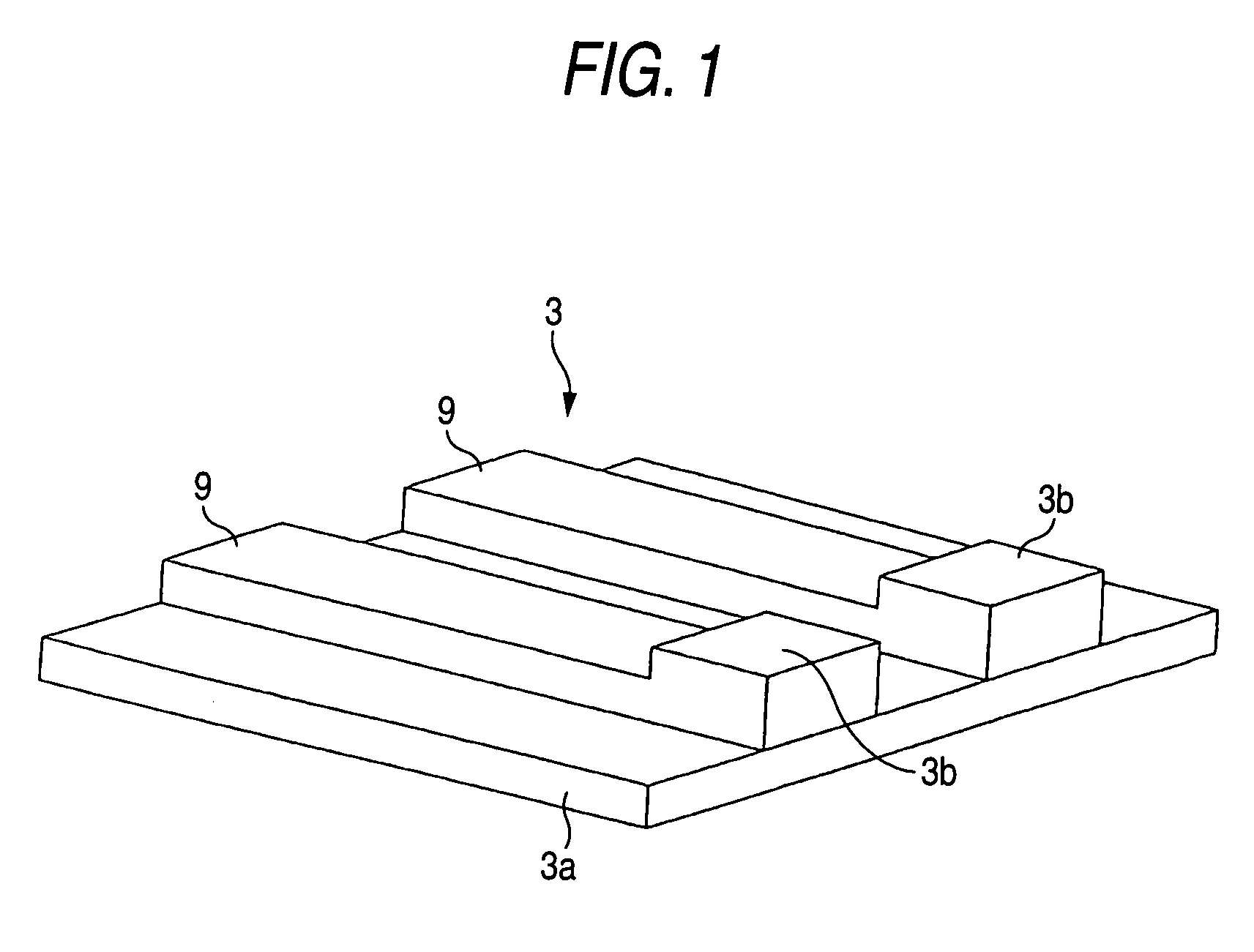

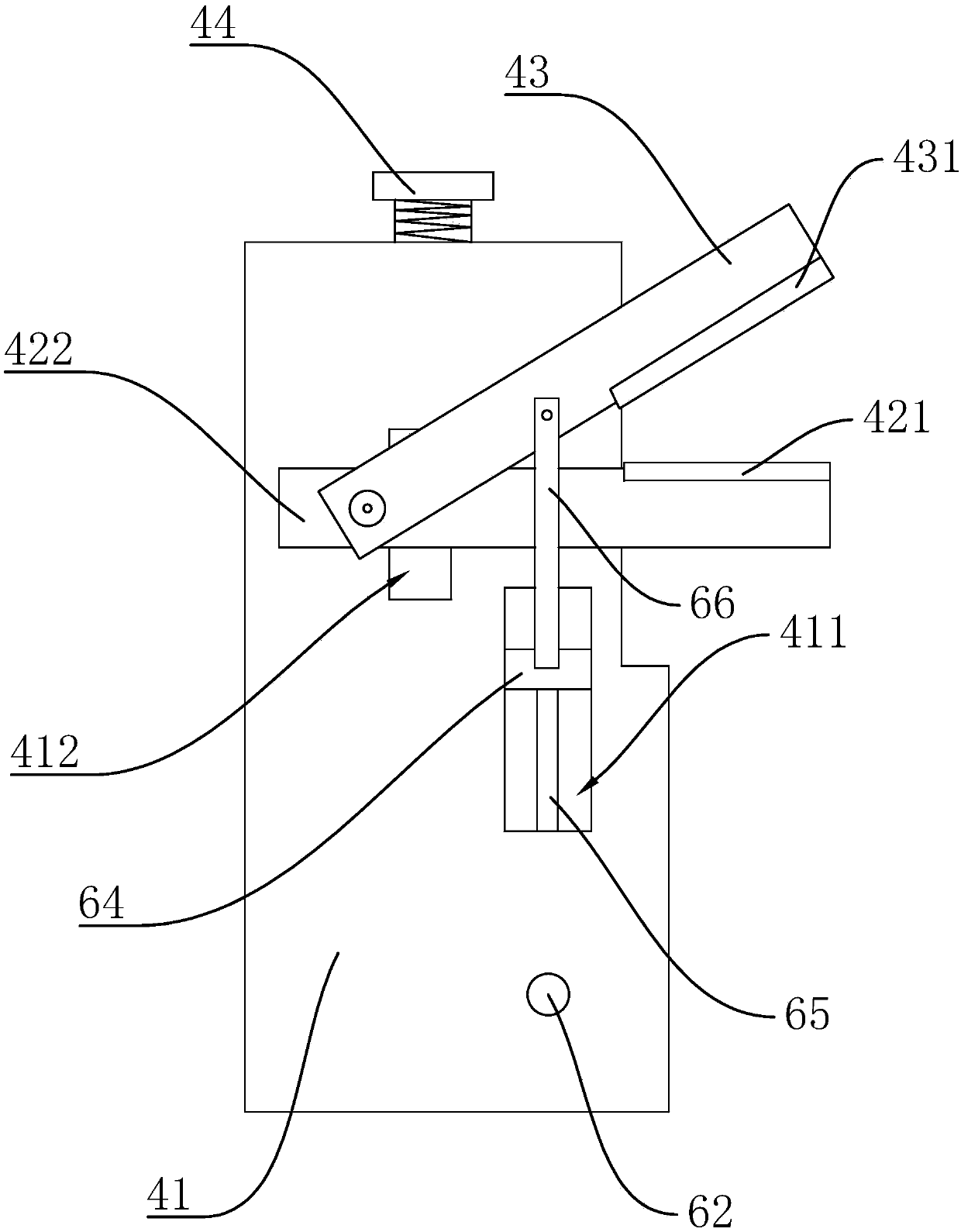

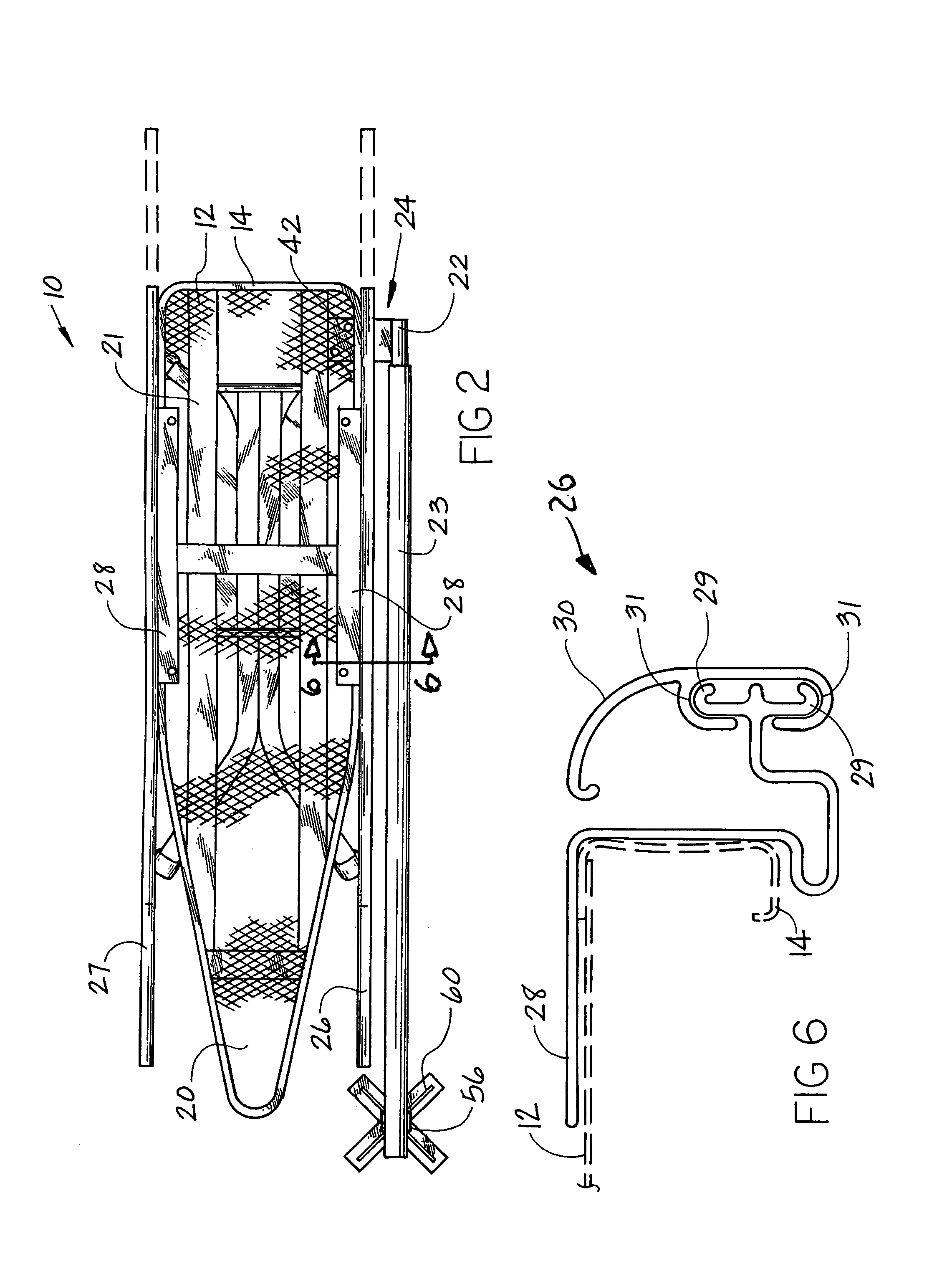

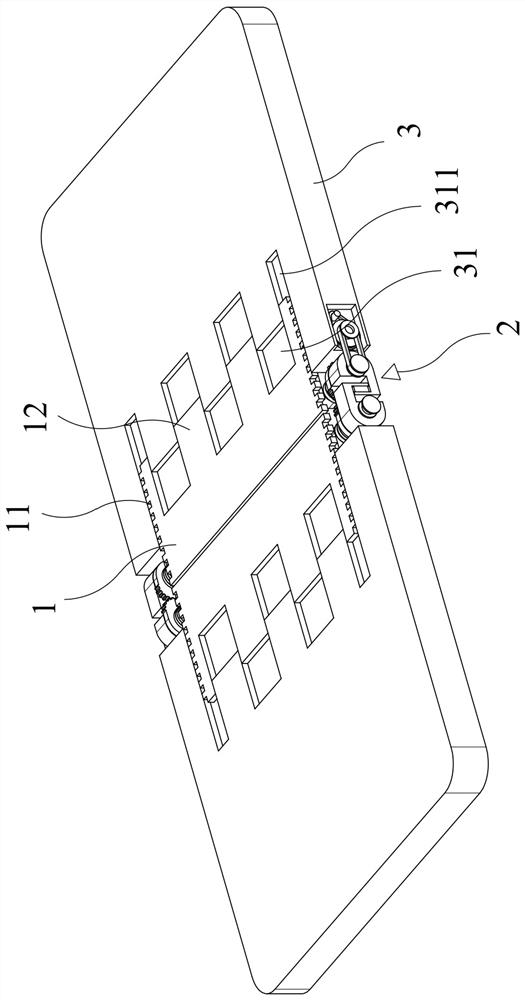

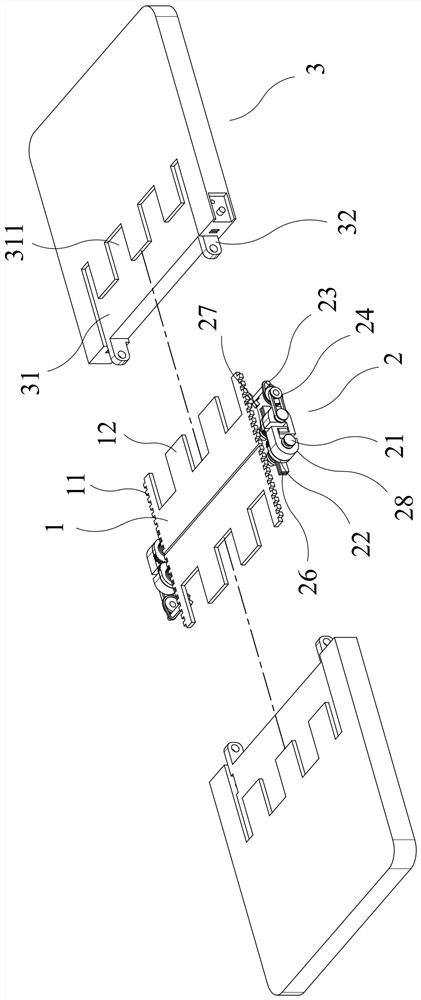

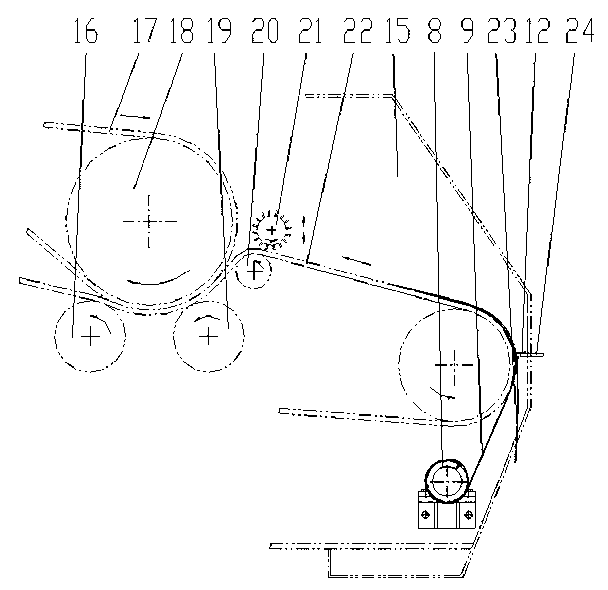

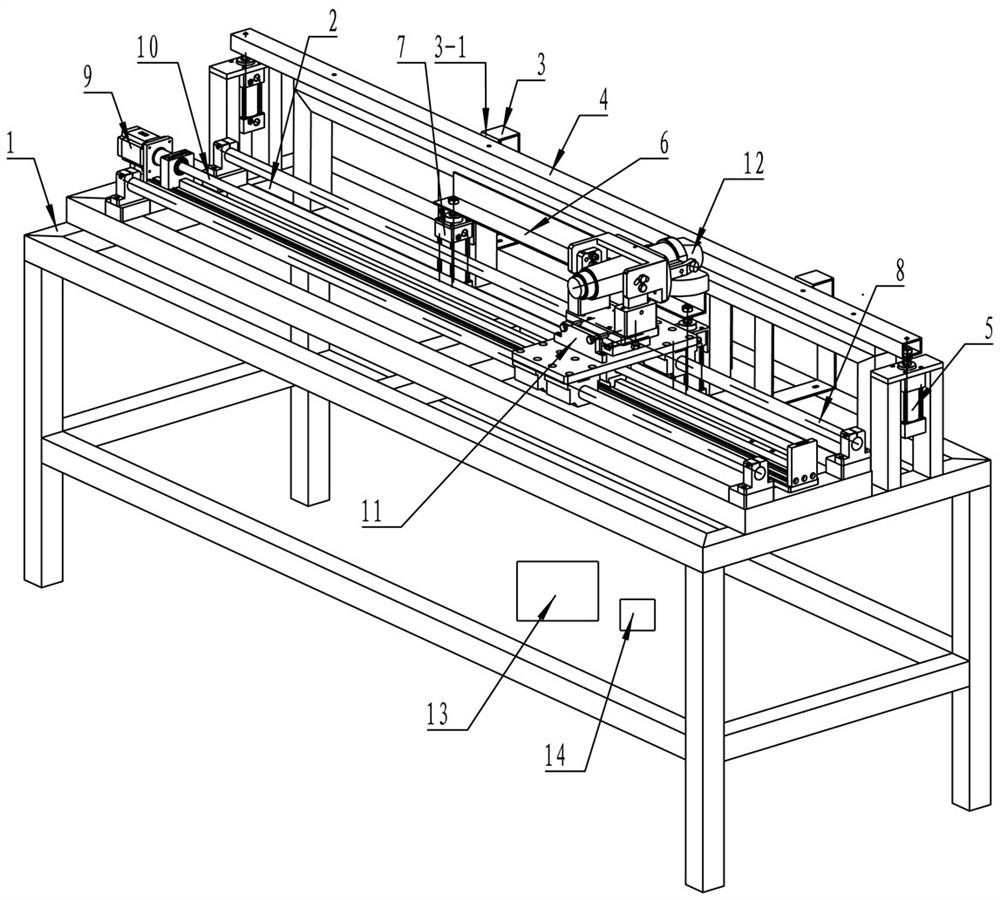

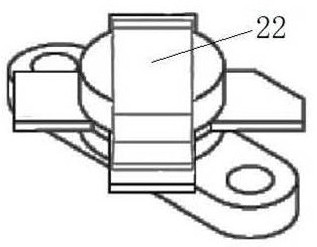

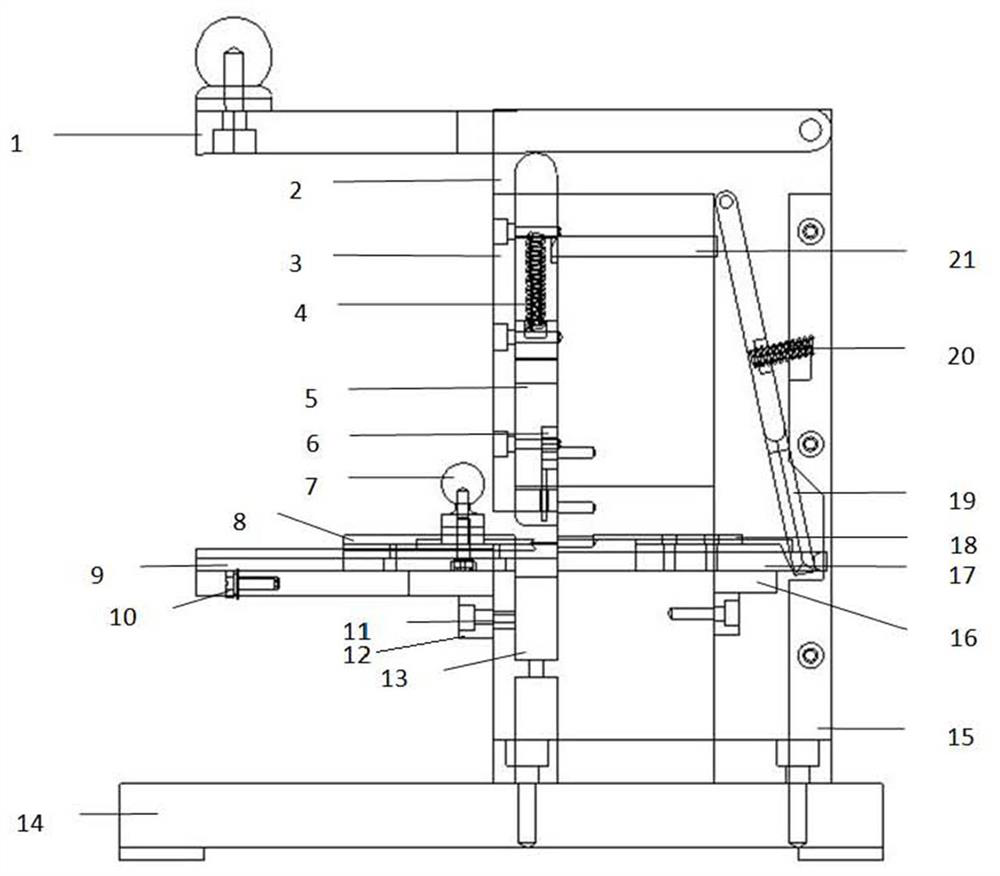

Cloth spreading device

InactiveCN105293147AFull release of tensionRemove creasesWebs handlingEngineeringMechanical engineering

Owner:HUZHOU ZHILI HANYITONGSHE CLOTHING

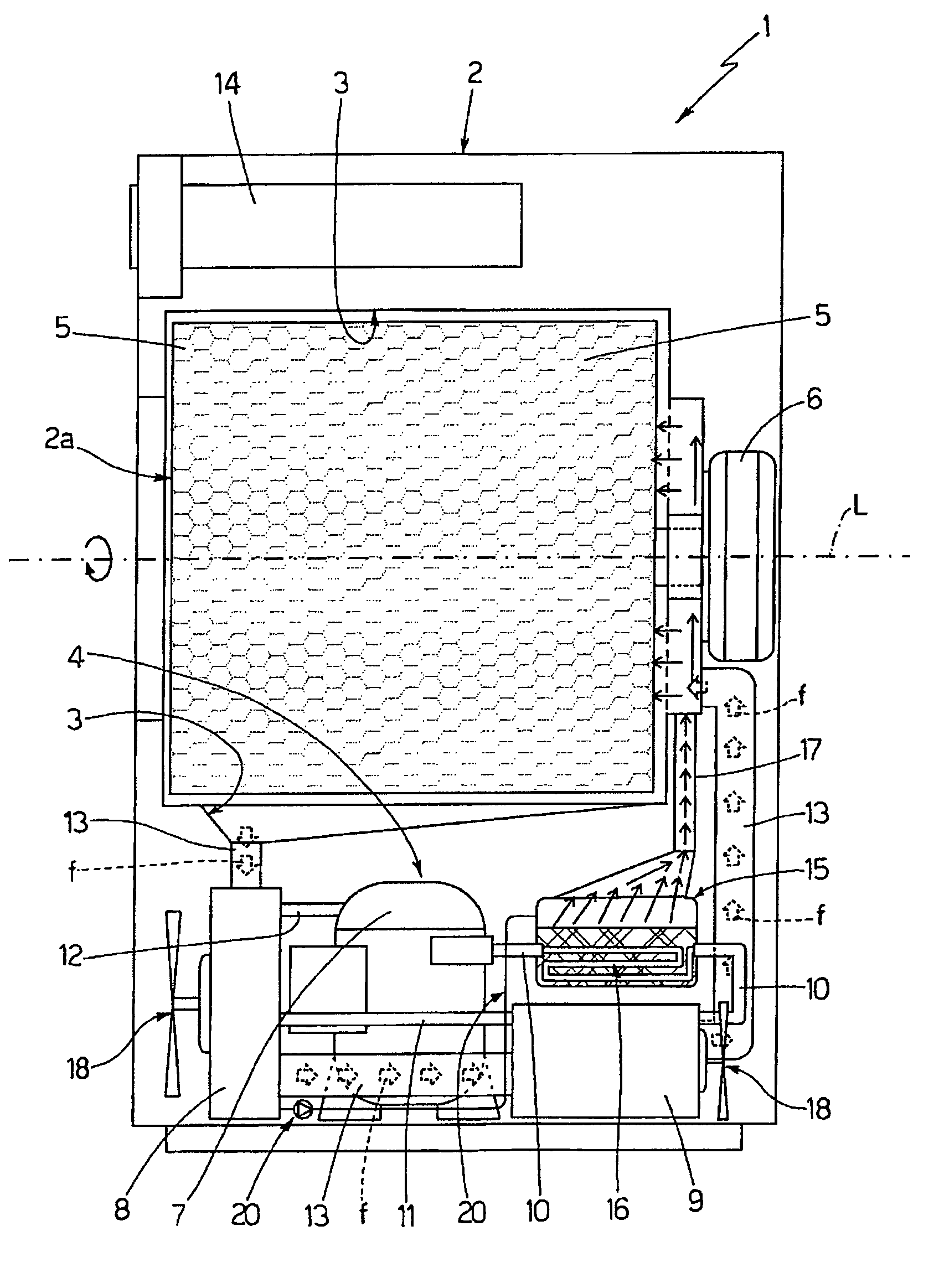

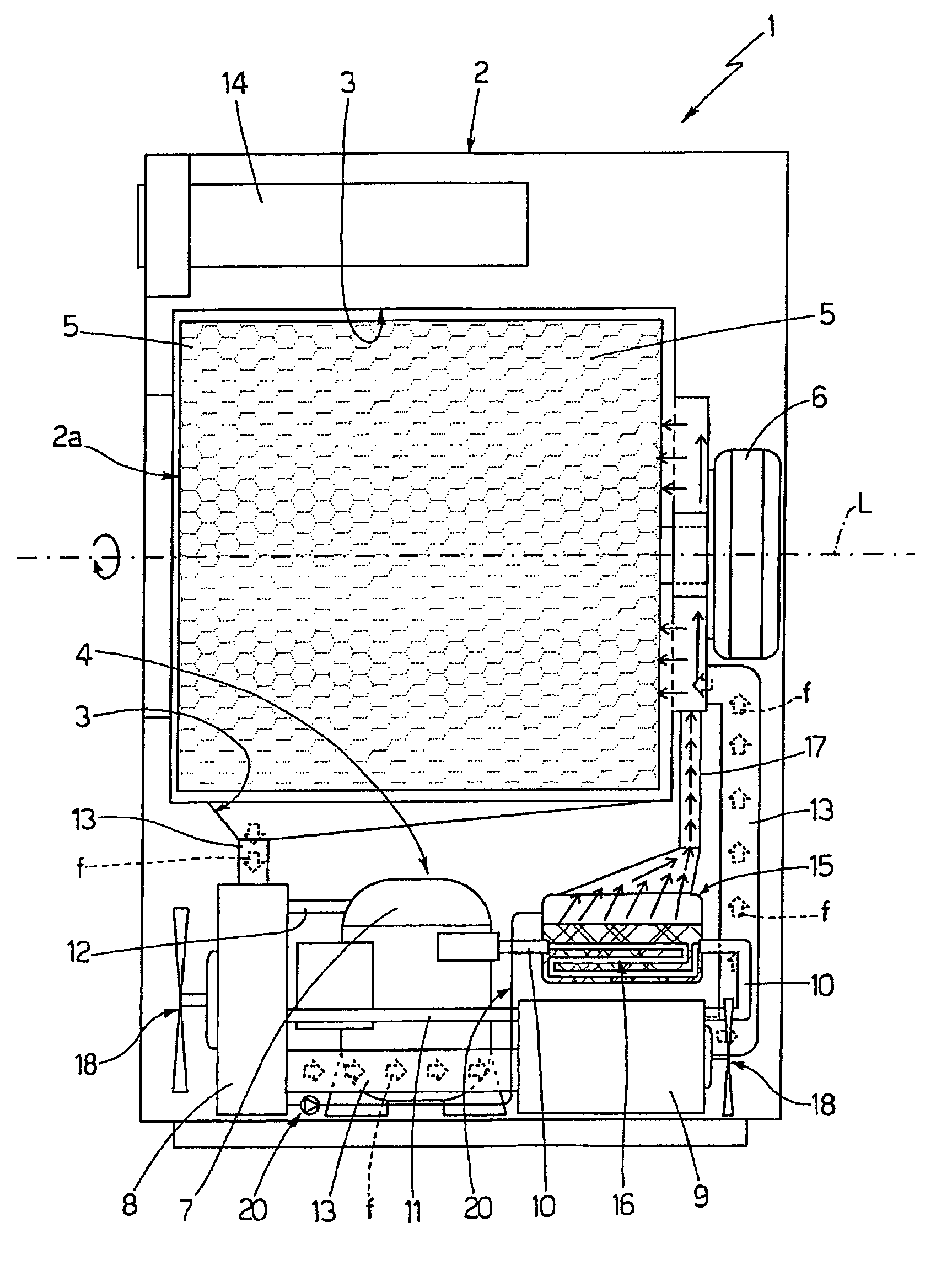

Home laundry drier

A home laundry drier (1) having a drying tub (3) housing the laundry to be dried, and a closed-circuit, heat-pump-type, hot-air generator (4) for circulating a stream of hot air inside the drying tub (3); the hot air generator (4) also having a tank (15) containing a predetermined amount of water, heating means for converting the water in the tank (15) to steam, and an exhaust manifold (17) for feeding the steam produced in the tank (15) to the drying tub (3); the heating means being defined by at least one portion (16) of the pipe (10) feeding refrigerant from the compressor (7) to the condenser (9).

