Atomizing nozzle structure of high-temperature high-voltage air flow dyeing machine and control method thereof

An airflow dyeing machine, high temperature and high pressure technology, applied in the direction of liquid/gas/steam jet propulsion fabric, textile material treatment, textile processing machine accessories, etc., can solve the problem of large pollution, insufficient level dyeing, liquor ratio of overflow dyeing machine major issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

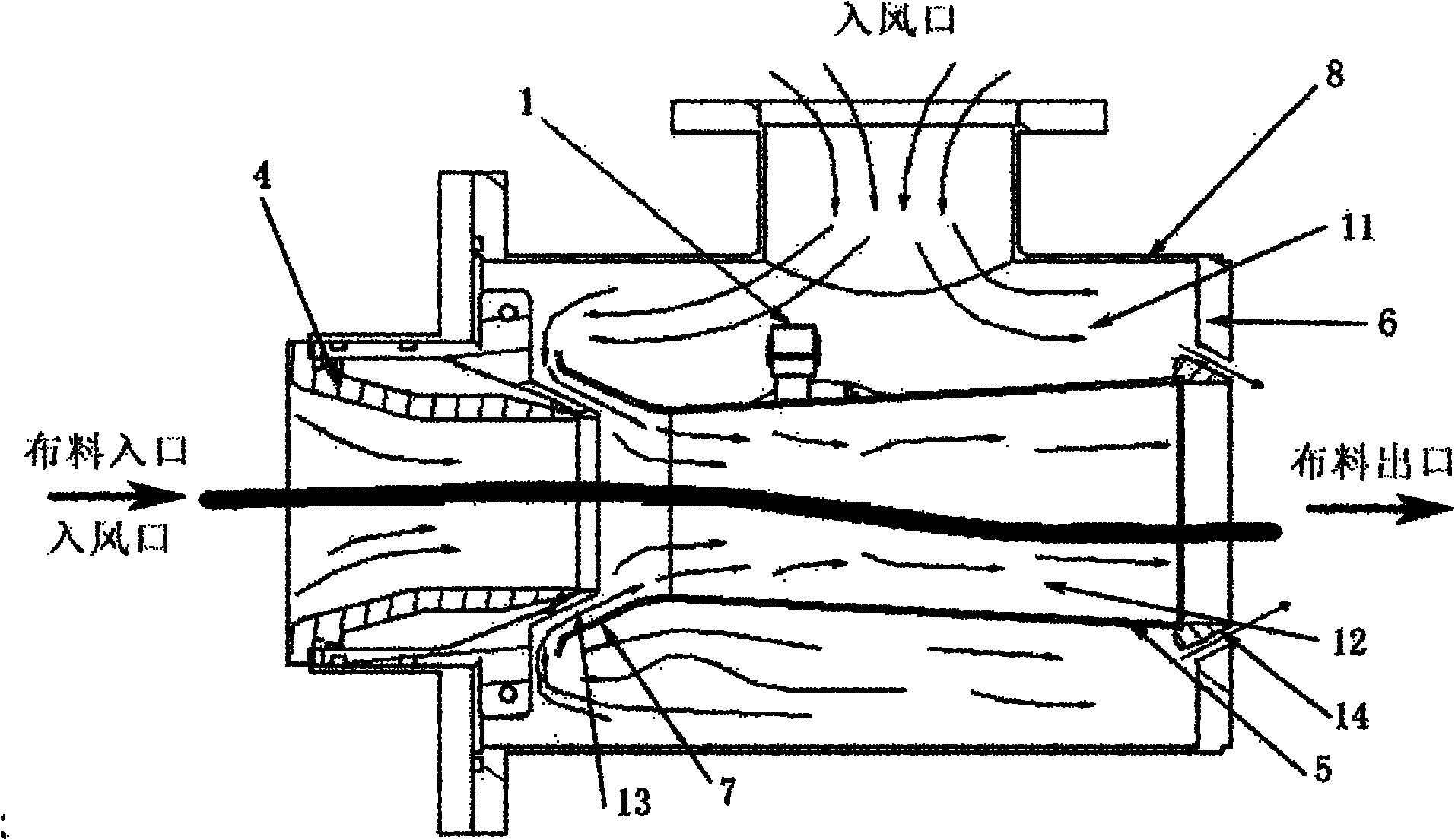