Owner:ELECTROLUX HOME PROD CORP NV

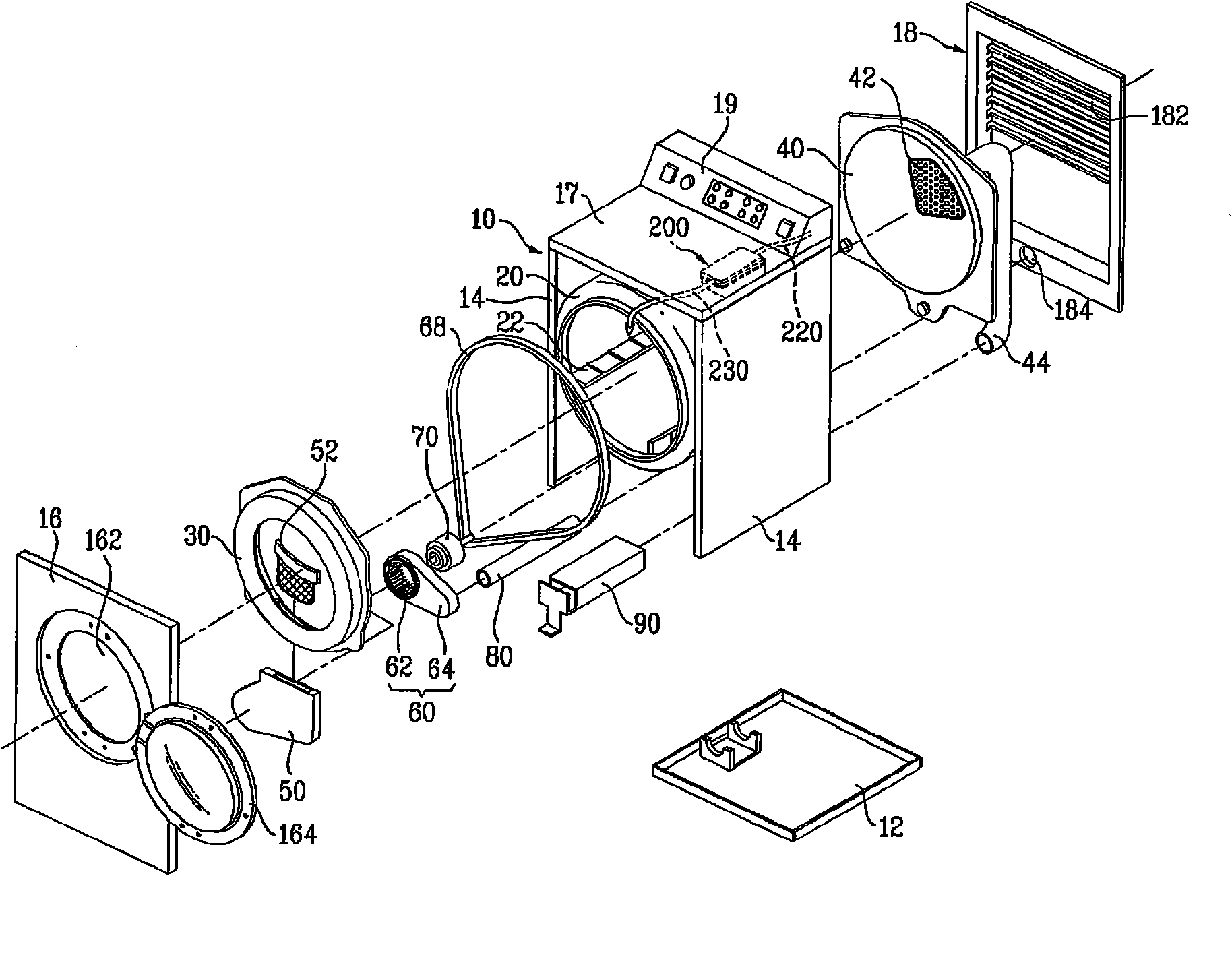

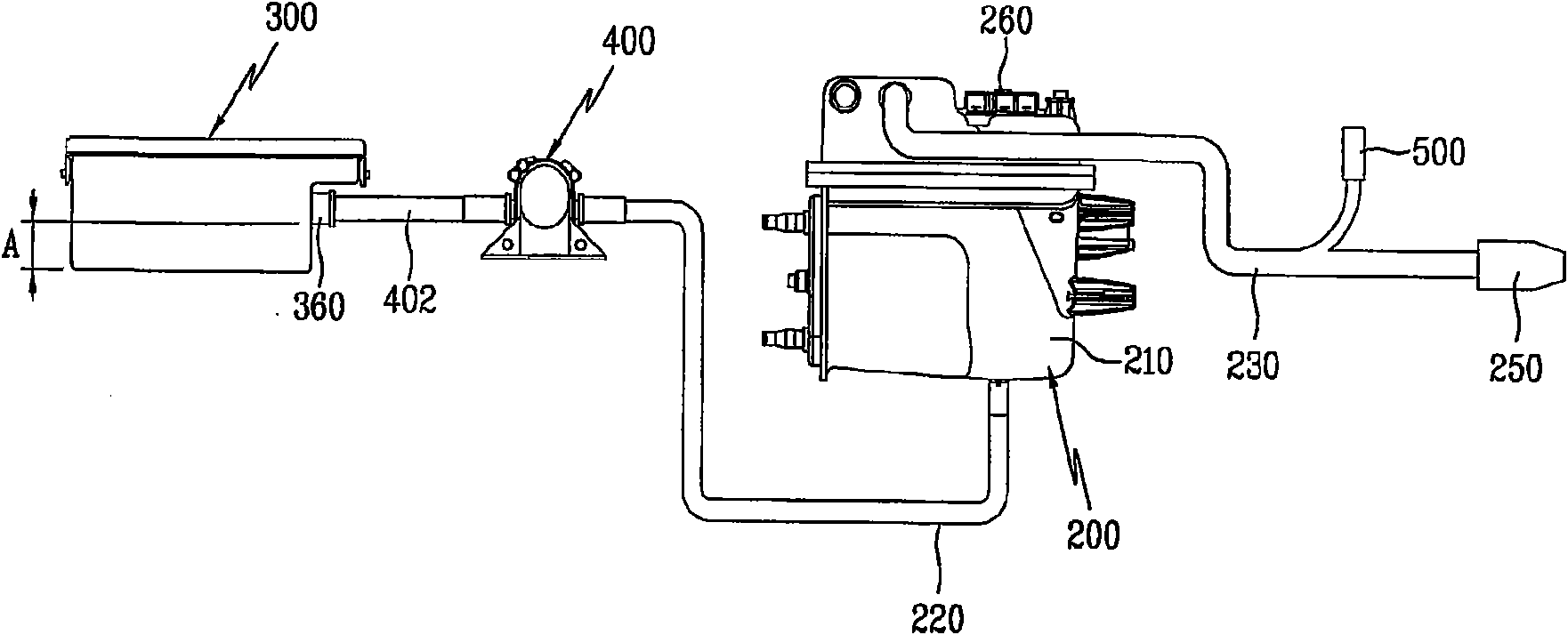

Steam laundry dryer

ActiveCN102084052ARemove creasesEliminate wrinklesOther washing machinesTextiles and paperEngineeringLaundry

The patent application relates to a steam laundry dryer including a drum rotatably mounted on a cabinet; a steam generator supplying steam to the drum; a water supply source supplying water to the steam generator; and a supporting member supporting the water supply source and the steam generator in the inside of the cabinet. The water supply source is detachably installed on the drawer, wherein the drawer is arranged at one side of the cabinet in pluggable and extractable manners.

Owner:LG ELECTRONICS INC

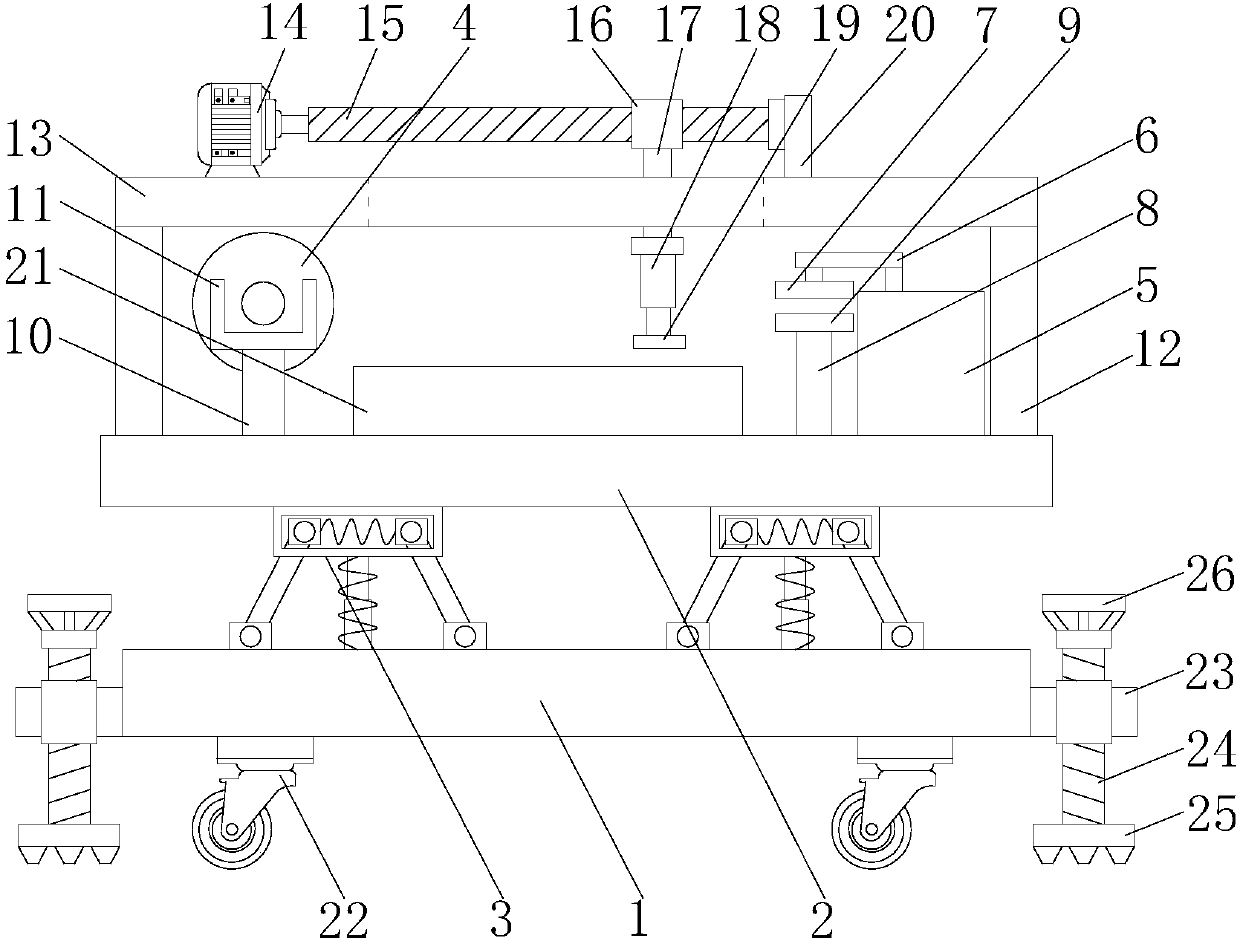

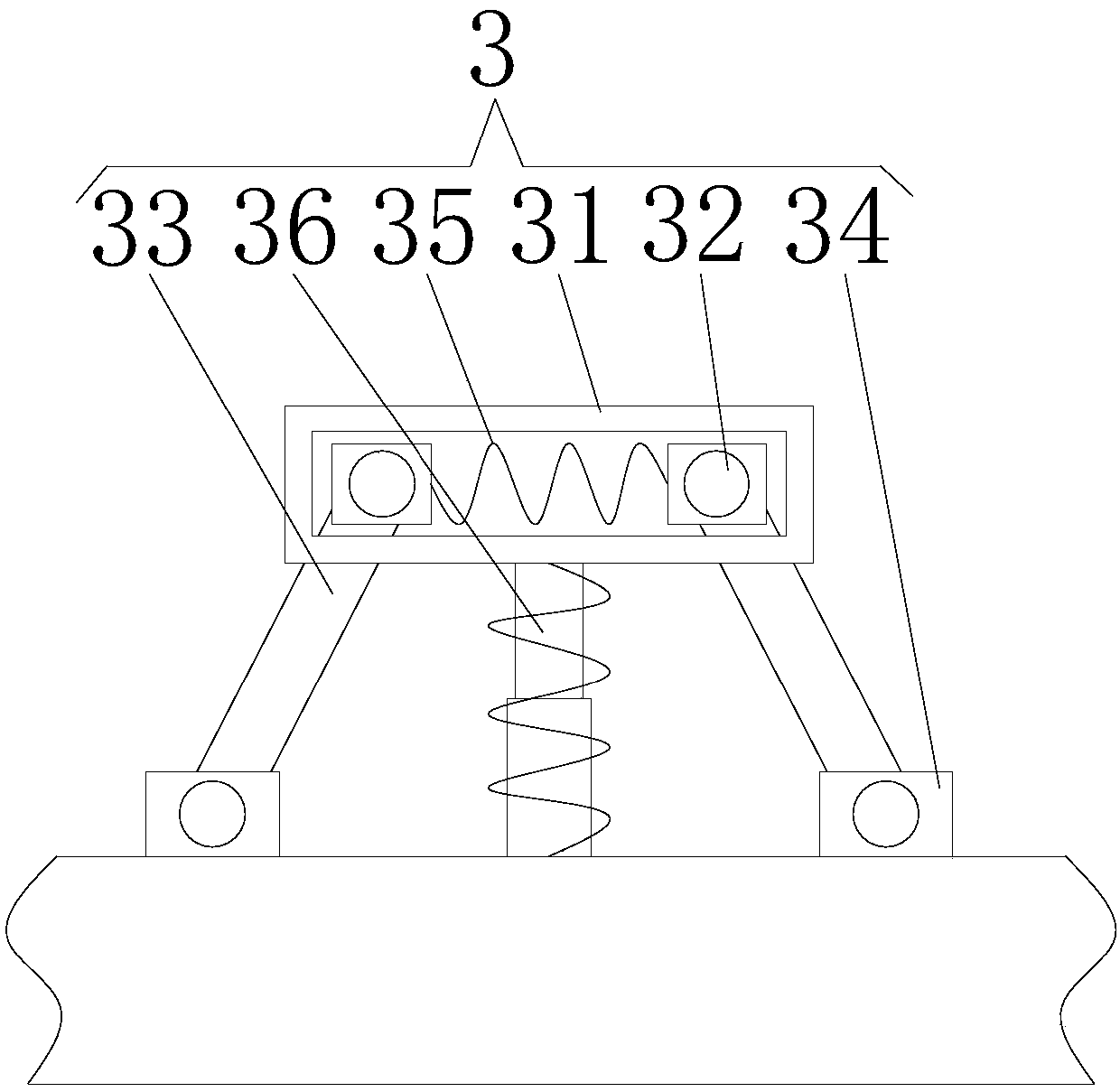

PVC (Polyvinyl Chloride) roll material pulling machine with good stability

The invention discloses a PVC (Polyvinyl Chloride) roll material pulling machine with good stability, which comprises a bottom plate. Damping devices are fixedly connected to two sides of the top partof the bottom plate; a cross plate is fixedly connected to the top parts of the damping devices; lifting devices are fixedly connected to the top part of the cross plate; a movement plate is fixedlyconnected to the top ends of the lifting devices; a pressing plate is fixedly connected to one side of the bottom part of the movement plate; a first support rod is fixedly connected to the top part of the cross plate; and a support plate is fixedly connected to the top end of the first support rod. The invention relates to the technical field of material pulling machines. According to the PVC roll material pulling machine with good stability, the movement plate conveniently flattens a PVC roll material, creases at the surface of the PVC roll material are eliminated, a mechanical structure isreasonable, the occurrence of the phenomenon that a work state of the device is influenced by vibration is avoided, the stability is improved, the interference suffered by the device is reduced, the device can conveniently move to different positions for working, and meanwhile, the device can be conveniently fixed with the ground, so that the practicability of the device is improved.

Owner:安吉腾新印刷厂

Paper money sorting machine based on expansion by spiral air

InactiveCN105869274AImprove reliabilityHigh degree of automationCoin/paper handlersPulp and paper industry

The invention discloses a paper money sorting machine based on expansion by spiral air. A core mechanism is a paper money expansion mechanism. The paper money expansion mechanism comprises an inner barrel. The inner barrel comprises a barrel wall and a barrel bottom which is connected with the barrel wall. The barrel bottom is provided with a closable opening. The barrel wall and / or barrel bottom is provided with a plurality of steam inlets and an air inlet. An outer barrel which sleeves the inner barrel is provided with a barrel wall, and two ends of the outer barrel are open. The inner surface of the wall of the outer barrel is provided with a material which rubs with the inner barrel for generating static. Furthermore the material clings to the outer wall of the inner barrel. The outer barrel can drive the material to perform movement relative to the inner barrel, thereby generating static on the inner barrel. A paper money separating mechanism is connected with the inner barrel. According to the paper money sorting machine, the paper money expansion mechanism is used as a core module, and integration of paper money expansion, sorting, counting and packaging can be realized. The paper money sorting machine has advantages of high response speed, flexible structure, high rigidity-to-weight ratio, low cost, etc.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

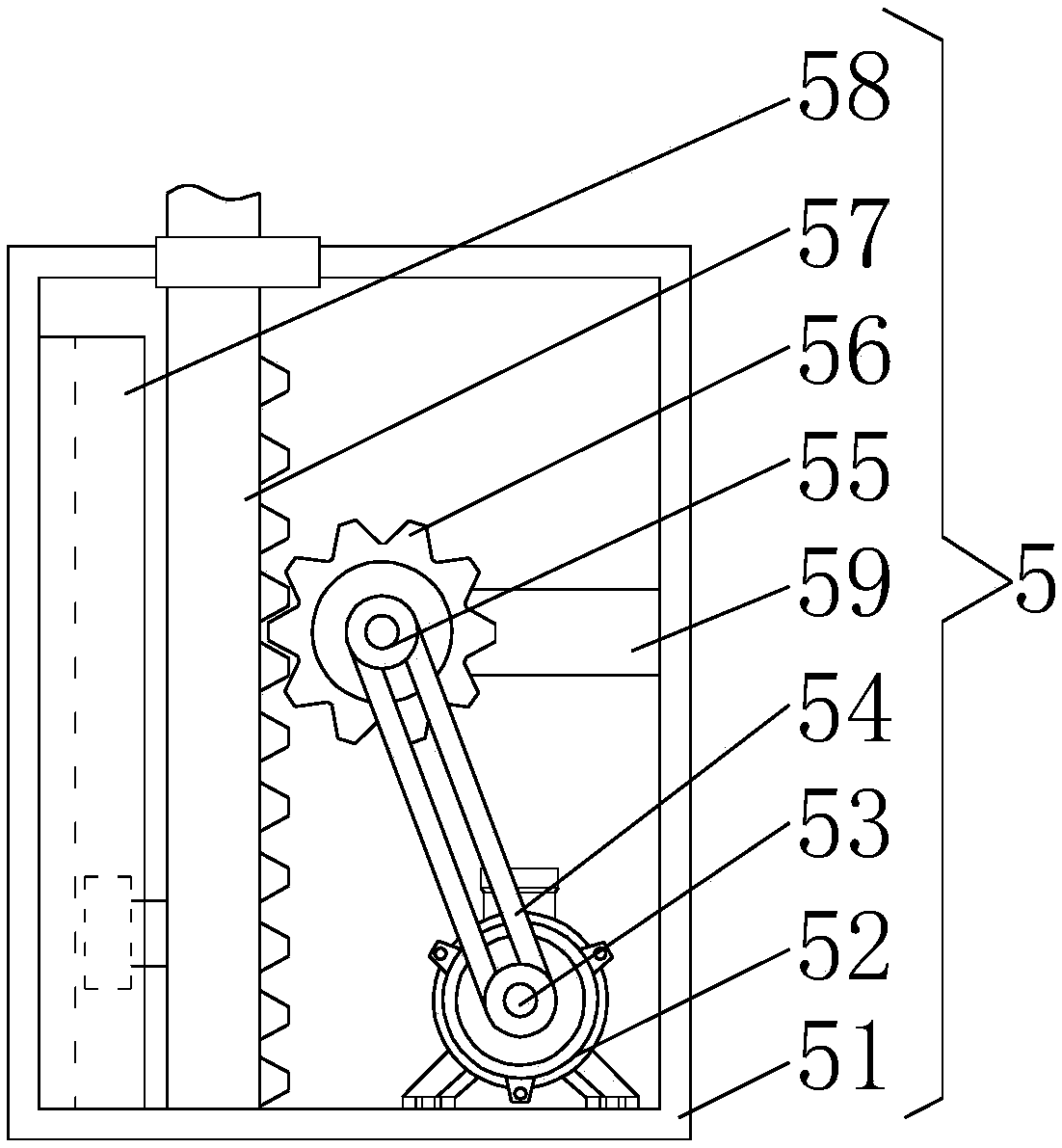

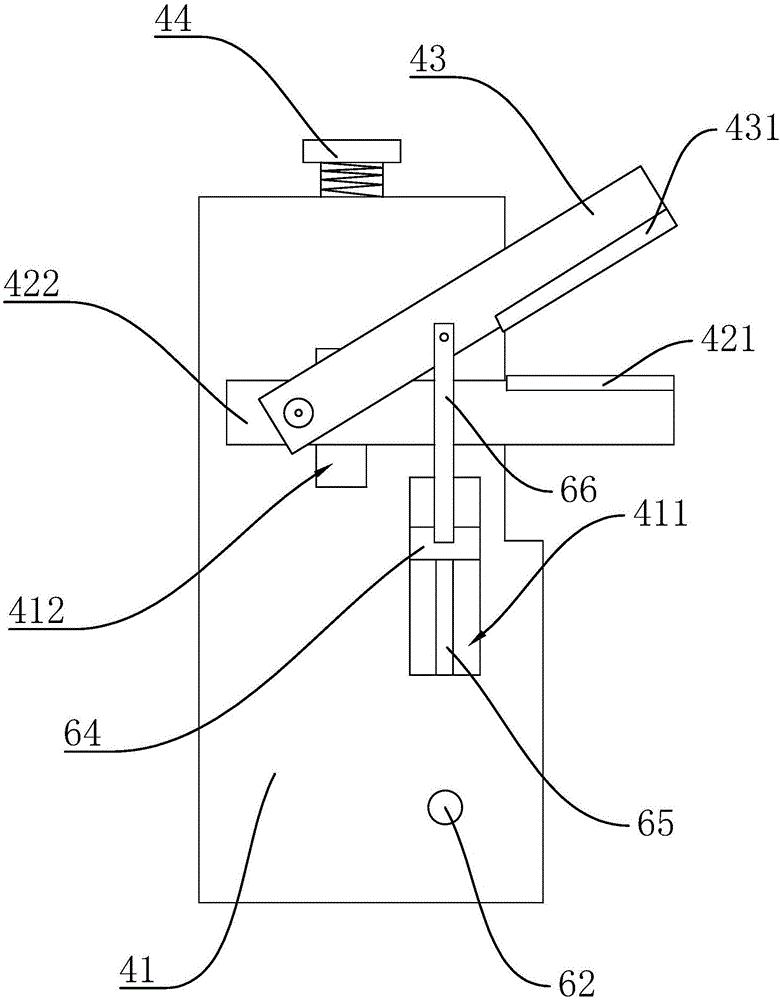

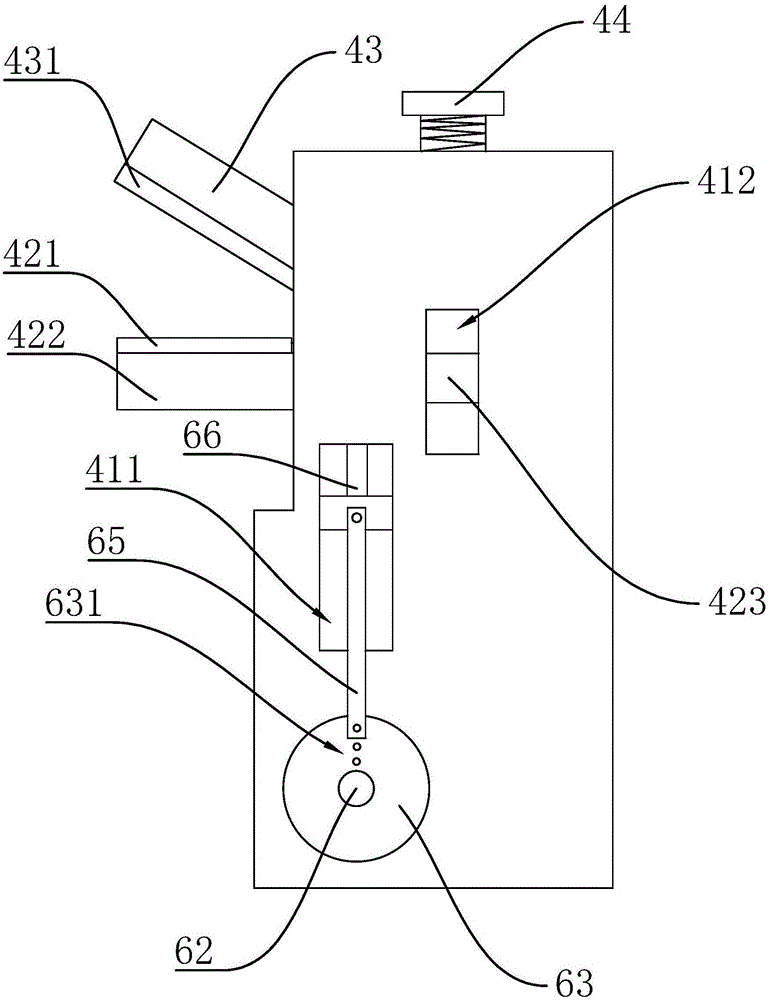

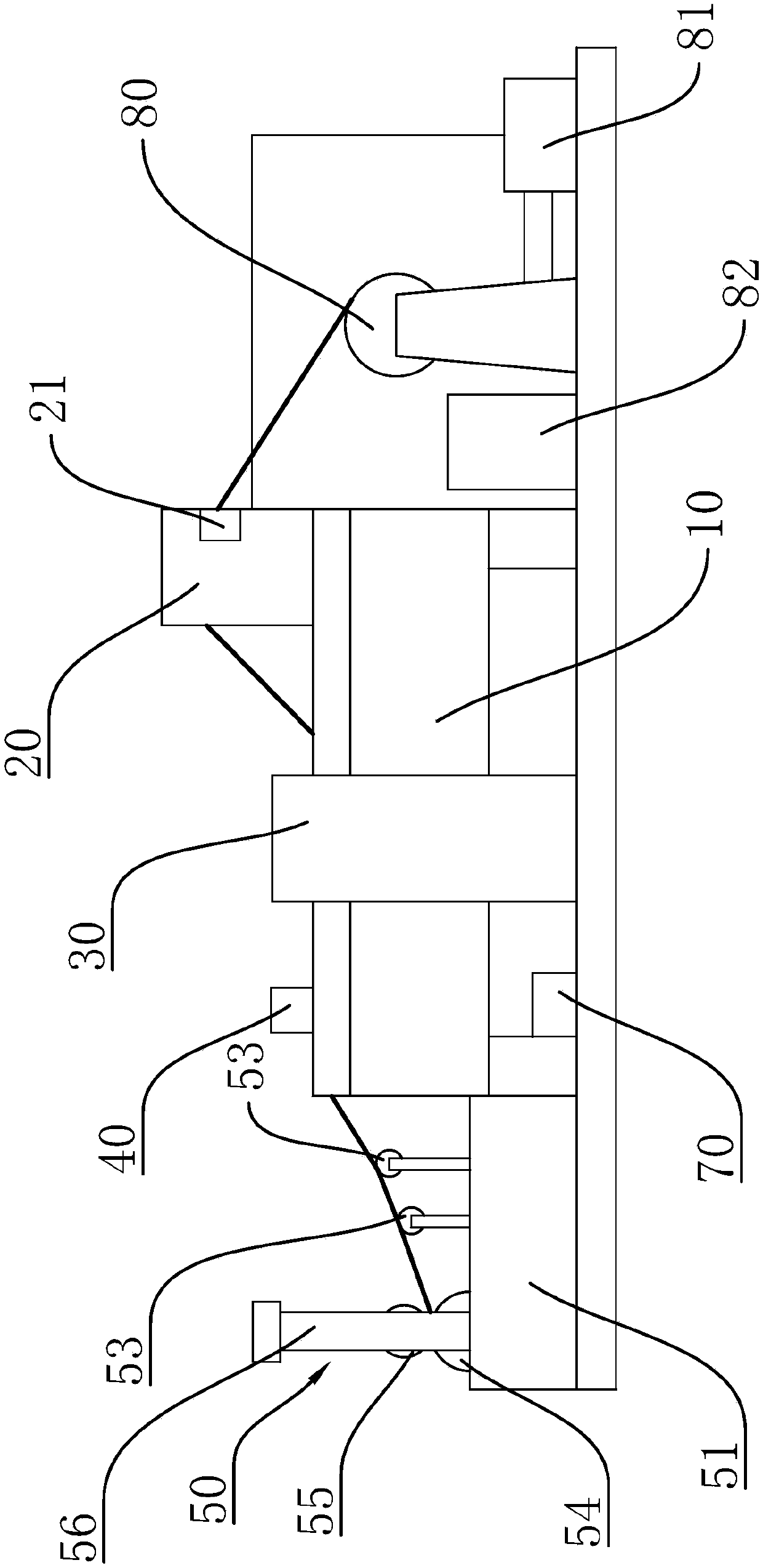

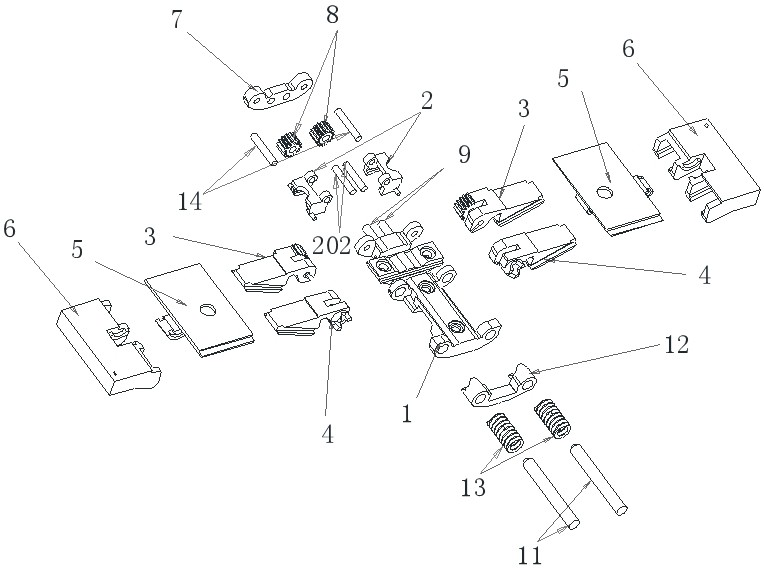

Rapier loom

ActiveCN106048864AImprove surface qualityAccurate and fast resetLoomsAuxillary apparatusPush and pullMotor drive

The invention provides a rapier loom which comprises a workbench, a warp let-off mechanism, a weft let-off mechanism, a slitter edge cutting mechanism and a rolling mechanism. The slitter edge cutting mechanism comprises a cutter rest, a fixed cutter body and a movable cutter body, the fixed cutter body is provided with a first blade, the movable cutter body is provided with a second blade, the fixed cutter body is fixed to the cutter rest in a height-adjustable mode, the movable cutter body is hinged to the fixed cutter body, and the first blade and the second blade abut against each other to form a cutting opening; the slitter edge cutting mechanism further comprises a motor driving the movable cutter body to rotate, a transmission shaft and a rotating disc, and the transmission shaft is controlled by the motor and fixedly connected to the center of the rotating disc; the cutter rest is provided with a longitudinal sliding groove, a sliding block is arranged in the sliding groove, a first connecting rod used for driving the sliding block to rise and fall is arranged between the sliding block and the rotating disc, a second connecting rod used for pushing and pulling the movable cutter body is arranged between the sliding block and the movable cutter body, one side of the sliding block is fixedly connected with the second connecting rod, and the second connecting rod is hinged to the movable cutter body; the other side of the sliding block is hinged to the first connecting rod, and the first connecting rod is hinged to the eccentric position of the rotating disc.

Owner:LANGXI YUANHUA TEXTILE

Cloth winding device for garment making

The invention discloses a cloth winding device for garment making. The cloth winding device comprises a base. A fixed rack and a mounting rack are welded to the two sides of the outer wall of the topof the base correspondingly, and a pressing mechanism is arranged in the fixed rack. A U-shaped pipe mounting hole is formed in the outer wall of one side of the fixed rack, and a U-shaped pipe is connected to the inner wall of the U-shaped pipe mounting hole in an inserted manner. Air spray holes are formed in the top inner wall and the bottom inner wall of the U-shaped pipe. Air spray nozzles are connected to the inner walls of the air spray holes in an inserted manner. An ironing box is fixed to the middle of the inner wall of the mounting rack through screws, a hydraulic cylinder is fixedto the outer wall of the top of the mounting rack through screws, and a press plate is fixed to the bottom end of a piston rod of the hydraulic cylinder through screws. According to the cloth windingdevice, humidity of cloth can be increased, the cloth is ironed through the ironing box and the press plate, water in the cloth is removed through drying, folds of the cloth can be eliminated, the cloth quality can be improved easily, the tension degree of the cloth between a pressing roller and a connecting roller can be guaranteed, and the winding quality can be improved easily.

Owner:天门市丰煜服饰有限公司

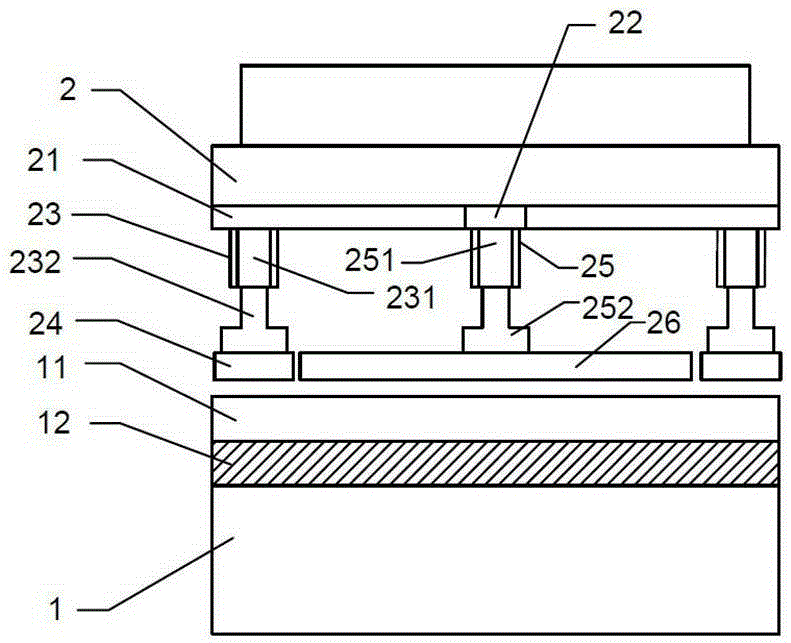

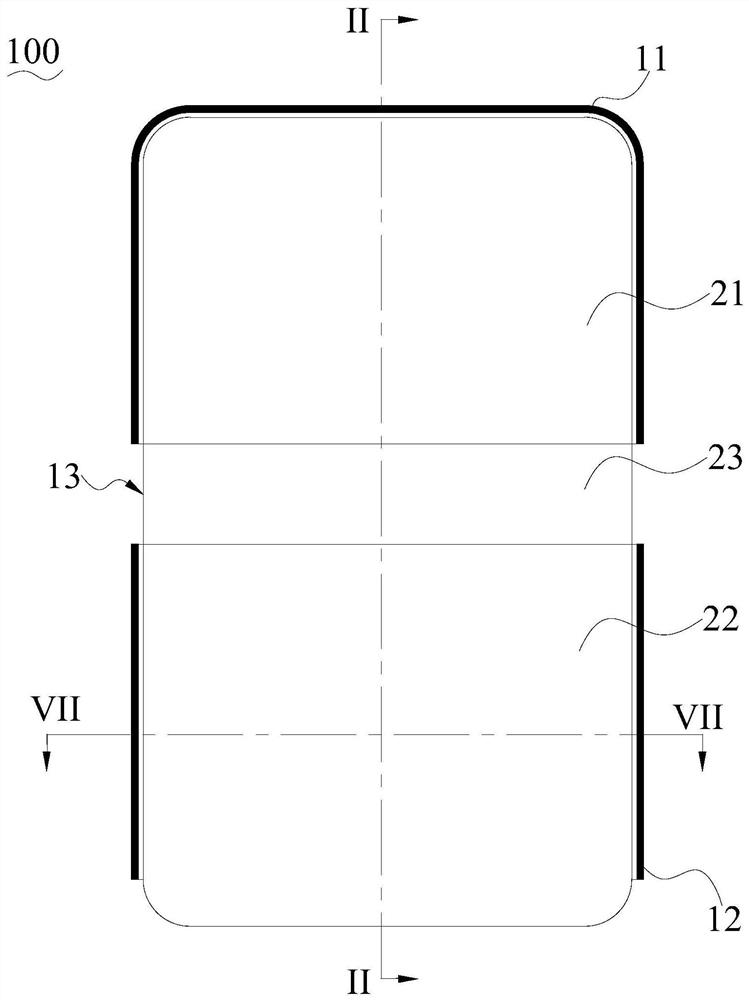

Folding screen and display device

ActiveCN111599276AAvoid technical issues that display exceptionsQuality improvementIdentification meansDisplay deviceMechanical engineering

The invention discloses a folding screen and a display device. The folding screen comprises a flexible screen, a screen body supporting piece used for supporting the flexible screen, crease eliminating structures located in the screen body supporting piece and / or on the surface of the side, deviating from the flexible screen, of the screen body supporting piece, the crease eliminating structures are used for being converted into a tightened state from a deformation state under stimulation of a preset temperature signal, and the shapes of the crease eliminating structures in the tightened stateare preset shapes. According to the technical scheme, in the process that the crease eliminating structure is converted from the deformation state to the straightening state, the force acting on thescreen body supporting piece is generated to eliminate the crease of the flexible screen, so that the quality of a display picture of the flexible screen is improved.

Owner:YUNGU GUAN TECH CO LTD

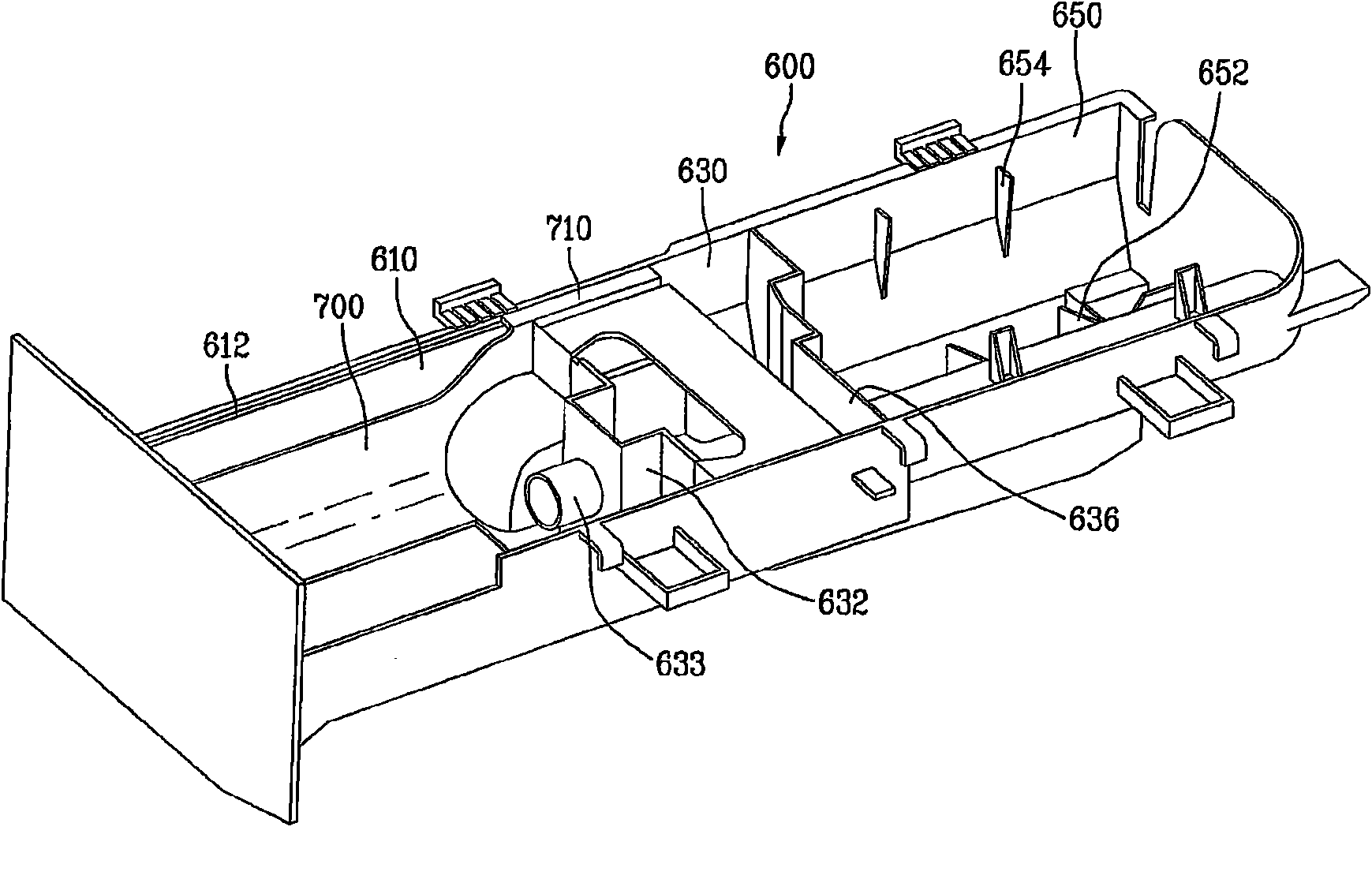

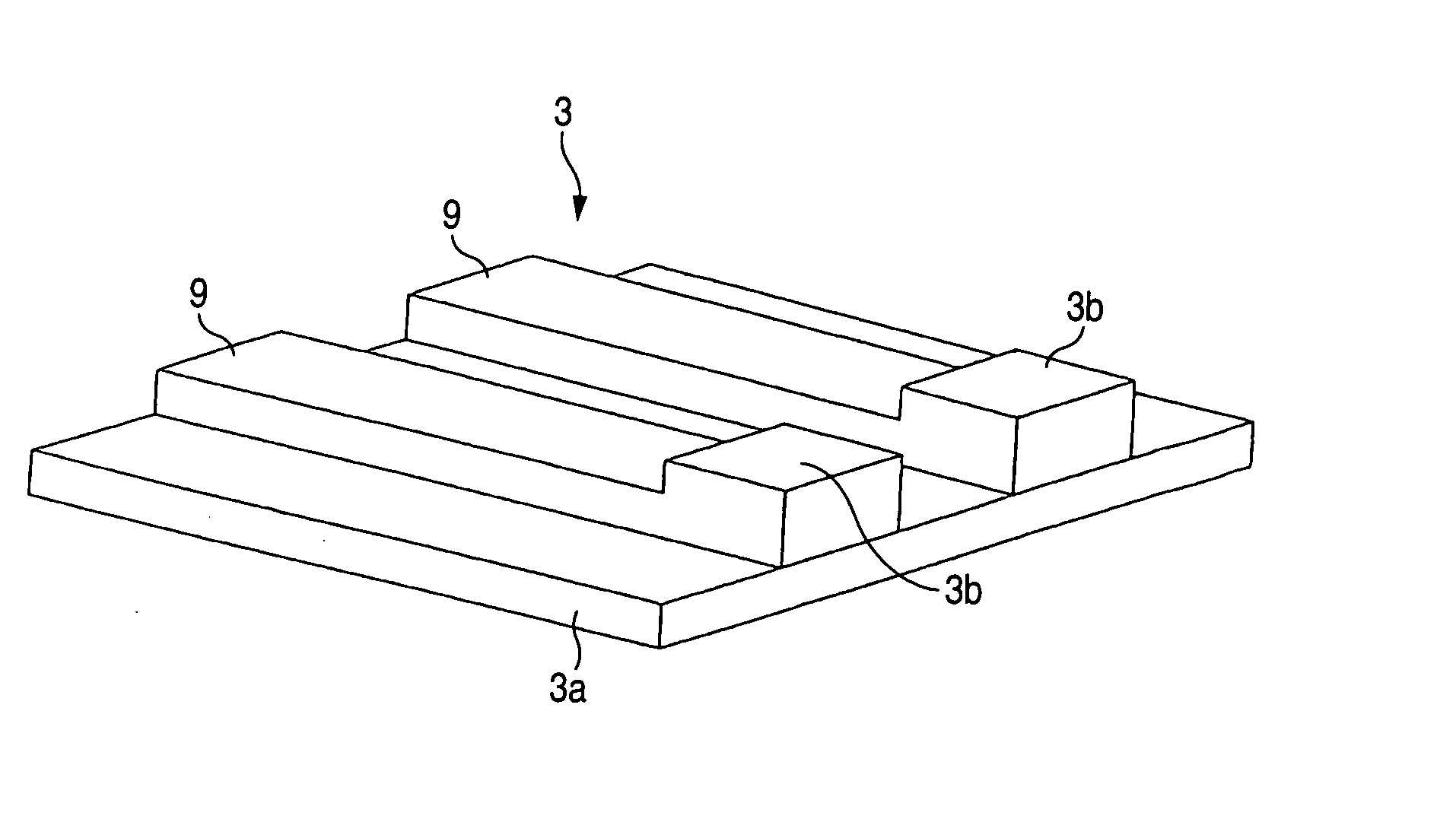

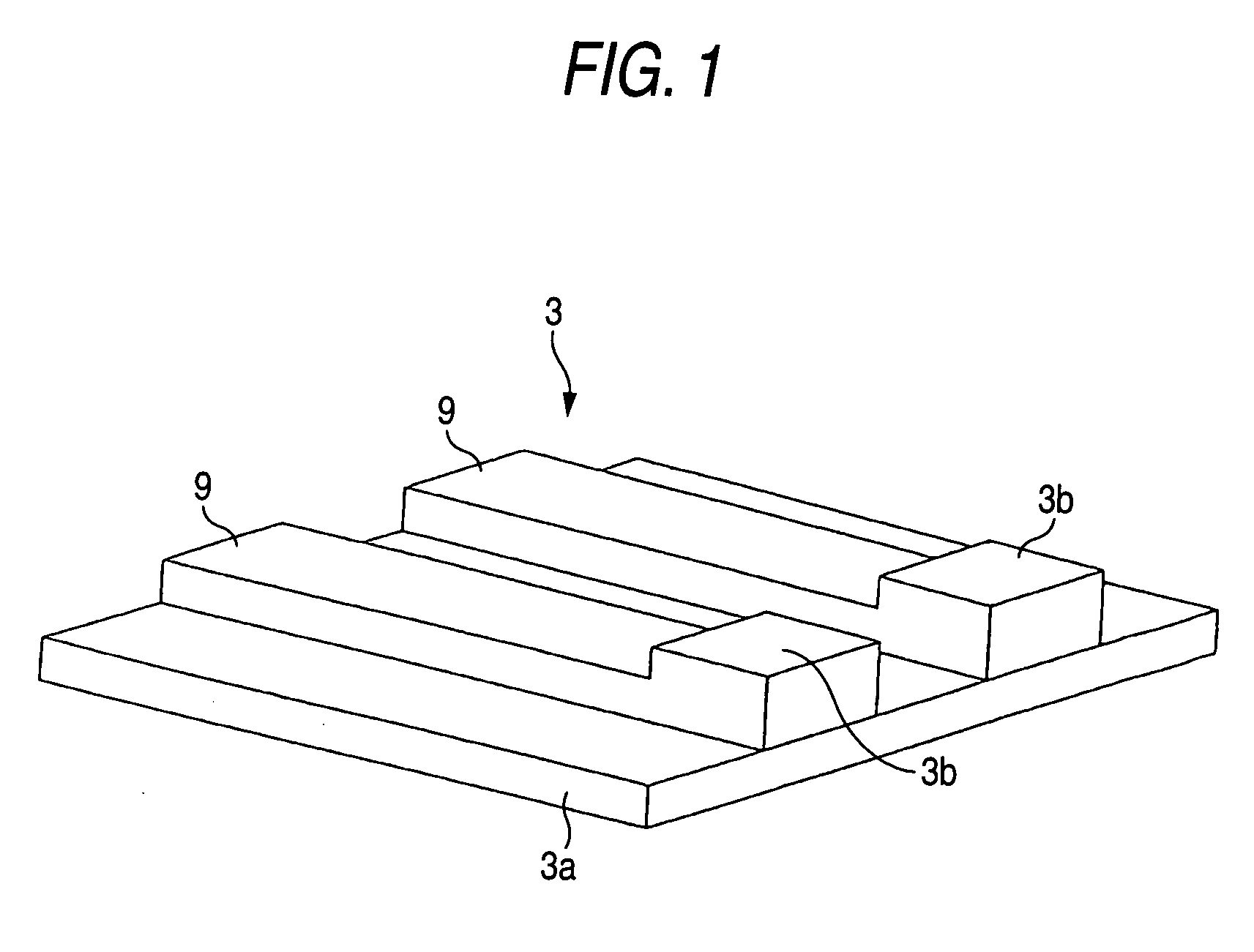

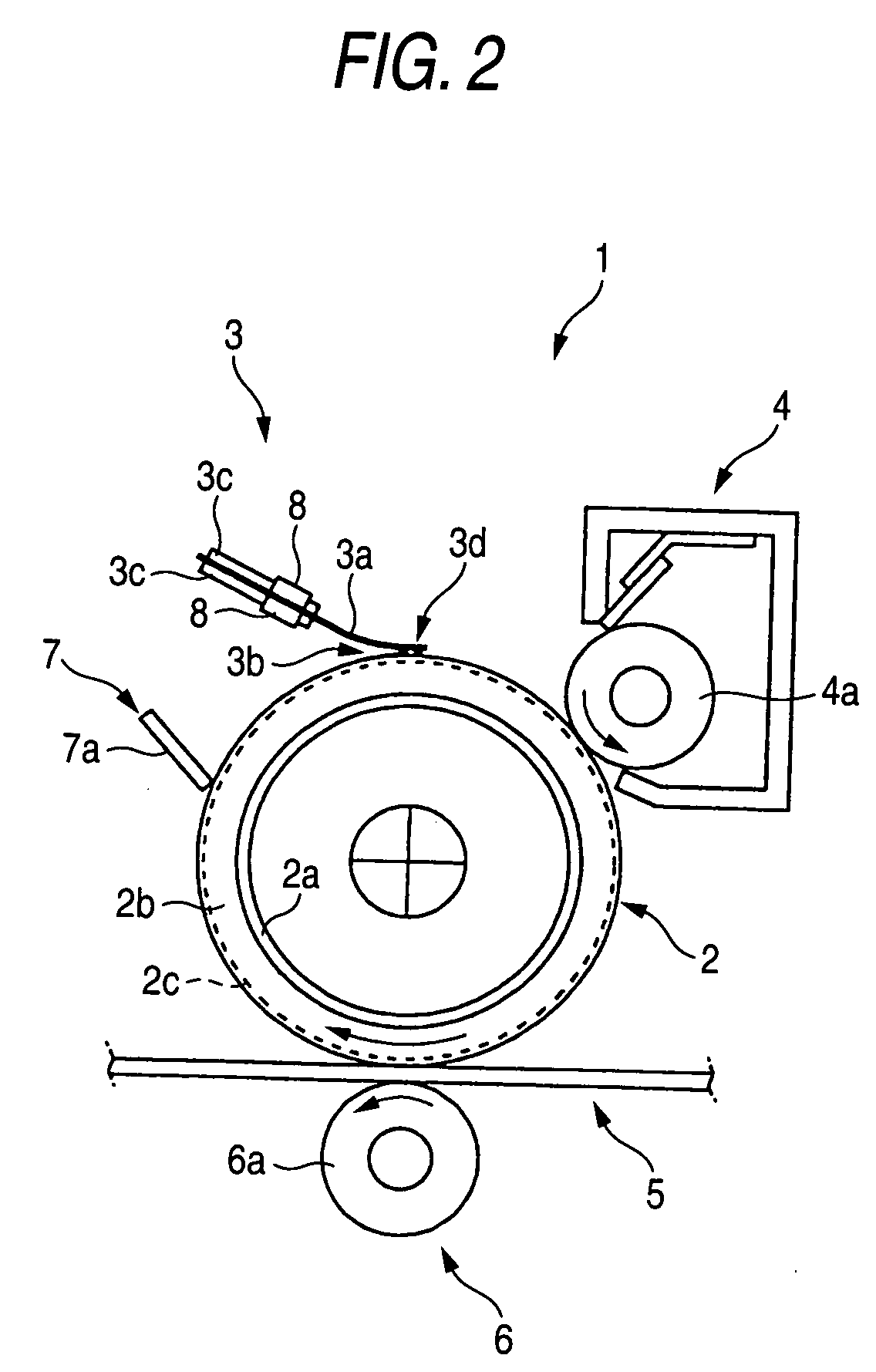

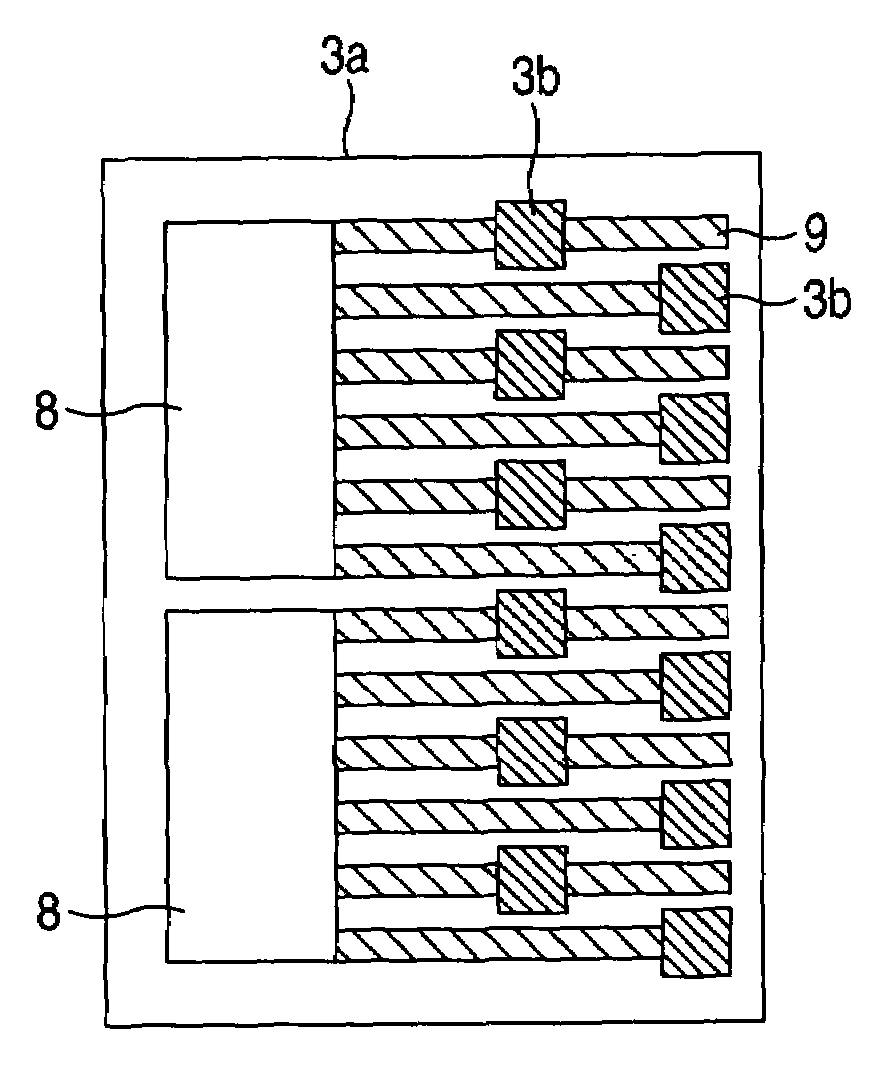

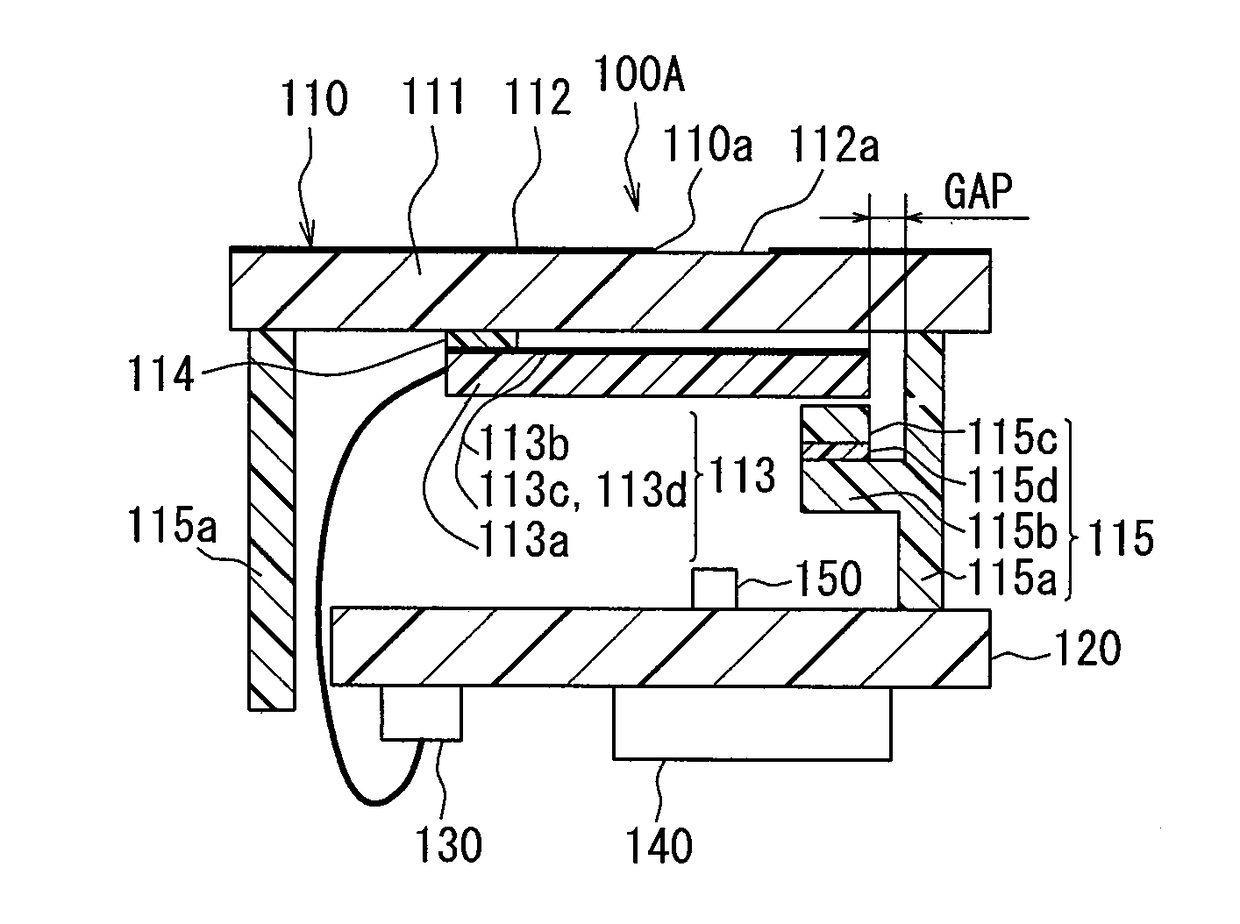

Image forming apparatus

InactiveUS20050104949A1Eliminate bendingRemove creasesMechanical recordingRecord information storageLatent imageImage formation