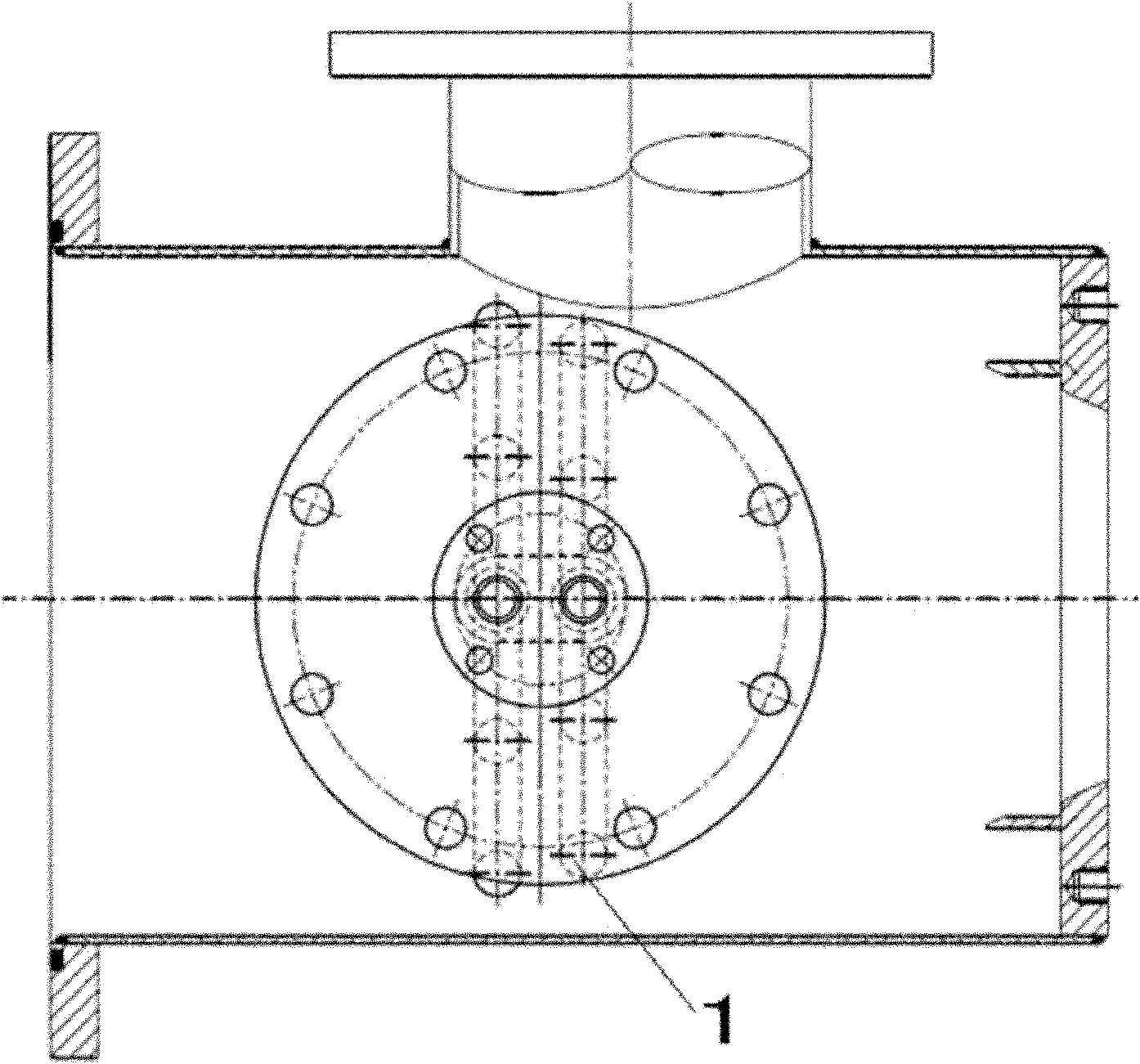

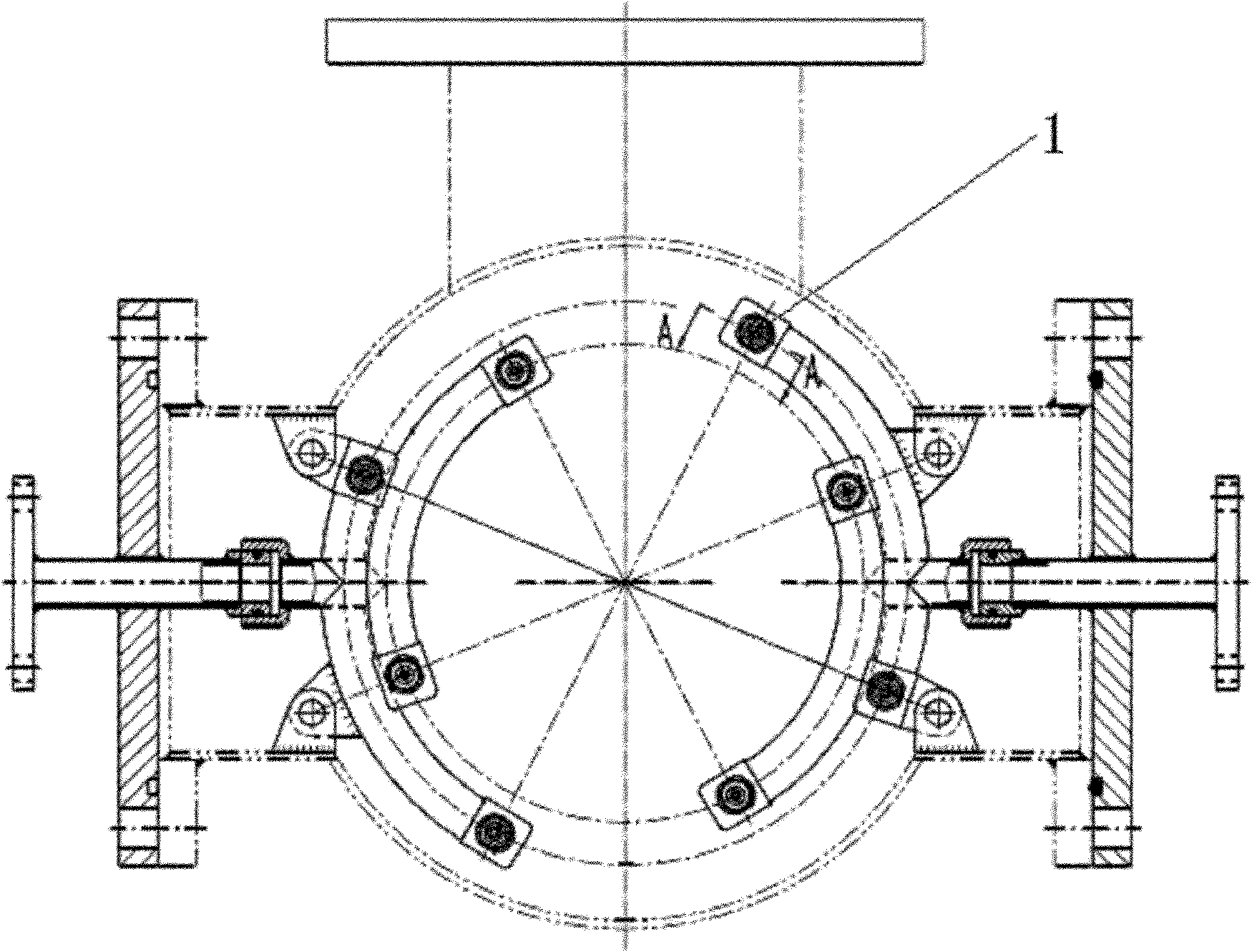

[0083] Generally speaking, the high temperature and high pressure airflow dyeing machine is mainly composed of the following components:

[0084] (1) The basic configuration includes: main cylinder body, reserve cylinder, feeding cylinder, material barrel II, material barrel I, heat exchanger, cloth outlet device, cloth lifting device, cloth guiding pipe arrangement device, tank washing device, fan, gas Filters, High Temperature Discharge Mixers, Soda Mixers, Pressure Transmitters, Differential Pressure Transmitters, Floats.

[0085] (2) Pumps and valves: feeding pump I, feeding pump II, main circulation pump, drainage and air supply valve, dye liquor circulation valve, feeding valve before the pump, feeding valve at the bottom of the tank, shut-off valve at the main pump port, horizontal check Valve, volume sensor water inlet valve, high temperature discharge cooling valve, high temperature mixed discharge valve, master vat drain valve II, master vat drain valve I, master vat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com