A head device is for writing an electrostatic latent image on an image carrier of an image forming apparatus which is movable in a first direction. In the head device, a plurality of writing electrodes are arrayed on a substrate in a second direction perpendicular to the first direction to form a plurality of electrode arrays which are arranged in the first direction. The writing electrodes are brought into contact with the image carrier with a flexibility of the substrate. A head driver is disposed on the substrate. A plurality of wirings are extending in the first direction to connect the head driver and the respective writing electrodes to supply writing voltages from the head driver to the writing electrodes. At least one of the wirings extended through one of the writing electrodes in one of the electrode arrays is placed between adjacent ones of the writing electrodes in another one of the electrode arrays.

Owner:SEIKO EPSON CORP

Image forming apparatus

InactiveUS7002610B2Eliminate bendingRemove creasesMechanical recordingRecord information storageLatent imageImage formation

A head device is for writing an electrostatic latent image on an image carrier of an image forming apparatus which is movable in a first direction. In the head device, a plurality of writing electrodes are arrayed on a substrate in a second direction perpendicular to the first direction to form a plurality of electrode arrays which are arranged in the first direction. The writing electrodes are brought into contact with the image carrier with a flexibility of the substrate. A head driver is disposed on the substrate. A plurality of wirings are extending in the first direction to connect the head driver and the respective writing electrodes to supply writing voltages from the head driver to the writing electrodes. At least one of the wirings extended through one of the writing electrodes in one of the electrode arrays is placed between adjacent ones of the writing electrodes in another one of the electrode arrays.

Owner:SEIKO EPSON CORP

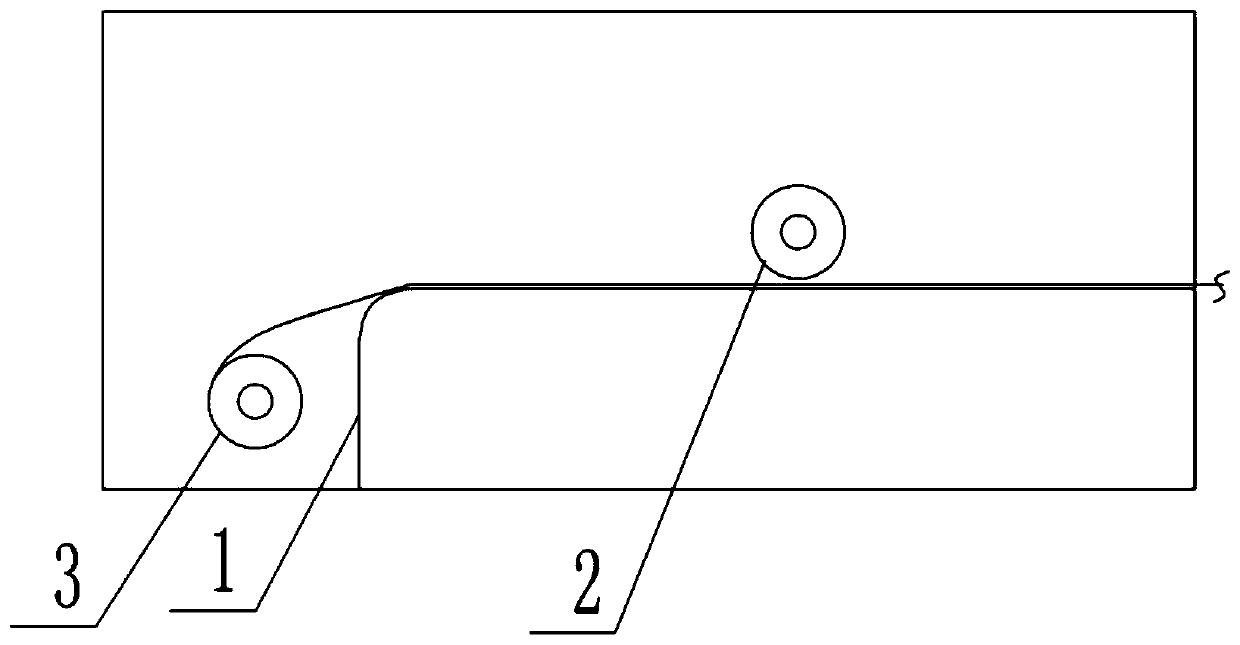

Anti-wrinkling press roller

The invention discloses an anti-wrinkling press roller. The anti-wrinkling press roller comprises a U-shaped bracket, a press roller is rotatably connected between the two support arms which are arranged in parallel on the support, two friction wheels are further arranged on a supporting plate which is connected with the two support arms and the two friction wheels are arranged on two sides of thepress roller, the friction wheel on the left side can rotate in the clockwise direction along the direction of the coiled material below the press roller, the friction wheel on the right can rotate in a counterclockwise direction; the position at which any point on the outer side wall of the friction wheels are at the lowest end is flush with the position at the lowest end of the outer side wallof the press roller. The friction wheels in the anti-wrinkling press roller are not rotating in the non-working state, when it was found that the coiled material was creased or wrinkled, the frictionwheels are driven to rotate through the corresponding power structure, the friction wheel on the left side can rotate in the clockwise direction along the direction of the coiled material, the friction wheel on the right can rotate in a counterclockwise direction, under the action of the friction force, the creased or wrinkled coiled material is flattened towards both sides, and this serves to eliminate creases or wrinkles.

Owner:TIANJIN XUHUIHENGYUAN PLASTIC PACKAGING CORP

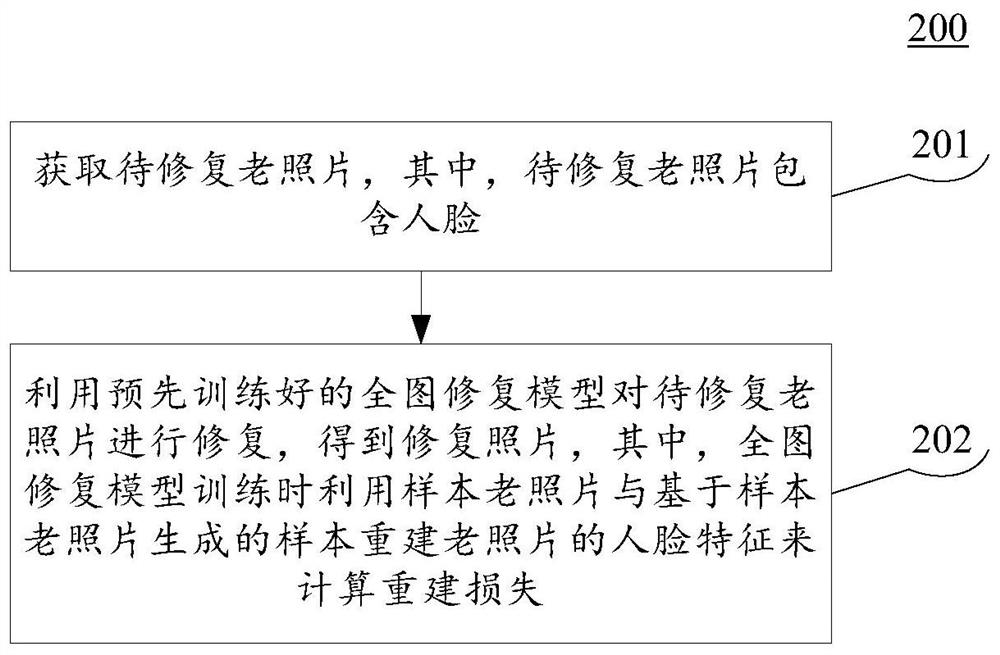

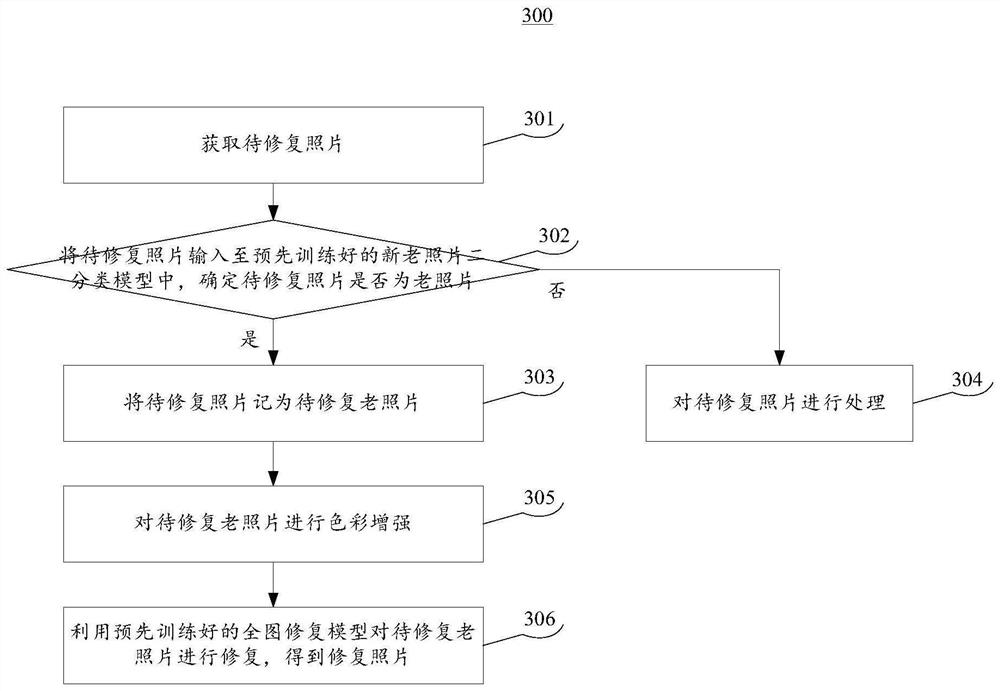

Photo restoration method and device, equipment and storage medium

PendingCN113034393ARemove creasesRemove stainsImage enhancementImage analysisImaging processingRestoration method

The invention discloses a photo restoration method and device, equipment and a storage medium, relates to the technical field of artificial intelligence, in particular to the technical field of computer vision and deep learning, and can be applied to an image processing scene. A specific embodiment of the method comprises the steps: acquiring an old photo to be restored, wherein the old photo to be restored comprises a human face; and repairing the to-be-repaired old photo by using a pre-trained full-image repair model to obtain a repaired photo, and calculating reconstruction loss by using face features of the sample old photo and a sample reconstruction old photo generated based on the sample old photo when the full-image repair model is trained. According to the embodiment, creases, stains and noisy points in the old photo can be removed, the learning threshold is low, and a common user can also use the method.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

A rapier loom

ActiveCN106048864BFinished product quality impactAccurate and fast resetLoomsAuxillary apparatusPush and pullDrive shaft

The invention provides a rapier loom which comprises a workbench, a warp let-off mechanism, a weft let-off mechanism, a slitter edge cutting mechanism and a rolling mechanism. The slitter edge cutting mechanism comprises a cutter rest, a fixed cutter body and a movable cutter body, the fixed cutter body is provided with a first blade, the movable cutter body is provided with a second blade, the fixed cutter body is fixed to the cutter rest in a height-adjustable mode, the movable cutter body is hinged to the fixed cutter body, and the first blade and the second blade abut against each other to form a cutting opening; the slitter edge cutting mechanism further comprises a motor driving the movable cutter body to rotate, a transmission shaft and a rotating disc, and the transmission shaft is controlled by the motor and fixedly connected to the center of the rotating disc; the cutter rest is provided with a longitudinal sliding groove, a sliding block is arranged in the sliding groove, a first connecting rod used for driving the sliding block to rise and fall is arranged between the sliding block and the rotating disc, a second connecting rod used for pushing and pulling the movable cutter body is arranged between the sliding block and the movable cutter body, one side of the sliding block is fixedly connected with the second connecting rod, and the second connecting rod is hinged to the movable cutter body; the other side of the sliding block is hinged to the first connecting rod, and the first connecting rod is hinged to the eccentric position of the rotating disc.

Owner:LANGXI YUANHUA TEXTILE

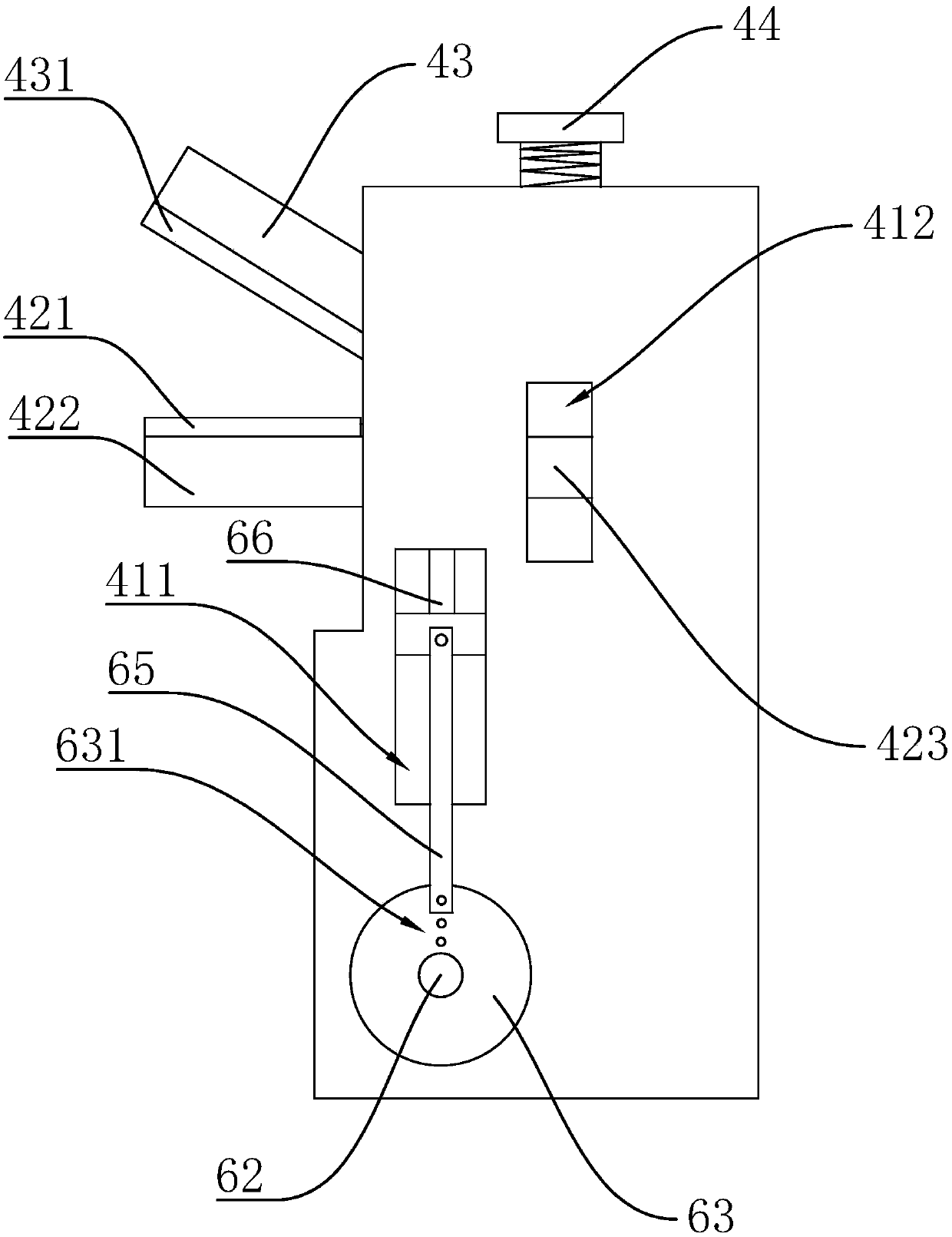

Dyeing process of high-grade environment-friendly clothing flannel fabric

InactiveCN113249905AQuality improvementUniform moisture contentSucessive textile treatmentsLiquid/gas/vapor treatment of propelled fabricsFiberPolymer science

The invention discloses a dyeing process of a high-grade environment-friendly clothing flannel fabric. The dyeing process comprises gray fabric which can be dyed after being unwound. According to the dyeing process, the gray fabric is pre-shaped, so that the molecular structure of the gray fabric is stable, the water content of the fabric is uniform, the fabric surface is flat, creases are eliminated, the quality of the dyed gray fabric is better, the obtained flannel fabric is more high-grade and environment-friendly, the fabric is soaped after being dyed, dye molecules on fibers can be associated to form microcrystals, thus the color of the fabric is bright and full, the solarization and chlorine bleaching fastness is improved, the fabric is softened, the surface of the fabric is smooth, the internal friction force of the fabric is reduced, the rebound resilience is improved, and creases and scratches generated in subsequent processing of the fabric are avoided; the fabric is dehydrated and shaped, the whole crack degree of fiber molecules and the compactness of the molecular structures are improved, and the dimensional stability of the fabric can be improved.

Owner:JIANGSU YREDAR TEXTILE TECH CO LTD

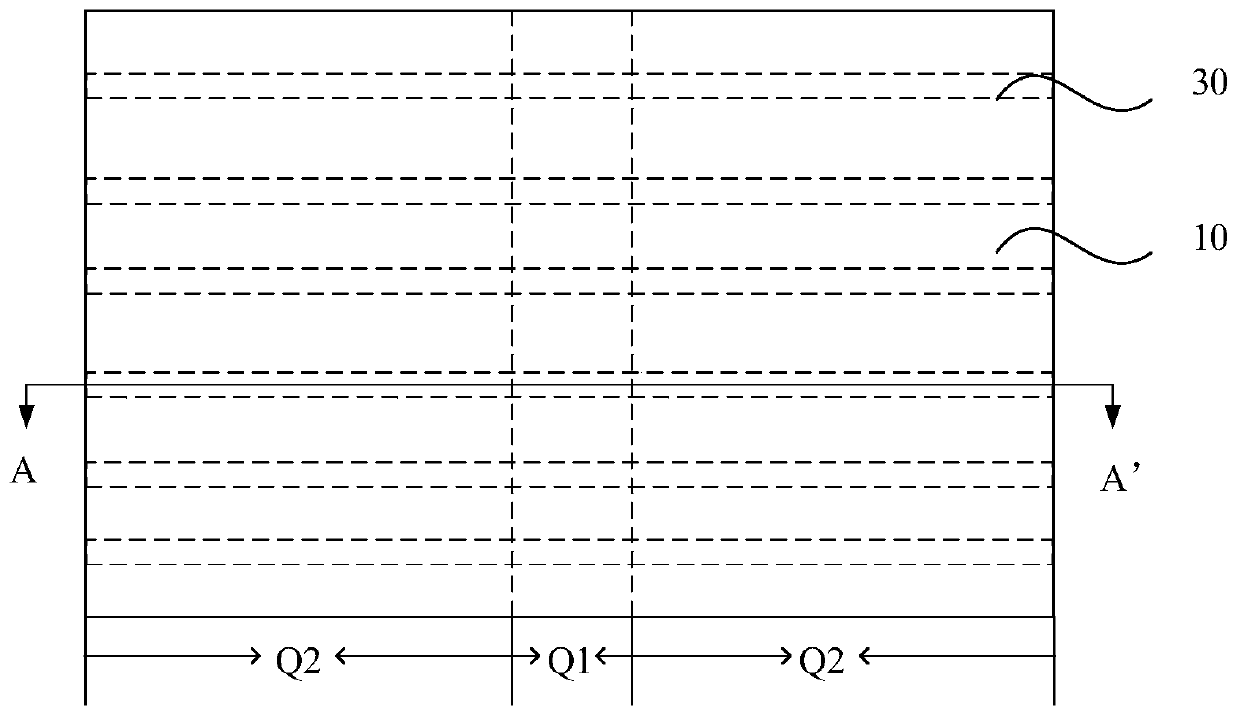

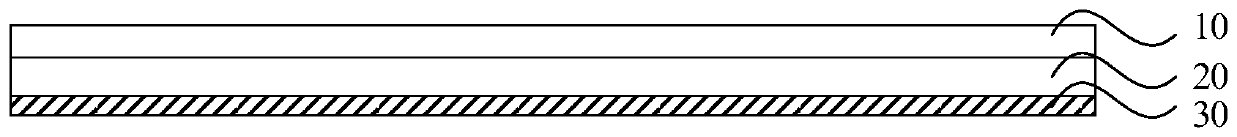

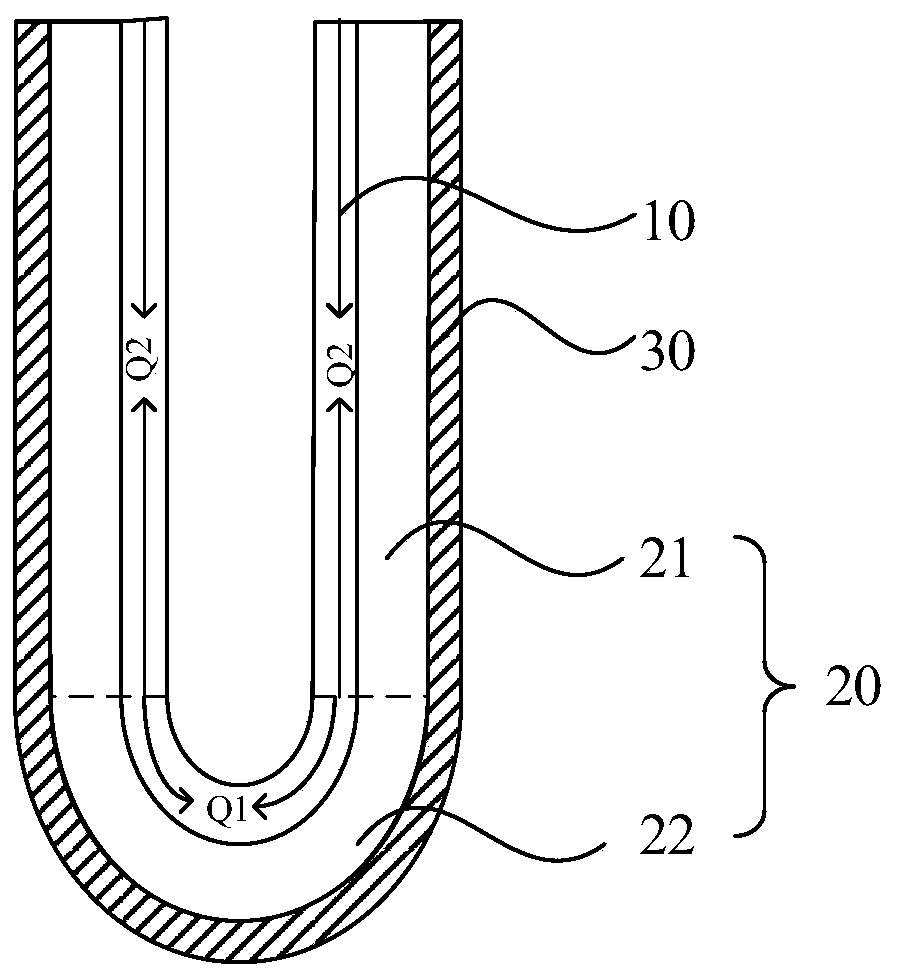

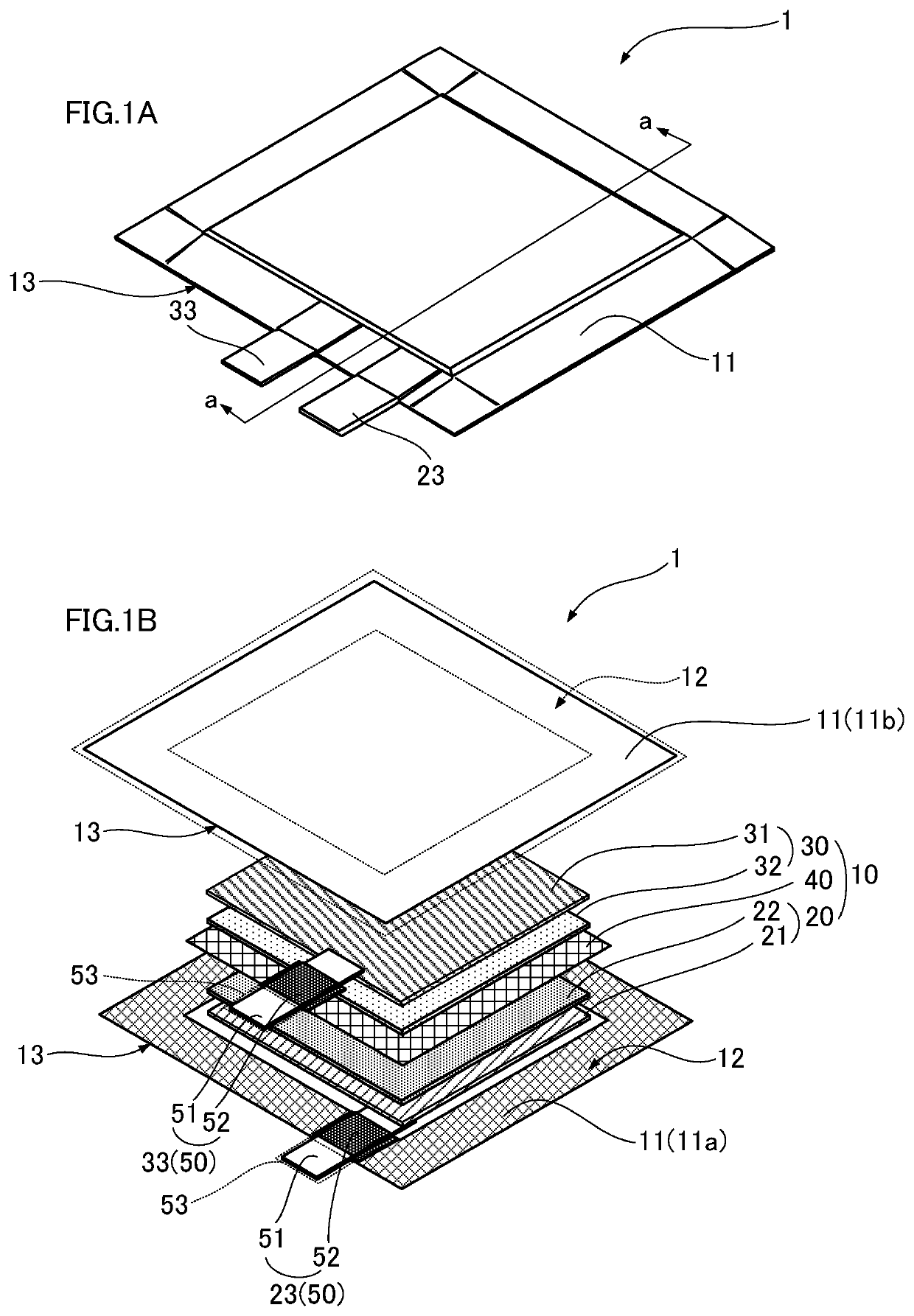

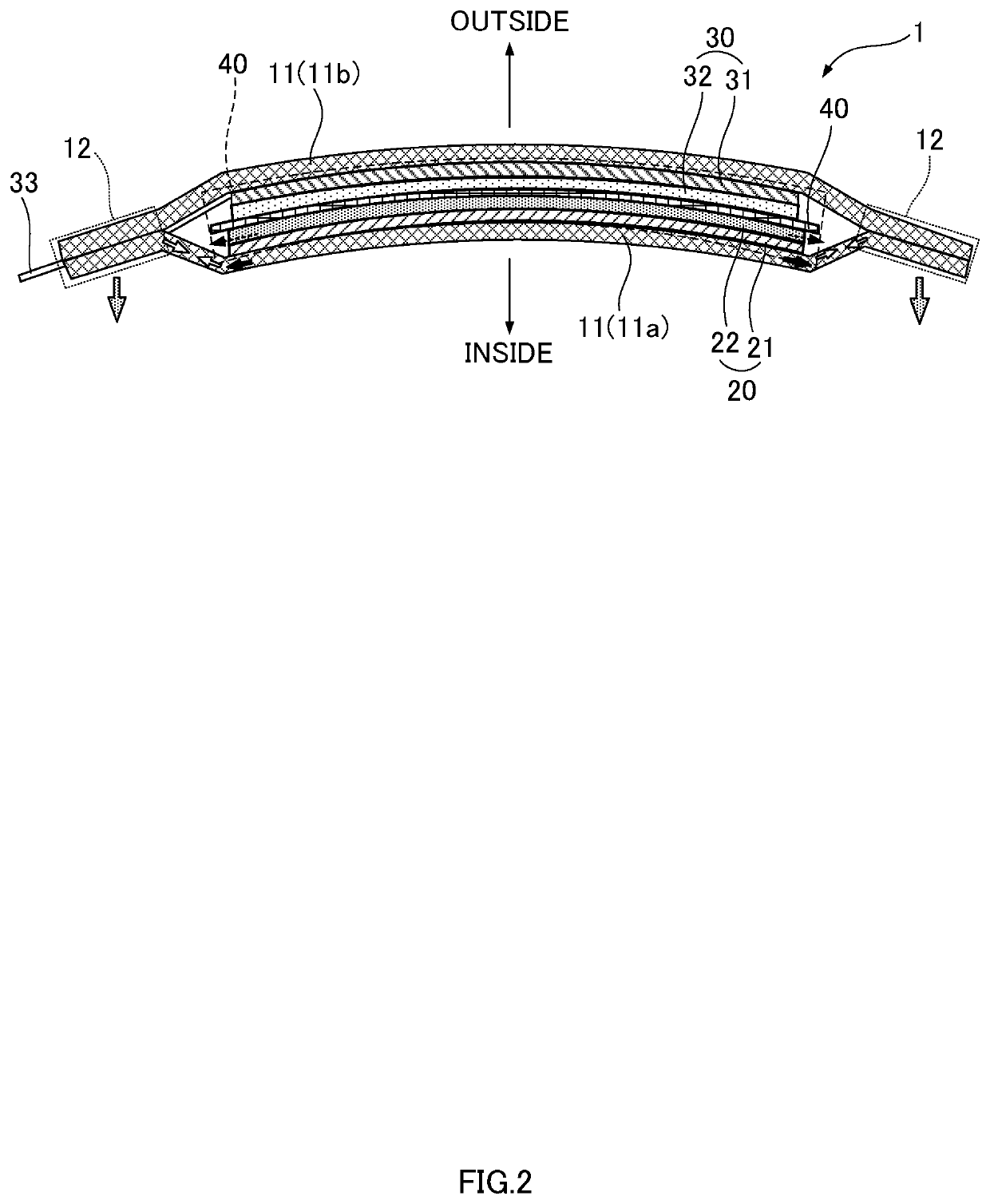

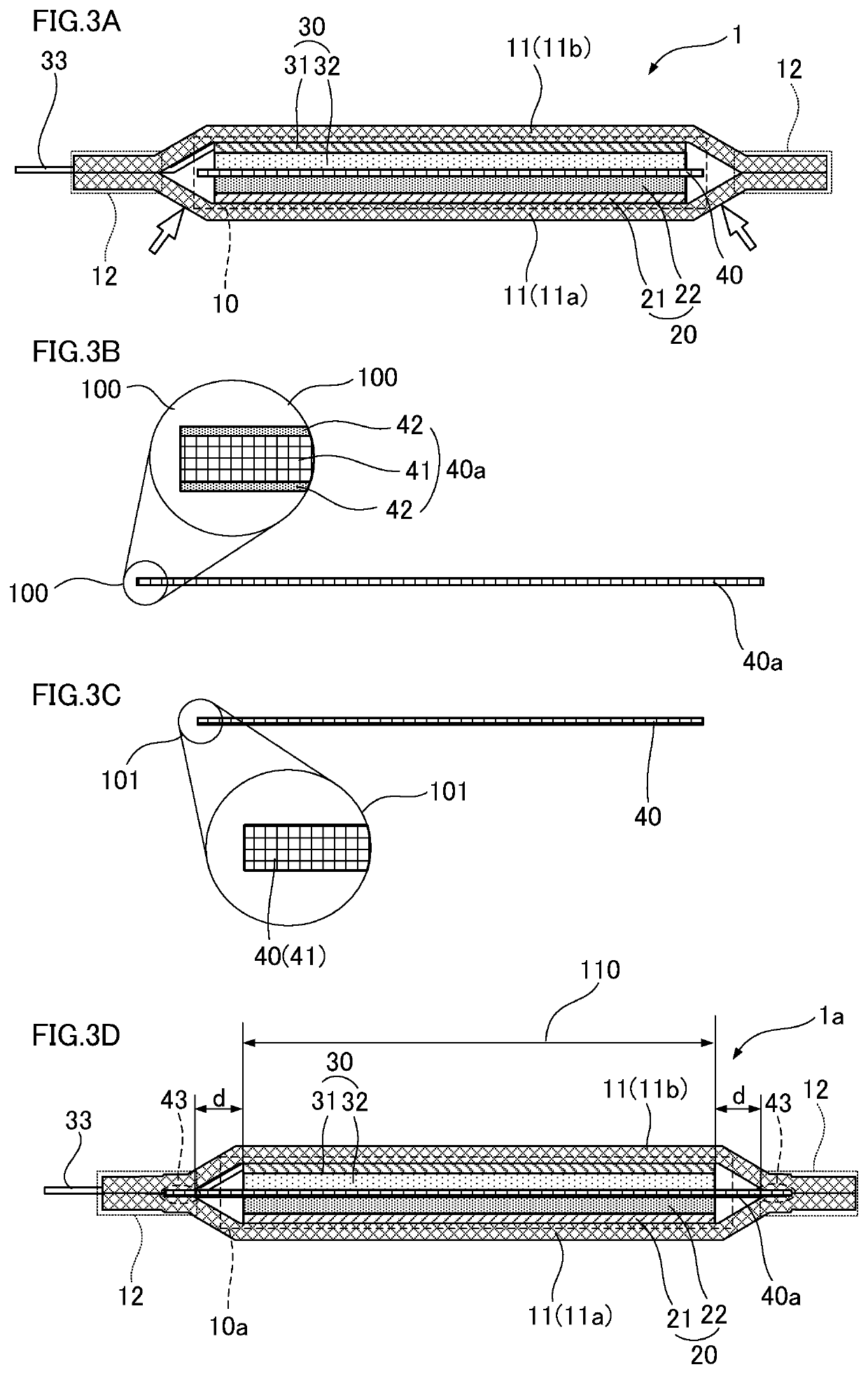

Laminate-type power storage element

ActiveUS10923698B2Remove creasesPrecise alignmentFinal product manufactureSmall-sized cells cases/jacketsStructural engineeringElectrolyte

A laminate-type power storage element includes a flat plate-shaped electrode body and an exterior body. The electrode body is configured by stacking a sheet-shaped positive electrode and a sheet-shaped negative electrode on either side of a separator. The exterior body is formed in a flattened bag-shape by thermocompression bonding peripheral edge regions of two opposing laminated films, to seal the electrode body inside the flattened bag-shape of the exterior body together with an electrolyte. The separator has a sheet-shaped substrate and at least one bonding layer formed on at least one surface of the substrate. A peripheral edge portion of the separator is sandwiched between and bonded by the two laminated films at a peripheral inside of the peripheral edge regions of the two laminated films.

Owner:FDK CORP

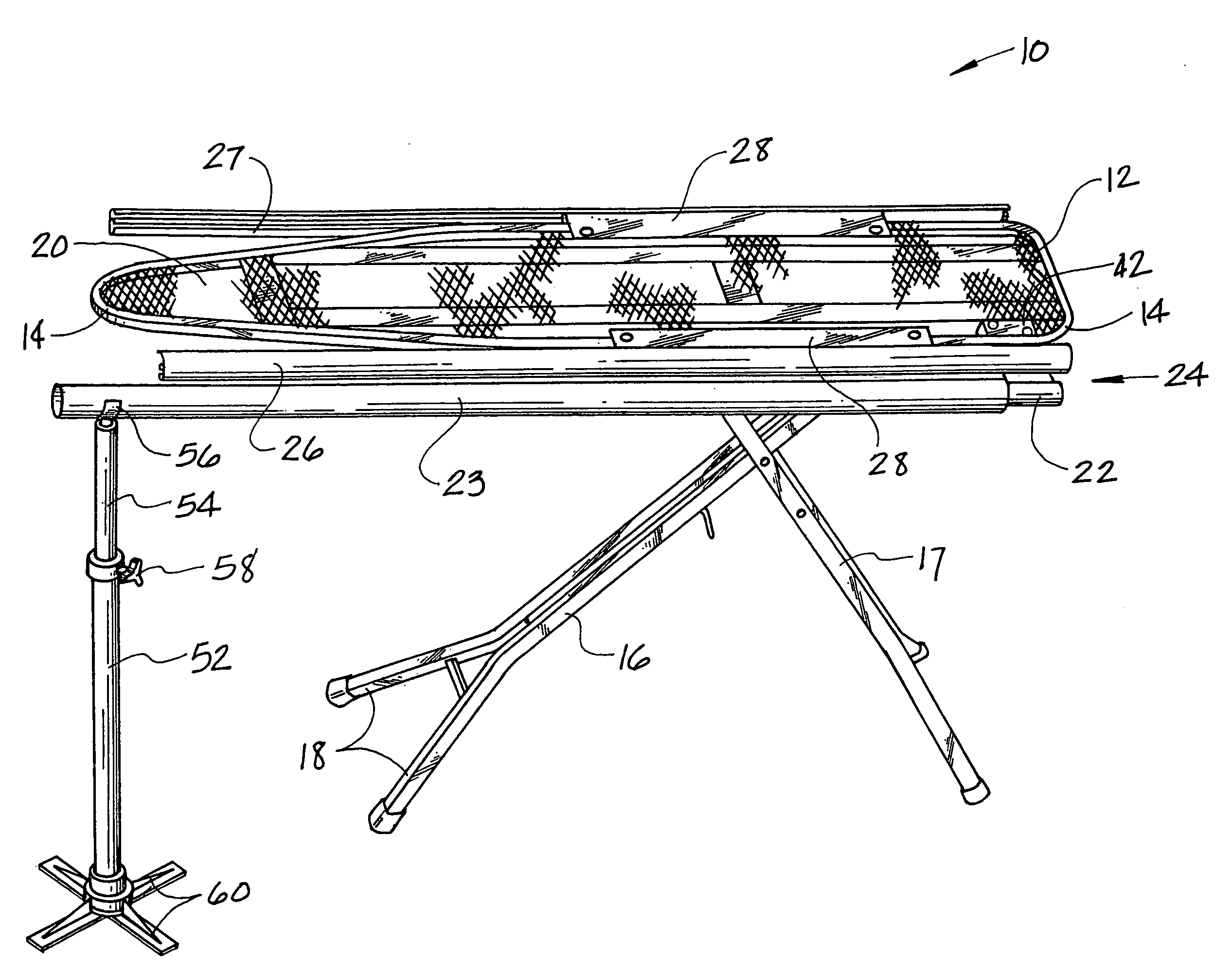

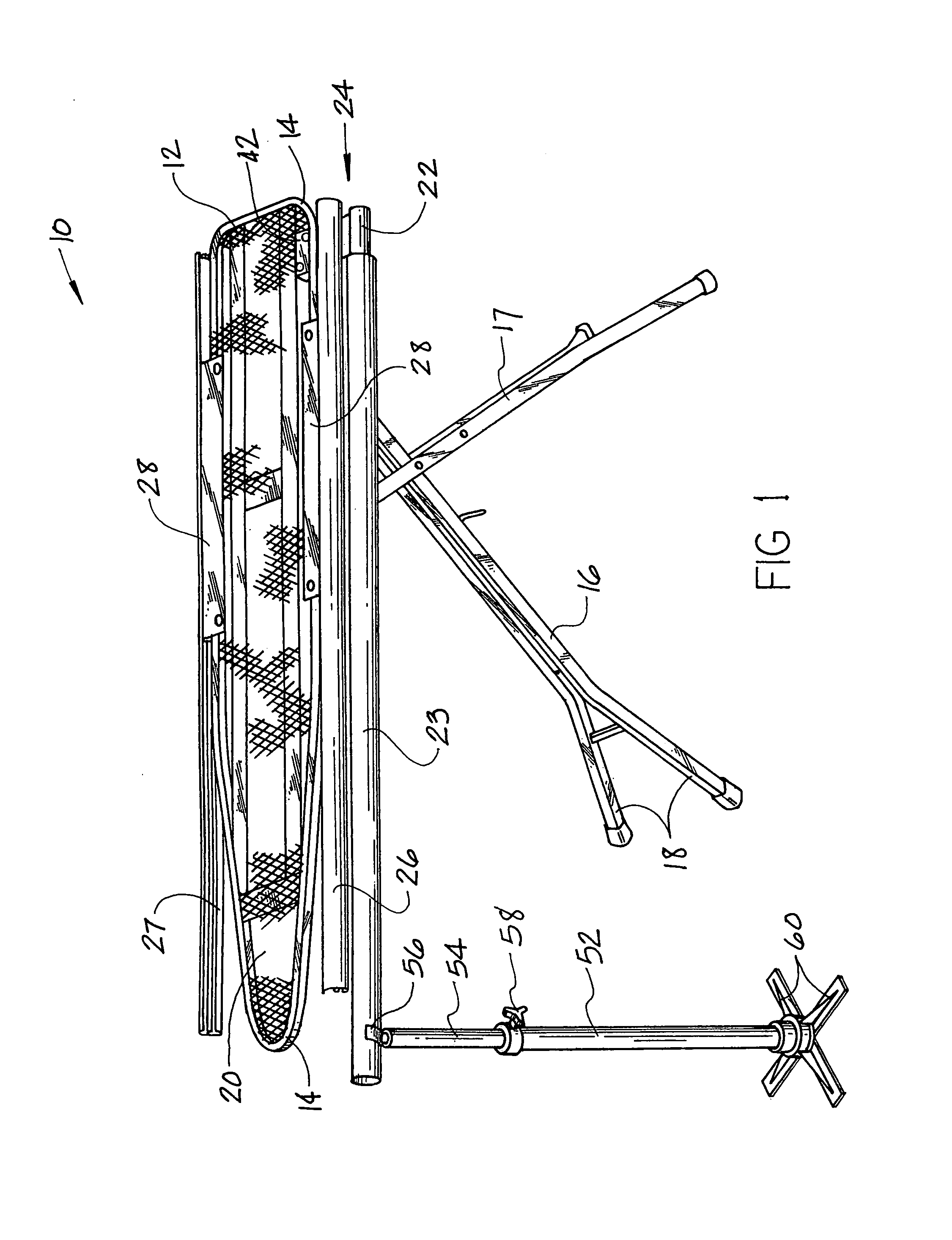

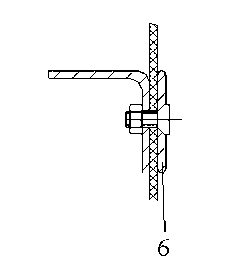

Ironing board attachment apparatus

InactiveUS7162819B1Avoid creasesRemove creasesIroning boardsIroning apparatusEngineeringArm position

Ironing board attachment apparatus for use on conventional ironing boards comprising a laterally movable extension arm positioned adjacent one side of the ironing board which can move laterally towards or away from the board, the arm comprising an arcuate surface in cross-section for support of fabric being ironed. The extension arm being supported by a mounting bracket supporting the extension arm in a cantilevered manner to the ironing board and a pair of shoulder arms, one positioned on each side of the ironing board in juxtaposed relation to the sides of the board; the shoulder arms including a radius portion in cross-section similar to the extension arm and a bracket for each shoulder arm mountable on the ironing board sides permitting sliding longitudinal movement of each shoulder arm.

Owner:JOHNSON JANICE M

Atomizing nozzle structure of high-temperature high-voltage air flow dyeing machine and control method thereof

InactiveCN102080318BGood level dyeingSuitable for processing environmentLiquid/gas/vapor treatment of propelled fabricsTextile treatment machine partsAir volumeHigh pressure

The invention discloses an atomizing nozzle structure of a high-temperature high-voltage air flow dyeing machine and control method thereof. The nozzle structure comprises a front nozzle cover, an inner main stream pipe, a rear nozzle head and a sleeve, wherein the sleeve is sleeved outside the inner main stream pipe, and two ends of the sleeve are respectively connected with the front nozzle cover and the rear nozzle head through a connecting piece; the sleeve is provided with an air inlet which is connected with a fan; and the sleeve and the inner main stream pipe form a circular outer chamber atomizing region; a nozzle head is arranged in the outer chamber atomizing region and is fixed on the outer wall of the inner main stream pipe, and the nozzle head is connected with a dye liquid pipeline; and the outer chamber atomizing region is provided with two outlets which are connected with a channel through which the cloth to be dyed passes in the inner main stream pipe. The invention also provides a control method based on the atomizing nozzle structure of the high-temperature high-voltage air flow dyeing machine. According to the types of the cloth to be dyed, the number of the nozzle heads started in the nozzle structure, the flow rate of the nozzle heads, the air flow of the fan and the temperature process curves adopted are defined. According to the invention, the levellingproperty is high, and the problem of cloth blocking can not happen.

Owner:高勋绿色智能装备(广州)有限公司

Mobile terminal

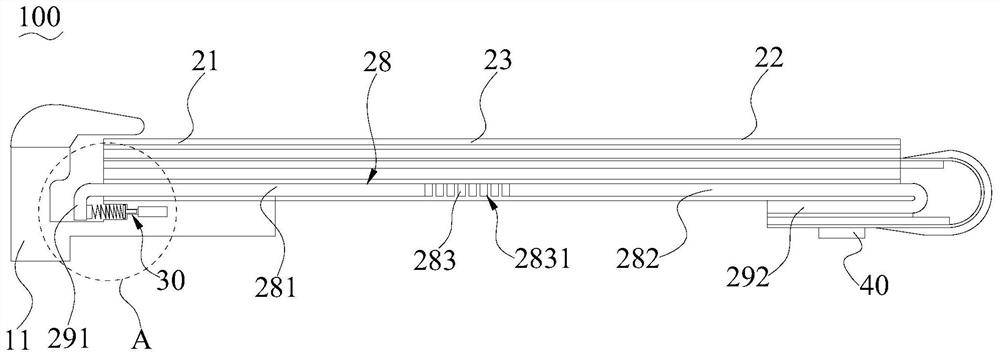

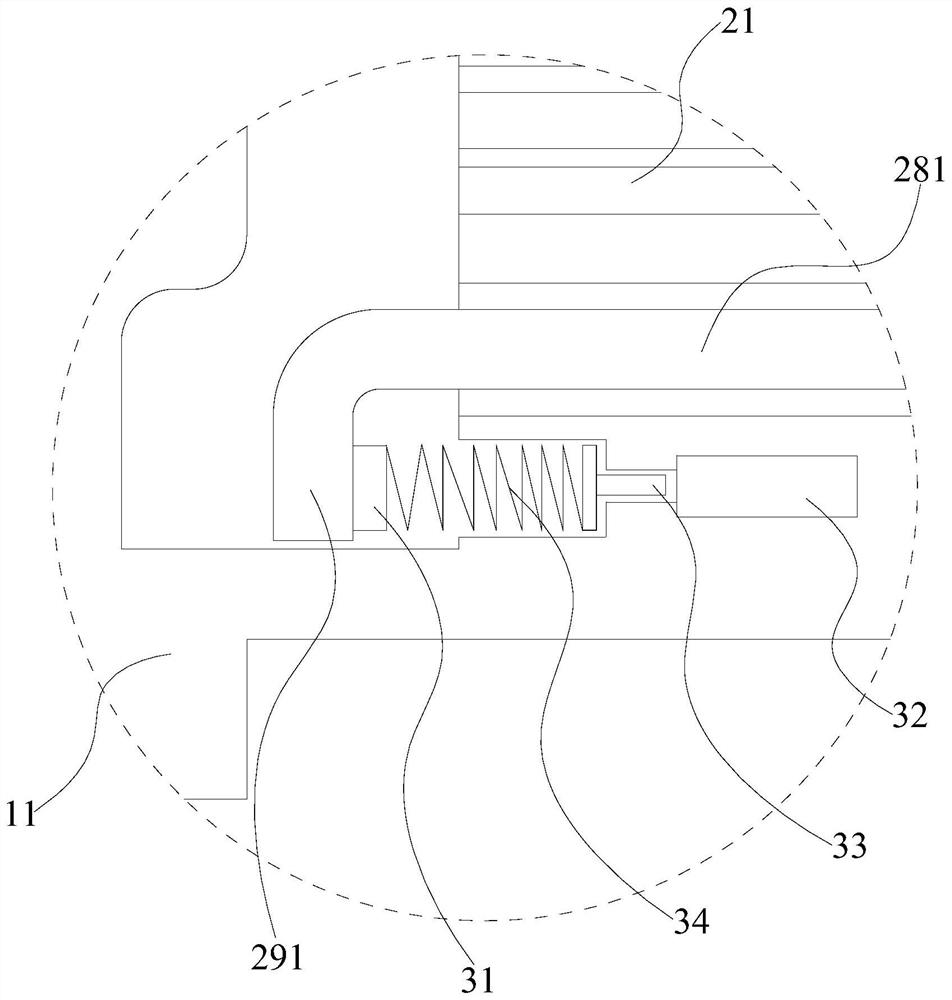

The invention discloses a mobile terminal. The mobile terminal comprises a first shell, a second shell, a flexible display screen and a thrust mechanism. The second shell and the first shell are connected through a rotating shaft and can rotate around the rotating shaft. The flexible display screen comprises a first display area, a second display area and a third display area, the third display area is located between the first display area and the second display area, the first display area is connected with the first shell, the second display area is connected with the second shell, and the third display area is located at the rotating shaft. when the flexible display screen is in a folding state, the first display area and the second display area are opposite or back to back. The thrust mechanism is arranged on the first shell and can apply thrust to the first display area in the direction, away from the third display area, of the first display area. Therefore, if the flexible display screen deforms and cannot be completely recovered to cause an arching or sinking phenomenon, the thrust mechanism can apply thrust to the first display area to enable the flexible display screen to recover to be flat, and creases are eliminated.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

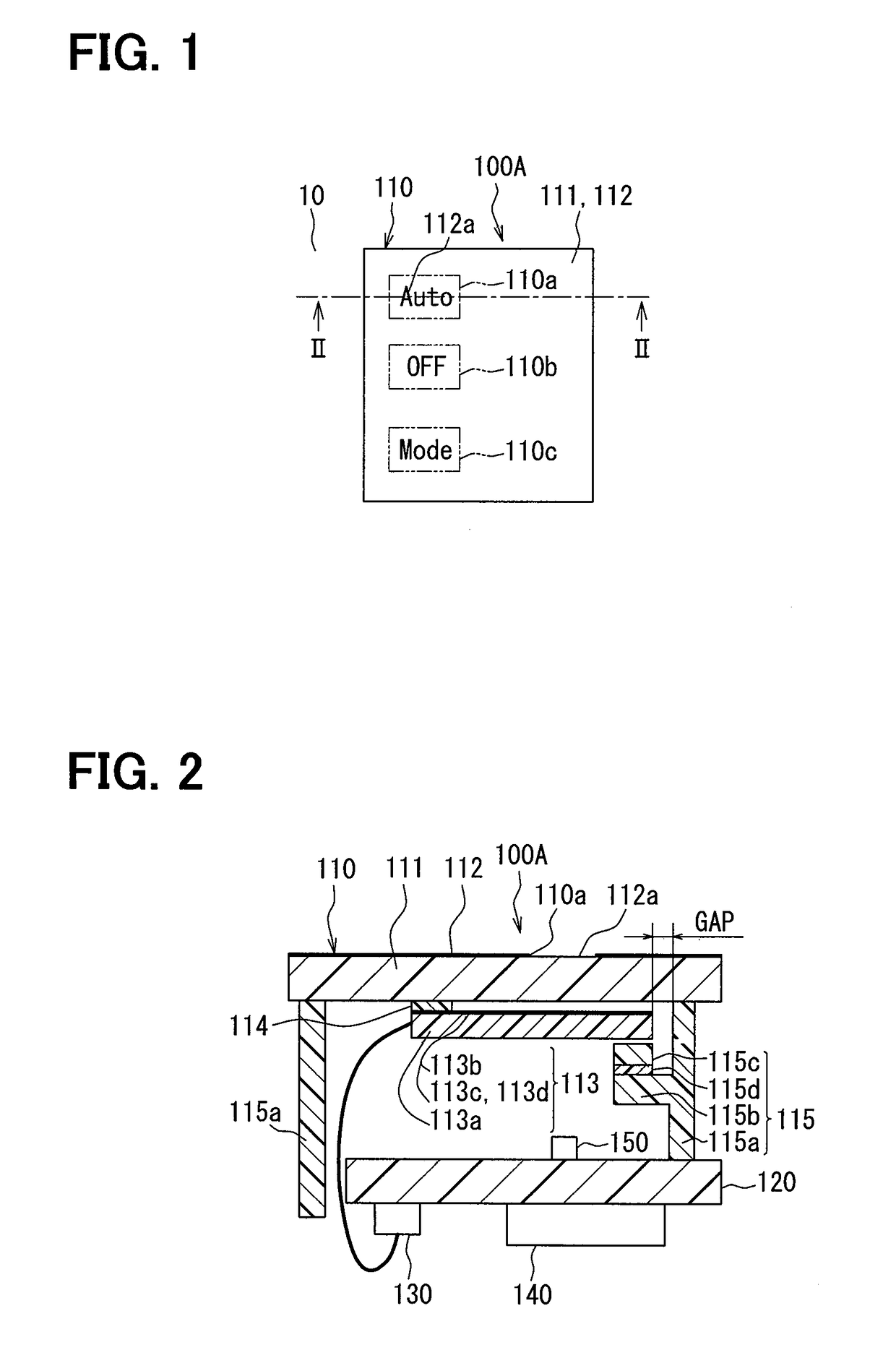

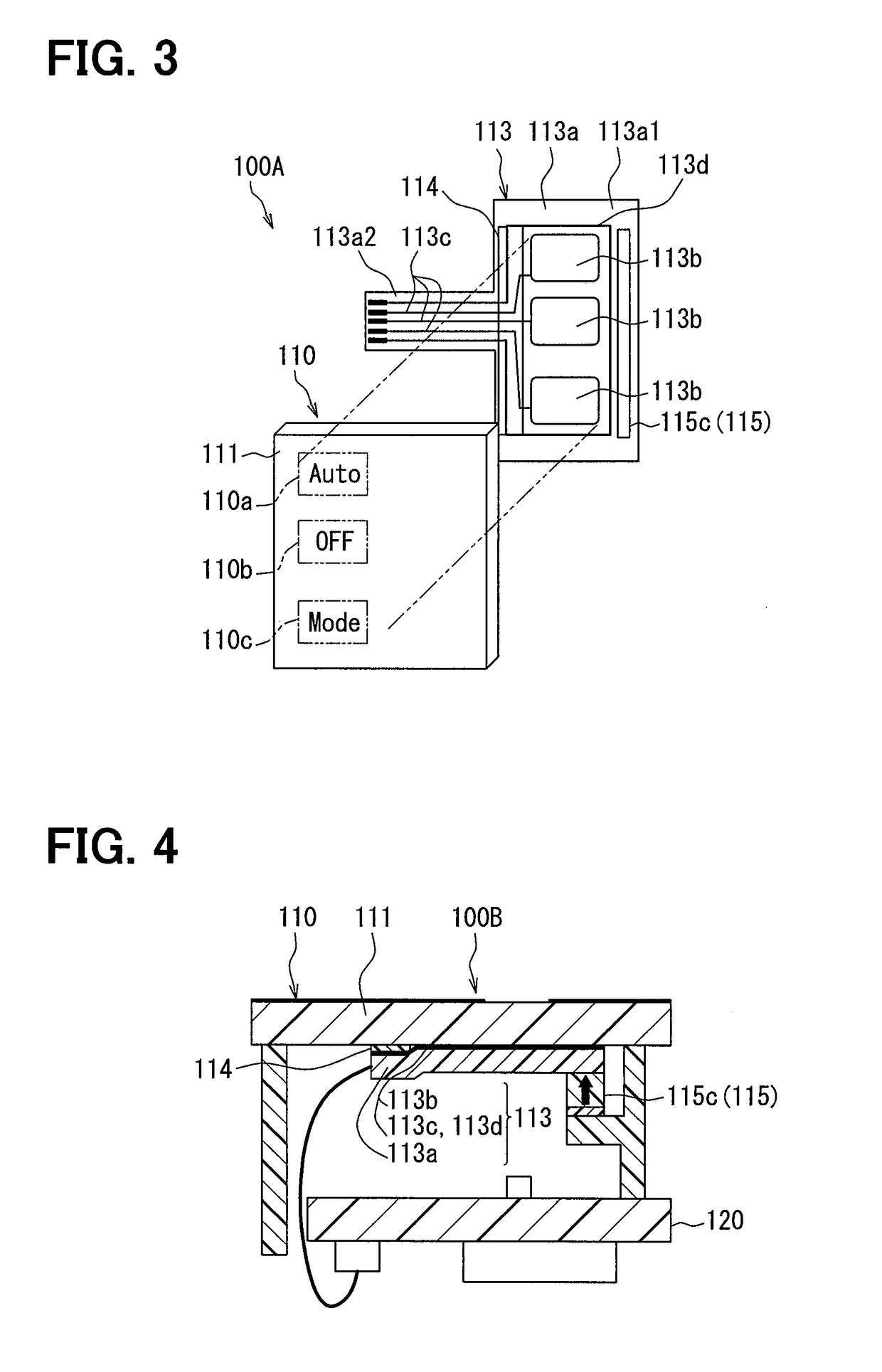

Capacitive switch device

ActiveUS20180145688A1Remove creasesEliminate liftElectronic switchingPressure sensitiveThermal contraction

A capacitive switch device includes an operation panel operated by a user with a touch operation, a film member provided along a surface of the operation panel on an opposite side from a surface operated with the touch operation, and an electrode portion forming a capacitor with a finger of the user and a wiring portion, both the electrode portion and the wiring portion being provided to the film member. The film member is bonded to the operation panel by a pressure-sensitive adhesive at a predetermined first portion of the film member and supported at a second portion of the film member different from the first portion by a supporting portion which allows the film member to move due to thermal expansion and thermal contraction in an in-plane direction of the film member.

Owner:DENSO CORP

Folding structure of mobile phone

PendingCN112492071AImprove imaging effectRemove creasesTelephone set constructionsEngineeringStructural engineering

The invention discloses a folding structure of a mobile phone. The folding structure comprises a mobile phone body, stretching plates and pivoting devices, wherein the mobile phone body comprises twoshells which are movably connected, and sliding grooves are formed in the front surfaces of the shells; the front faces of the two stretching plates are used for being connected with the flexible screen, and the stretching plates are in sliding fit with the two sliding grooves respectively. The two pivoting devices are arranged at the two ends of the joint of the two shells respectively so that the two shells can be pivoted, the two pivoting devices are in transmission connection with the two stretching plates respectively, and when the shells are unfolded, the pivoting devices drive the stretching plates to move in the sliding grooves so that the stretching plates can be separated to stretch the flexible screen. The sliding groove is formed in the front face of the shell and used for assembling the stretching plates, the two stretching plates are used for being connected with the flexible screen, the pivoting device achieves pivoting of the shell and can drive the stretching plates tostretch the flexible screen while the shell is turned over, creases formed after the flexible screen is folded can be eliminated, it is guaranteed that the surface of the flexible screen is smooth, and the screen development effect of the folding mobile phone is improved.

Owner:徐州斯特林工业设计有限公司

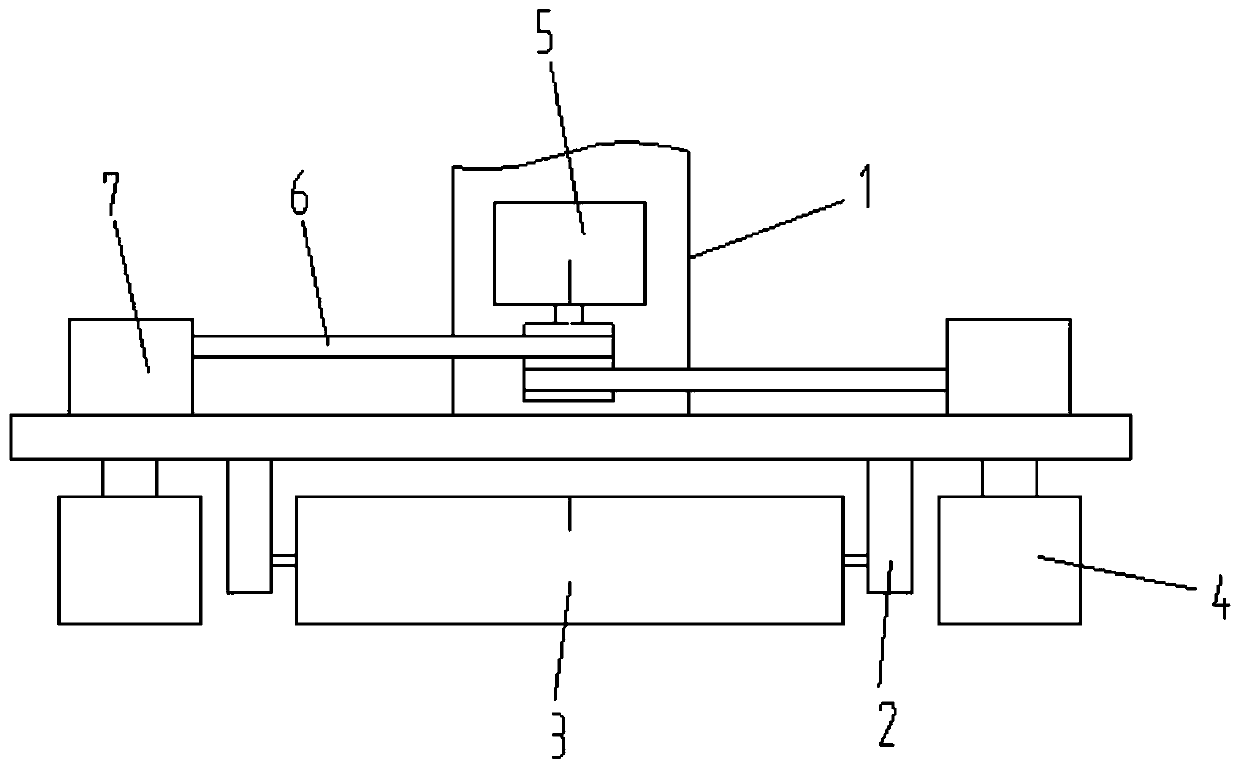

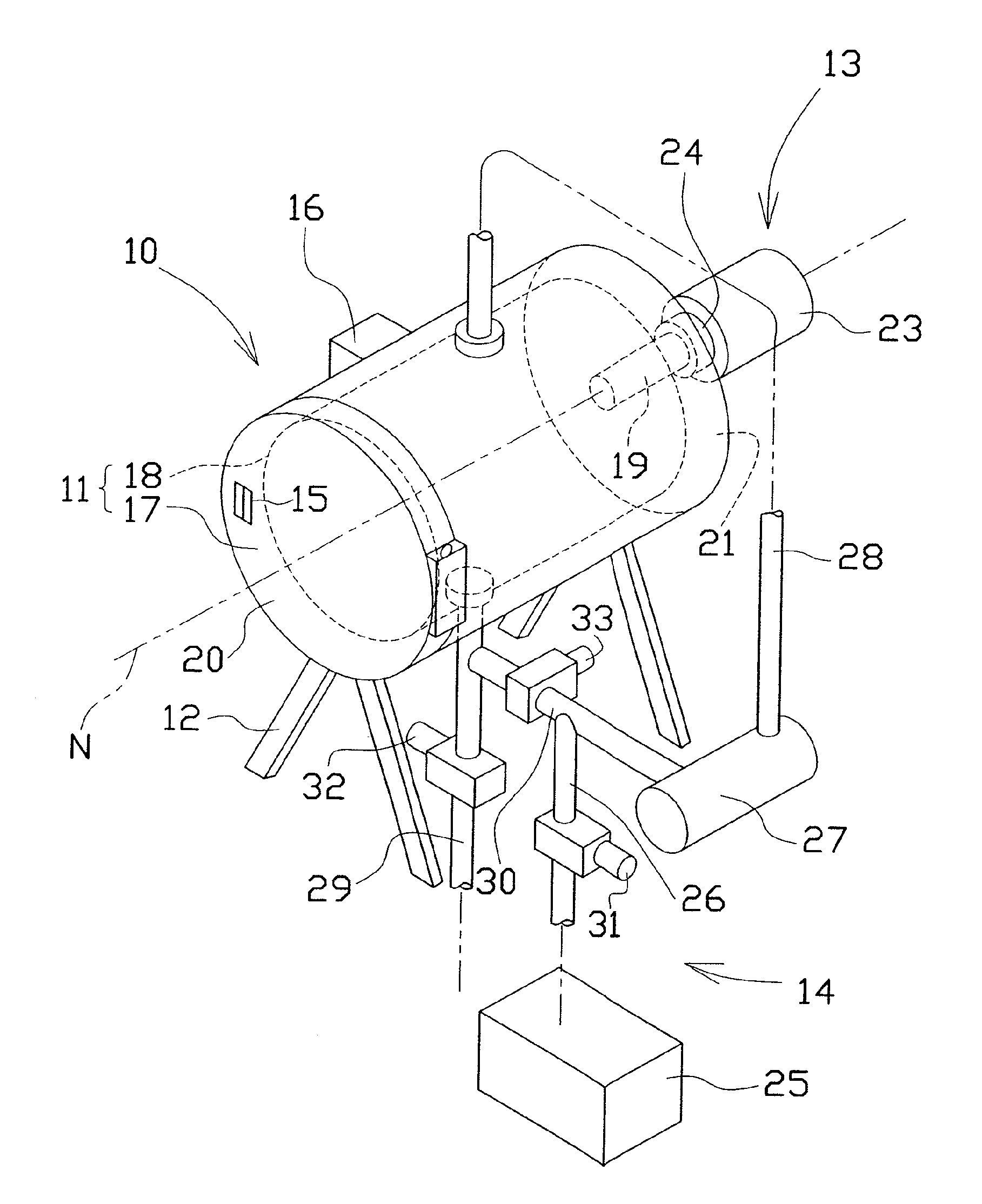

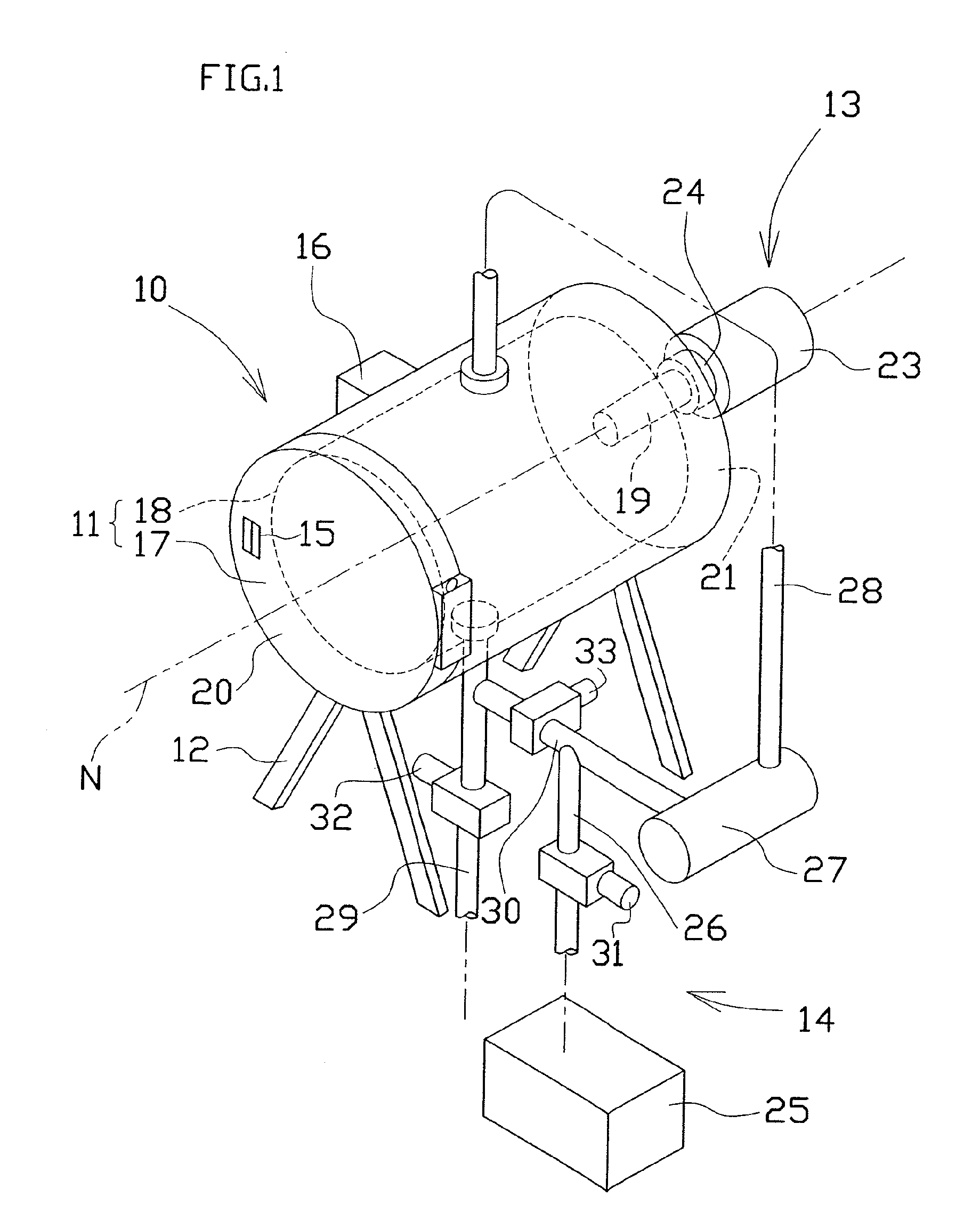

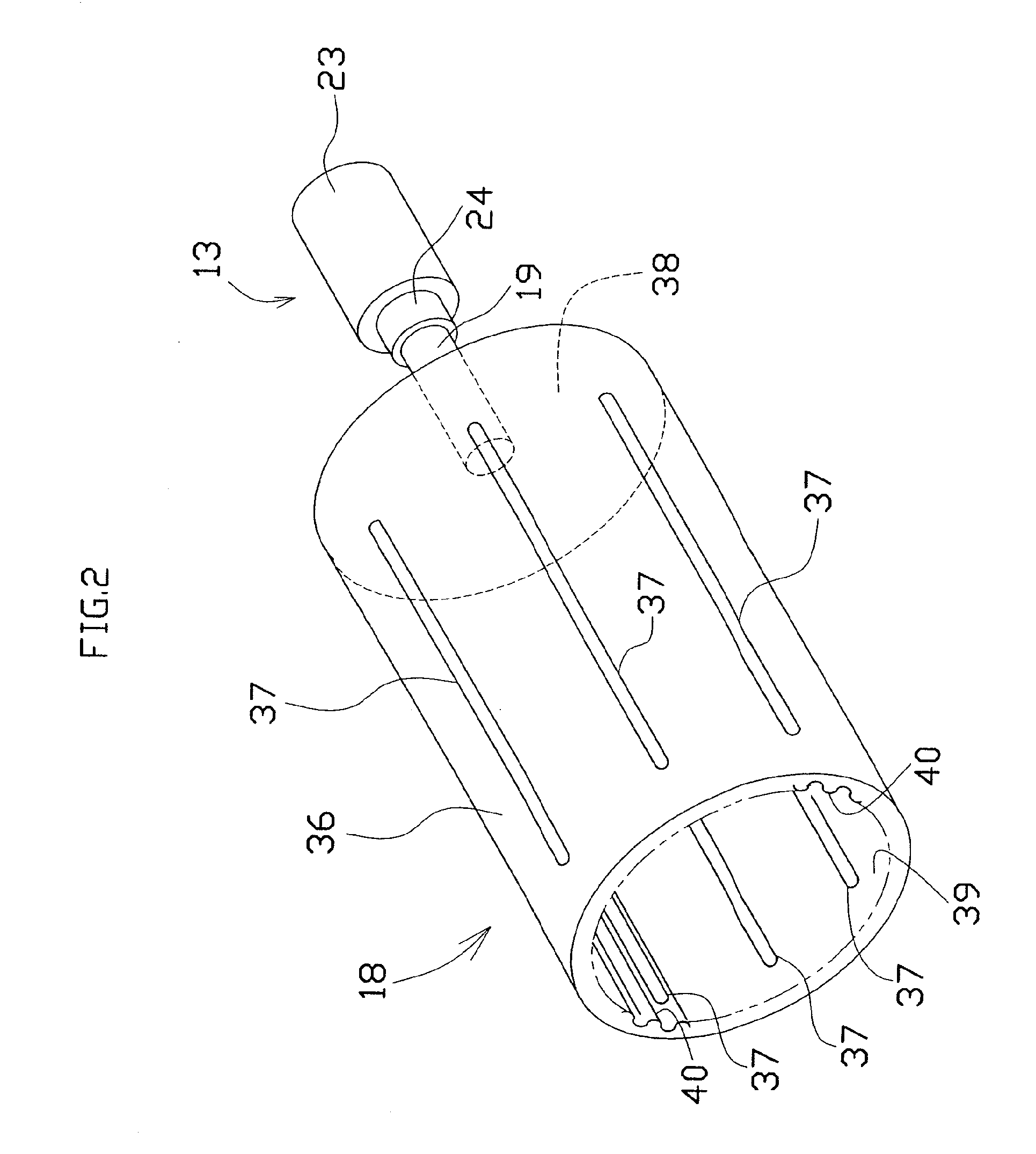

Washing method

InactiveUS20100077802A1Reliable removalEasy to disassembleDry-cleaning apparatusOther washing machinesWater solubleDrive motor

[Problems to be Solved] It is intended to provide a washing method for reliably cleaning water-soluble contaminations such as sweat without damaging fabrics.[Solution] A frame body 18 is disposed horizontally in a casing. The frame body 18 is rotated by a drive motor 23 in the casing. The casing and the frame body 18 are filled with water, and then clothes are placed in the frame body 18. A plurality of protrusions 40 are formed in order that an inner periphery 39 of the frame body 18 has a wavy pattern. A height of the protruding parts is set to from 3.0% to 6.0% of an inner diameter of the frame body 18. A surfactant contained in a cleaning liquid permeates deep into clothes.

Owner:HAPPY CO LTD

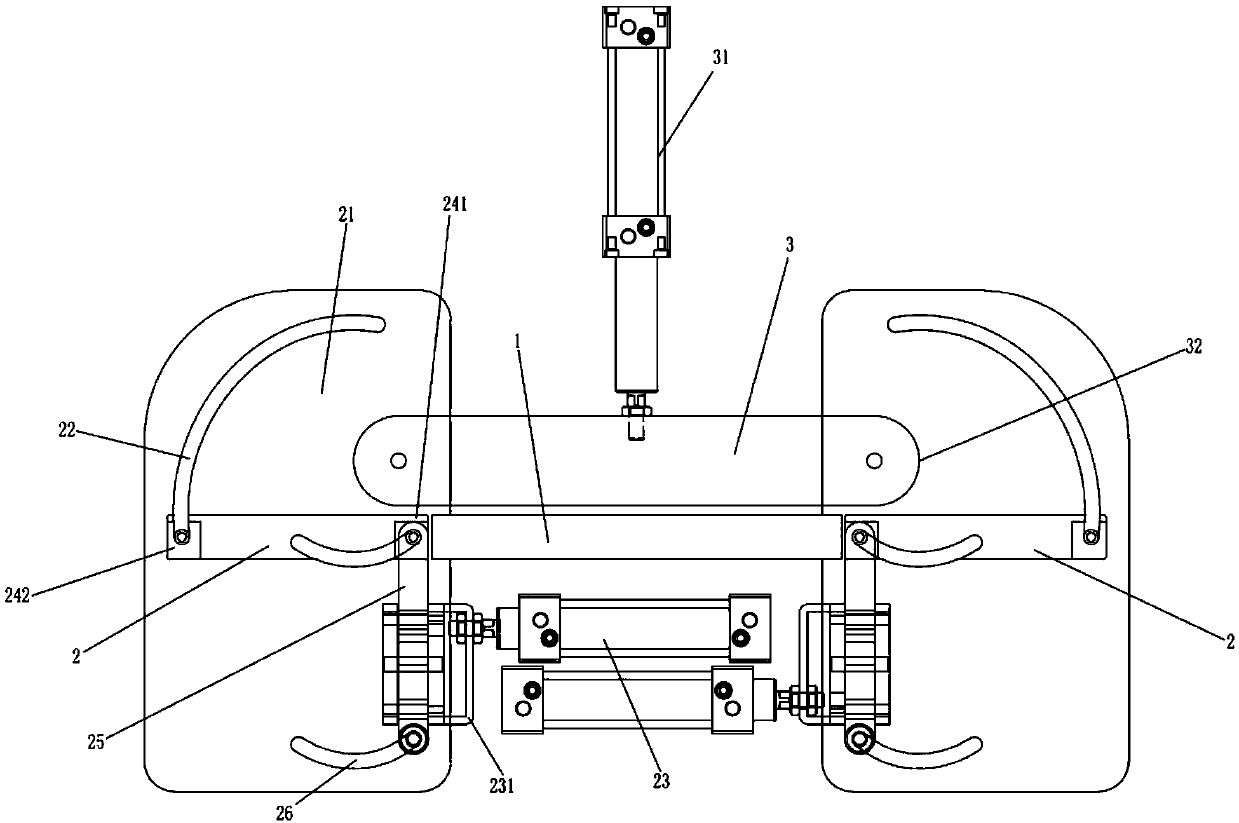

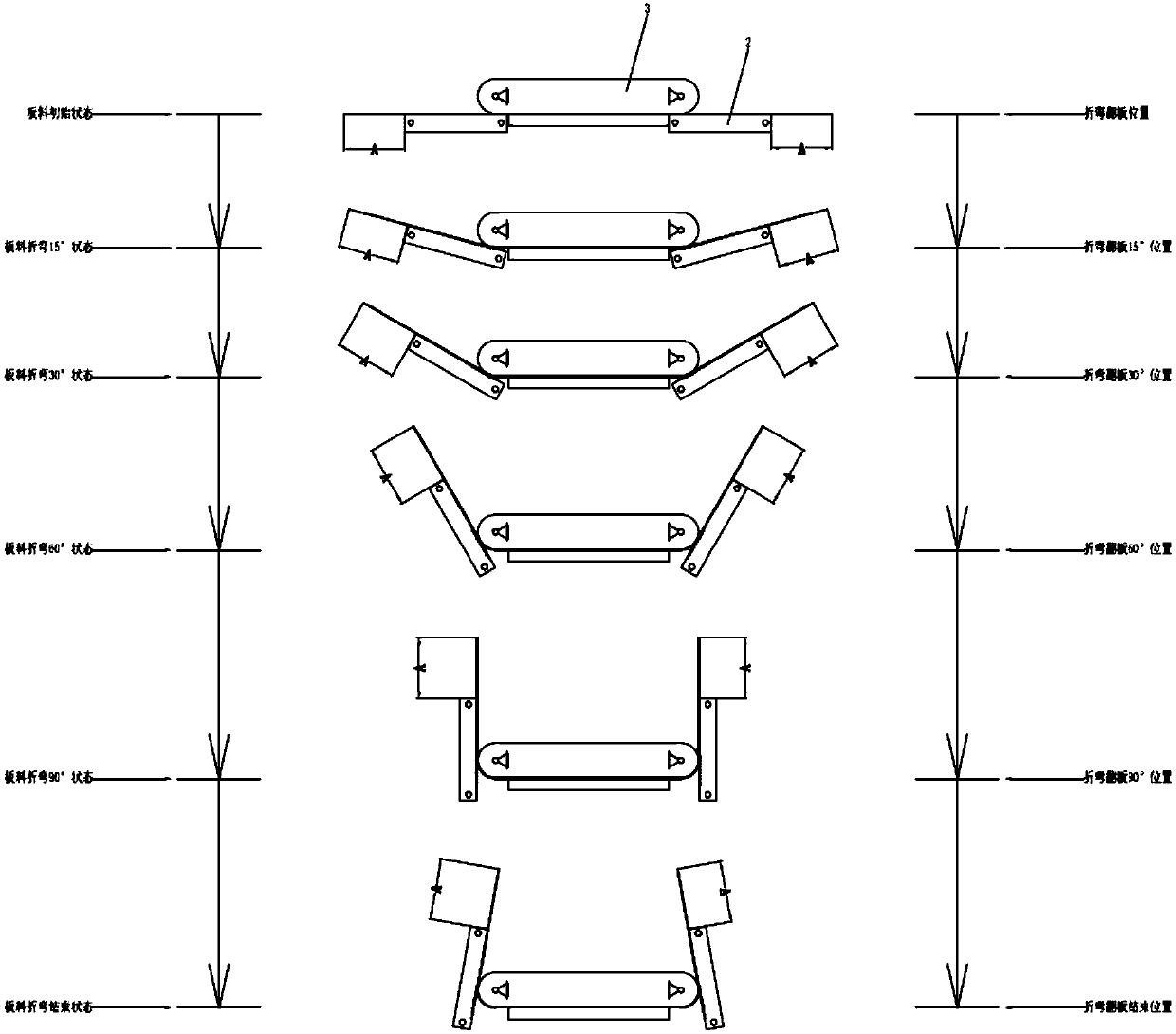

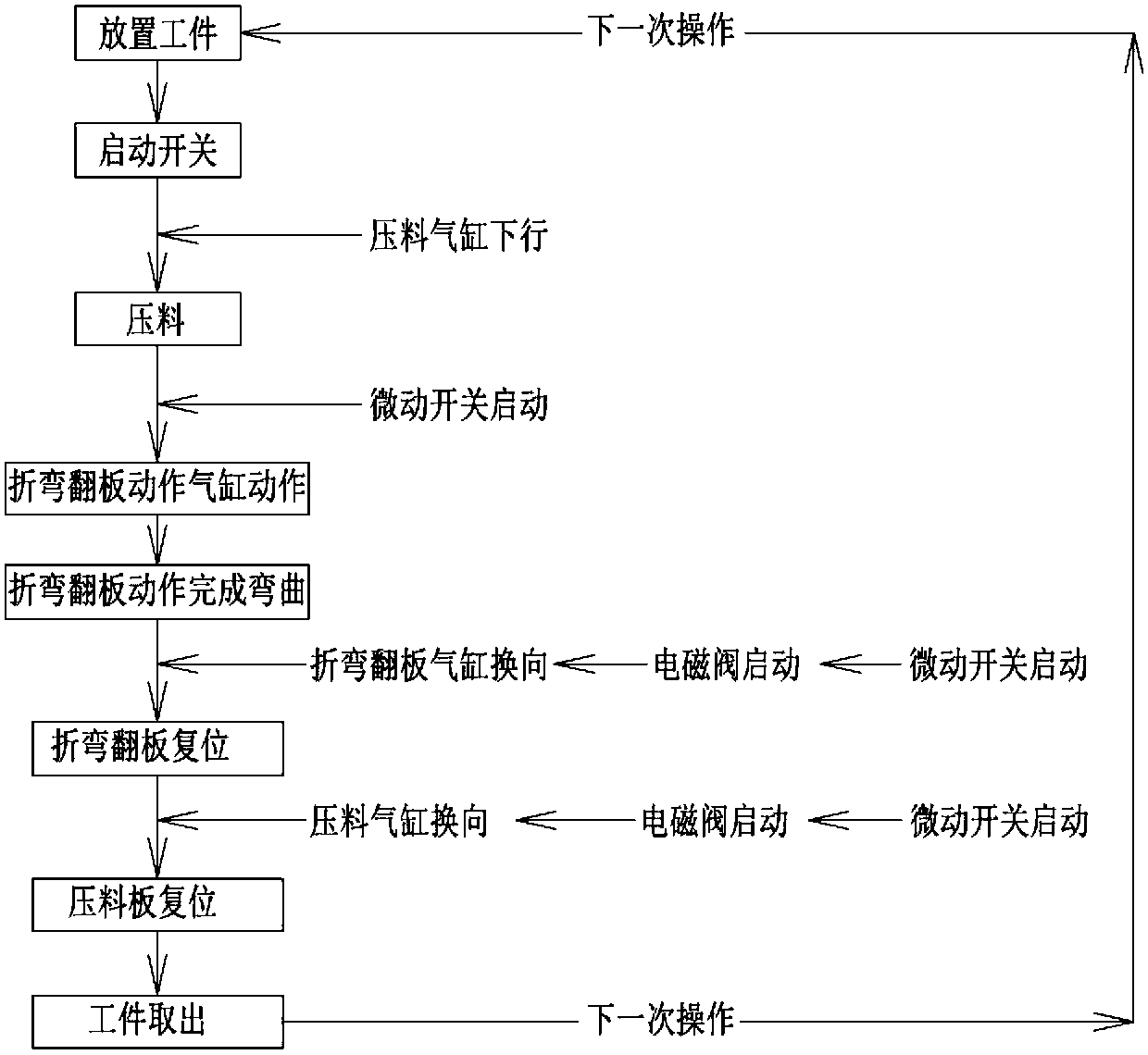

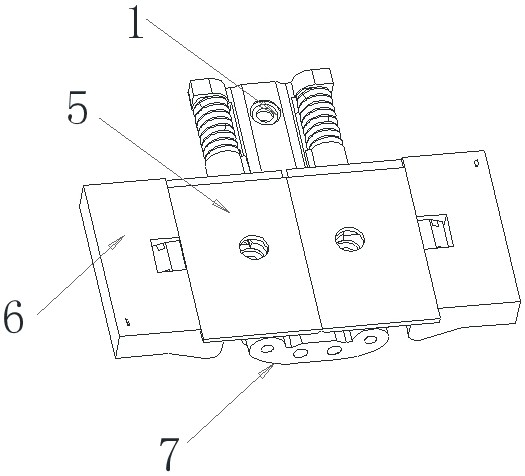

Fold-free bending die applied to plate

PendingCN109647939ARemove creasesRealize bending workShaping toolsGlass productionMechanical engineeringEngineering

Owner:苏州协朗精密机械有限公司

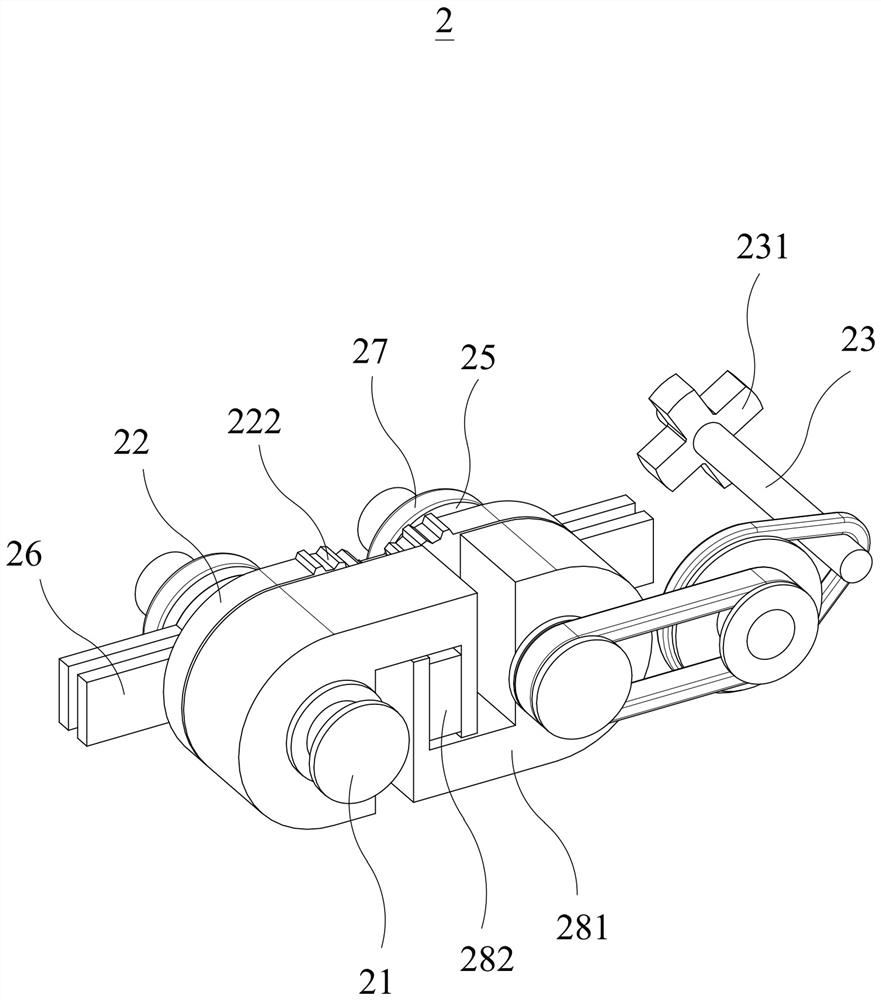

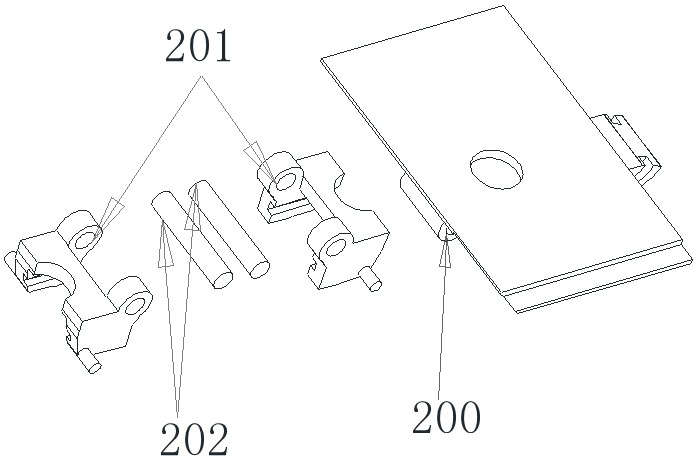

Lateral movement type bending hinge of flexible screen folding mobile phone

ActiveCN114726940AOverall design flexibilityGuaranteed service lifePivotal connectionsTelephone set constructionsStructural engineeringMechanical engineering

The invention discloses a lateral moving type bending hinge of a flexible screen folding mobile phone, which comprises a base, the base is provided with symmetrically distributed lateral moving sliding blocks, the front and rear ends of each lateral moving sliding block are provided with a first connecting arm and a second connecting arm which are symmetrically distributed, and one side of each lateral moving sliding block is provided with a first movable frame and a second movable frame. The lateral moving sliding block is connected with the base in a sliding mode, the first connecting arm and the second connecting arm are in linkage with the lateral moving sliding block to achieve track control, and the lateral moving sliding block is in linkage with the first movable frame to synchronously achieve lateral moving bending rotation. The lateral moving sliding block is provided with a pin hole and a shaft pin, the first movable frame is provided with a connecting hole, and the shaft pin is connected and positioned through the pin hole and penetrates through the connecting hole to achieve linkage matching of the first movable frame and the lateral moving sliding block. A sliding groove is formed in the lateral moving sliding block, a sliding block is arranged on the base, and relative sliding of the lateral moving sliding block and the base is achieved through sliding fit of the sliding groove and the sliding block.

Owner:DONGGUAN JINFENG ELECTRONICS

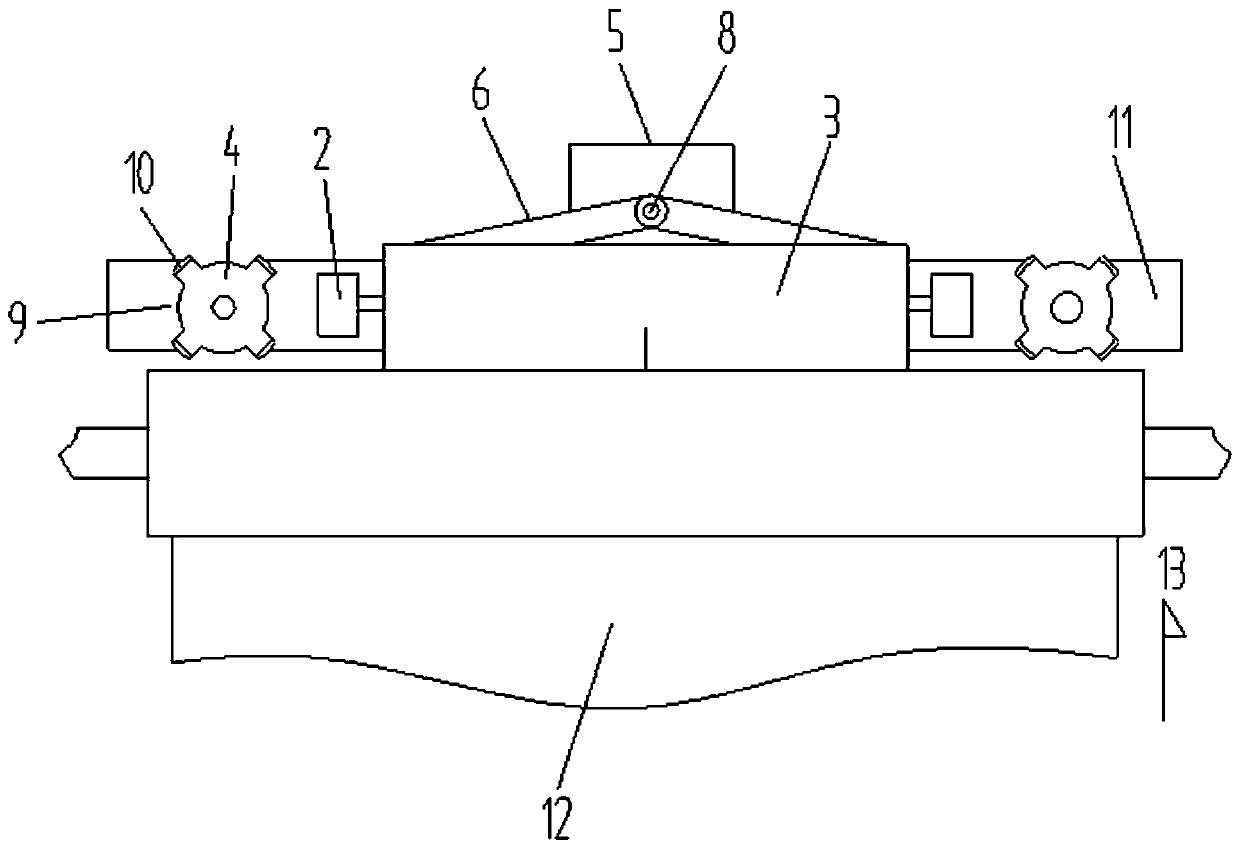

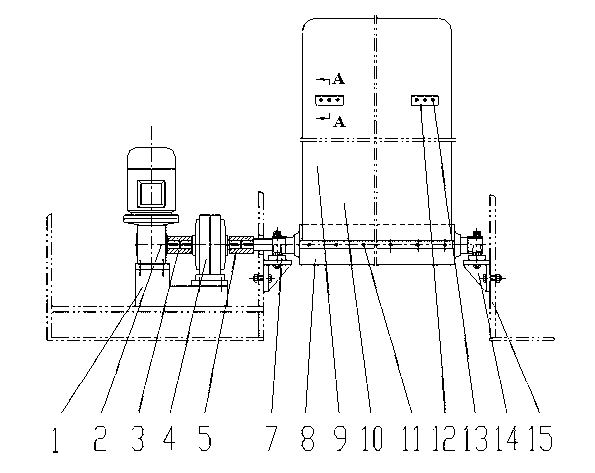

Auxiliary extension device of through-type wringing machine

InactiveCN102181585BStretching is effectiveIncrease the areaLeather manufacturingWrinkle skinEconomic benefits

The invention discloses an auxiliary extension device of a through-type wringing machine. The through-type wringing machine comprises a wringing felt jacket and a guard plate which is arranged on a frame. The auxiliary extension device comprises a reeling and unreeling roller and an expanding band, wherein one end of the expanding band is fixed on the reeling and unreeling roller, and the other end of the expanding band is arranged on the wringing felt jacket; the reeling and unreeling roller is driven by a driving device; and a baffle block which is matched with the guard plate is arranged on the expanding band. Compared with the conventional extension device of the through-type wringing machine, the invention has the main advantages that: the auxiliary extension device has a simple structure and a reasonable design, is easy to mount, and is flexibly and conveniently controlled; leather can be effectively extended while water is squeezed; wrinkles and folding marks on leather grains can be further eliminated; appearance is effectively improved; the area of the leather is increased, the difference between the extensibility of the leather and the extensibility in various directions is reduced, the yield of the leather is improved, and the grade of the leather is improved; and better social and economic benefits can be achieved.

Owner:扬州扬宝机械有限公司

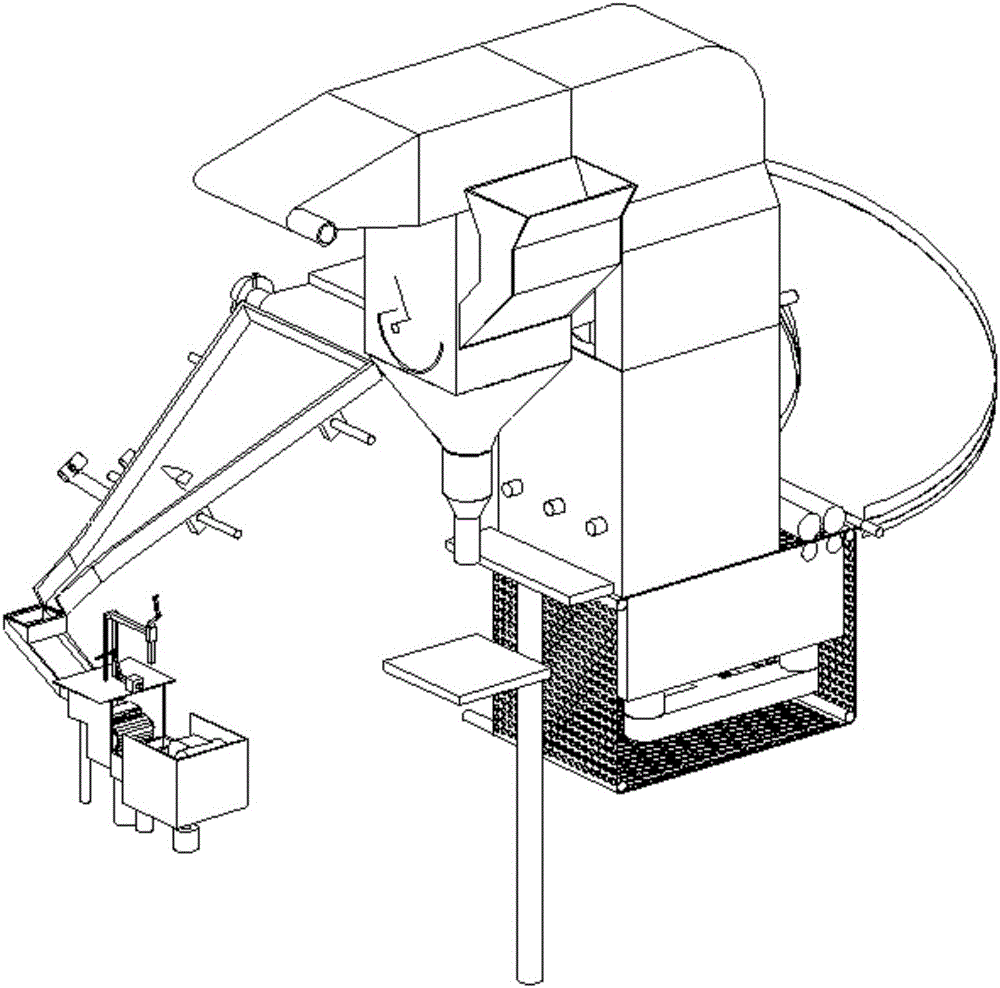

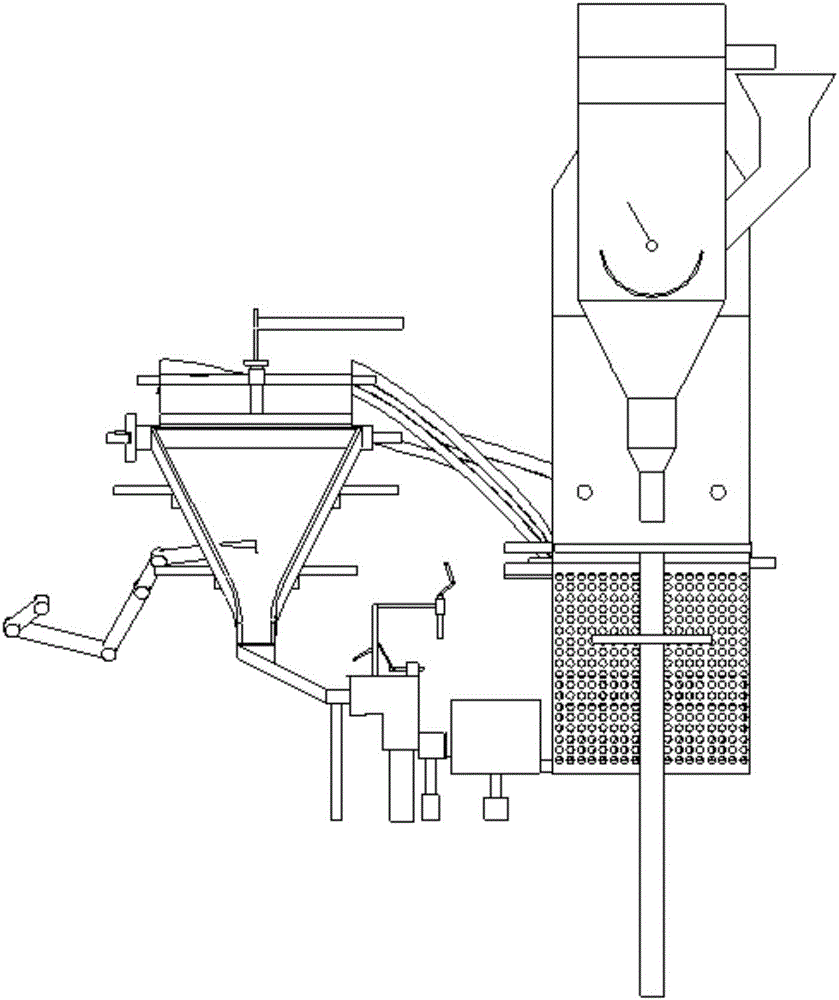

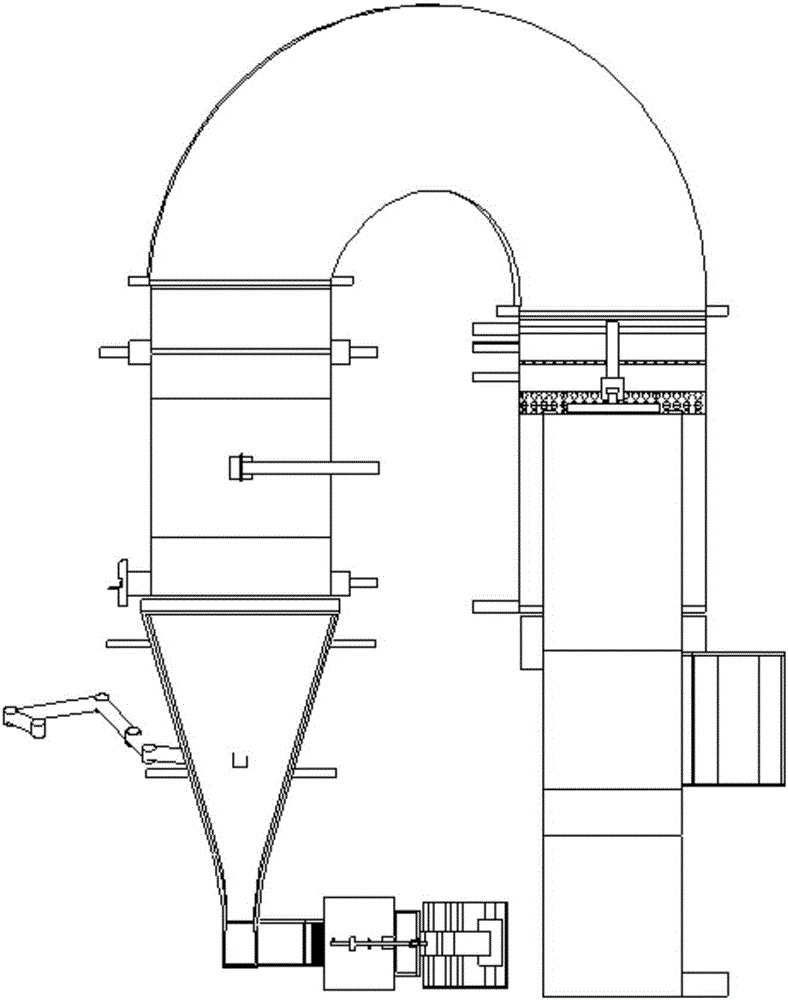

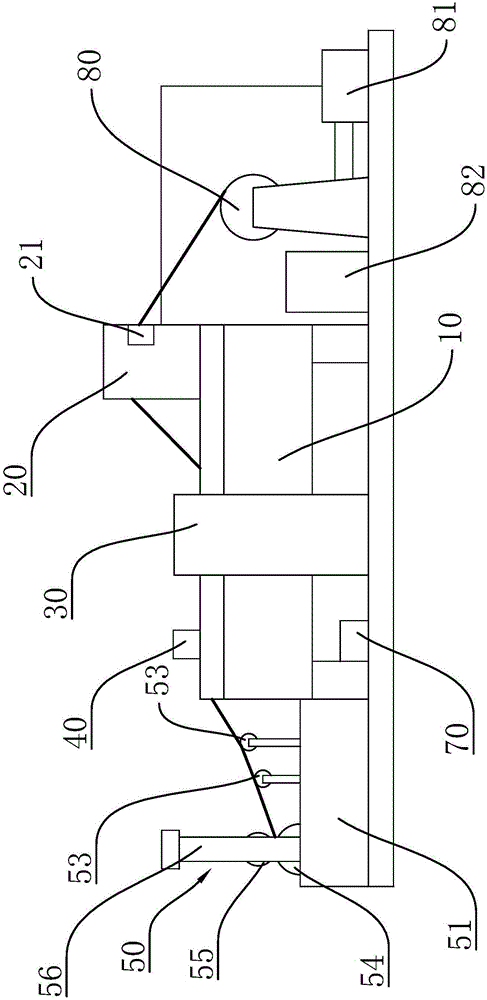

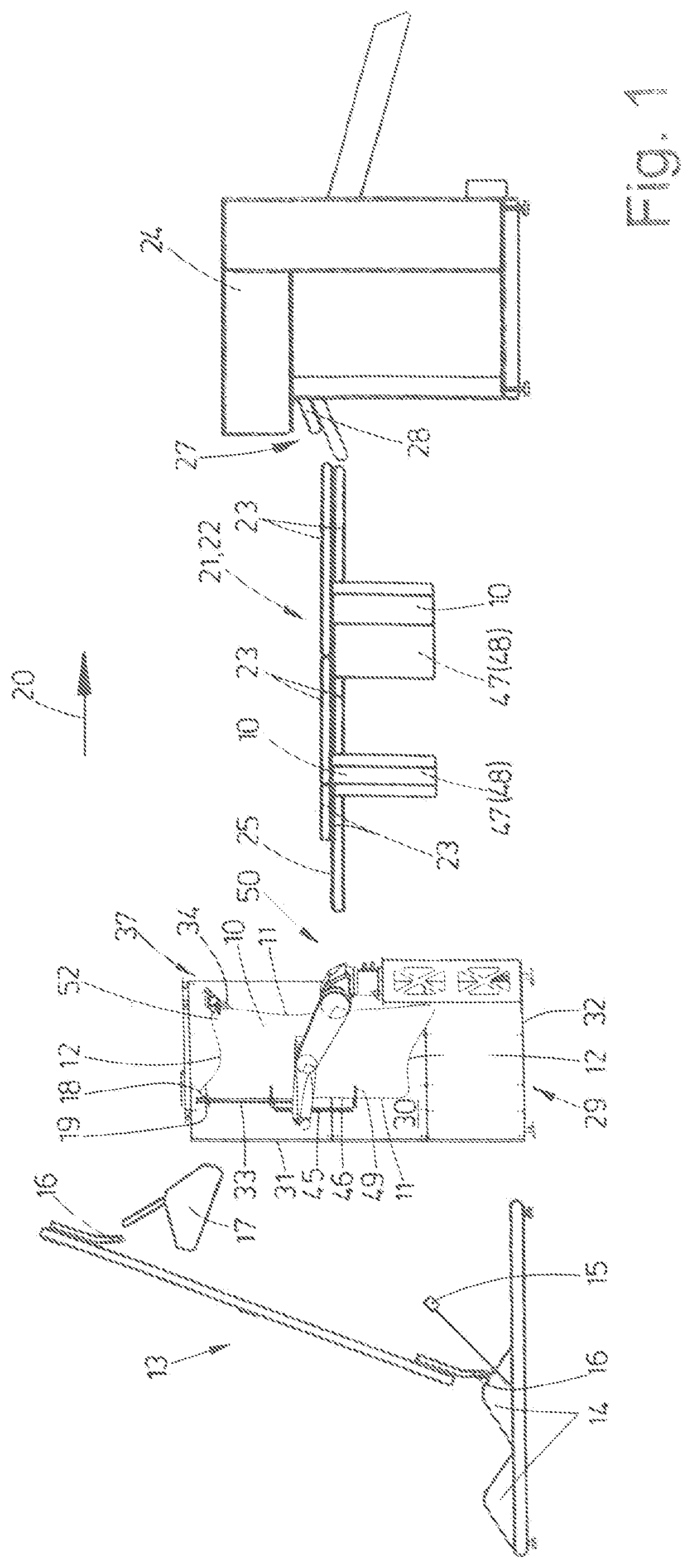

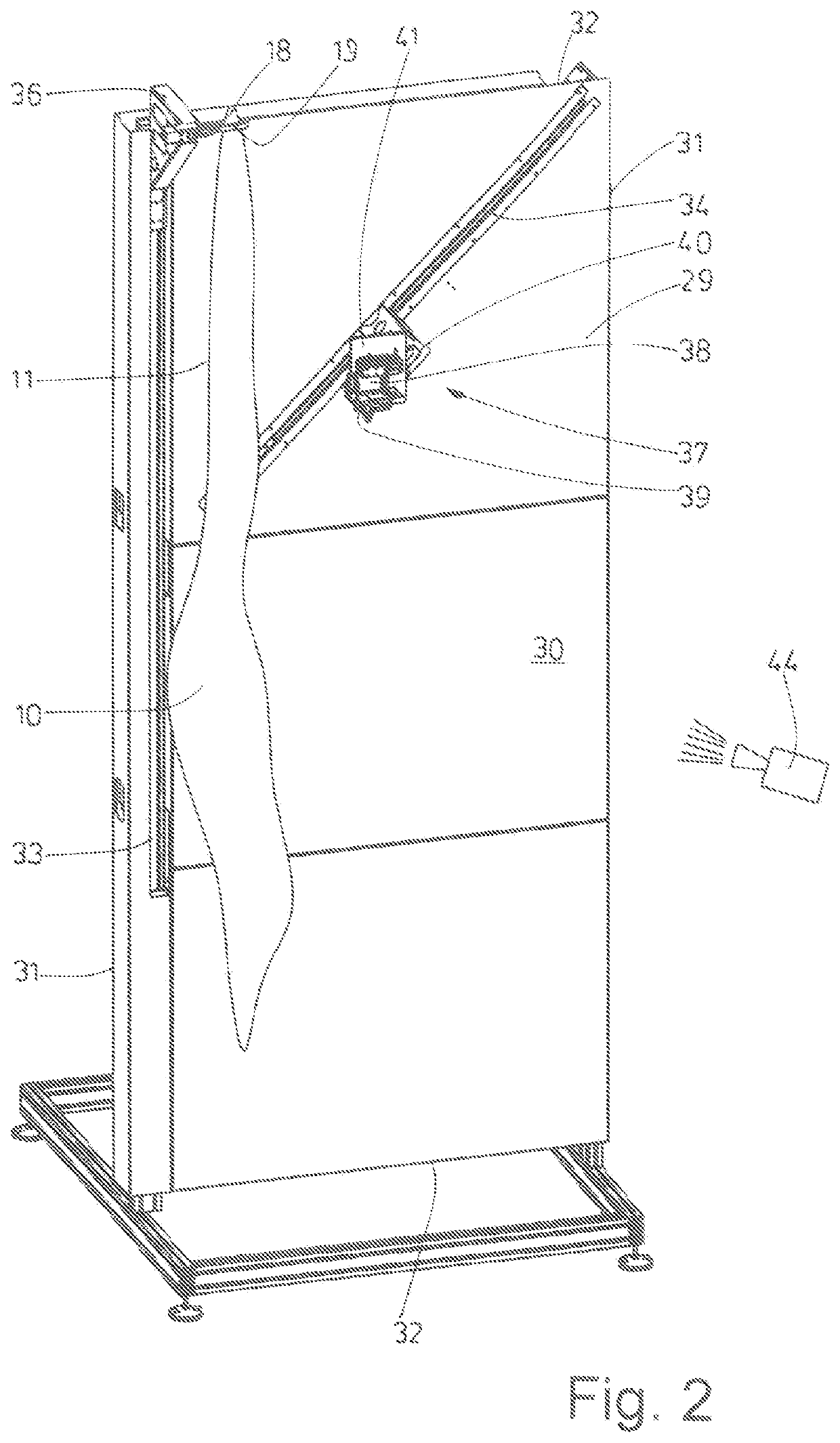

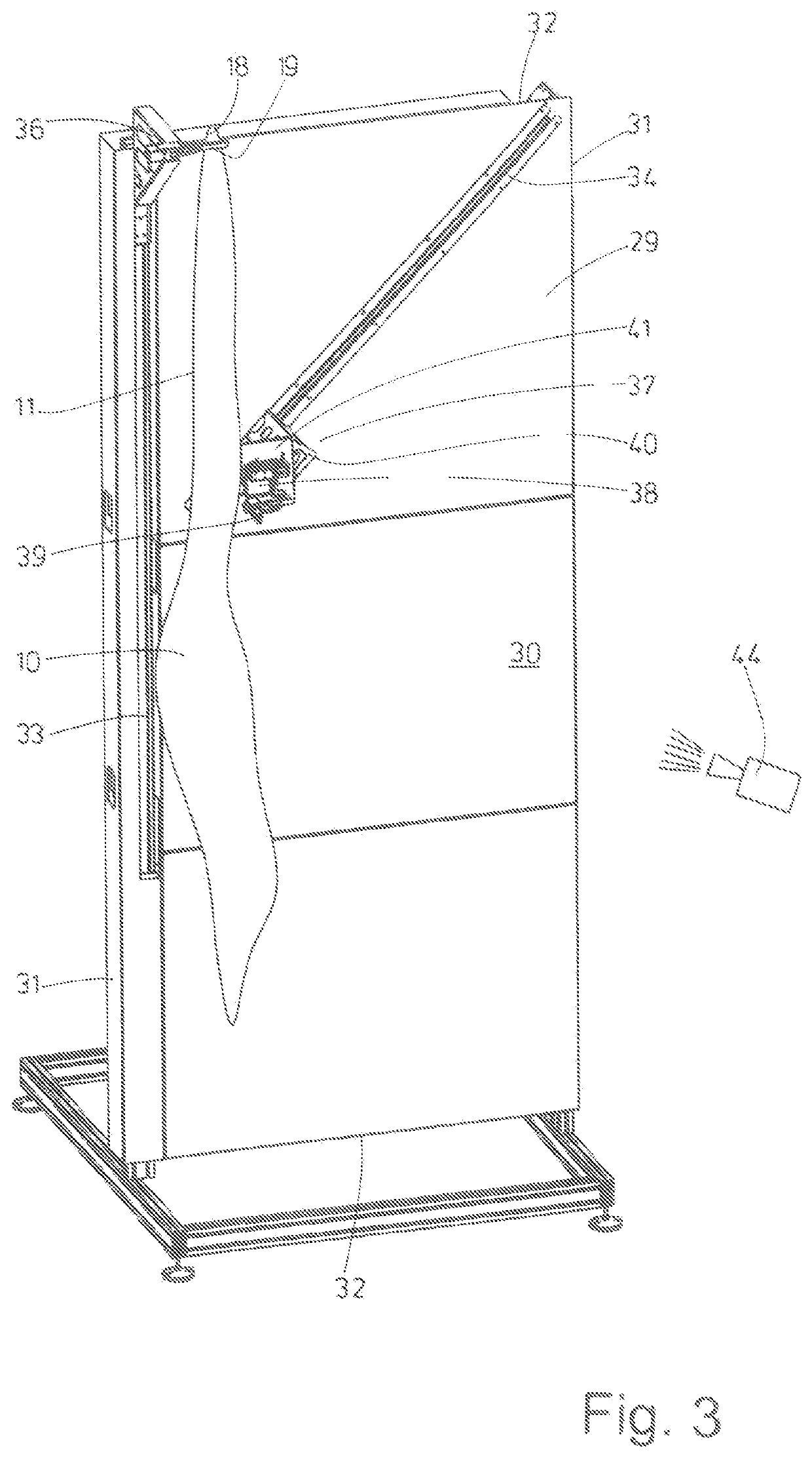

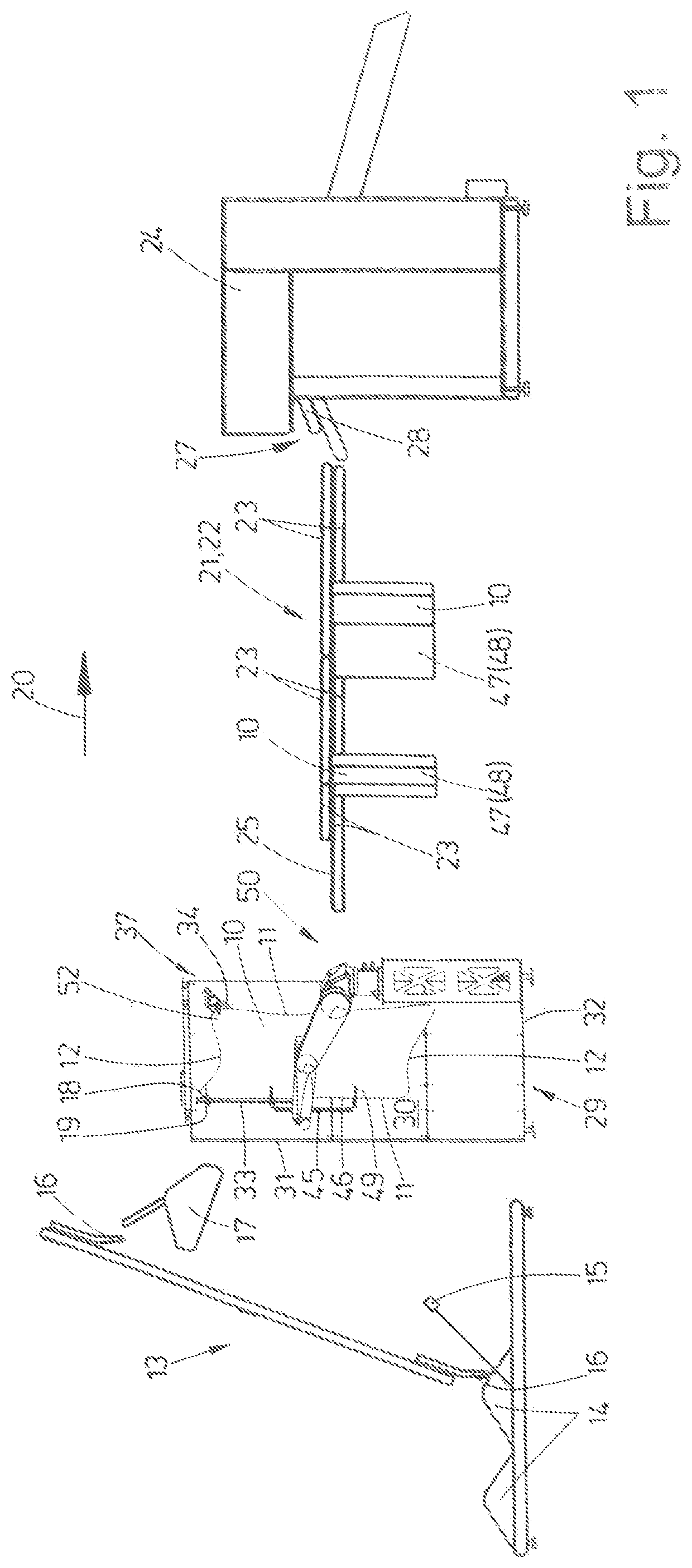

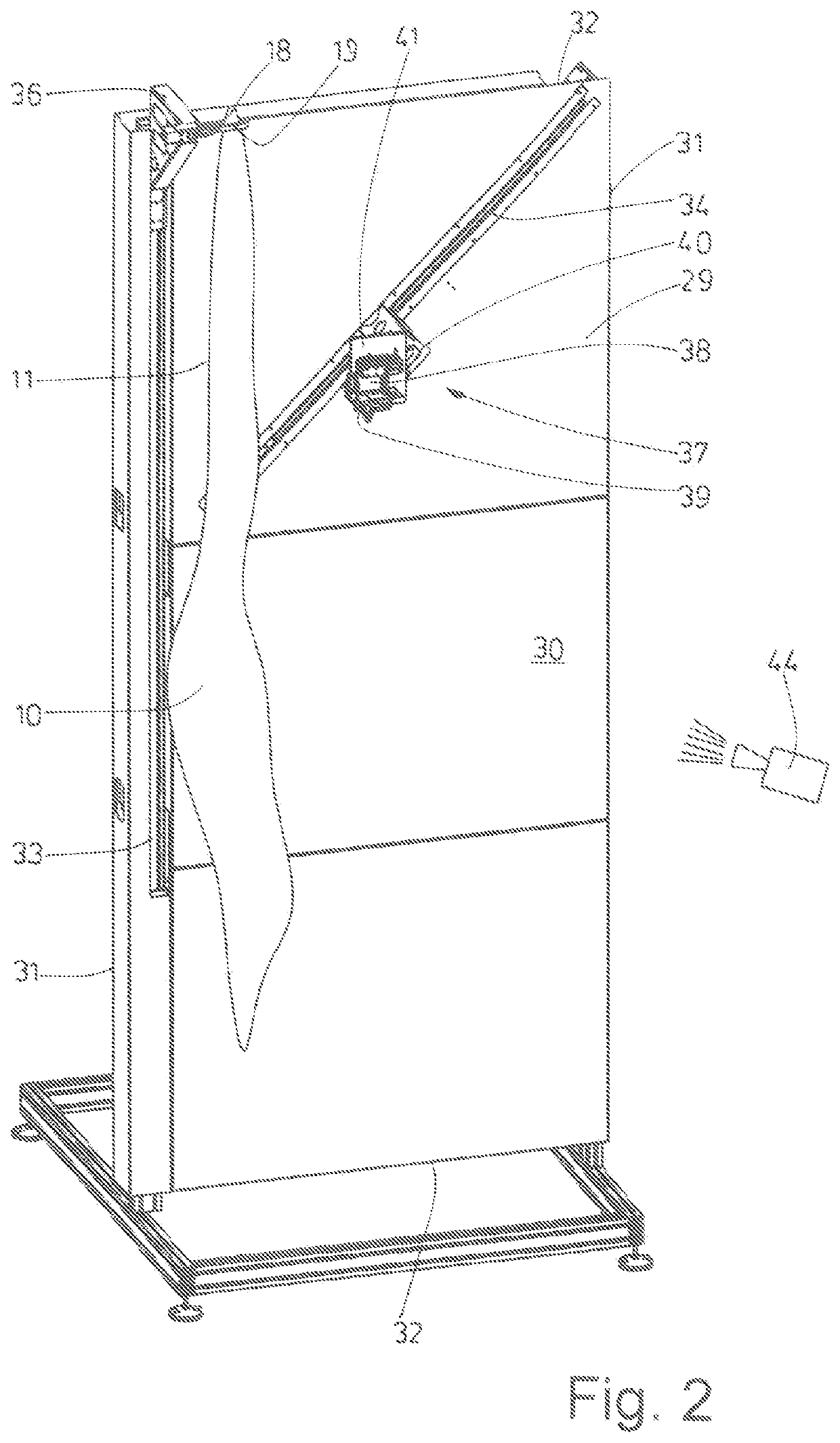

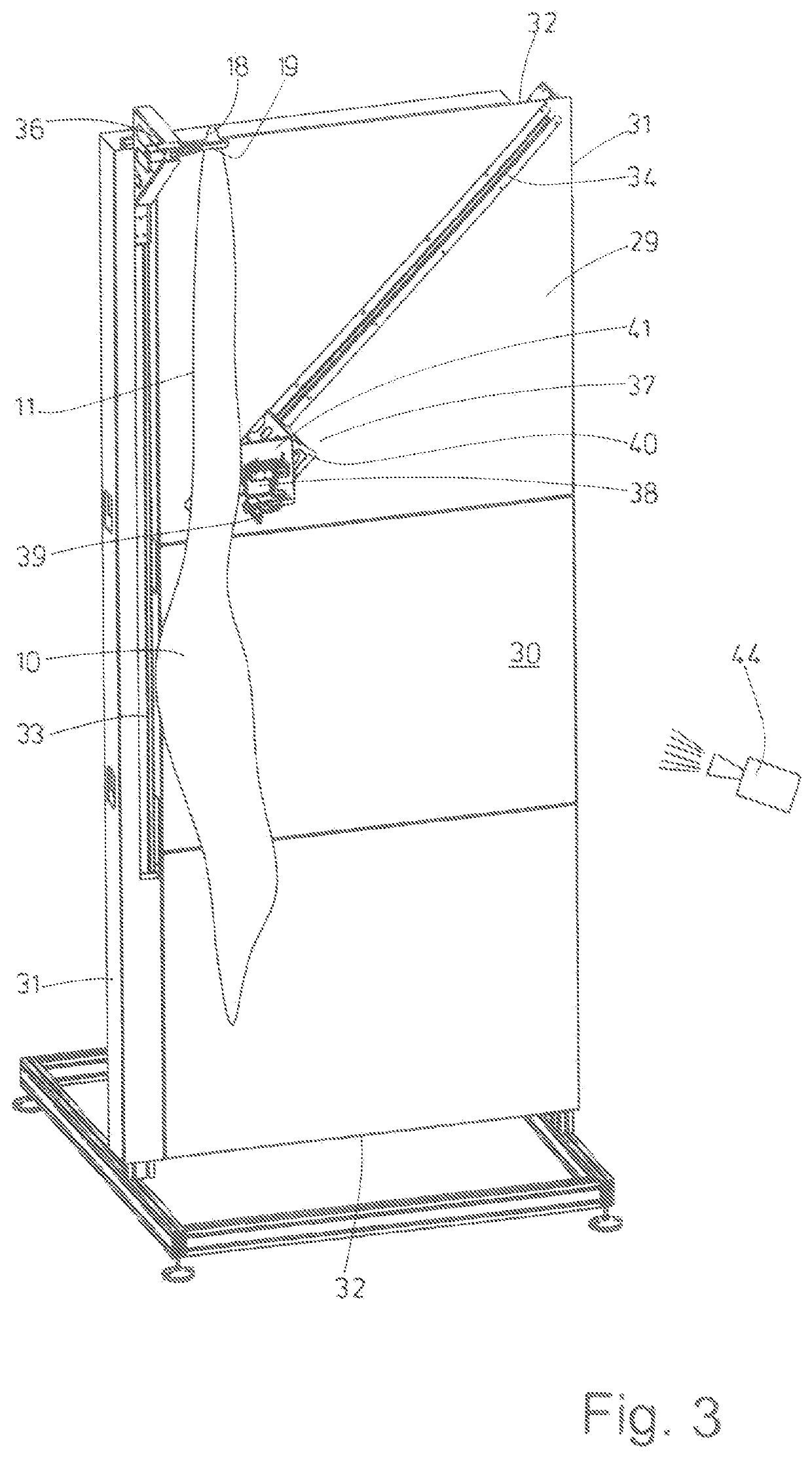

Method and device for gripping rectangular textile items and/or for feeding rectangular textile items to a treatment installation

ActiveUS20210163237A1Accurate configurationRapid and reliable and exact automatic grippingConveyorsIroning machinesLaundryMechanical engineering

A method and device in which a respective laundry piece initially is automatically gripped at a location and pulled apart. The automatic gripping of laundry pieces for feeding to an infeed machine requires a plurality of handling procedures which for reliable automation have to be coordinated. The laundry piece is subsequently reoriented such that said laundry piece can be acquired in a manner which is favorable in terms of the subsequent steps, which can take place in front of a wall that stabilizes the laundry piece. Once the laundry piece has been gripped in the region of a periphery, the laundry piece, as a function of which periphery has been gripped and by way of which alignment the laundry piece is to be fed to the infeed machine, is pulled longitudinally or transversely onto a conveyor that transports said laundry piece to the infeed machine.

Owner:KANNEGIESSER GMBH CO HERBERT

Polishing tool and polishing method for leather roll core paper tube tongue

PendingCN112548783AReduce wasteRemove creasesGrinding drivesGrinding machinesPolishingElectric machinery

The invention discloses a polishing tool for a leather roll core paper tube tongue. The polishing toll comprises a base platform on a rack, a support set used for transversely placing a paper tube isarranged at one side, on the base platform, of the rack, a pressing rod is transversely arranged above the base platform beside the support set, limiting rods are transversely arranged at one side ofthe pressing rod side by side, guide rail are transversely arranged at one side of the limiting rods side by side, the guide rails are provided with a polishing base through a screw rod driven by a motor, and a polishing wheel used for polishing the paper tube tongue is arranged on the polishing base. According to the polishing tool, compared with the prior art, the problems of resource waste andhigh usage cost due to the fact that a conventional leather paper tube tongue has a crease part which is not easy to use can be solved.

Owner:广西鑫深科技有限公司

Workpiece profiling device

PendingCN113441581AFlat and smooth appearanceStable structureMetal-working feeding devicesPositioning devicesEngineeringMechanical equipment

The invention relates to a workpiece profiling device and belongs to the technical field of mechanical equipment. The workpiece profiling device comprises a pressing rod, a stamping rod and a lower cushion block. One end of the pressing rod is fixed on a support, the other end of the pressing rod is arranged at the top of the stamping rod, the stamping rod is arranged in the support, the lower cushion block is arranged below the stamping rod, the shape of the contact surface of the stamping rod is matched with that of the contact surface of the lower cushion block, the stamping rod is pressed downwards by the pressing rod to move towards the lower cushion block, and the stamping rod is matched with the lower cushion block in an extrusion mode. According to the workpiece profiling device, one-time profiling deformation can be carried out on a workpiece, the consistency of shielding strips is ensured, and the production efficiency is improved.

Owner:SHENYANG RAILWAY SIGNAL +1

Method and device for gripping rectangular textile items and/or for feeding rectangular textile items to a treatment installation

ActiveUS11377308B2Remove creasesRapid and reliable and exact automatic grippingConveyorsIroning machinesLaundryMechanical engineering

A method and device in which a respective laundry piece initially is automatically gripped at a location and pulled apart. The automatic gripping of laundry pieces for feeding to an infeed machine requires a plurality of handling procedures which for reliable automation have to be coordinated. The laundry piece is subsequently reoriented such that said laundry piece can be acquired in a manner which is favorable in terms of the subsequent steps, which can take place in front of a wall that stabilizes the laundry piece. Once the laundry piece has been gripped in the region of a periphery, the laundry piece, as a function of which periphery has been gripped and by way of which alignment the laundry piece is to be fed to the infeed machine, is pulled longitudinally or transversely onto a conveyor that transports said laundry piece to the infeed machine.

Owner:KANNEGIESSER GMBH CO HERBERT

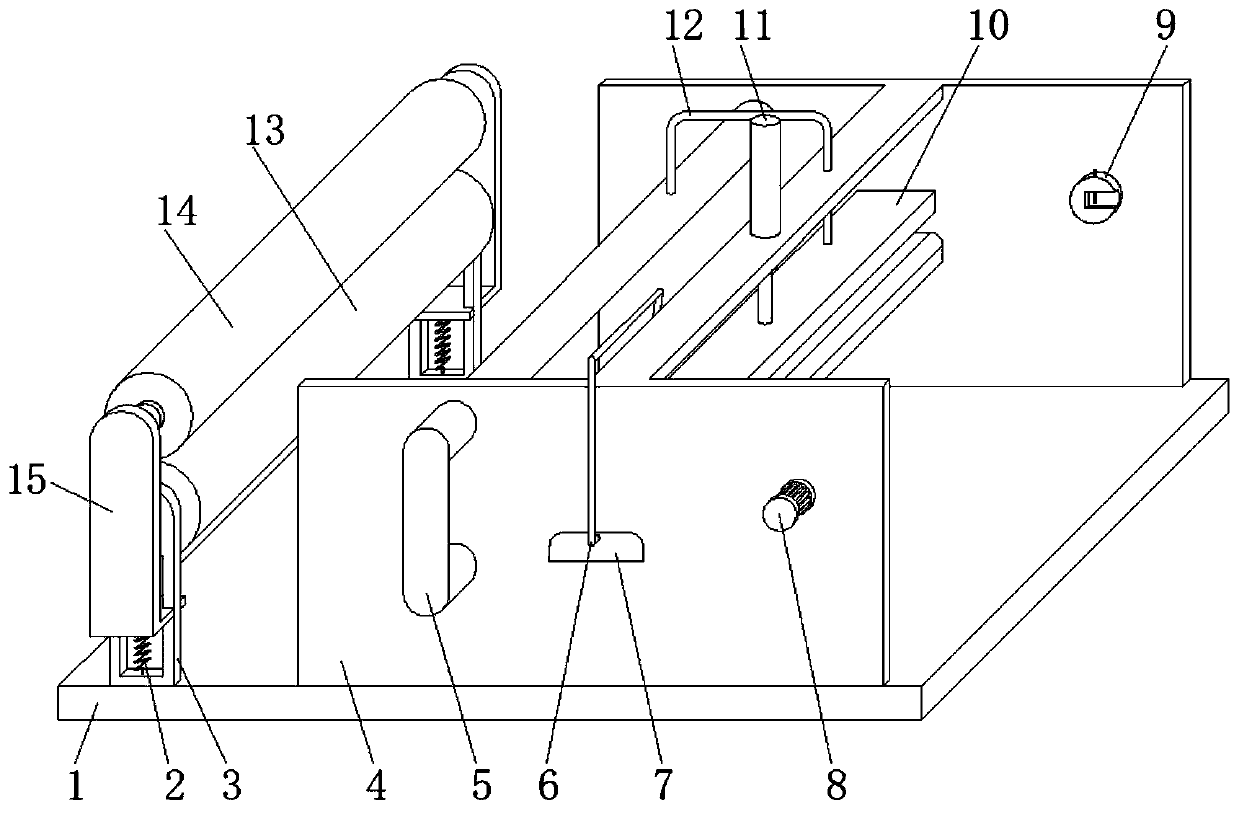

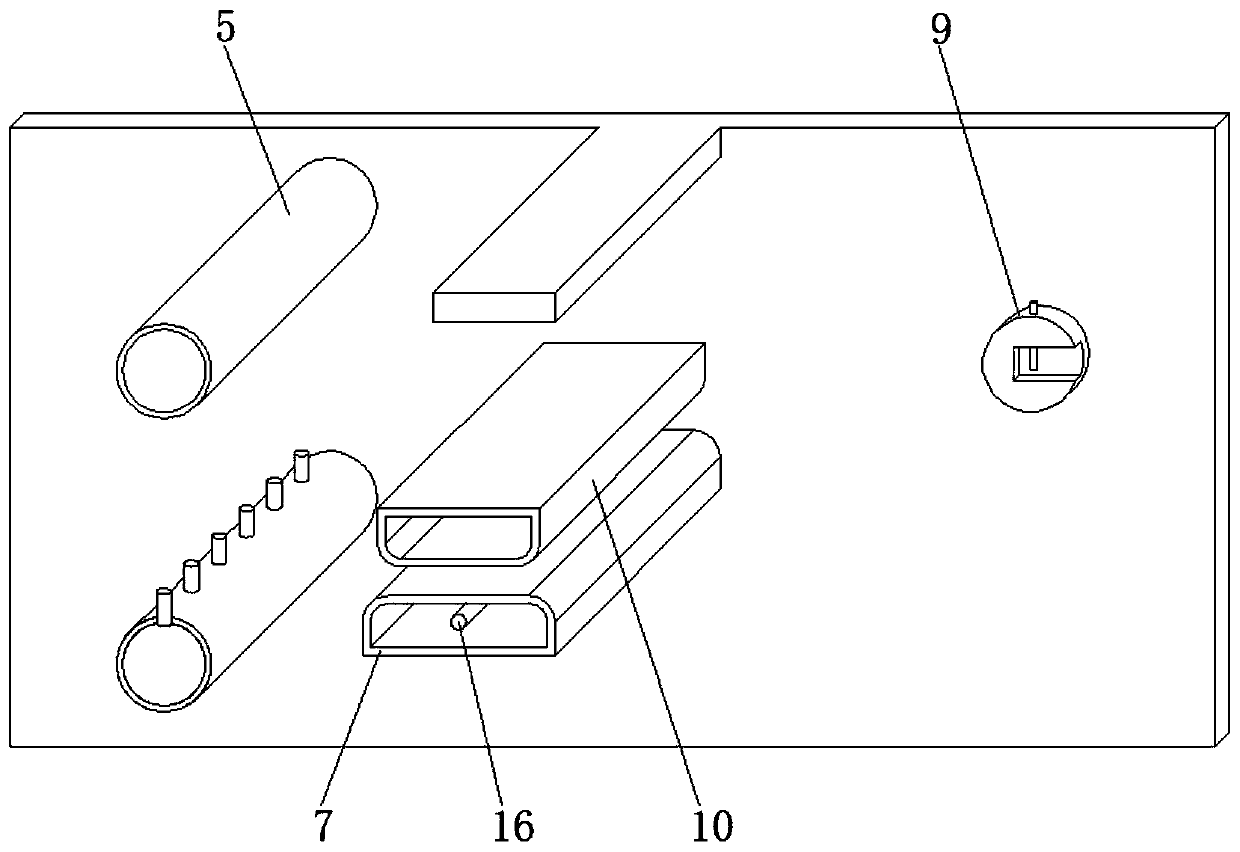

Weaving equipment

ActiveCN107956028BRemove creasesRealize intermittent transmissionLoomsAuxillary apparatusEngineeringMechanical engineering

The invention relates to the technical field of weaving, and especially relates to a device used for weaving. The device comprises a transmission table, a transmission roller used to transmit a clothon the transmission table, and a wind-up roller used to wind up the cloth. The wind-up roller is on a discharge end of the transmission table. The transmission roller comprises a roller body, a pressing column, and a smoothing platform. The roller body is internally provided with a steam channel. The roller body is provided with an air outlet hole and a sliding hole. The sliding hole is internallyslidably connected with a sliding rod. The sliding rod is fixedly connected with the smoothing platform. A spring is arranged between the smoothing platform and the roller body. The pressing column is used to insert into the steam channel and control sliding of the sliding rod. The pressing column is provided with a blocking column used to block the air outlet hole. An end of the transmission roller is rotatably connected with a steam pipe. One end of the pressing column, close to the steam pipe, can contact with an orifice of the steam pipe. The transmission roller is also provided with a positioning portion used to fix the pressing column in the steam channel. The pressing column, the sliding rod, and the smoothing platform are made of a heat conduction material. The scheme can eliminate folds on a surface of the cloth.

Owner:NINGBO HIGH TECH ZONE SHENGWENTU TEXTILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com